Lithium ion battery module thermal management system based on phase change material- fin composite structure

A lithium-ion battery and thermal management system technology, which is applied in the field of lithium-ion battery module thermal management systems, can solve the problems of small contact area between the battery surface and phase change materials, heat cannot be conducted quickly, and battery temperature rises. Achieve the effects of ensuring temperature uniformity, enhancing heat transfer efficiency, and increasing heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the drawings and examples:

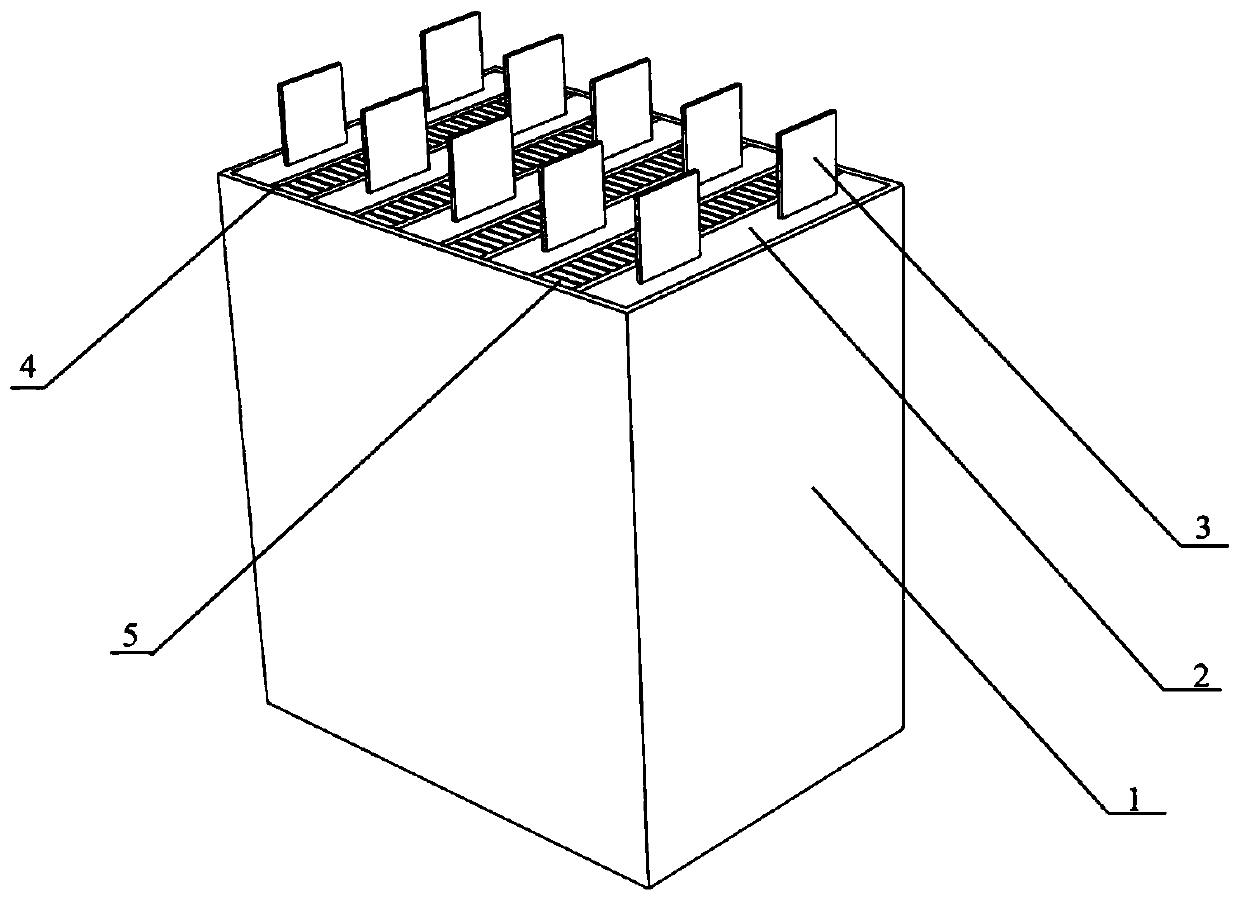

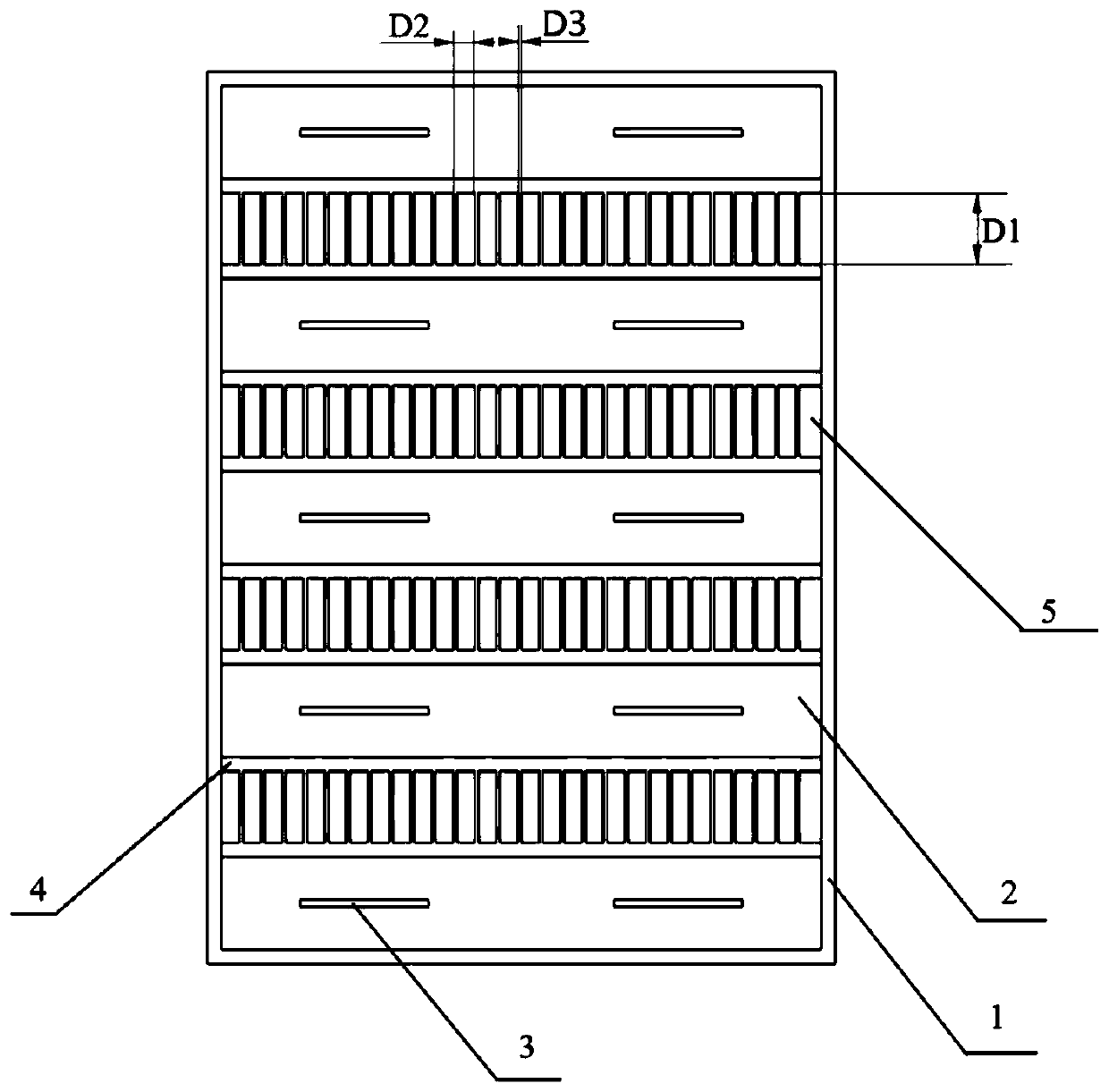

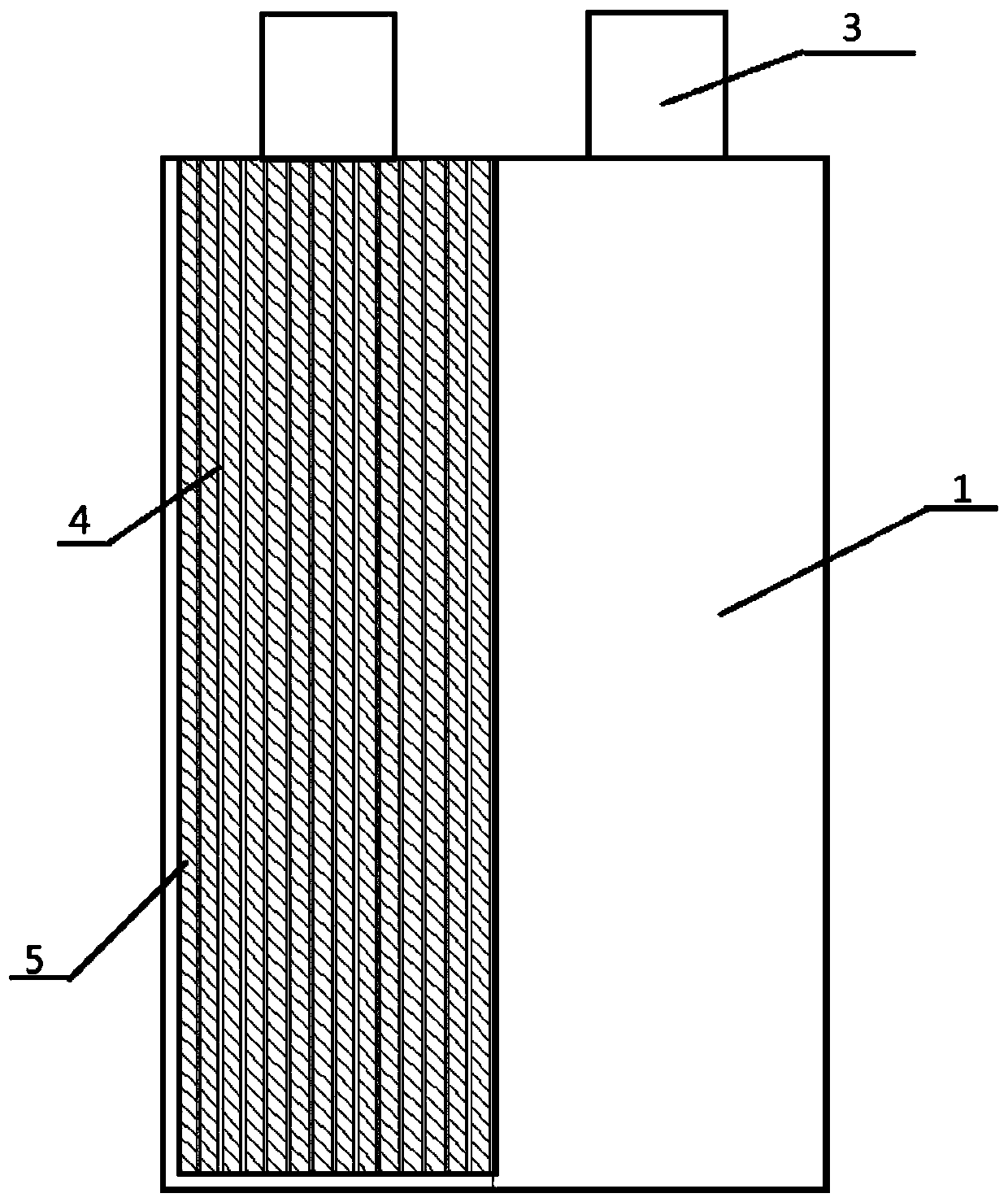

[0029] Such as Figure 1-6 As shown, the present invention provides a thermal management system for a lithium ion battery module based on a phase change material-fin composite structure, which includes an aluminum battery box 1 in which a number of square phosphoric acid are fixed at intervals. The lithium iron phosphate battery module 2 and the heat dissipation structure 4, the upper surface of the square lithium iron phosphate battery module 2 is fixed with a plurality of lithium iron phosphate battery tabs 3 by a viscous material, and the heat dissipation structure 4 is arranged by a pair of substrates 41 and A plurality of heat dissipation fins 42 are formed between a pair of substrates 41, a phase change material 5 is filled between two adjacent heat dissipation fins 42, and the substrate 41 is in contact with the side surface of the rectangular lithium iron phosphat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com