Cement floor paving equipment used for building construction

A construction and cement technology, applied in the field of cement floor laying equipment for construction, can solve the problems of high labor intensity, uneven cement laying, slow laying speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

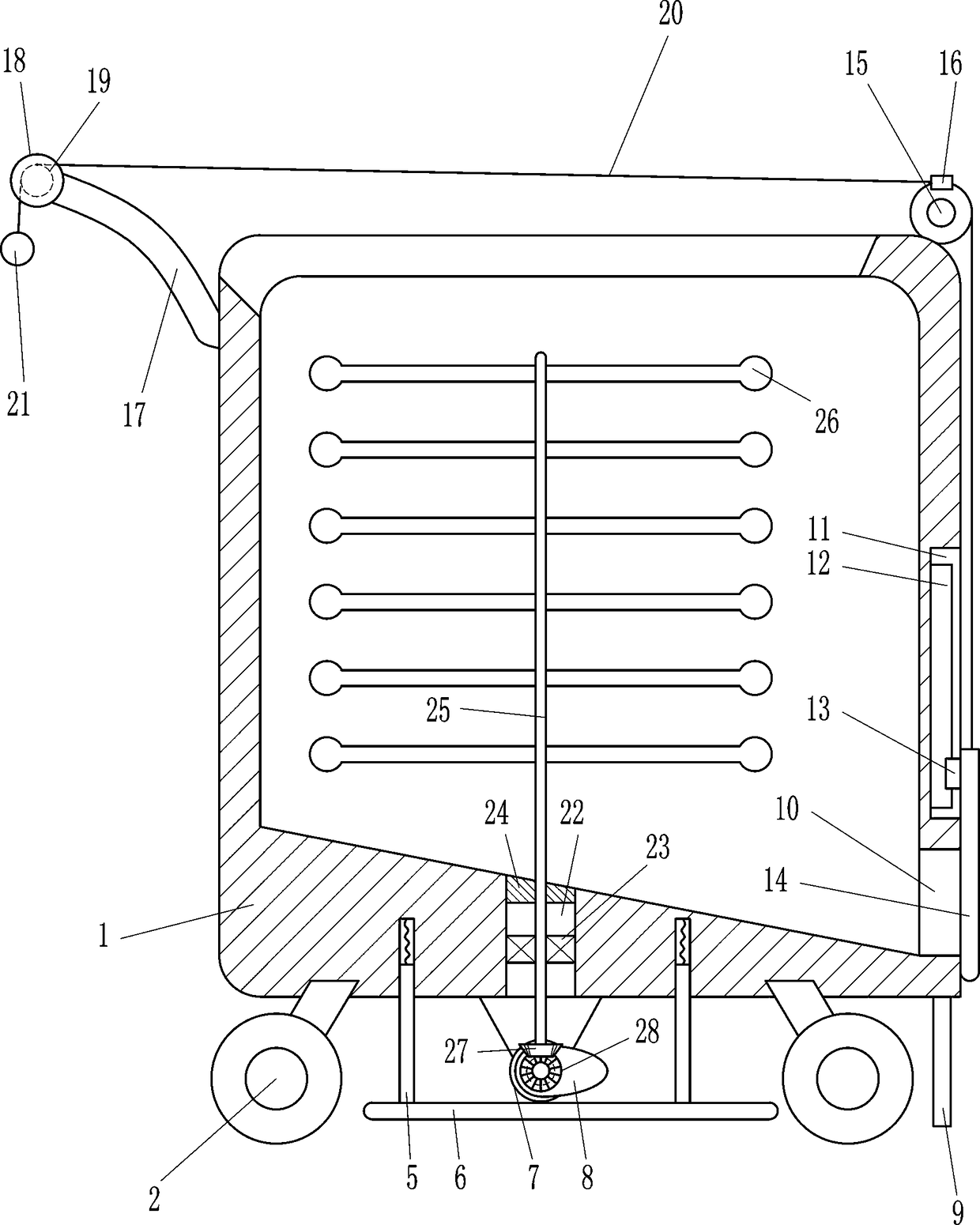

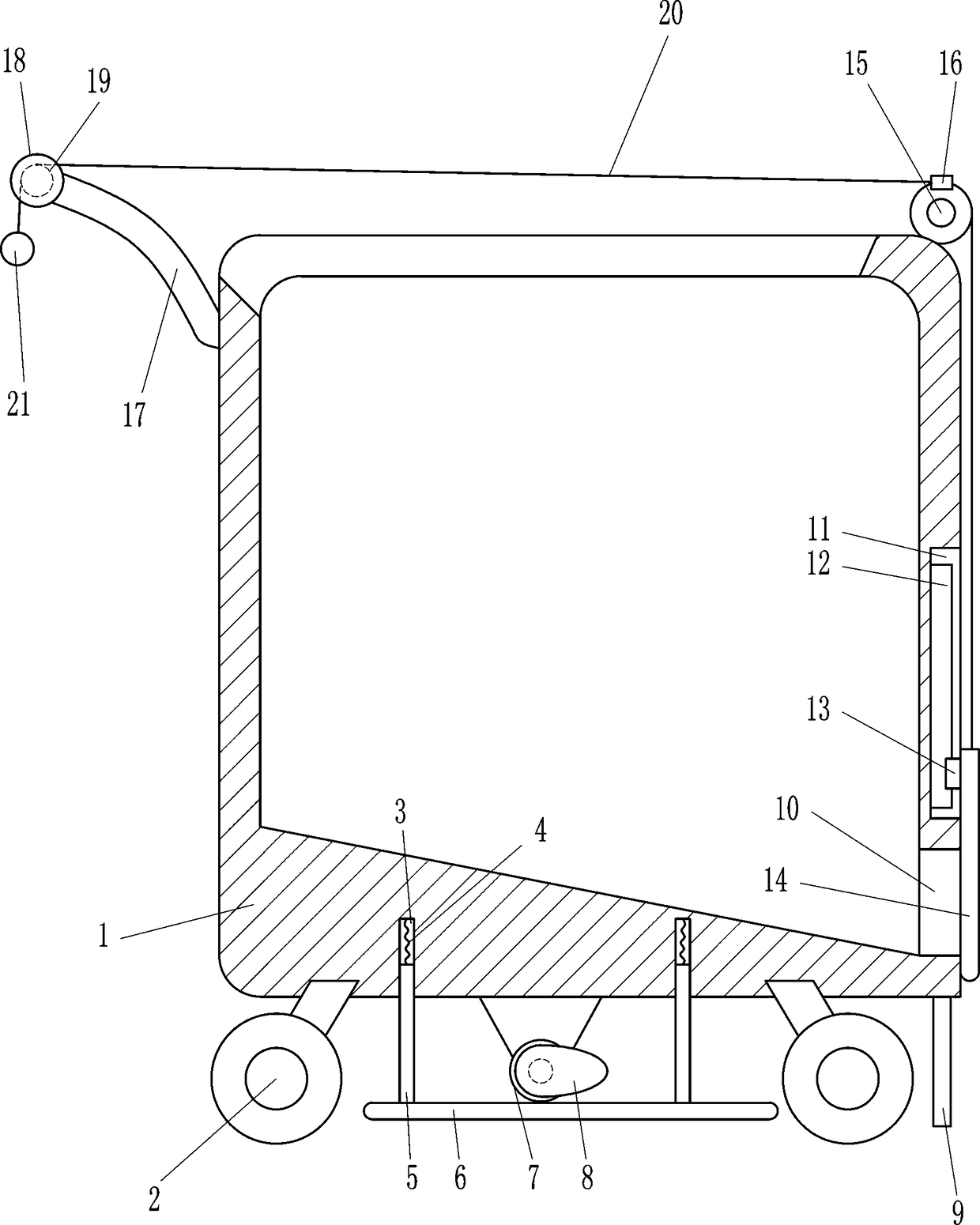

Embodiment 1

[0019] A kind of cement floor laying equipment for building construction, such as Figure 1-3 As shown, it includes frame body 1, wheel 2, first spring 4, guide rod 5, pressing plate 6, motor 7, cam 8, push plate 9, slide rail 12, slider 13, baffle plate 14, fixed pulley 15, Blocks 16, connecting rods 17, push rods 18, pull wires 20 and pull balls 21, wheels 2 are installed at the bottom of the frame body 1, guide grooves 3 are opened on the left and right sides of the bottom of the frame body 1, and the guide grooves 3 on the left and right sides The upper inner wall is connected with the first spring 4, and the bottom ends of the first springs 4 on the left and right sides are connected with guide rods 5, and the upper parts of the guide rods 5 on the left and right sides are all slidably positioned in the guide groove 3, and the guide rods on the left and right sides The bottom end of the rod 5 is connected with a pressure plate 6, the middle part of the lower side of the f...

Embodiment 2

[0021] A kind of cement floor laying equipment for building construction, such as Figure 1-3 As shown, it includes frame body 1, wheel 2, first spring 4, guide rod 5, pressing plate 6, motor 7, cam 8, push plate 9, slide rail 12, slider 13, baffle plate 14, fixed pulley 15, Blocks 16, connecting rods 17, push rods 18, pull wires 20 and pull balls 21, wheels 2 are installed at the bottom of the frame body 1, guide grooves 3 are opened on the left and right sides of the bottom of the frame body 1, and the guide grooves 3 on the left and right sides The upper inner wall is connected with the first spring 4, and the bottom ends of the first springs 4 on the left and right sides are connected with guide rods 5, and the upper parts of the guide rods 5 on the left and right sides are all slidably positioned in the guide groove 3, and the guide rods on the left and right sides The bottom end of the rod 5 is connected with a pressure plate 6, the middle part of the lower side of the f...

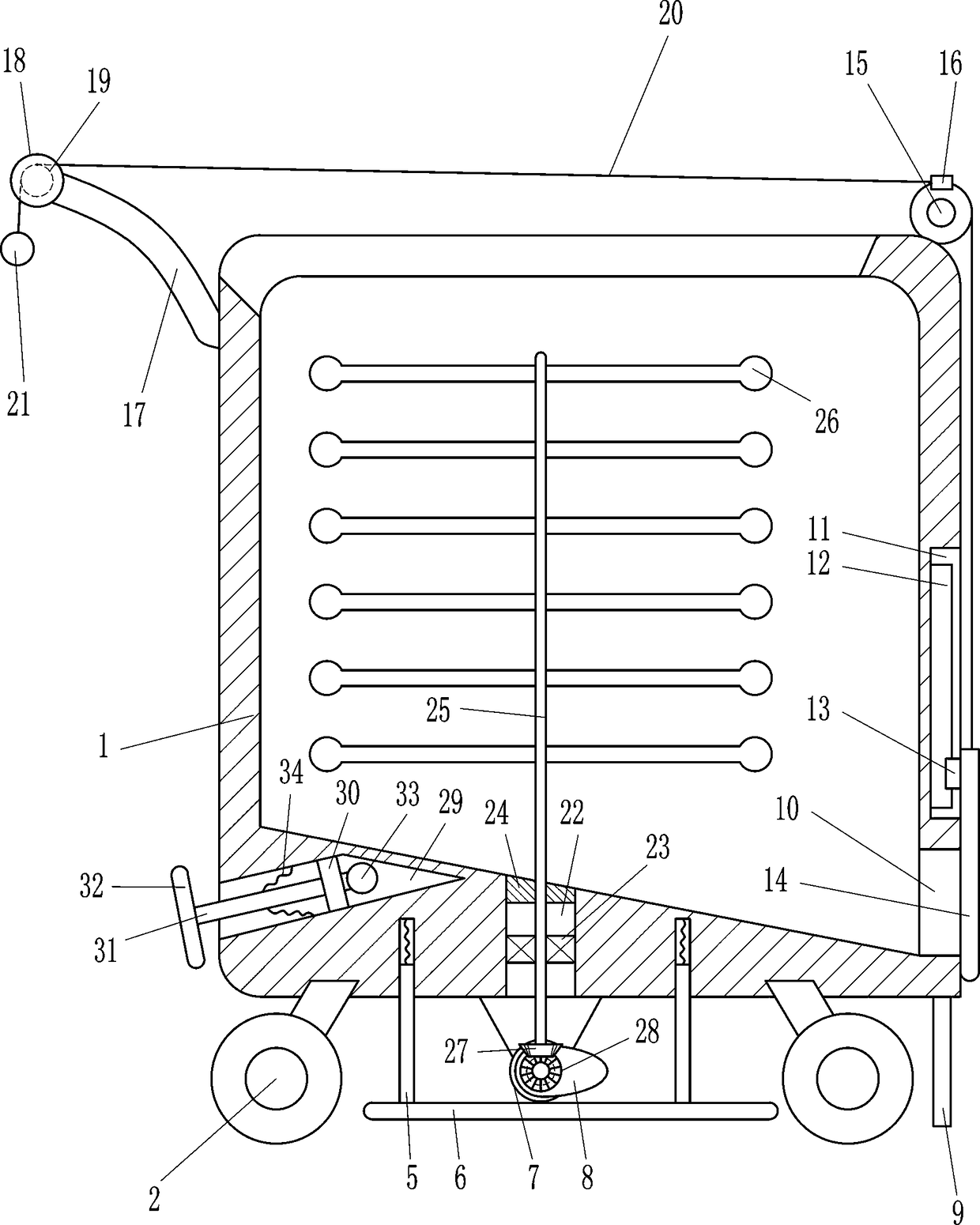

Embodiment 3

[0024] A kind of cement floor laying equipment for building construction, such as Figure 1-3As shown, it includes frame body 1, wheel 2, first spring 4, guide rod 5, pressing plate 6, motor 7, cam 8, push plate 9, slide rail 12, slider 13, baffle plate 14, fixed pulley 15, Blocks 16, connecting rods 17, push rods 18, pull wires 20 and pull balls 21, wheels 2 are installed at the bottom of the frame body 1, guide grooves 3 are opened on the left and right sides of the bottom of the frame body 1, and the guide grooves 3 on the left and right sides The upper inner wall is connected with the first spring 4, and the bottom ends of the first springs 4 on the left and right sides are connected with guide rods 5, and the upper parts of the guide rods 5 on the left and right sides are all slidably positioned in the guide groove 3, and the guide rods on the left and right sides The bottom end of the rod 5 is connected with a pressure plate 6, the middle part of the lower side of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com