Thermal-insulation fireproof cement composite board and manufacturing process thereof

A cement composite board and manufacturing process technology, which is applied in the field of board processing, can solve the problems of non-deformable grid cloth stretching and paving, uneven grid cloth laying, and functional limitations, so as to improve cutting unevenness and ensure Laying effect, to ensure the effect of laying flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The manufacturing process of the thermal insulation and fireproof cement composite board in this embodiment, step A: making the mold 400;

[0047] Step B: placing the mold 400;

[0048] Step C: use manufacturing equipment to make the lower fabric layer with the lower mesh surface layer;

[0049] Step D: placing the core material;

[0050] Step E: using manufacturing equipment to make an upper fabric layer with an upper upper layer;

[0051] Step F: Palletizing and standing still;

[0052] Step G: Release the finished product.

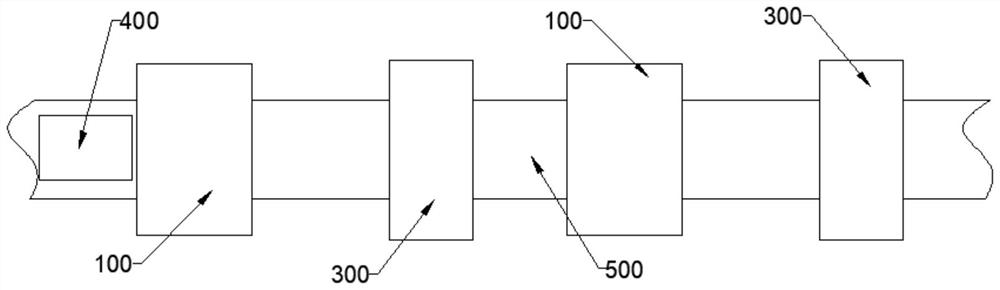

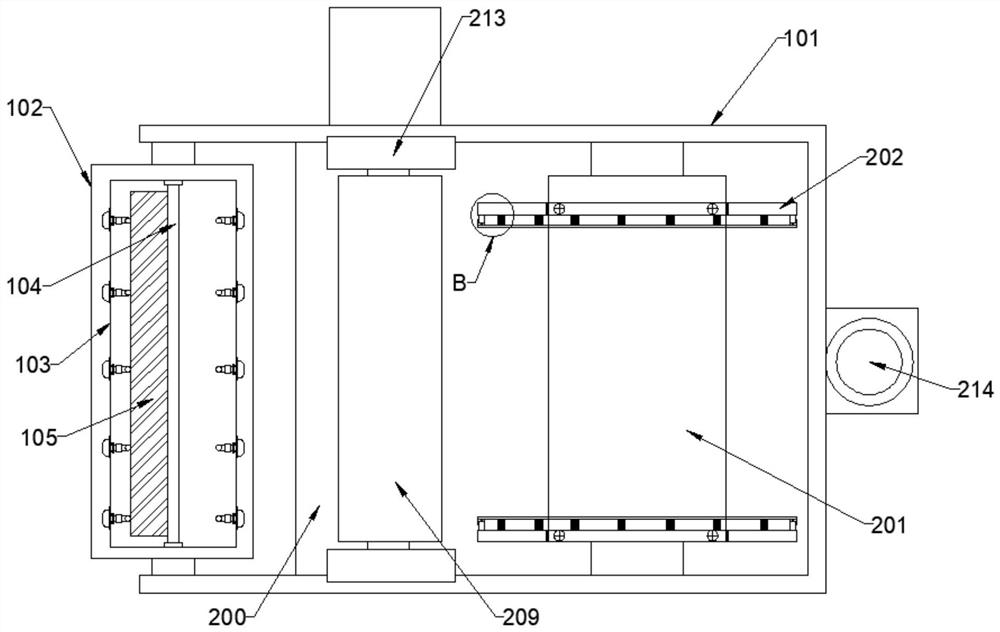

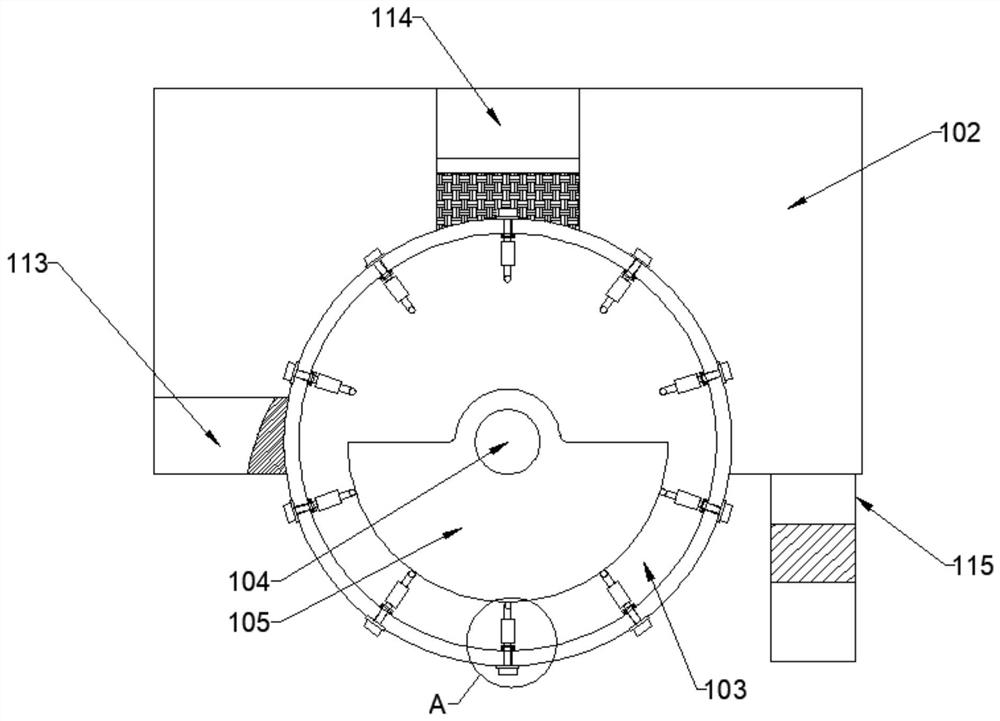

[0053] Such as figure 1 As shown, in step C and step E: the manufacturing equipment includes a mesh laying mechanism 100, a laying auxiliary mechanism 200, a scraping mechanism 300 and a conveyor belt 500; the laying auxiliary mechanism 200 is located at the inlet end of the mesh laying mechanism 100, The scraping mechanism 300 is located at the outlet end of the mesh laying mechanism 100 , the mold 400 is located on the outer surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com