Constructing method for laying seamless line track of CPG 500 type seamless line long rail laying machine set

A technology of seamless lines and construction methods, which is applied in the direction of laying tracks, tracks, and track maintenance, and can solve problems such as inapplicability, the efficiency and quality of seamless line track laying that cannot meet the development requirements, and the inability to complete all work simultaneously. , to achieve the effect of high operating efficiency and good laying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] About ballastless bed track laying

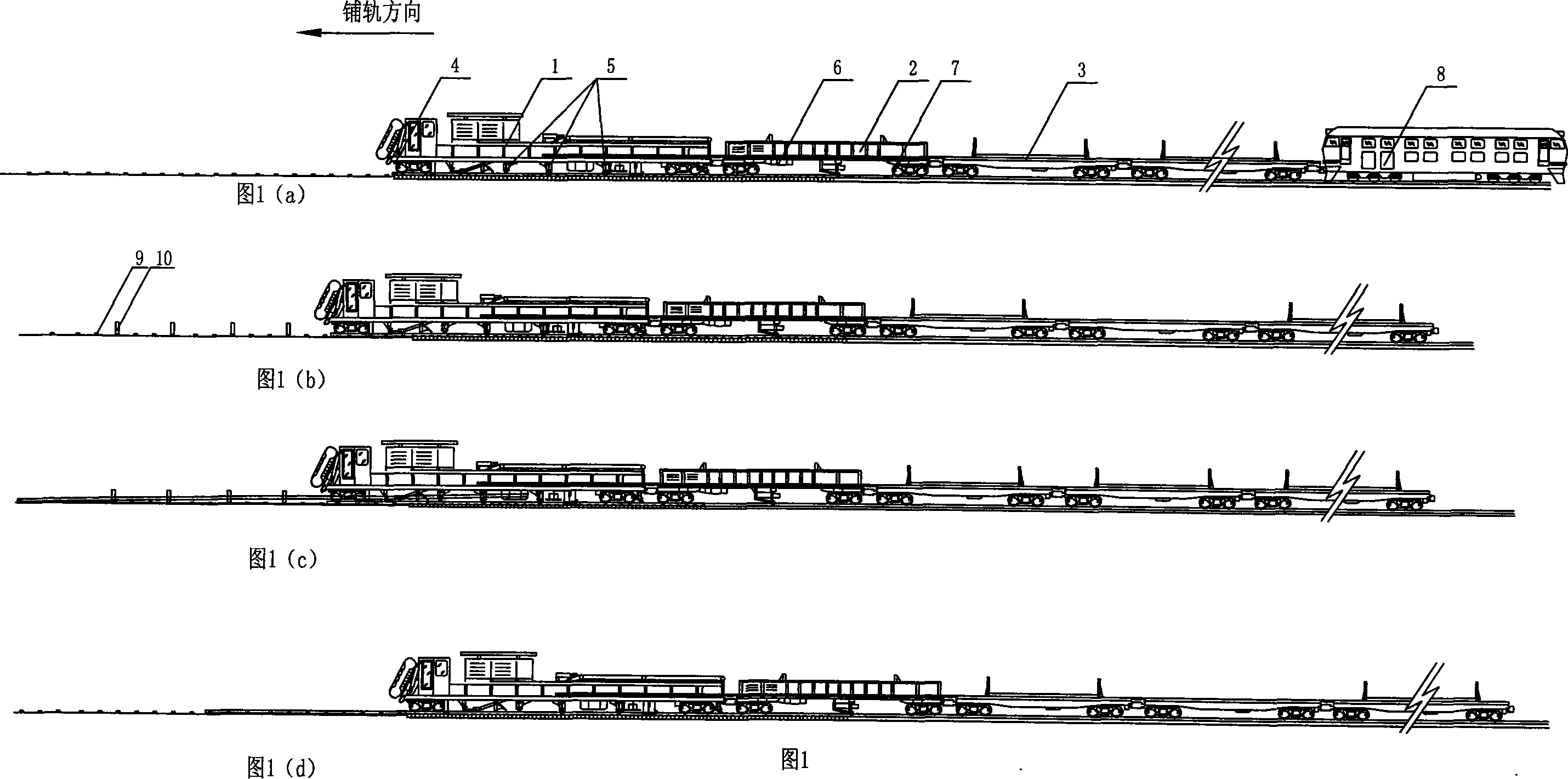

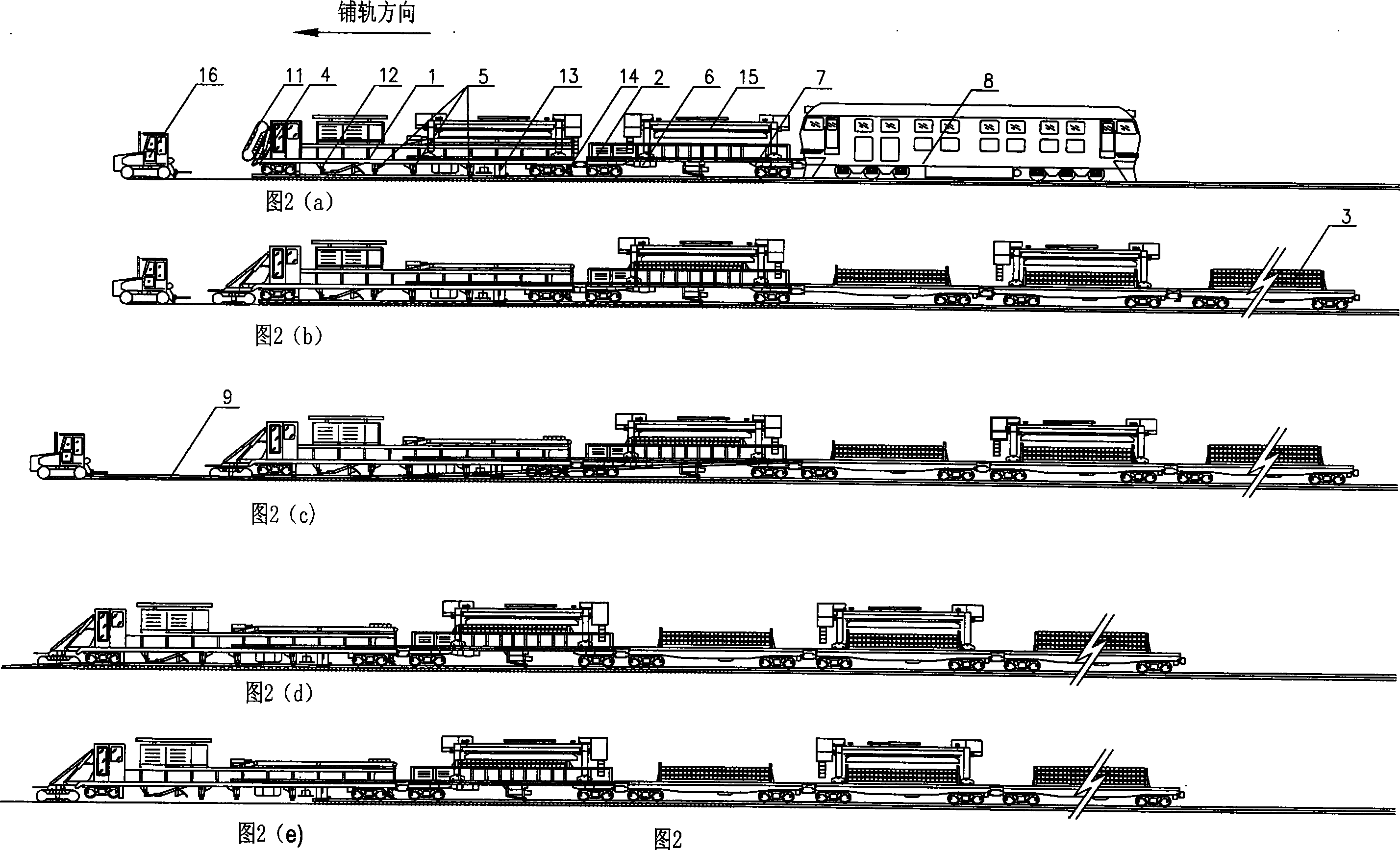

[0038] See Figure 1: Construction is carried out according to the following process:

[0039] The track laying unit is grouped sequentially according to the track laying direction: work car 1, auxiliary power car 2, sleeper rail transport car group 3 and locomotive 8.

[0040] 1. Preparation

[0041] The track laying unit must first reach the state of laying ballastless track.

[0042] (1) The locomotive 8 sends the track-laying unit to the ballastless bed to stop, and the locomotive 8 picks up and returns to the base; the unit is adjusted to the self-propelled state (as shown in Figure 1(a))

[0043] (2) 4m short rails are pre-laid, and the unit aligns itself; 10 sets of rail guides are installed every 5m, and there are four sets in total, and then a pair of rollers 9 are preset every 5m along the bearing groove of the ballastless ballast bed; (as shown in Figure 1(b))

[0044] (3) Unload the locking device of a pair of long rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com