Machine for laying salt-resisting mulching film under plough layer of coastal saline-alkali land and use method of machine

A saline-alkali soil and salt blocking technology, which is applied in the fields of botanical equipment and methods, agricultural machinery and implements, and applications, can solve the problems of complex soil layers in saline-alkali land, cannot guarantee normal cutting, and has a small scope of application, so as to promote agricultural development and solve the Contradictions between people and land, ensuring the effect of the laying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

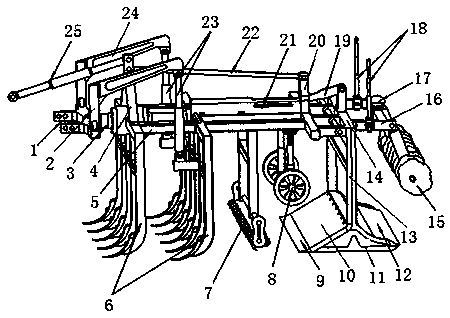

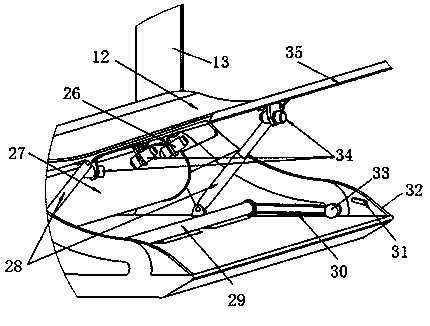

[0053] A salt-resistance plastic film laying machine under a coastal saline-alkali soil plow layer, comprising a frame 5, a film spreading device is provided below the frame 5, and the film spreading device includes a soil raising slope 10, and the soil raising slope 10 includes a front end The blade portion 9 and the slope backward by the blade portion 9, the top sides of the soil slope 10 are respectively fixed with the frame 5 by the column 13, and the bottom edge of the soil slope 10 extends backwards along the horizontal direction with a film The bottom plate 11, and the top edge of the soil-raising slope 10 is rotatably connected with a film-laying shield 12 that can wrap the rear edge of the bottom plate 11, and the two sides of the film-laying bottom plate 11 extend upward respectively to raise the soil slope 10, film-laying The bottom plate 11 and the film-laying shield 12 enclose the support plate 32 of the film-laying cavity. As an embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com