Balanced type triple-screw vibrating force field reinforced plasticizing mixing extrusion method and equipment

A vibration force field, mixing extrusion technology, applied in the field of balanced three-screw vibration force field strengthening plasticization mixing extrusion method and equipment, can solve the problem that the periodic change of the axial meshing tooth gap cannot be realized, the plasticization mixing It is difficult to improve the refining effect, and there is no breakthrough in the mechanism of plasticization and mixing, so as to achieve the effects of reducing external heating power consumption, increasing thermal kinetic energy, and increasing fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

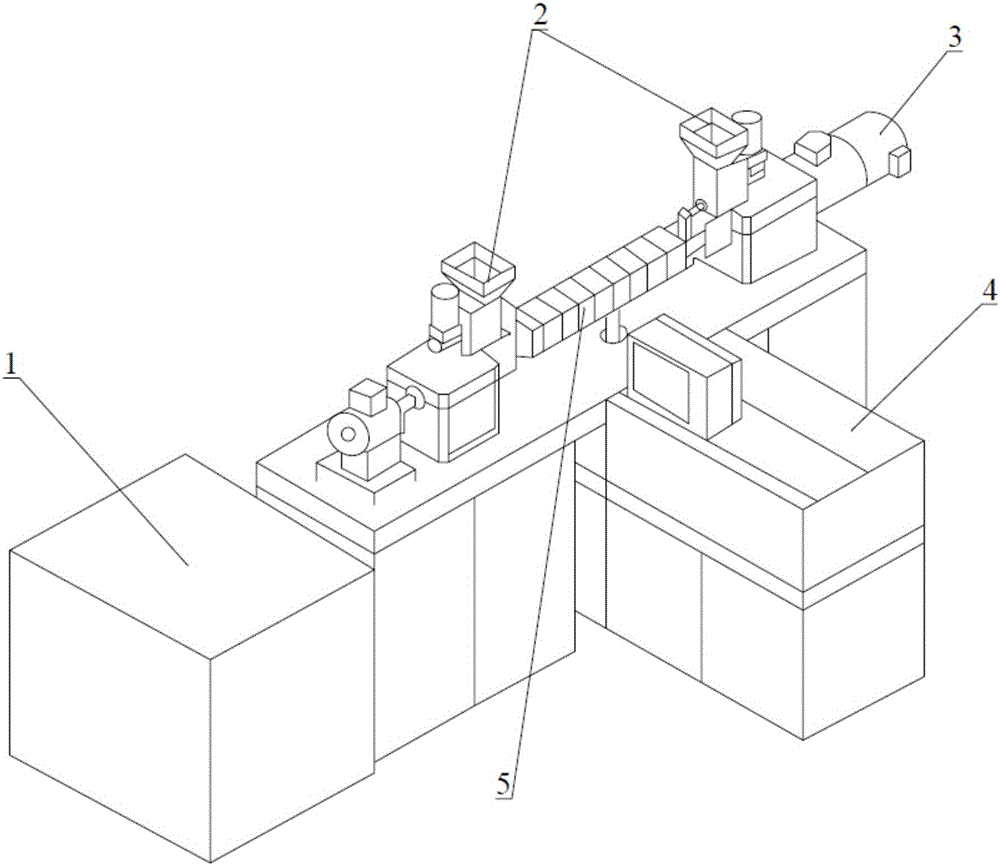

[0038] In this embodiment, a balanced three-screw vibration force field reinforced plasticizing mixing extrusion equipment, such as figure 1 As shown, it includes a hydraulic vibration excitation device 1, a three-screw system 5, a measurement and control device 4, a drive motor 3, and a feeding hopper 2. The two ends of the three-screw system are respectively provided with a feeding hopper, and the two ends of the main screw of the three-screw system are respectively connected to the hydraulic vibration excitation device. The device is connected with the drive motor, the measurement and control device is arranged on one side of the three-screw system, and the drive motor and the hydraulic vibration excitation device are respectively electrically connected with the measurement and control device. Its working process is: under the control of the measurement and control device, the drive motor drives the three-screw system to rotate, the hydraulic vibration device provides an axi...

Embodiment 2

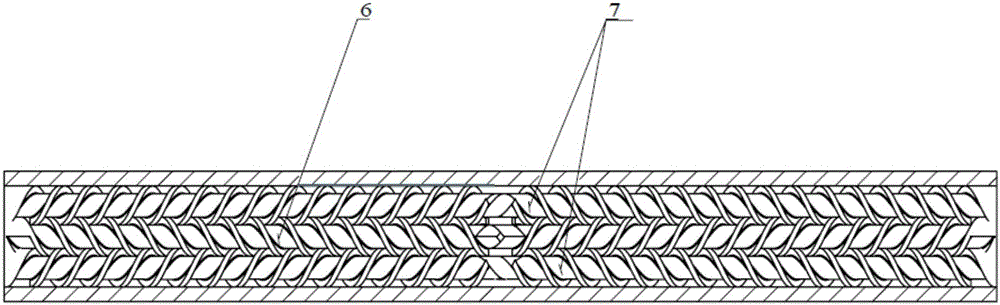

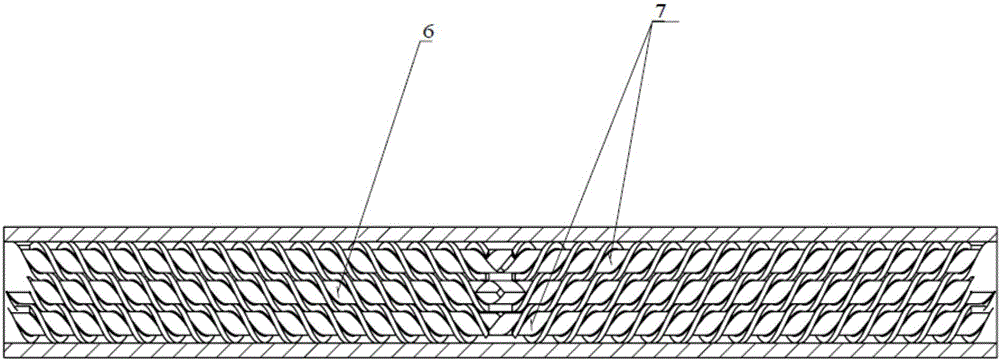

[0053] This embodiment is a balanced three-screw vibration force field reinforced plasticizing mixing extrusion equipment. Compared with Embodiment 1, the difference is that in the three-screw system, each screw is a structural form composed of kneading block elements ,Such as Figure 7 As shown, there is an axial gap m between the kneading block on the main screw and the meshing kneading block on the auxiliary screw, and the width of the axial gap is greater than the maximum amplitude h when the main screw vibrates axially.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com