Design drawing binding equipment for industrial design

A technology for designing drawings and binding equipment, which is applied in the direction of binding, book binding, and compound continuous process of book processing. Guaranteed neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

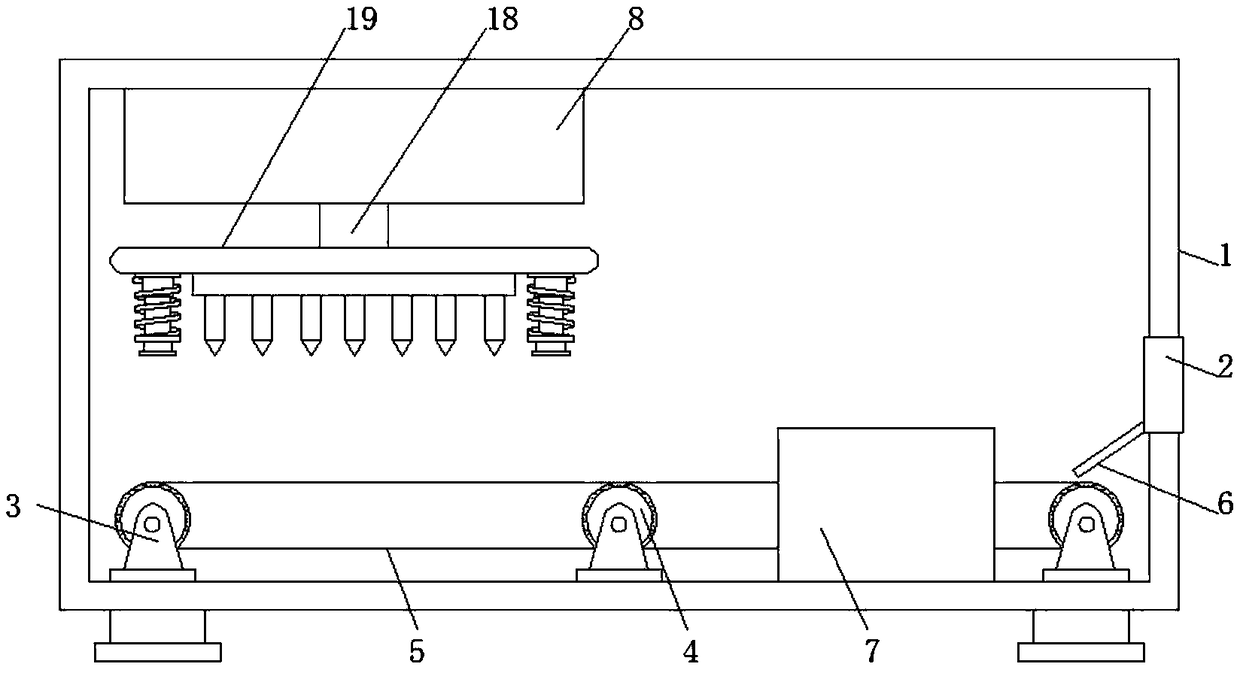

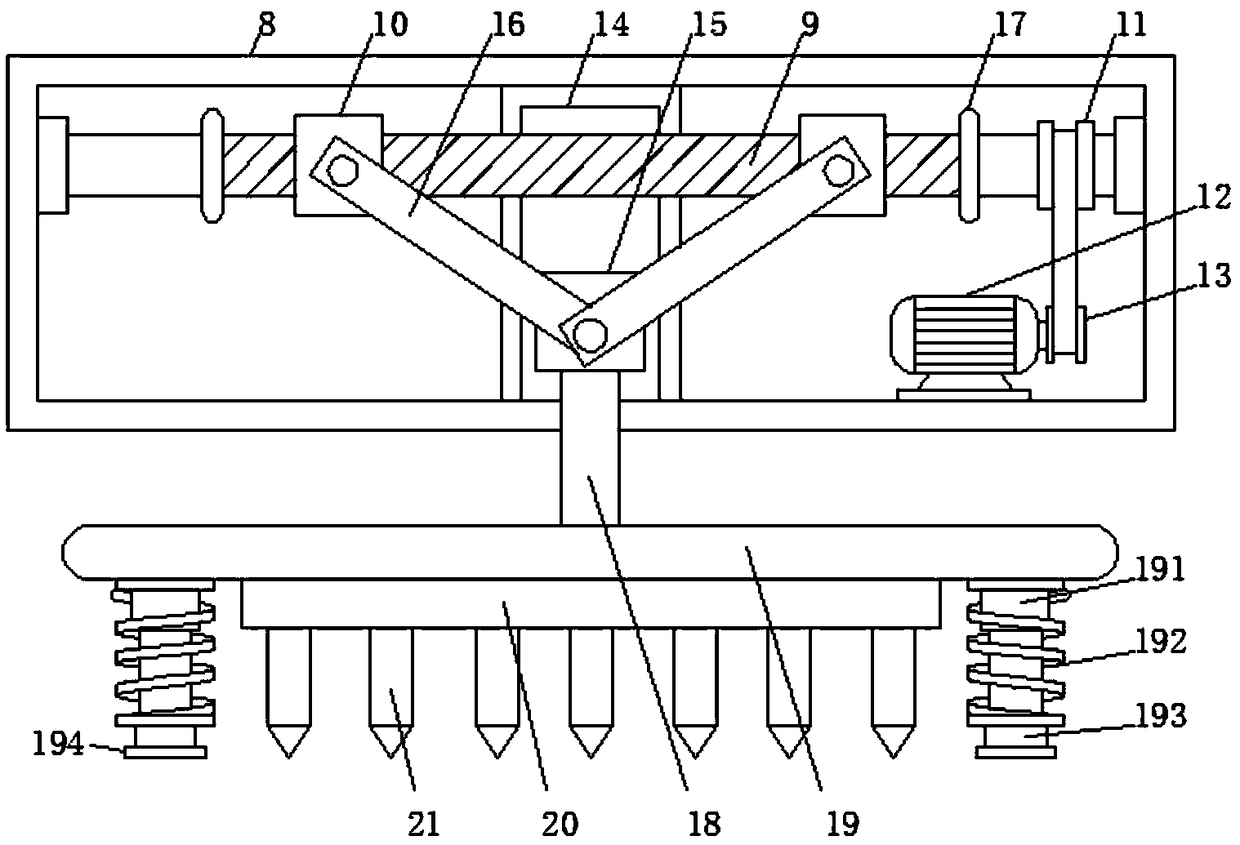

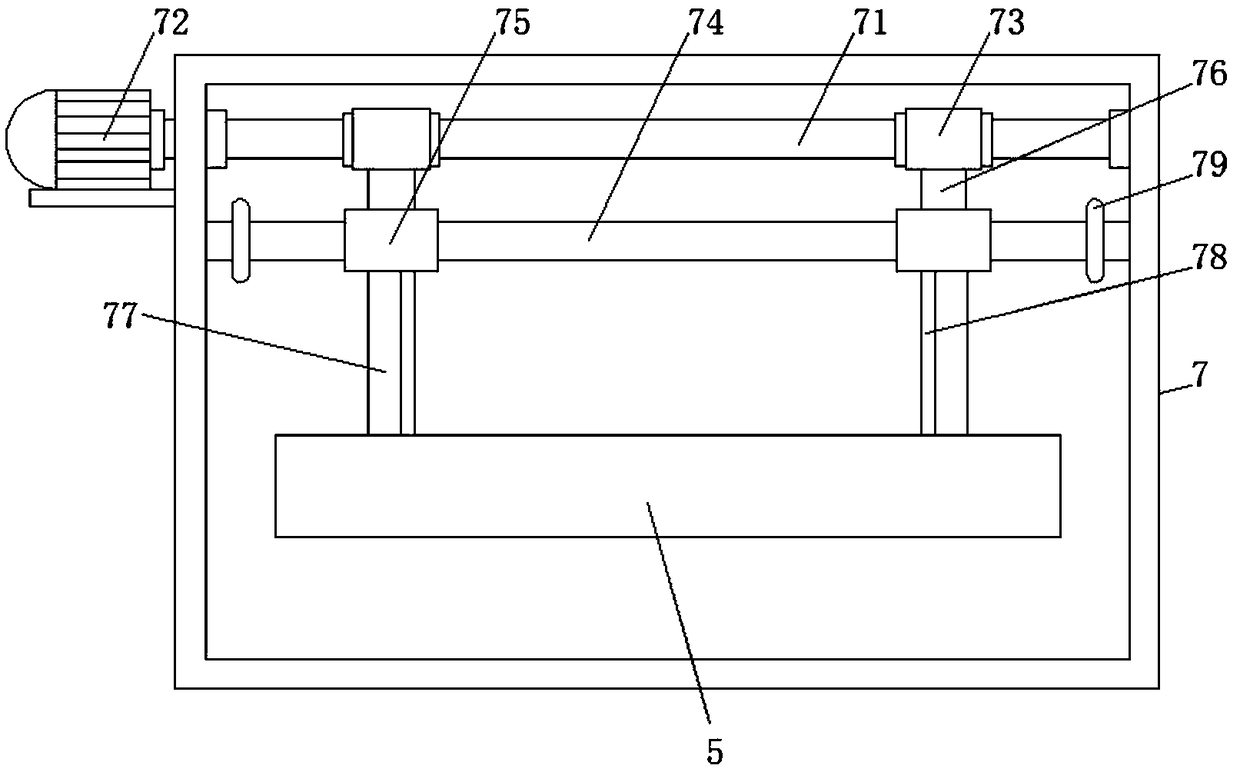

[0028] Such as Figure 1-3 As shown, the present invention provides a technical solution: a design drawing binding device for industrial design, including a binding box 1, an entrance 2 is opened on the right side of the binding box 1, and three support seats 3 are fixedly connected to the bottom of the inner wall of the binding box 1 , and the tops of the three support bases 3 are rotatably connected with the transmission roller 4, the three transmission rollers 4 are connected by transmission belt 5, the right side of the inner wall of the binding box 1 and the bottom of the entrance 2 are fixedly connected with one end of the swash plate 6, And the other end position of swash plate 6 is above the top of the right end of conveyor belt 5, and the right side of the bottom of the inner wall of the binding box 1 is fixedly connected with a sorting box 7, and the top of the right side of the inner wall of the box 7 is fixed to the right end of the second threaded rod 71 by a beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com