Method for processing and manufacturing aluminum ingot by utilizing and recovering waste aluminum powder

A technology for waste aluminum powder and aluminum ingots, applied in the direction of improving process efficiency, can solve the problems of difficult purification and production of aluminum ingots, pollution of oil and other sundries, unclear components, etc., to improve the metal melting rate and save fuel use. , the effect of improving the metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

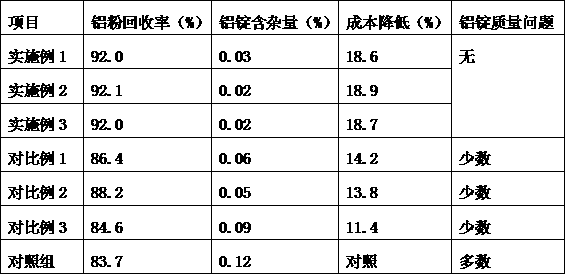

Examples

Embodiment 1

[0017] A method for processing aluminum ingots by recycling waste aluminum powder, comprising the following steps:

[0018] (1) First, use permanent magnets to recover the impurity iron in the waste aluminum powder, use a mesh screen with a particle size of 6 mm beyond the aluminum chips to sieve out the dust and sand in the remaining components, and pour the screened aluminum powder into the cleaning machine. In the cleaning tank of the cleaning agent, the temperature of the cleaning liquid is 45 °C, and the aluminum powder is 20 cm long, and the stirring rod is inserted into the bottom for stirring, and the suspended impurities are continuously floated out during the stirring process;

[0019] (2) After stirring and cleaning until there are no suspended impurities, filter, dry in an oven at 200°C, turn over every half hour, dry for 3 hours, and then use a press to press into a compressed aluminum cake with a thickness of 3 cm for smelting. Prepare the furnace before smelting...

Embodiment 2

[0026] A method for processing aluminum ingots by recycling waste aluminum powder, comprising the following steps:

[0027] (1) First, use permanent magnets to recover the impurity iron in the waste aluminum powder, use a mesh screen that exceeds the particle size of aluminum scraps by 7 mm to sieve out the dust and sand in the remaining components, and pour the screened aluminum powder into the cleaning machine. In the cleaning tank of the cleaning agent, the temperature of the cleaning liquid is 50 °C, and the aluminum powder is 25 cm long, and the stirring rod is inserted into the bottom for stirring, and the suspended impurities are continuously floated out during the stirring process;

[0028] (2) After stirring and cleaning until there are no suspended impurities, filter, dry in an oven at 210°C, stir once every half hour, dry for 3.5 hours, and then use a press to press into a compressed aluminum cake with a thickness of 4 cm for smelting. Prepare the furnace before sme...

Embodiment 3

[0035] A method for processing aluminum ingots by recycling waste aluminum powder, comprising the following steps:

[0036] (1) First, use permanent magnets to recover the impurity iron in the waste aluminum powder, use a mesh screen with a particle size of 8 mm beyond the aluminum chips to sieve out the dust and sand in the remaining components, and pour the screened aluminum powder into the cleaning machine. In the cleaning tank of the cleaning agent, the temperature of the cleaning liquid is 55 ° C, and the aluminum powder is 30 cm long, and the stirring rod is inserted into the bottom for stirring, and the suspended impurities are continuously floated out during the stirring process;

[0037] (2) After stirring and cleaning until there are no suspended impurities, filter, dry in an oven at 220°C, stir once every half hour, dry for 4 hours, and then use a press to press into a compressed aluminum cake with a thickness of 5 cm for melting. Prepare the furnace before smelting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com