Full-automatic bagging, metering and packaging system based on vision detection

A fully automatic packaging and visual inspection technology, applied in the fields of quantitative weighing, packaging and bag sewing, bagging, and automatic material transportation, can solve the problems of inaccurate positioning, large precision deviation, and limited quantity, etc., to achieve accurate positioning and guarantee Effects of Speed and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

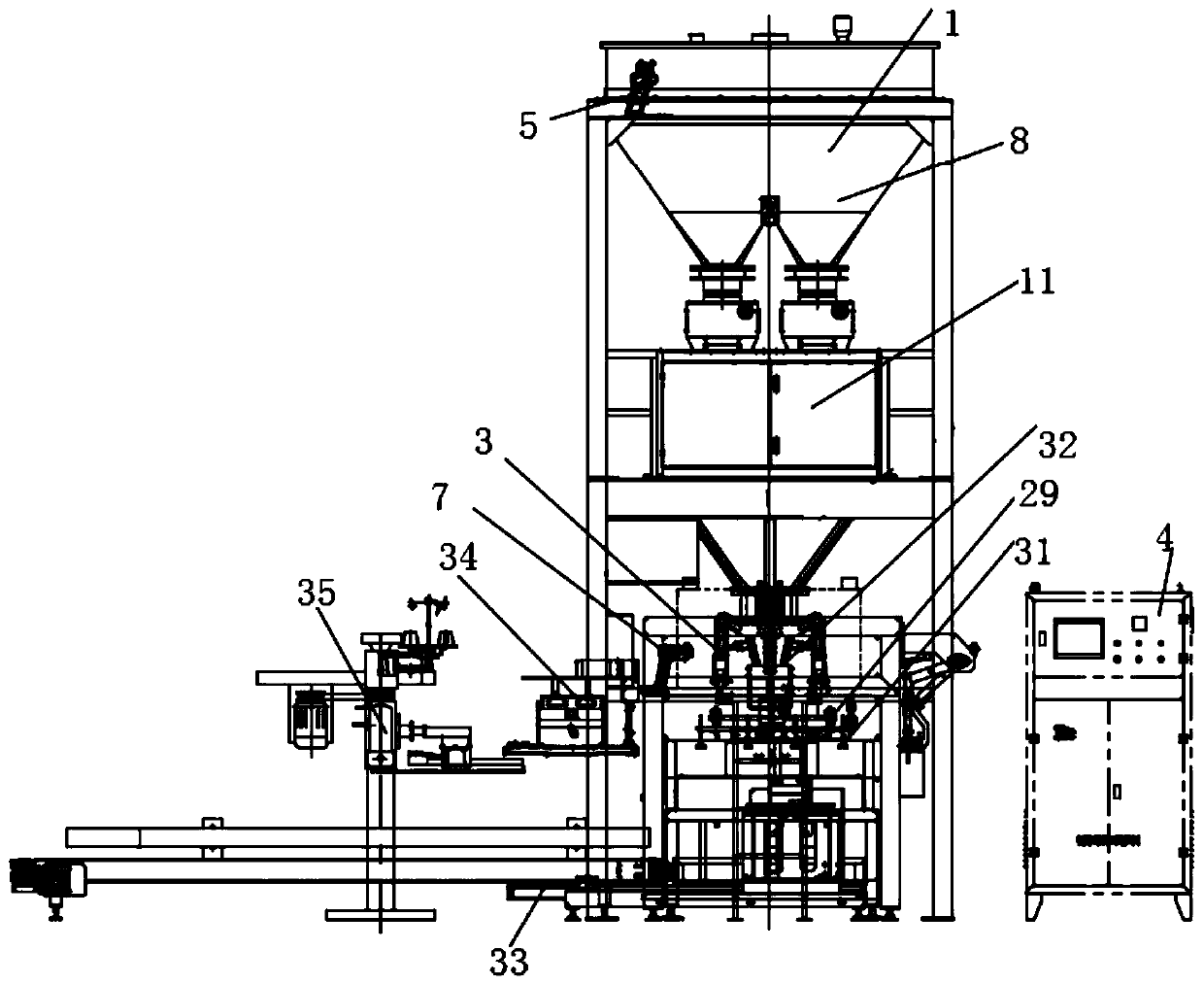

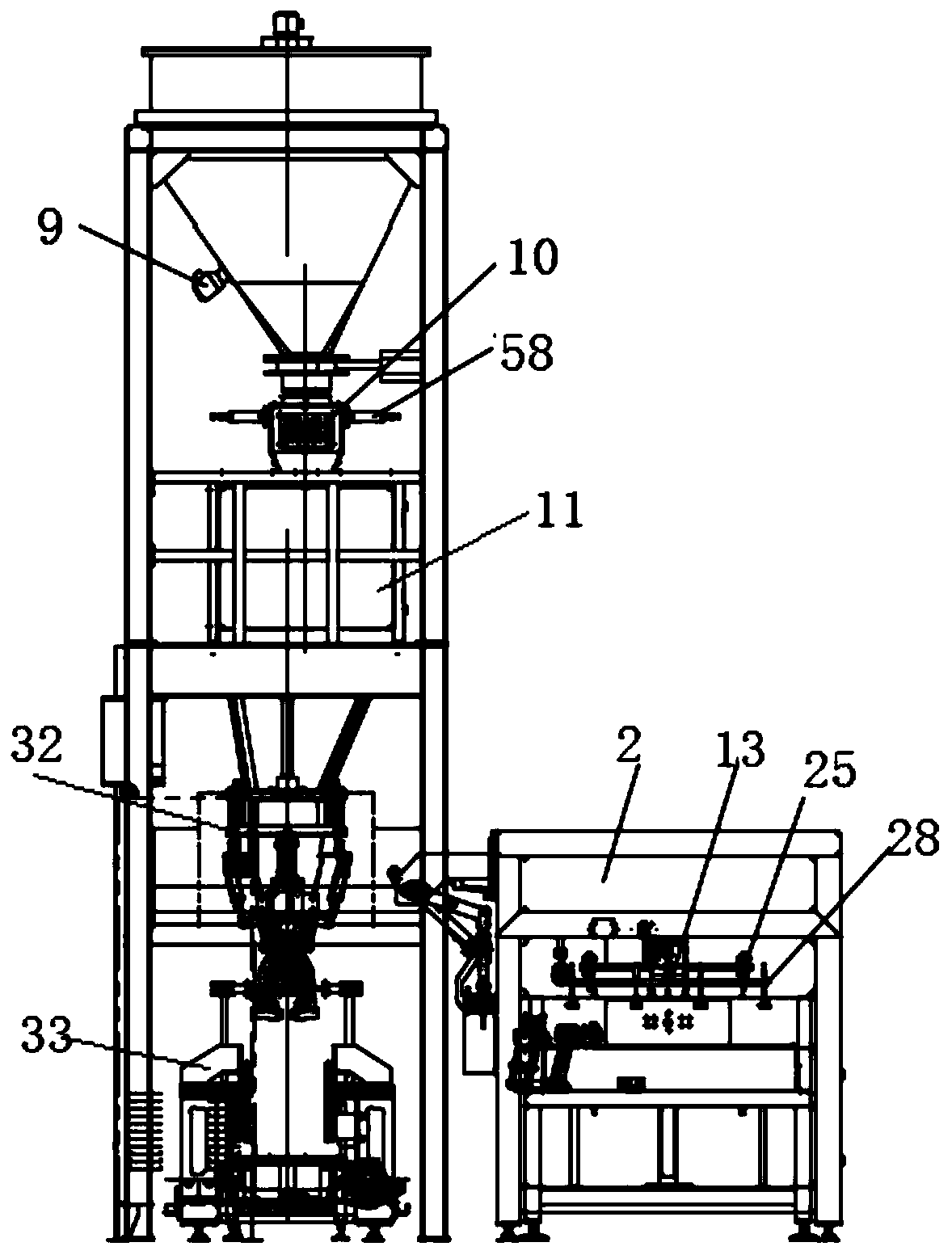

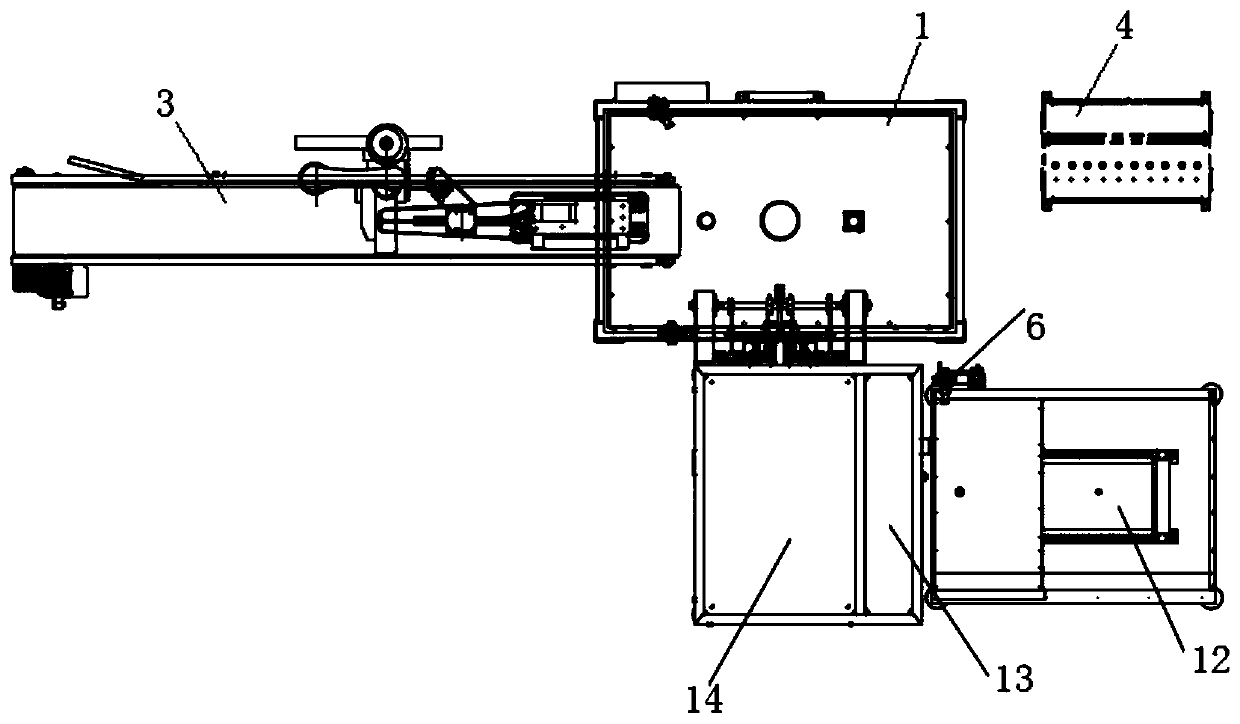

[0059] Such as figure 1 , 2 , 3, a fully automatic bagging and measuring packaging system based on visual inspection, including:

[0060] Fully automatic quantitative metering unit 1 for feeding and metering;

[0061] Fully automatic bagging unit 2 for bag supply, replacement and bagging;

[0062] Fully automatic packaging unit 3 for bag clamping, bag transfer, and bag sewing;

[0063] An electric control device 4 for controlling the automatic quantitative metering unit 1, the automatic bagging unit 2 and the automatic packaging unit 3;

[0064] The full-automatic quantitative metering unit 1 is equipped with a visual detection mechanism one 5, and the fully automatic bagging unit 2 is respectively equipped with a visual detection mechanism two 6 and a visual detection mechanism three 7. The visual detection mechanism one 5, visual Both the detection mechanism 2 6 and the visual detection mechanism 3 7 are in communication connection with the electric control device 4 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com