Washing machine feet with automatic levelling function and washing machine

An automatic leveling and washing machine technology, applied to other washing machines, engine frames, legs of general furniture, etc., can solve problems such as narrow setting space, inconvenient operation for users, damage to washing machines, etc., achieve large adjustment range, good adjustment effect, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The washing machine feet and washing machine with automatic leveling function of the present invention will be described in detail below in conjunction with the accompanying drawings:

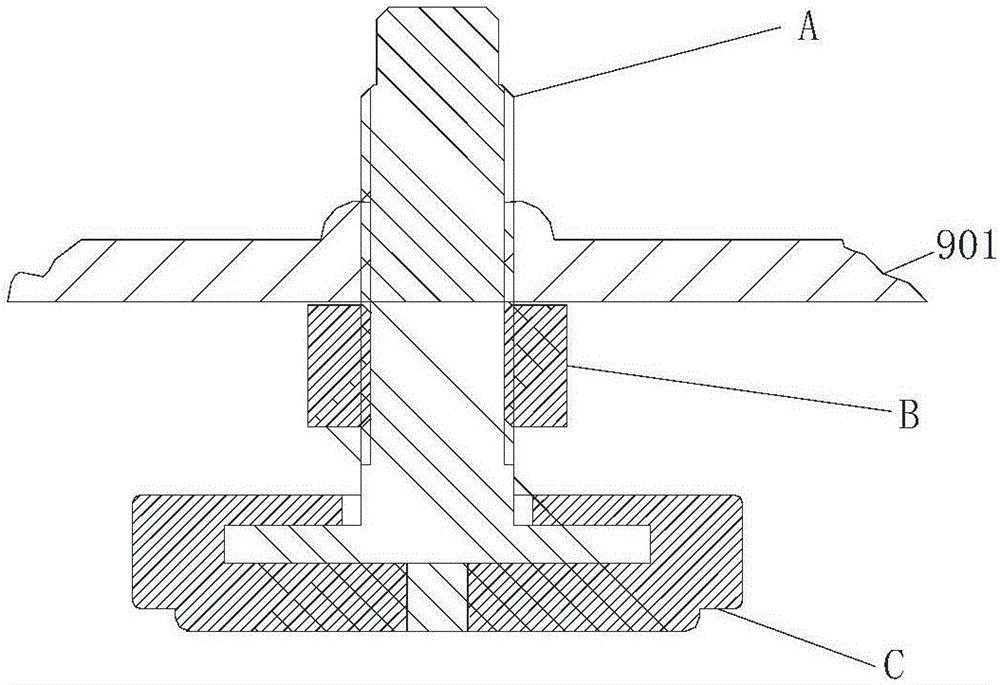

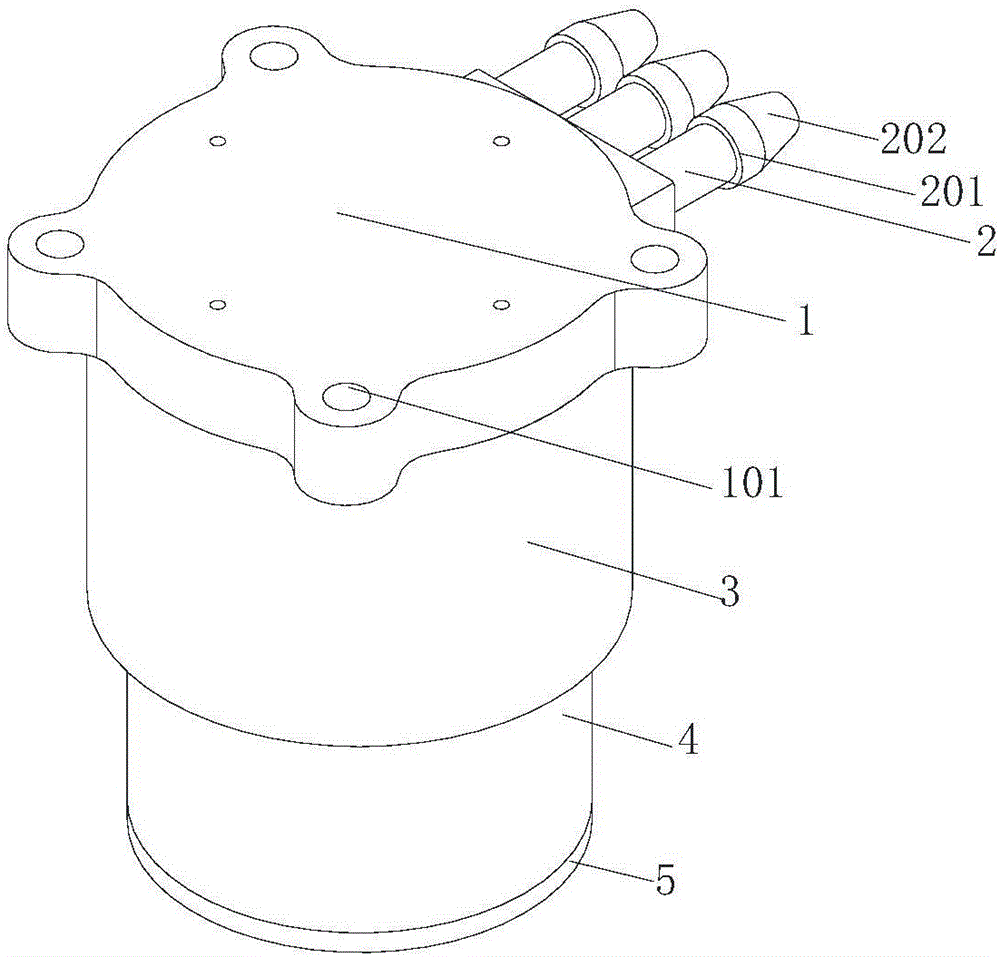

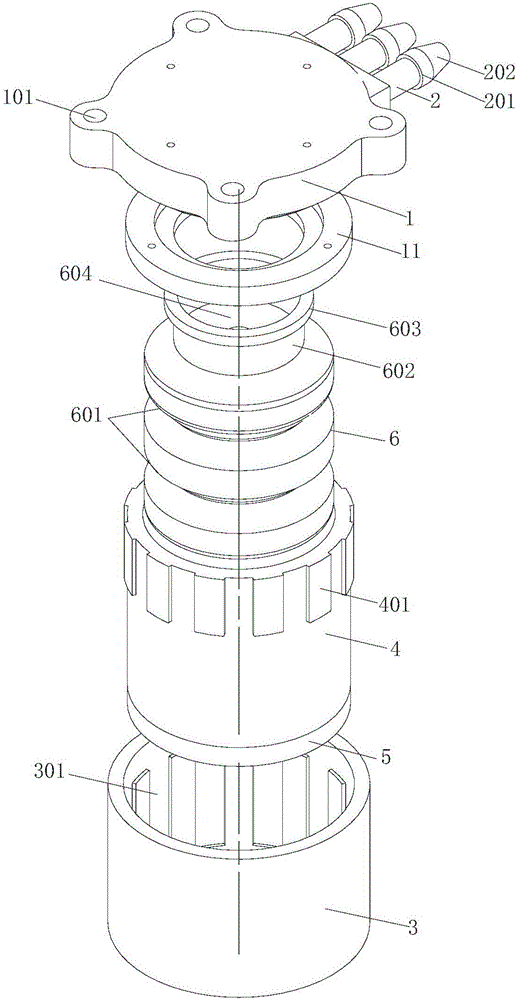

[0049] Such as Figure 2-Figure 9As shown, the foot of the washing machine with automatic leveling function in this embodiment includes a foot seat, a flexible container 6 and an adjustment foot 4; the foot seat has a hollow chamber, and the foot seat is respectively provided with a The throttling hole 7 and the valve hole 8 communicated with each other, and the throttling hole 7 and the valve hole 8 are respectively connected to the high-pressure oil pipe; the flexible containing body 6 is arranged in the hollow chamber, and the flexible containing body 6 has an accommodating chamber inside, and the accommodating chamber The interior of the chamber is filled with hydraulic medium, and under the action of pressure, the hydraulic medium in multiple feet can communicate with each other thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com