Automatic prepreg tape laying head and guide rail bracket

A prepreg tape and laying head technology, applied in the field of automatic laying, can solve the problems of low laying efficiency, only layer by layer laying, anvil knife and tape surface adhesion and pulling, etc., to ensure the laying effect, The effect of improving production efficiency and saving laying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

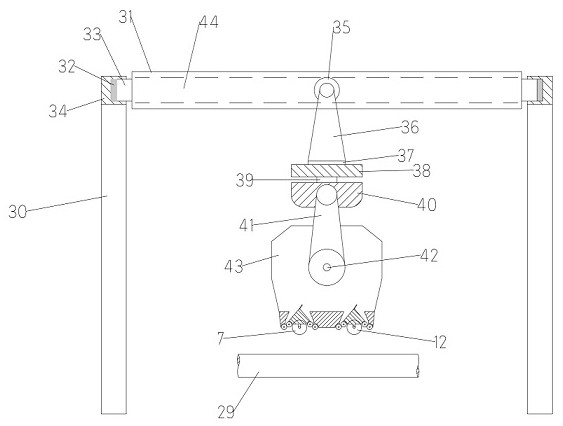

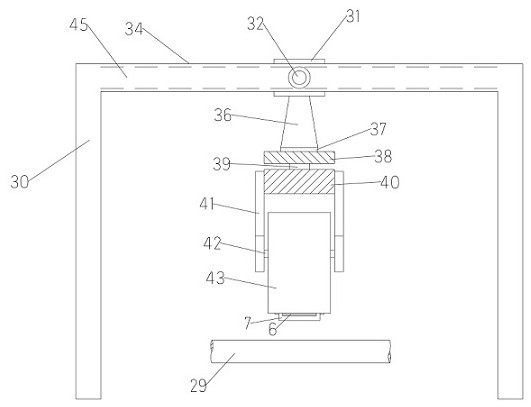

[0035] As shown in the figure: a prepreg tape automatic laying head and guide rail support, the guide rail support includes two U-shaped support columns 30, a rolling beam 31 and a laying head fixing device, the two U-shaped support columns 30 Symmetrically arranged on both sides of the prepreg tape automatic placement head, the top of the U-shaped support column 30 is provided with a bracket guide rail 45, and the rolling beam 31 is fixed to the first rolling wheel 32 through the first connecting shaft 33 , the first rolling wheel 32 can roll in the bracket guide rail 45, a beam guide rail 44 is provided inside the rolling beam 31, and a cover 43 is provided outside the automatic placing head of the prepreg tape, and the cover 43 passes through The laying head fixture is connected to the rolling beam 31 .

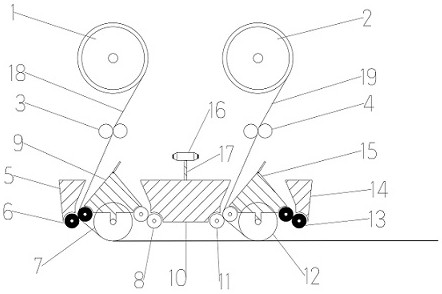

[0036] The prepreg tape automatic placement head includes a feeding mechanism, a laying mechanism, a cutting mechanism, a guiding mechanism and a reversing mechanism, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com