A kind of automatic tape laying device and method based on six-axis robot

The technology of a six-axis robot and a tape laying device is applied in the field of composite material forming, which can solve the problems of complex structure of forming equipment, high manufacturing cost, difficult control, etc., so as to improve the laying efficiency, reduce the manufacturing cost, and have a good application prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

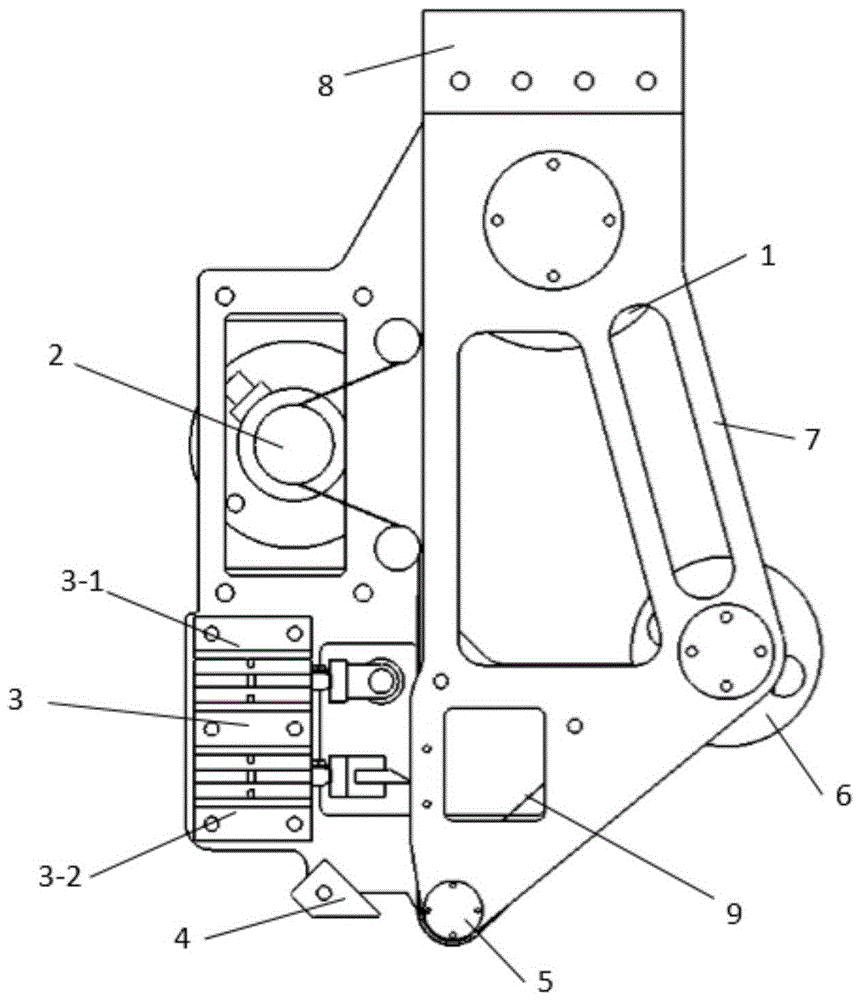

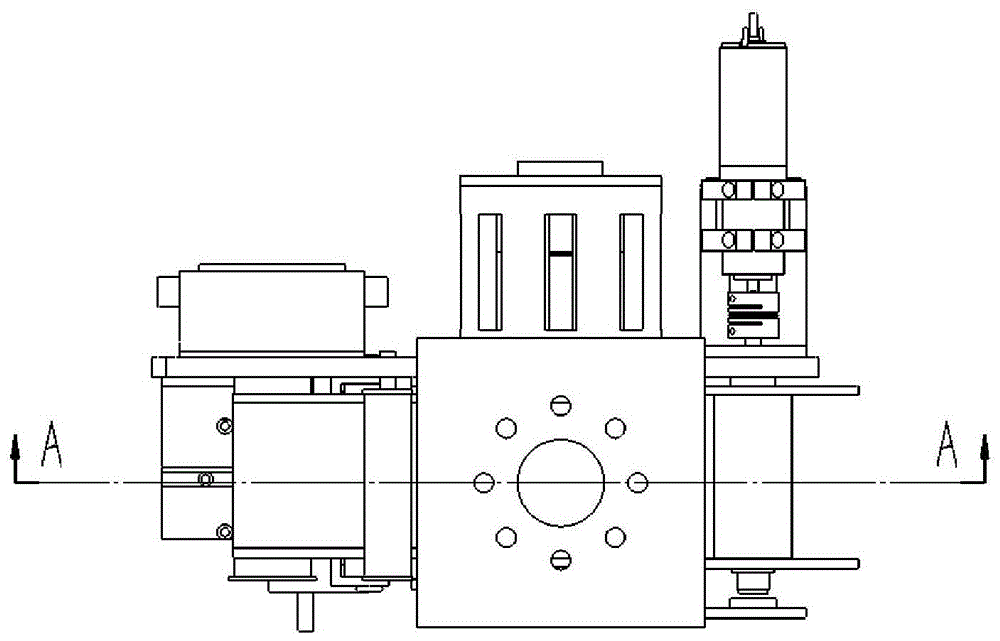

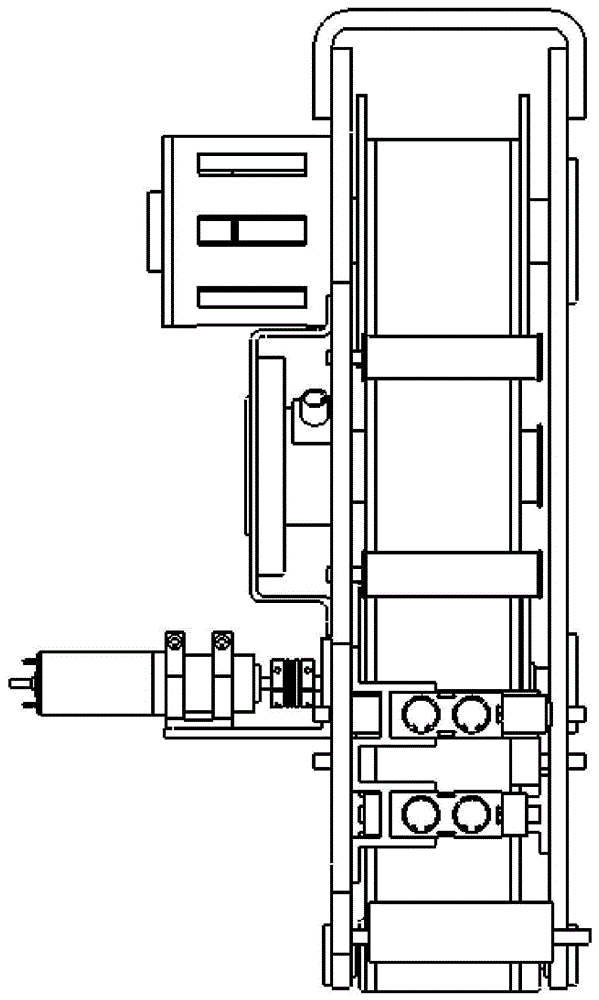

[0069] Specific implementation mode one: combine figure 1 , 6 , 7, 8, and 9 illustrate the implementation of Embodiment 1. During the laying process of the fiber prepreg tape 3-5, the tension detection device 2 detects the tension of the tape during the laying process, the heating device 4 heats the fiber prepreg tape 3-5 to be laid or the laid surface, and the pressing roller device 5 Compact the prepreg tape 3-5 onto the heated mandrel or lay-up surface. Before the prepreg tape 3-5 enters the shearing device 3-2, the backing paper 9 is separated from the fiber tape 3-5, and passes through the fixing wheel 3-7 of the pressing device, the backing paper guide wheel 10, and the pressing roller 5-2 , and finally wound on the delivery roller 6-2.

specific Embodiment approach 2

[0070] Specific implementation plan two: combine figure 1 , 7 , 12, 13, and 14 illustrate the implementation of Embodiment 1. This embodiment is identical with embodiment one except shearing and compacting device. Before the prepreg tape 3-5 enters the shearing device 3-2, the pressing wheel first compresses the prepreg tape 3-5 to prevent the prepreg tape 3-5 from rebounding under tension after shearing. After entering the shearing device, the backing paper 9 and the fiber tape 3-5 are attached to the upper and lower sides of the wedge-shaped block 3-12 respectively, so that the backing paper is not cut off when being convenient to mechanical cutting. After the cutting is completed, the pressing wheel will compress the backing paper and the fiber tape again to ensure that the fiber tape is in the correct position relative to the backing paper and laid on the laying surface without deviation. Like this just can neither cut backing paper 9 and the normal delivery of the fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com