Energy-saving environment-friendly building bricklaying device

An energy-saving and environmental-friendly brick-laying technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems affecting the quality of high-rise buildings, uneven cement filling, brick-laying flatness and verticality errors, etc., to achieve Prevent cement leakage from polluting the environment, reduce waste, and ensure the tidy effect of bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

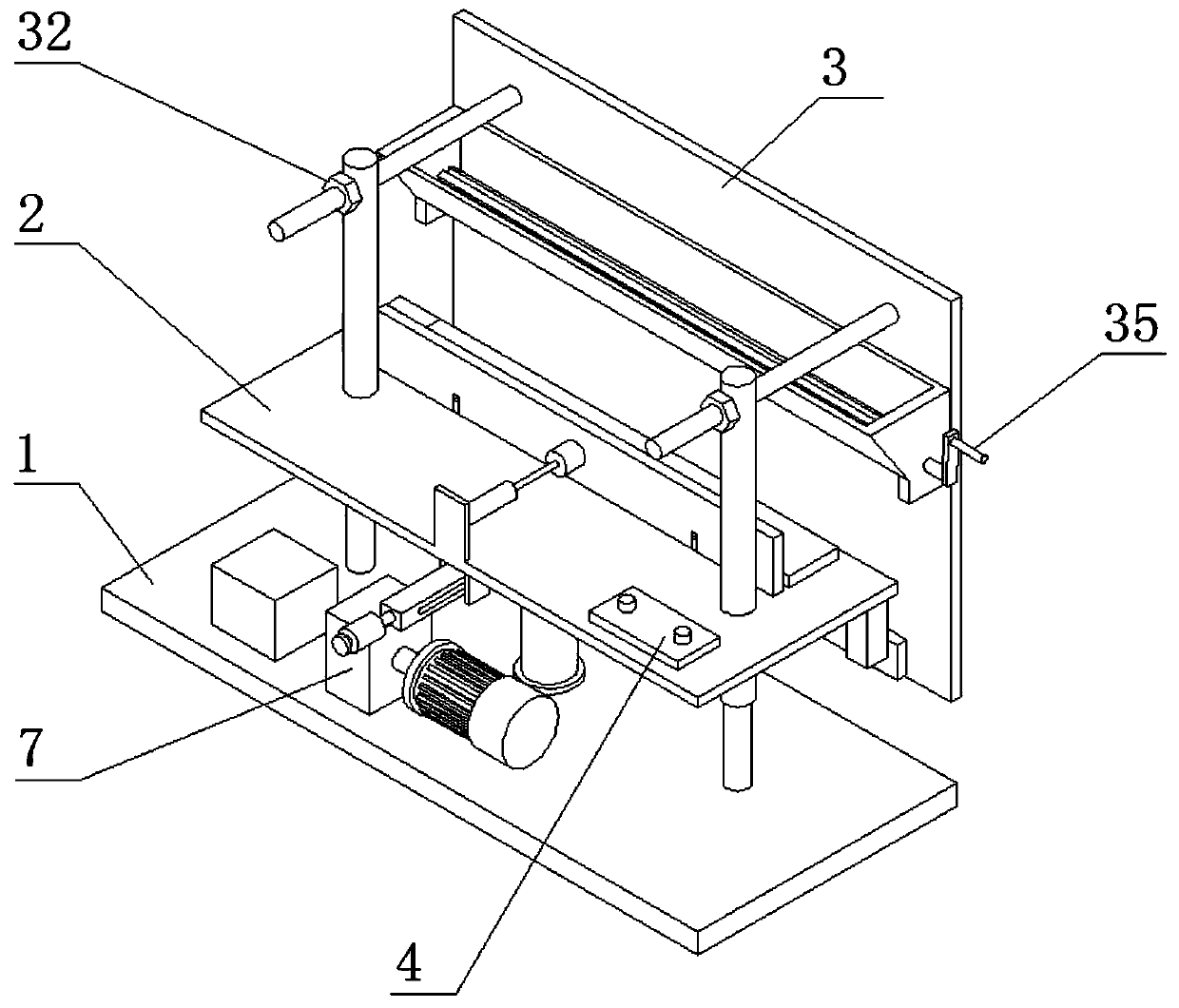

[0032] As a preferred embodiment of the present invention, the outer side of one end of the adjustment cylinder 28 is provided with threads and an adjustment nut 32 is connected thereto.

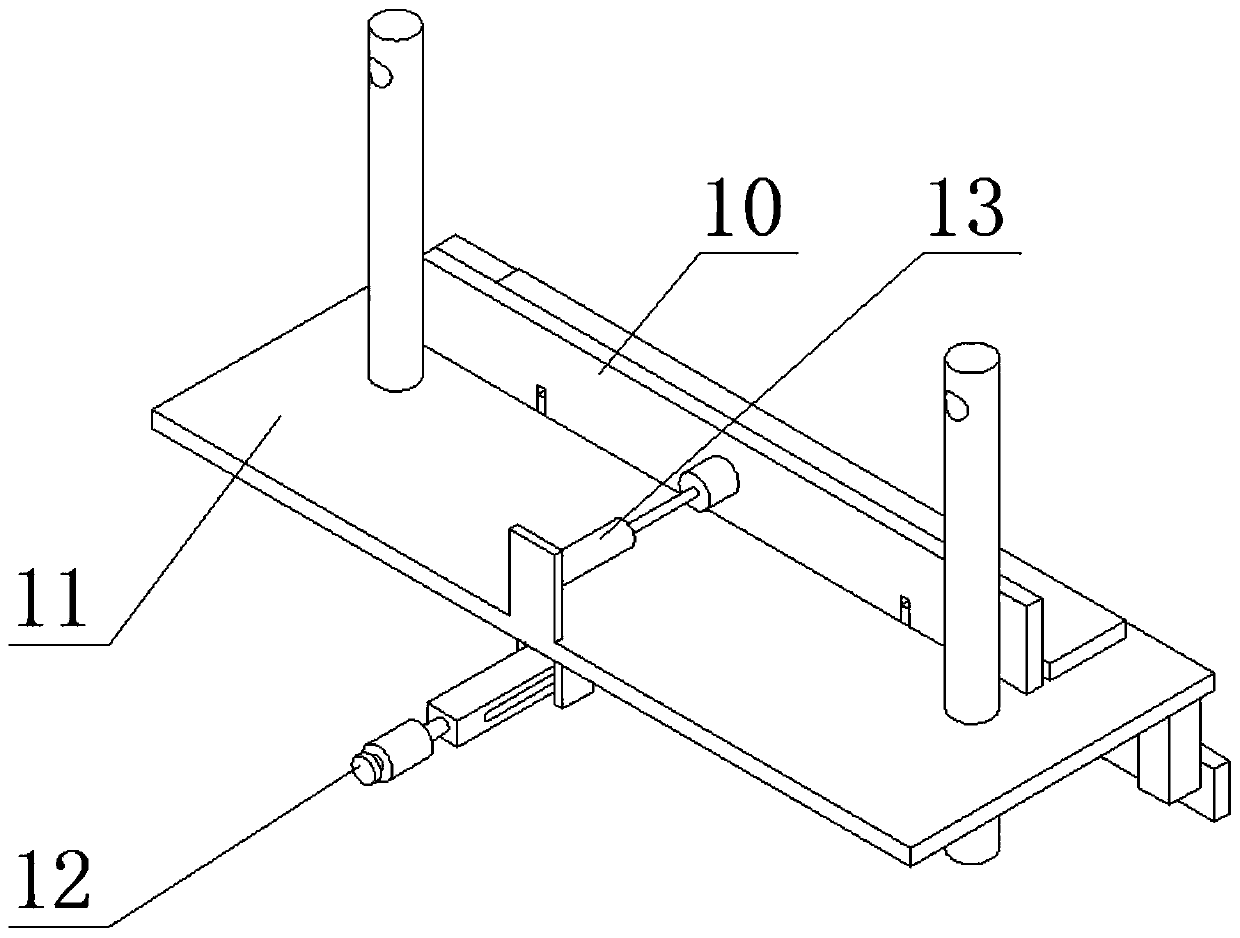

[0033] As a preferred embodiment of the present invention, a connecting rod is welded on the bottom side wall of the supporting plate 11 , and a leakproof plate 33 is welded on one side of the connecting rod.

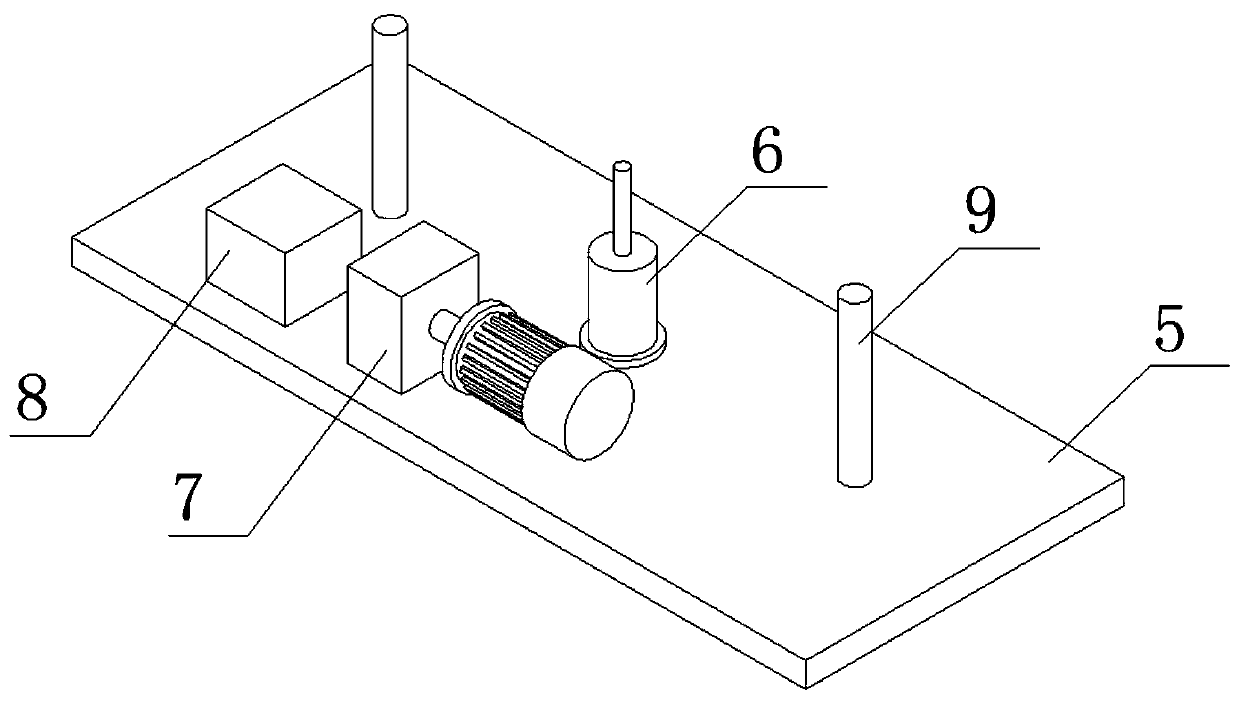

[0034] As a preferred embodiment of the present invention, the outer side of the discharge wheel 27 is uniformly provided with a material picking groove 34 , and one end of the discharge wheel 27 is provided with a rotating handle 35 .

[0035] As a preferred embodiment of the present invention, the control buttons include a start button, a lift button, a drop button, a push button, a return button and a close button, and the control buttons are connected to the hydraulic pump 7 through wires.

[0036] Working principle: first connect the control box 4 to the external power supply throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com