Ground heating film buckle plate module

A heating film and gusset technology, applied in the field of ground heating film gusset module, can solve problems such as unfavorable ground heating film gusset module, affecting the effect of laying, affecting product reliability, etc., to improve construction efficiency, use safety, The effect of preventing leakage switch action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

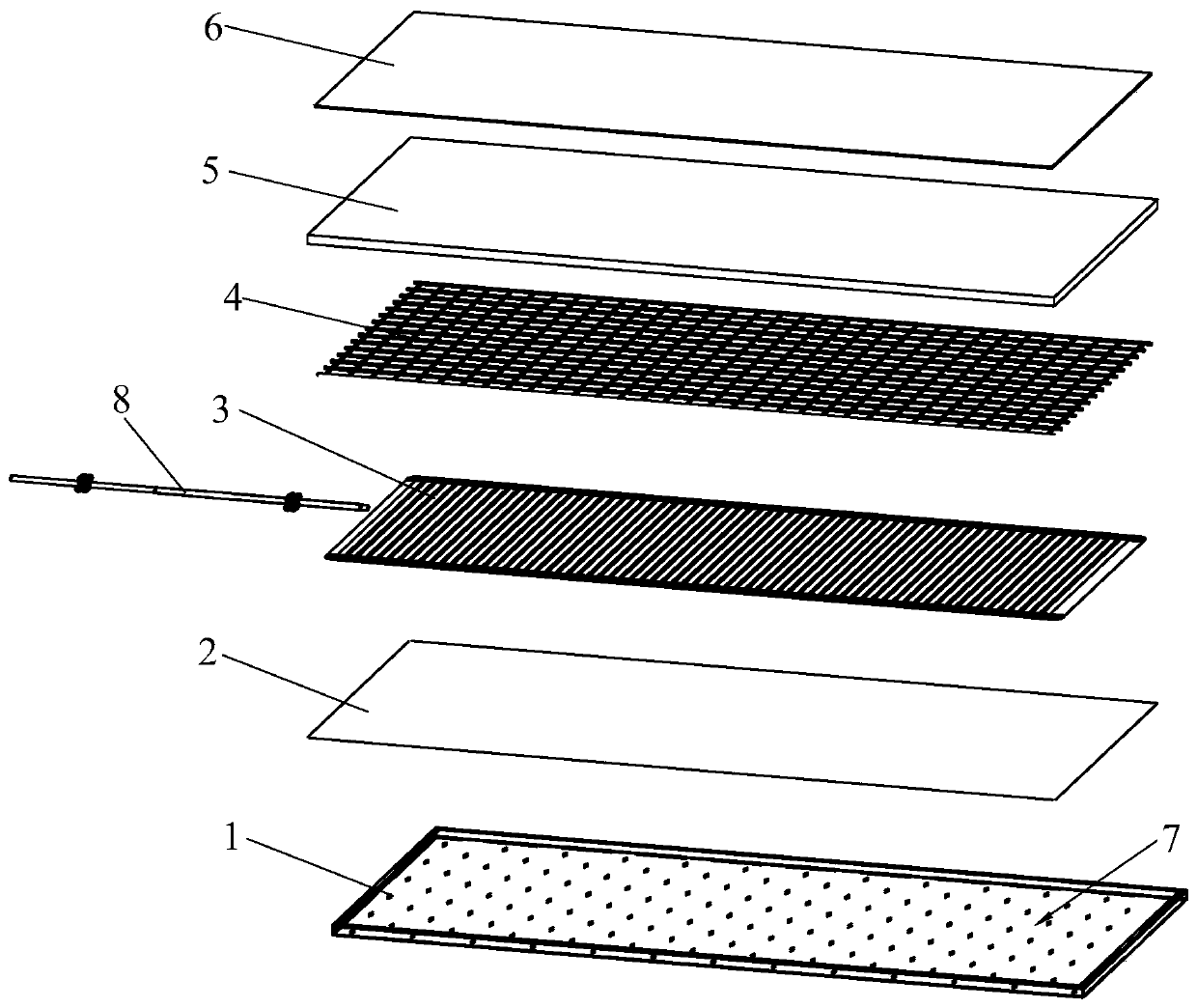

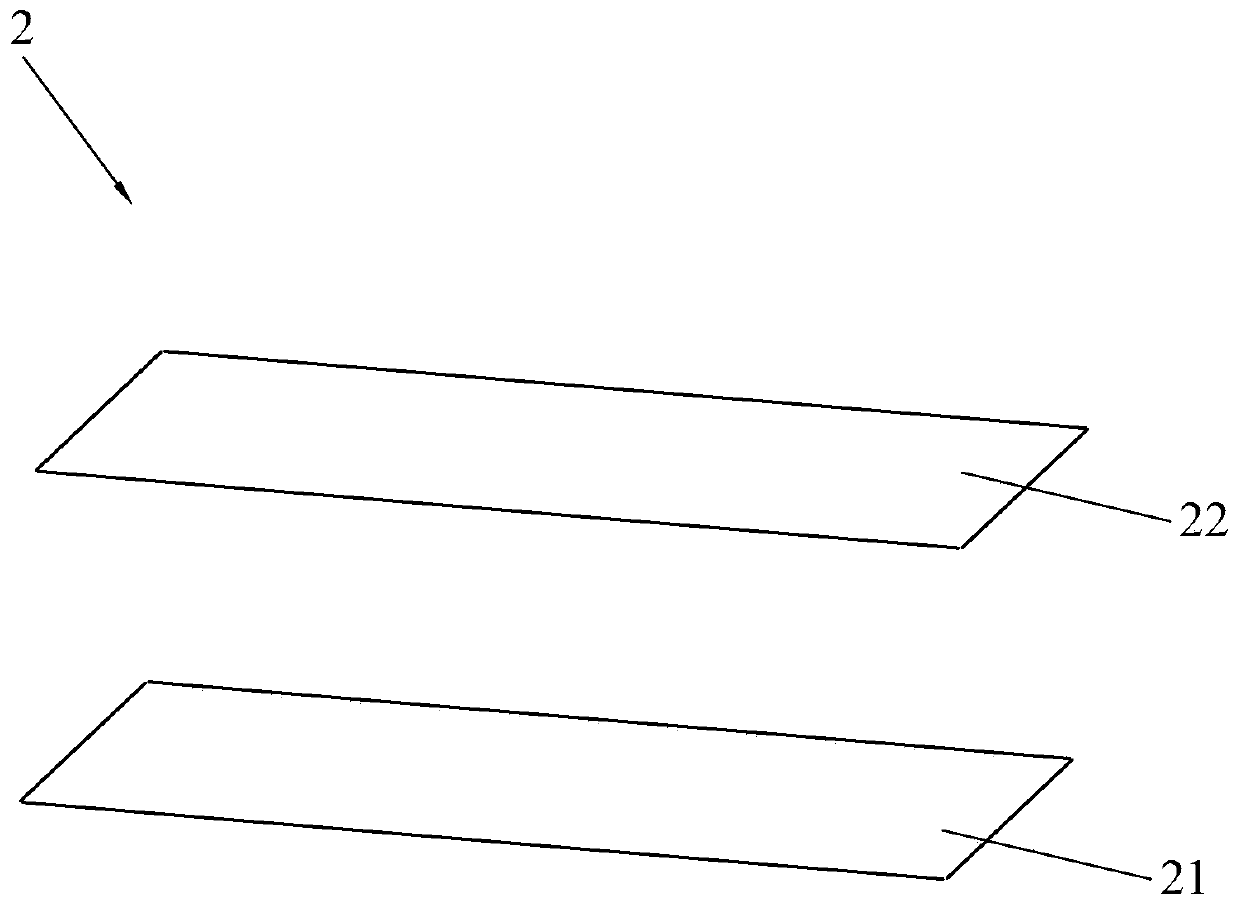

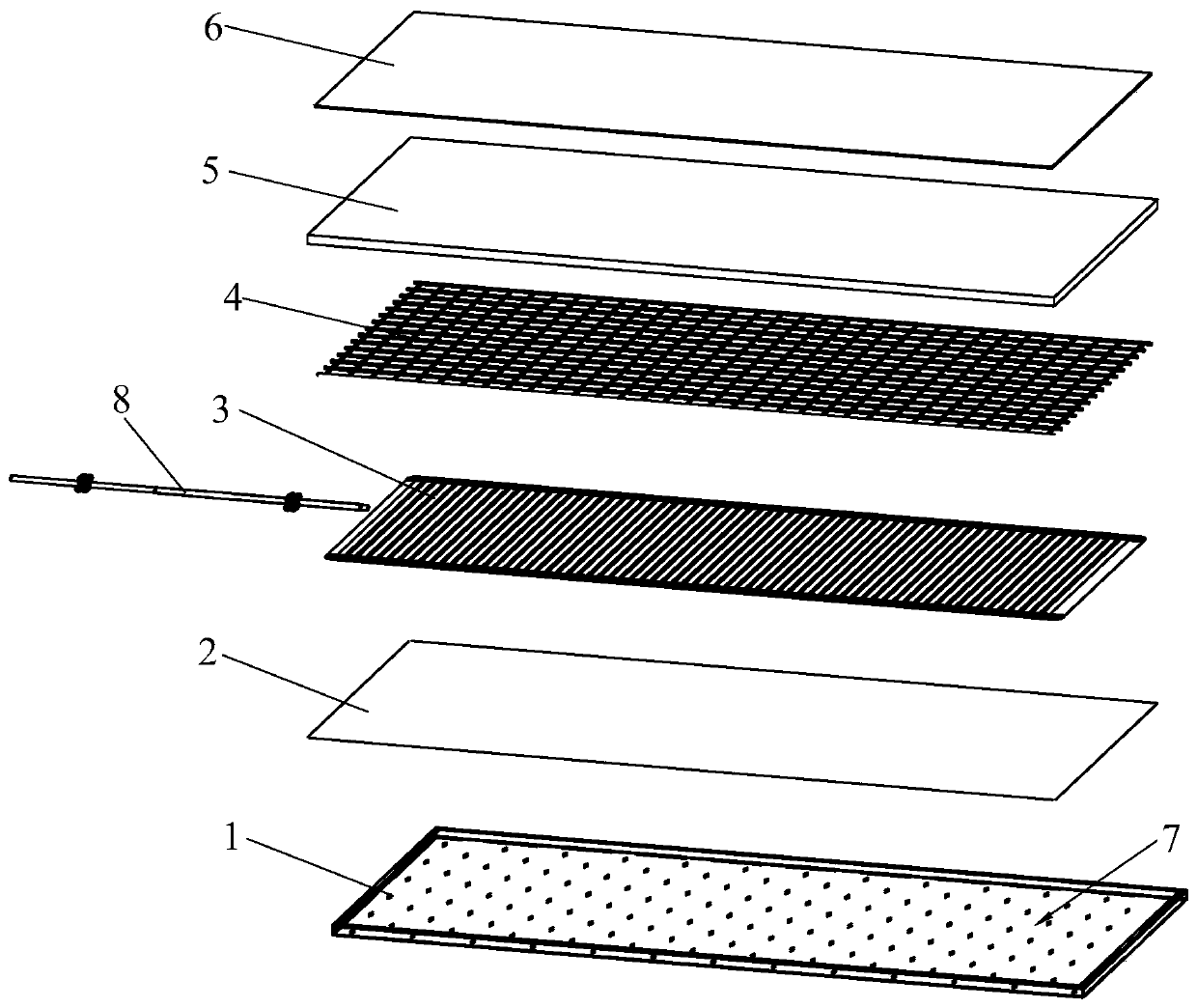

[0017] see figure 1 , the invention discloses a ground heating film gusset module, comprising a lower shell 1, a distributed capacitance current absorbing layer 2, an electrothermal film 3, an anti-twist structure layer 4, a polyurethane heat preservation and flame retardant layer 5, and an upper cover 6, an upper cover 6 It is fixed and integrated with the lower shell 1, and the accommodation cavity 7 is formed between the upper cover 6 and the lower shell 1. The distributed capacitance current absorption layer 2, the electric heating film 3, the anti-twist structure layer 4 and the polyurethane heat preservation and flame-retardant layer 5 are from bottom to bottom. The upper and lower layers are sequentially stacked in the accommodating cavity 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com