A construction technique of soft and soft stone pasted in indoor floor decoration

A technology for indoor ground and construction technology, which is applied to floors, buildings, building structures, etc. It can solve problems such as short service life, unevenness of soft and soft stone paste, and poor user experience, so as to achieve fast construction and increase cleanliness and smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

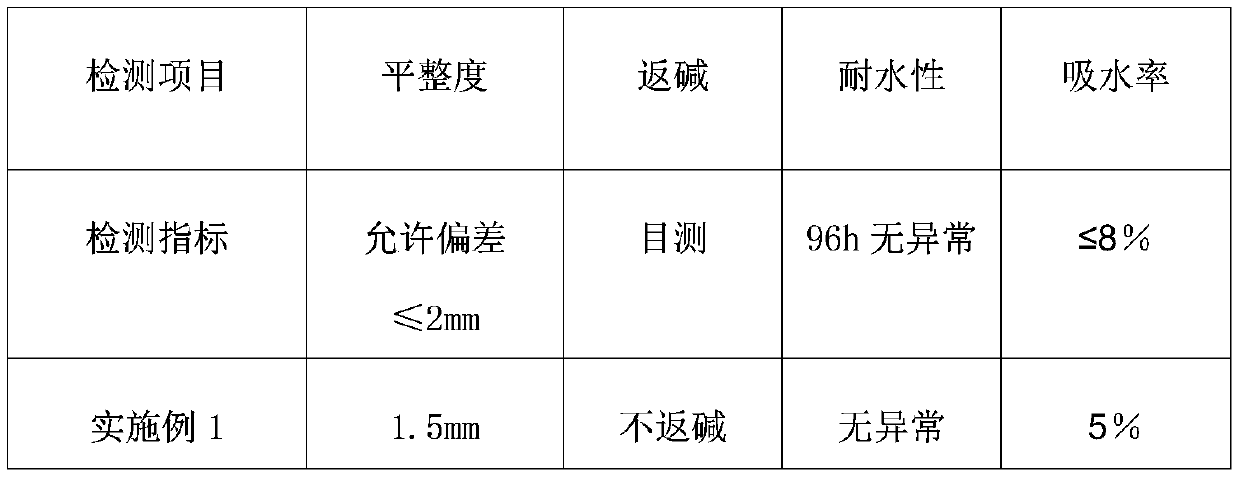

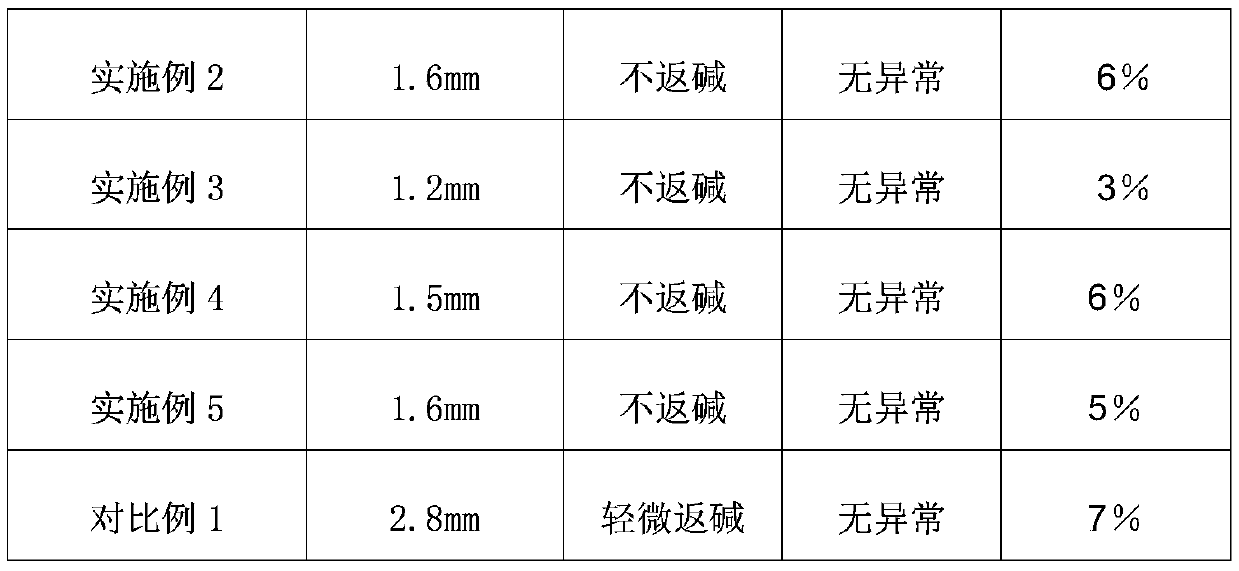

Examples

Embodiment 1

[0024] The construction process of the soft soft stone in the indoor floor decoration described in this embodiment includes the following process steps:

[0025] (1) Pretreatment of the base layer: first clean the dust and debris, and use leveling putty for local repair to ensure that there are no holes, cracks and sanding defects on the construction ground;

[0026] (2) Base layer treatment: The pretreated base layer is applied twice with special putty, the thickness of the first construction is 1mm, after drying for 4 hours, the thickness of the second construction is 0.5mm, and after drying for 4 hours, use sandpaper above 80# Grinding treatment; wherein the special putty is composed of the following components by weight: 20 parts of cement, 15 parts of fly ash, 12 parts of Nanjing red sand with a particle size of 120-180 meshes, and quartz sand with a particle size of 80-120 meshes 18 parts, 0.1 part of alkyl polyoxyethylene ether, 1 part of tartaric acid;

[0027] (3) gr...

Embodiment 2

[0031] The construction process of the soft soft stone in the indoor floor decoration described in this embodiment includes the following process steps:

[0032] (1) Pretreatment of the base layer: first clean the dust and debris, and use leveling putty for local repair to ensure that there are no holes, cracks and sanding defects on the construction ground;

[0033] (2) Base layer treatment: The pretreated base layer is applied twice with special putty, the thickness of the first construction is 1.5mm, after drying for 5 hours, the thickness of the second construction is 0.7mm, and after drying for 5 hours, use more than 80# Sandpaper polishing treatment; wherein the special putty is composed of the following components by weight: 25 parts of cement, 13 parts of fly ash, 15 parts of Nanjing red sand with a particle size of 120-180 mesh, and a particle size of 80-120 mesh quartz 15 parts of sand, 0.3 part of alkyl polyoxyethylene ether, 0.2 part of tartaric acid;

[0034] (3)...

Embodiment 3

[0038] The construction process of the soft soft stone in the indoor floor decoration described in this embodiment includes the following process steps:

[0039] (1) Pretreatment of the base layer: first clean the dust and debris, and use leveling putty for local repair to ensure that there are no holes, cracks and sanding defects on the construction ground;

[0040] (2) Base layer treatment: The pretreated base layer is applied twice with special putty, the thickness of the first construction is 1mm, after drying for 4 hours, the thickness of the second construction is 0.5mm, and after drying for 4 hours, use sandpaper above 80# Grinding treatment; wherein the special putty is composed of the following components by weight: 33 parts of cement, 12 parts of fly ash, 17.5 parts of Nanjing red sand with a particle size of 120-180 meshes, and quartz sand with a particle size of 80-120 meshes 17.5 parts, 0.3 part of alkyl polyoxyethylene ether, 0.7 part of tartaric acid;

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com