Automatic prepreg tape laying device

A prepreg tape, laying technology, applied in the direction of final product manufacturing, manufacturing tools, laser welding equipment, etc., can solve problems such as layer-by-layer laying, affecting the effect of tape laying, wasting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

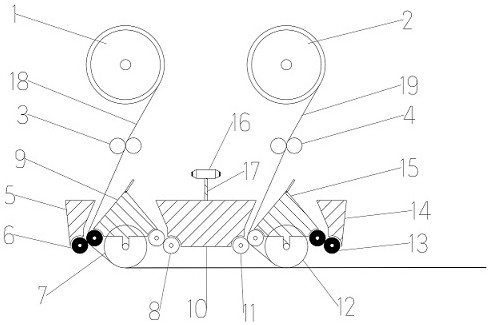

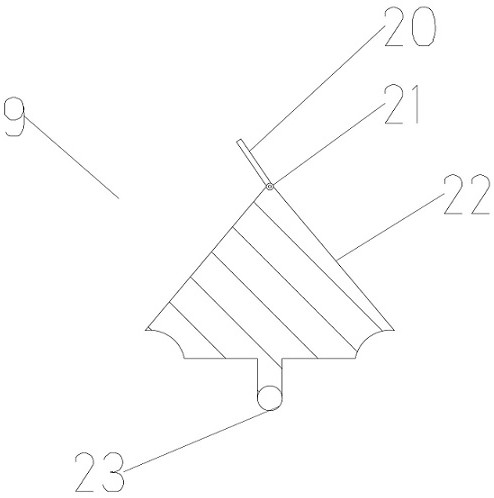

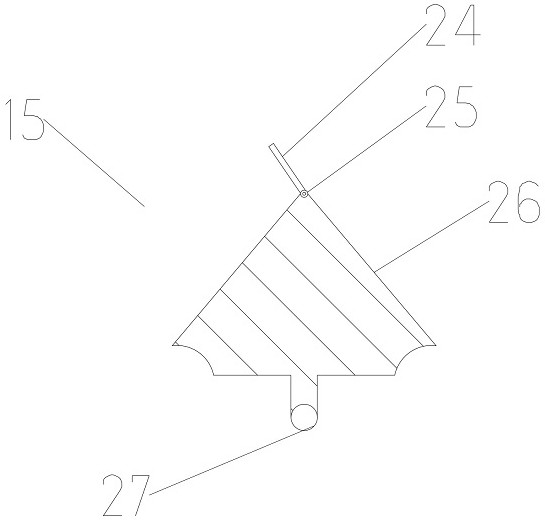

[0031] As shown in the figure: an automatic laying device for prepreg tape, including a feeding mechanism, a laying mechanism, a cutting mechanism, a guiding mechanism and a reversing mechanism, and the cutting mechanism is arranged horizontally between the feeding mechanism and the Between the reversing mechanism, the reversing mechanism is located directly below the feeding mechanism, wherein:

[0032] The feeding mechanism includes a left tape roll 1, a right tape roll 2, a first clamping pair of rolls 3, a second clamping pair of rolls 4, a first prepreg tape 18 and a second prepreg tape 19, the first The prepreg tape 18 is sleeved on the left tape roll 1, and the first clamping pair of rollers 3 are two symmetrically arranged nip rolls, and the first clamping pair of rollers 3 is located on the left tape roll 1 Below, the second prepreg tape 19 is sleeved on the right tape roll 2, the second clamping pair of rollers 4 is two symmetrically arranged nip rollers, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com