Patents

Literature

52results about How to "Achieve automatic alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

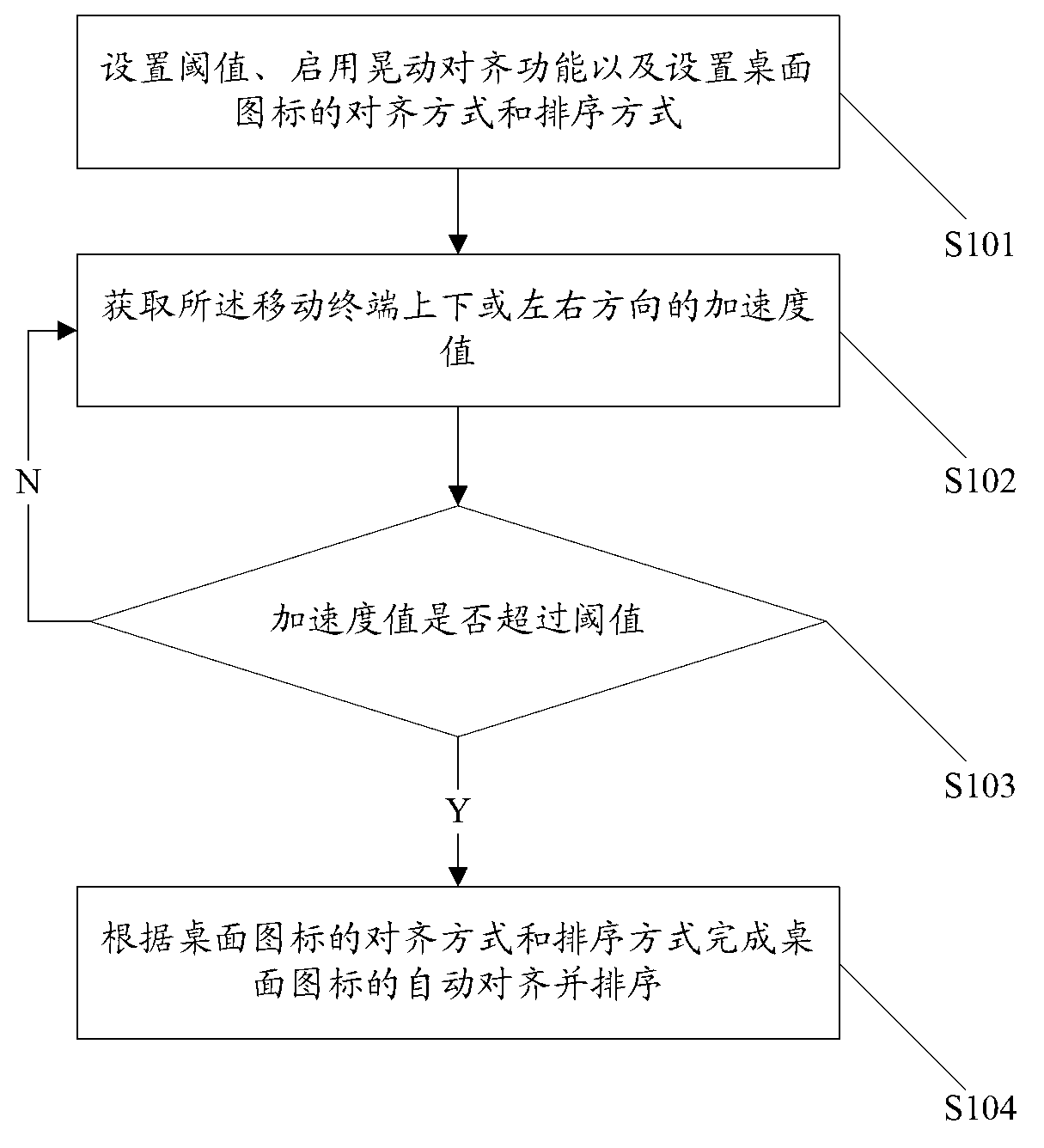

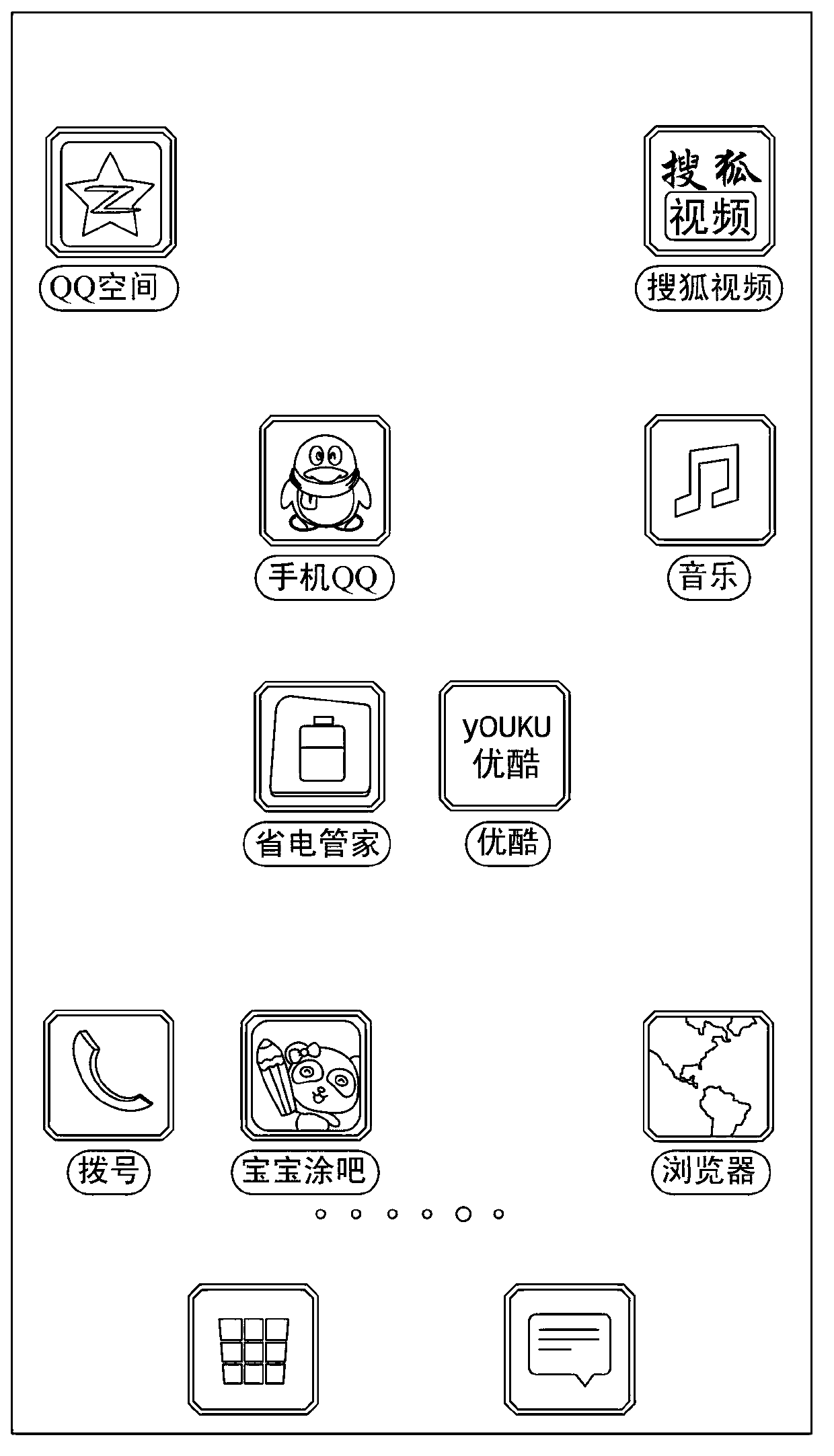

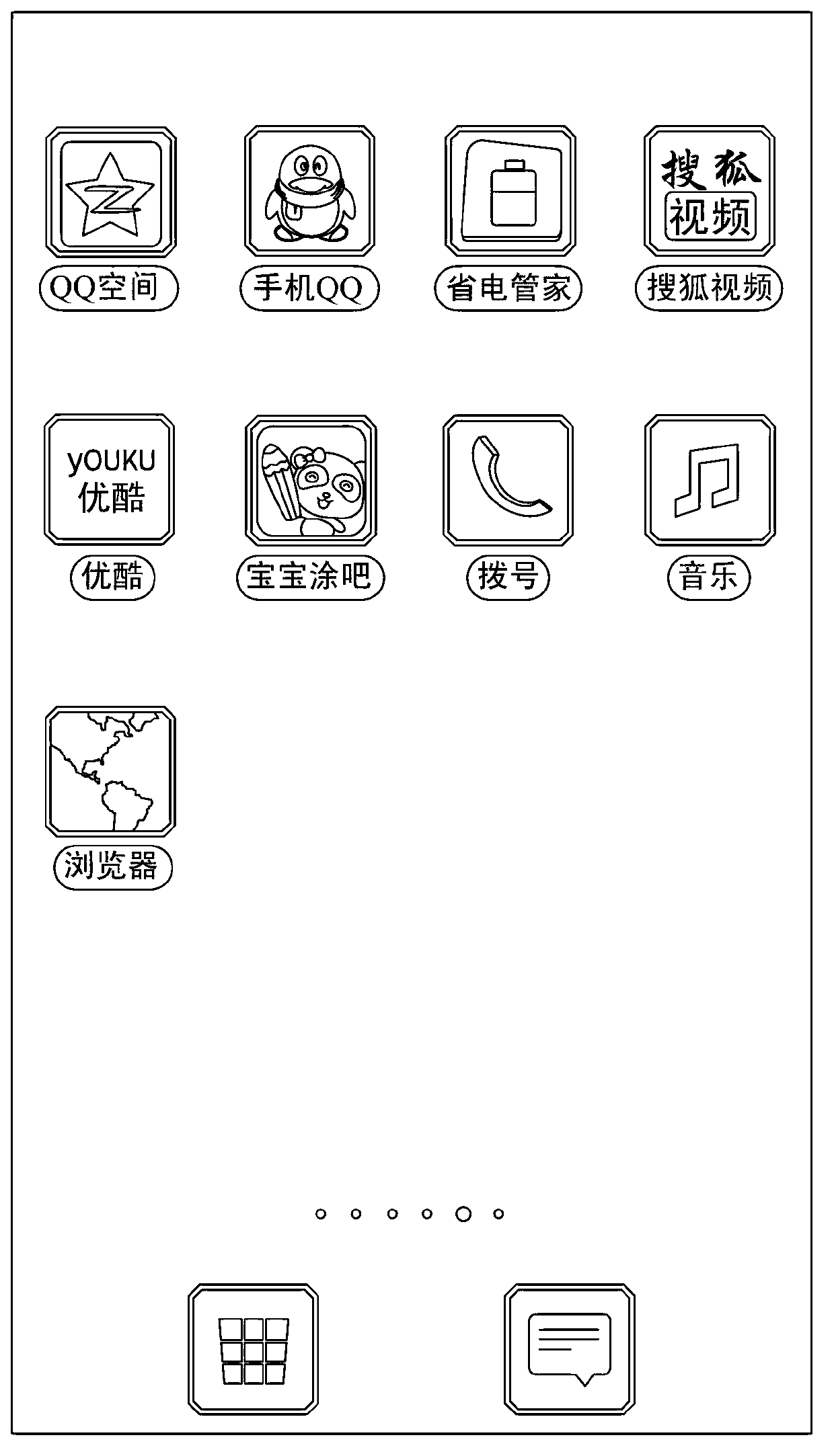

Method and mobile terminal for realizing automatic alignment and sorting of desktop icons by shaking

InactiveCN102968247AKeep tidyImprove user experienceInput/output processes for data processingComputer engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

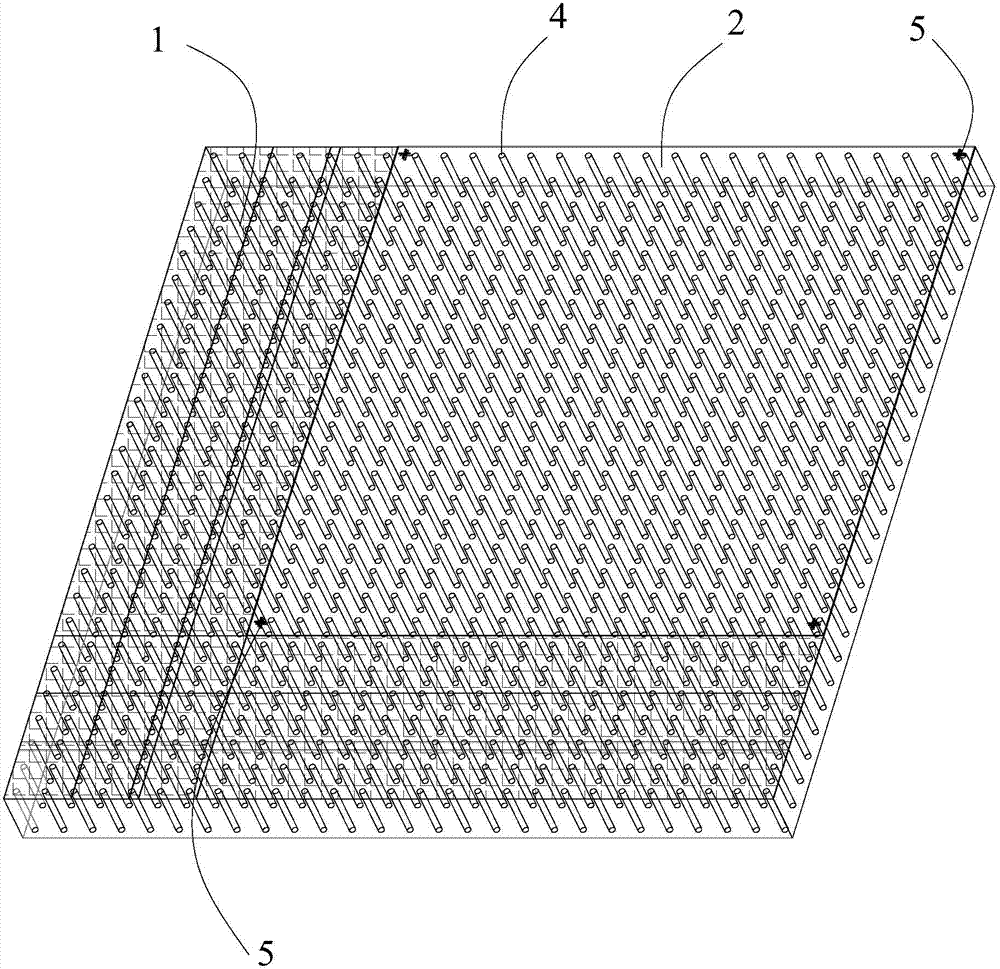

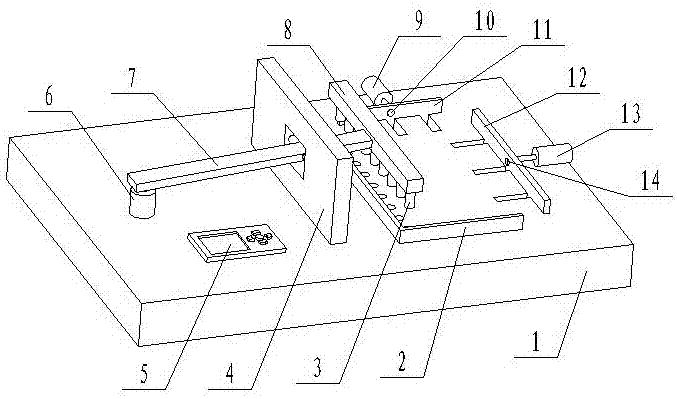

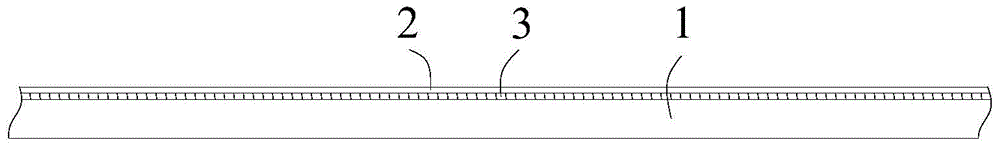

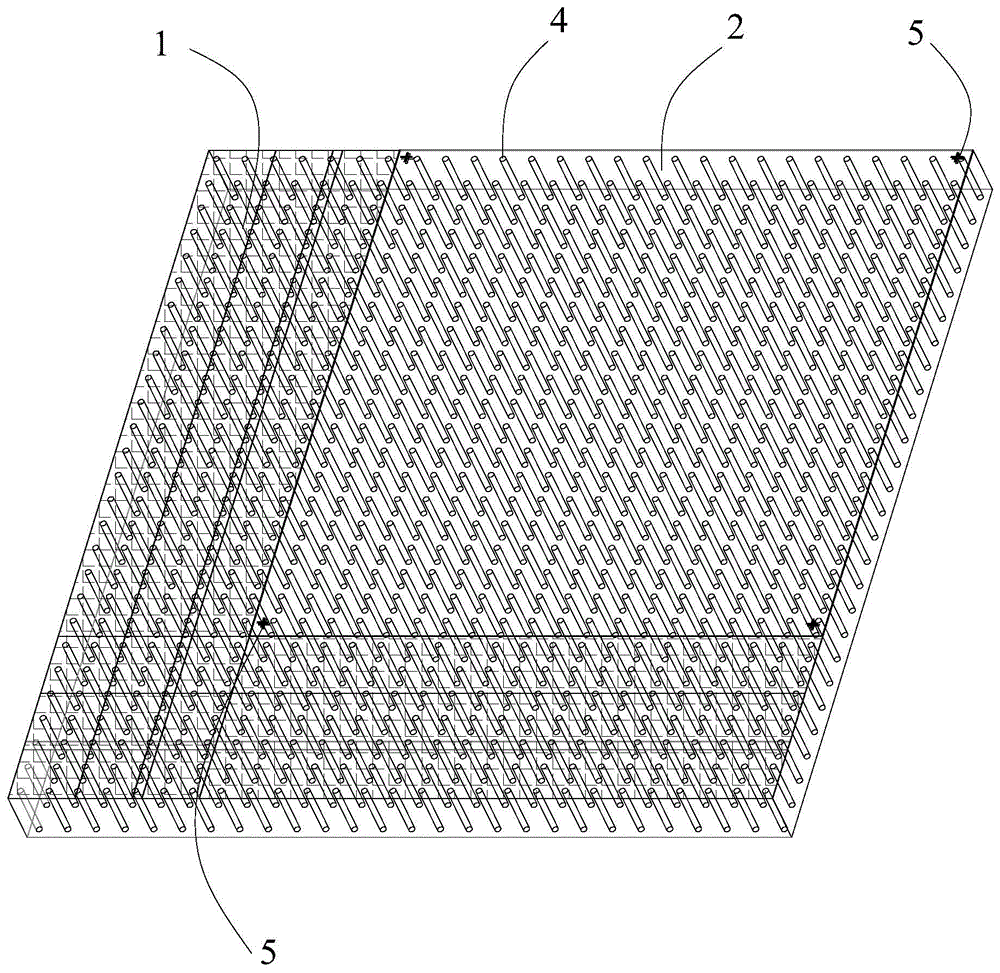

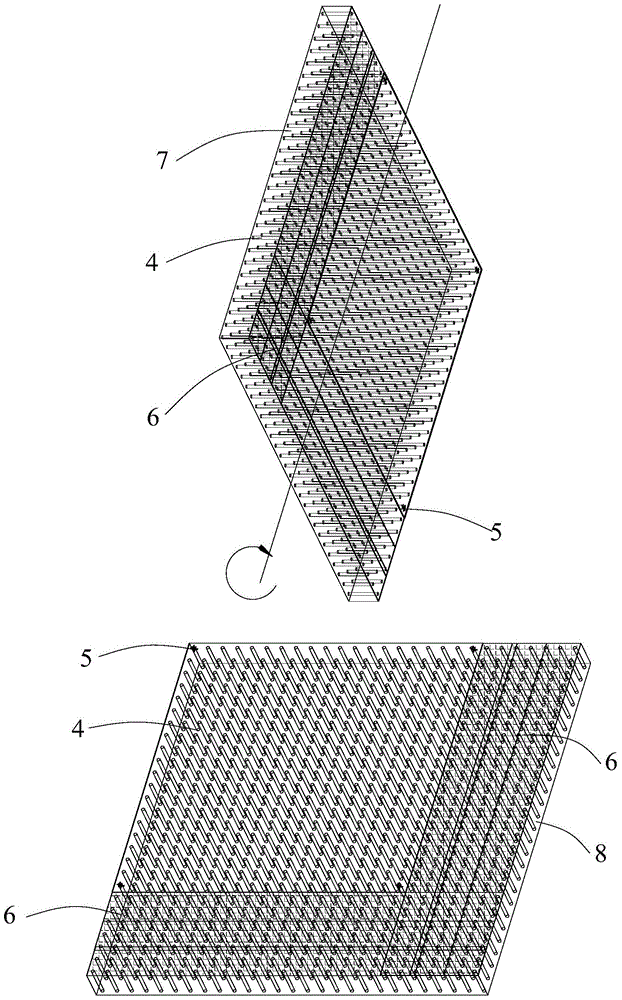

3D (three-dimensional) grating laminating process of LED display screen

The invention belongs to the technical field of LED display screens, and aims to provide a 3D (three-dimensional) grating laminating process of an LED display screen. The process includes the steps: providing a transparent substrate and a grating film with identification points, and a transparent optical adhesive; according to different transparent optical adhesives, flatly arranging two kinds of the raw materials on table tops of two working tables respectively, using cameras on the working tables for respectively capturing the identification points of the raw materials, and displaying related information on a display, using application software for calculating the position where the first workbench needs to be turned over and the distance by which the second workbench needs to be translated; performing edge sealing and ensuring that the raw materials flatly placed on the two workbenches are incapable of adhering to each other; performing turnover and lamination; finally, selectively subjecting a 3D grating sample to aftertreatment. Thus, a 3D grating is positioned without depending on human eyes, precision and slope of lamination are ensured, the edges are free of folds, product scrap rate is low, and requirements and dependency on operators are lowered.

Owner:SHENZHEN AOTO ELECTRONICS

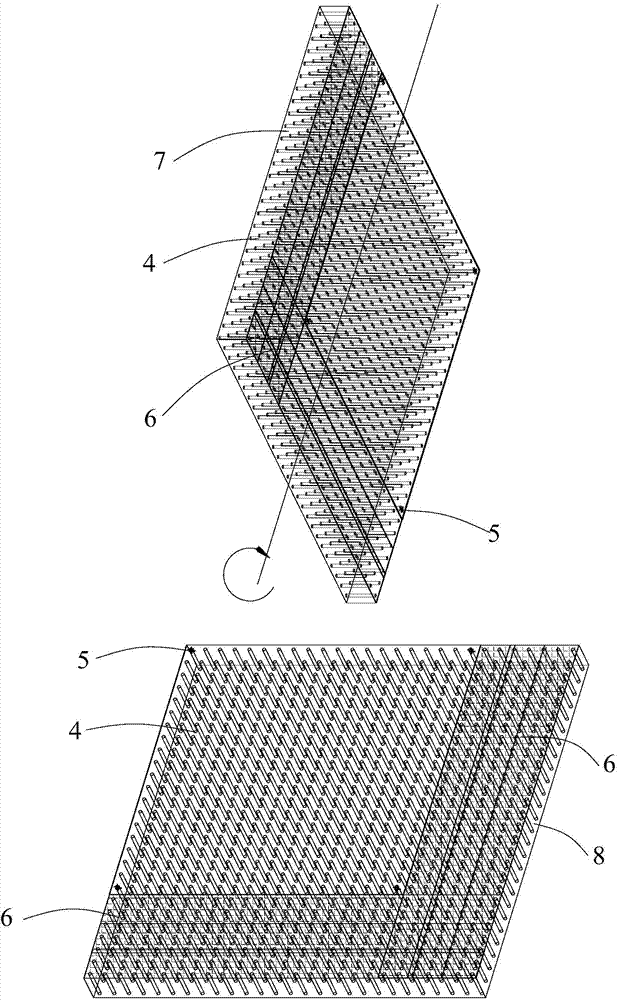

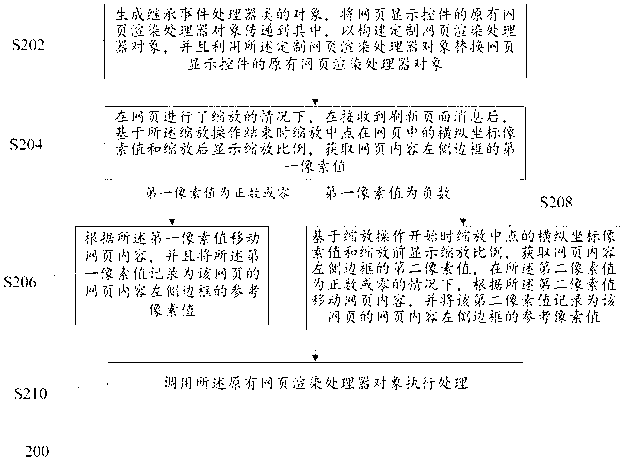

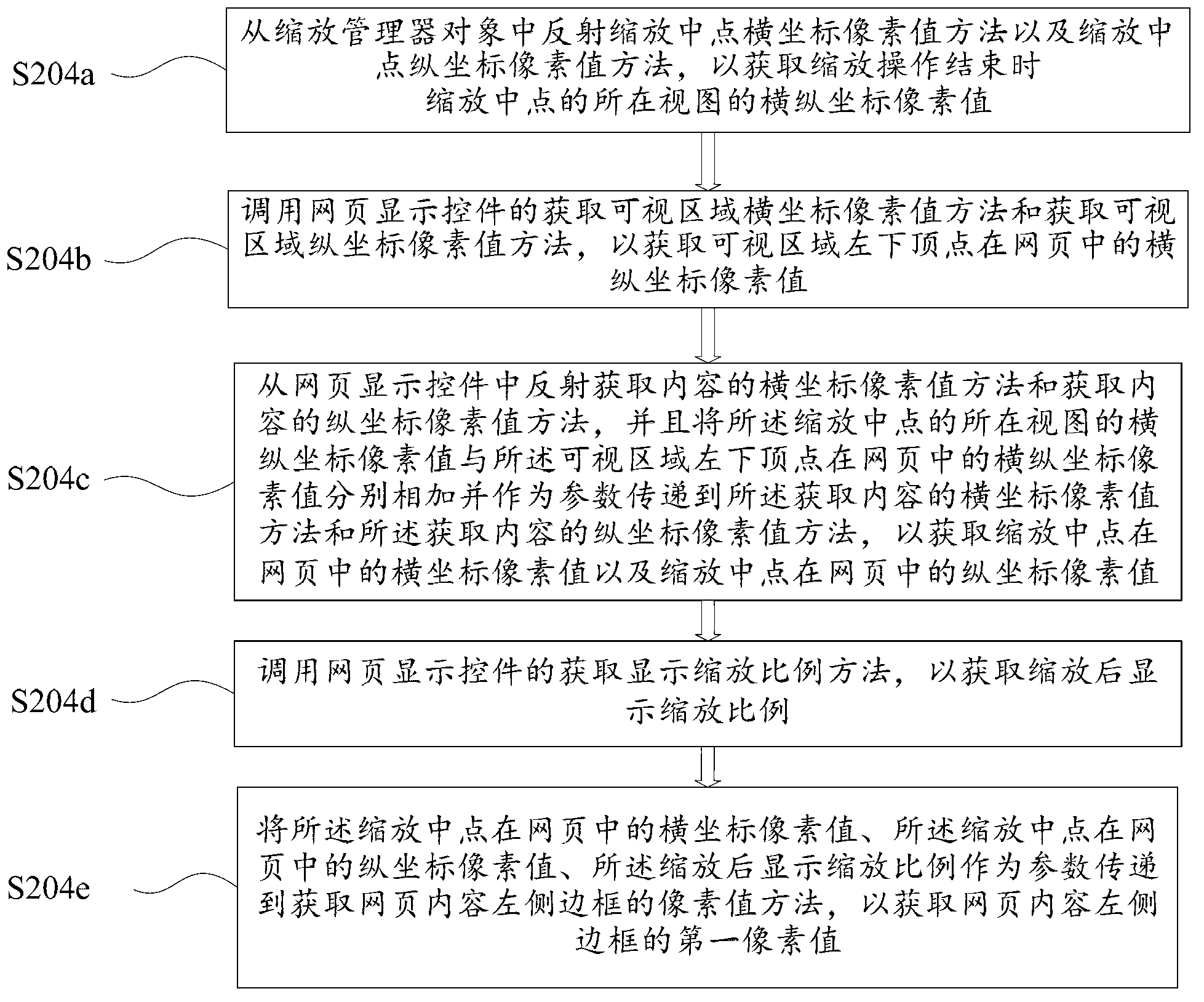

Method and device for webpage zooming and aligning on electronic equipment

InactiveCN103324738AAchieve automatic alignmentImplementation supportSpecial data processing applicationsComputer visionElectronic equipment

The invention discloses a method and a device for webpage zooming and aligning on electronic equipment. The method includes creating a customized webpage rendering processor object and utilizing the same to replace an original webpage rendering processor object; during webpage zooming, after a refreshing page information is received, acquiring a first pixel value of a left-side frame of webpage content based on horizontal-longitudinal pixel values of a zooming midpoint in a webpage when zooming operations are finished and a display zooming proportion after zooming; if the first pixel value is a positive number or zero, moving the webpage content according to the first pixel value, and recording the first pixel value as a reference pixel value; if the first pixel value is a negative number, acquiring a second pixel value of the left-side frame of the webpage content based on the horizontal-longitudinal pixel values of the zooming midpoint when the zooming operations are started and a display zooming proportion before zooming, if the second pixel value is a positive number or zero, moving the webpage content according to the second pixel value, and recording the second pixel value as a reference pixel value; invoking the original rendering processor object to execute processing.

Owner:BEIJING QIHOO TECH CO LTD +1

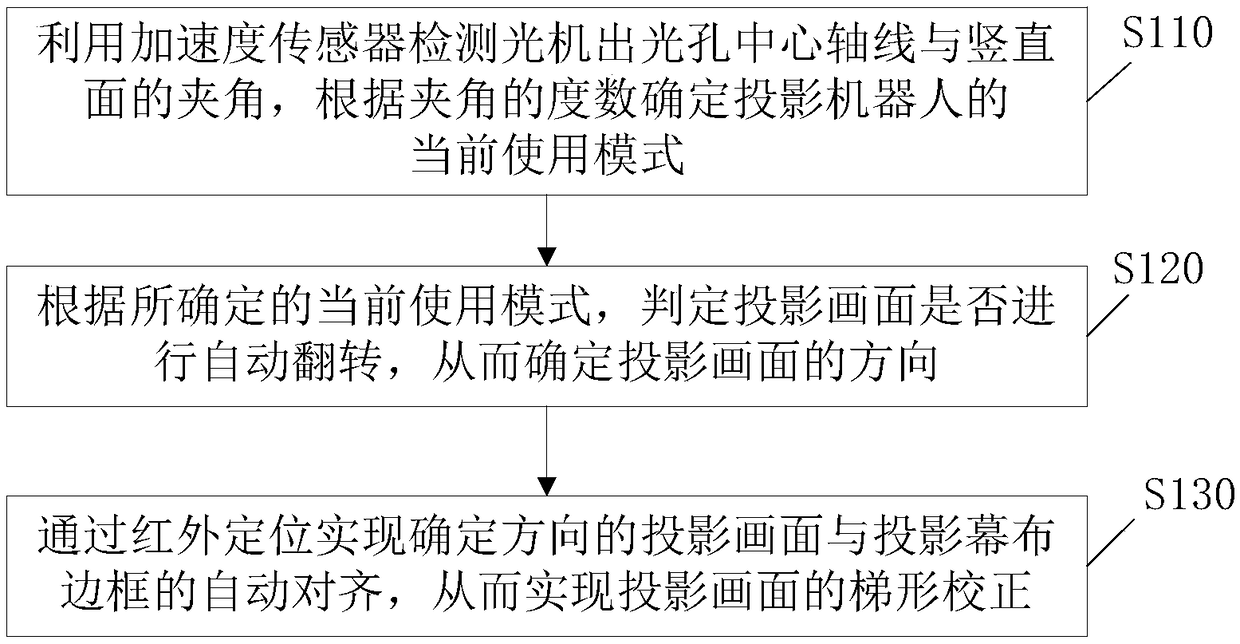

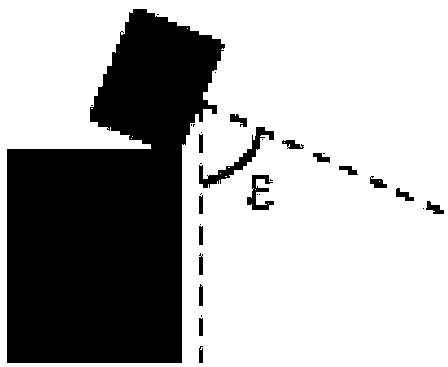

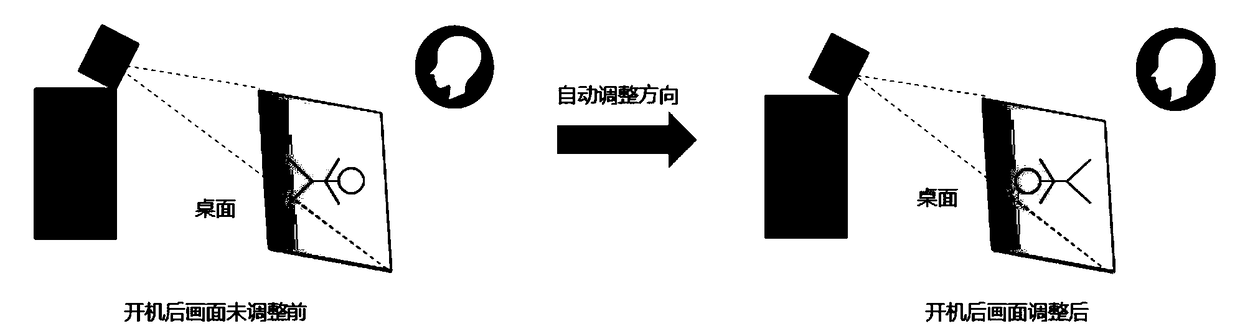

Projection robot device and projection robot image adjusting method

InactiveCN108519717AAchieve automatic alignmentAchieve regulationTelevision system detailsProjectorsVertical planeComputer graphics (images)

The invention provides a projection robot device and a projection robot image adjusting method. The image adjusting method comprises the automatic turning of the projection image and the trapezoid correction of the projection image; the included angle between the central axis of the optical machine light outlet hole and the vertical plane is detected through an acceleration sensor, and the currentuse mode is determined according to the degree of the included angle; according to the determined current use mode, whether the projection frame is turned automatically or not is determined, and thedirection of the projection image is determined; and the projection image in the determined direction is automatically aligned with the frame of the projection screen through infrared positioning so as to realize the trapezoidal correction of the projection image. According to the invention, the problems of single projection mode, automatic turnover of the projection frame, and automatic correction can be solved.

Owner:GOERTEK INC

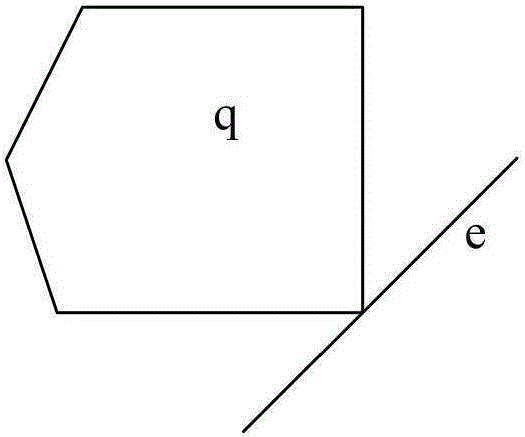

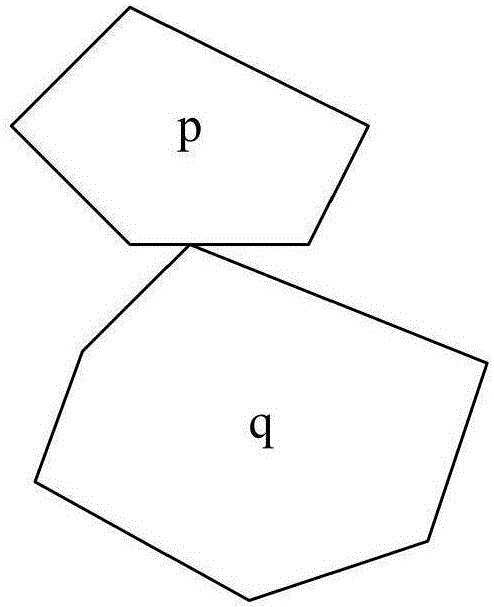

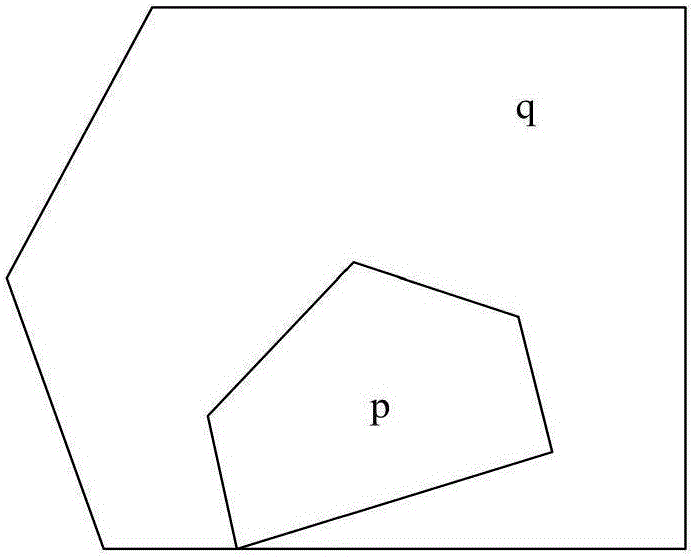

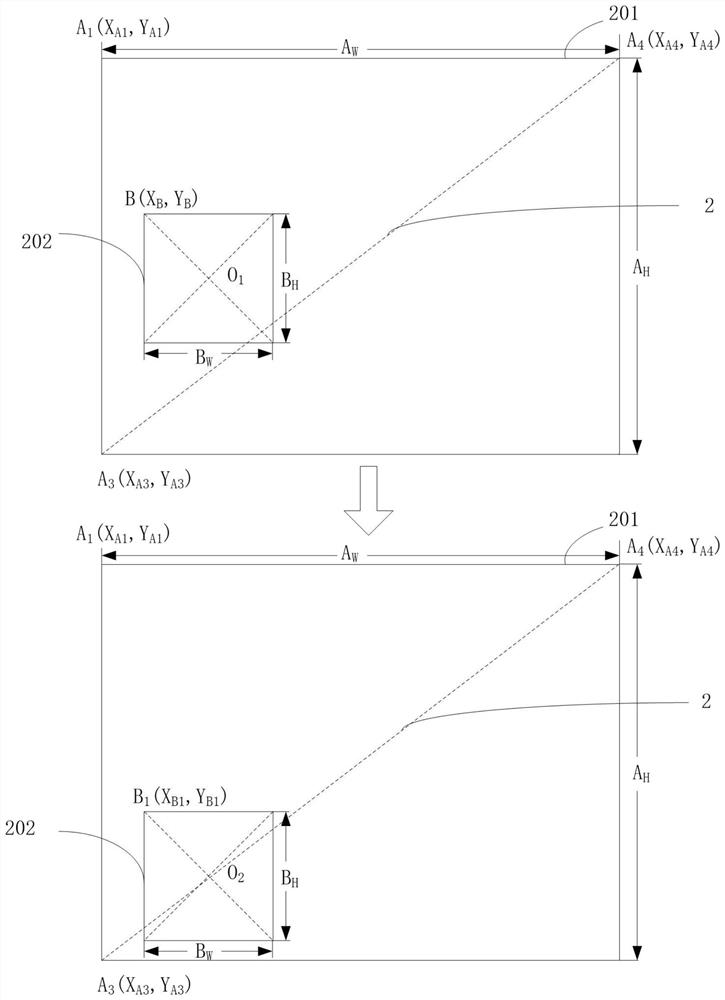

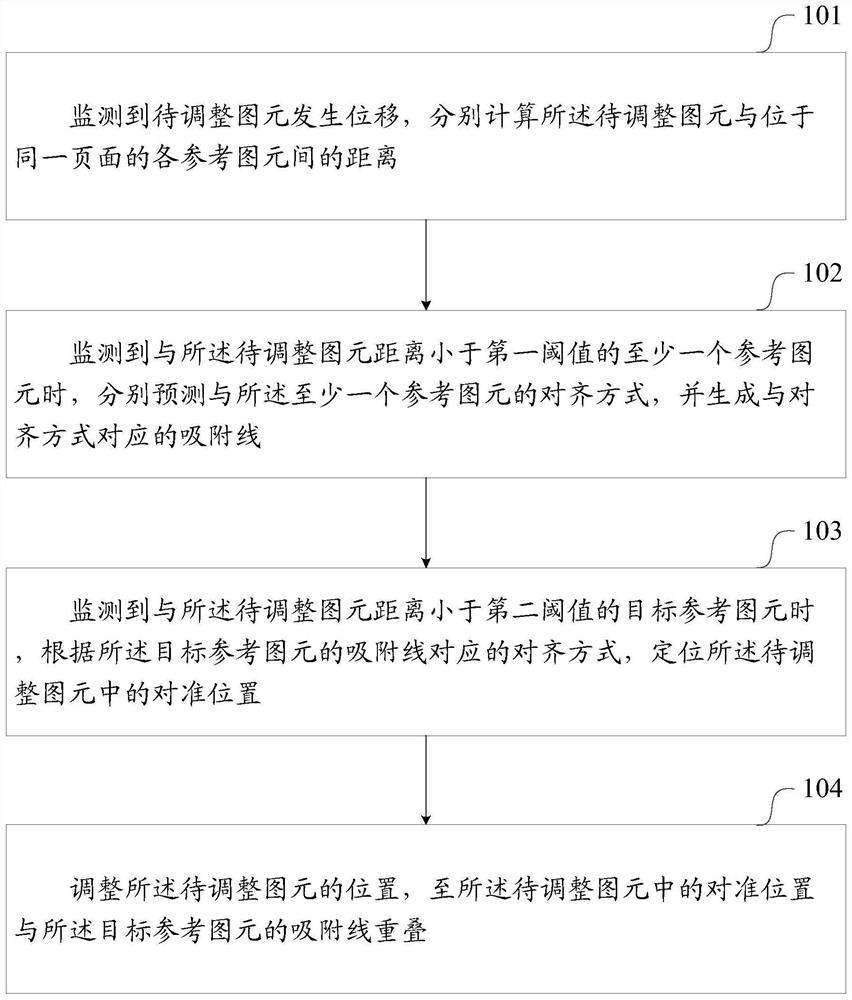

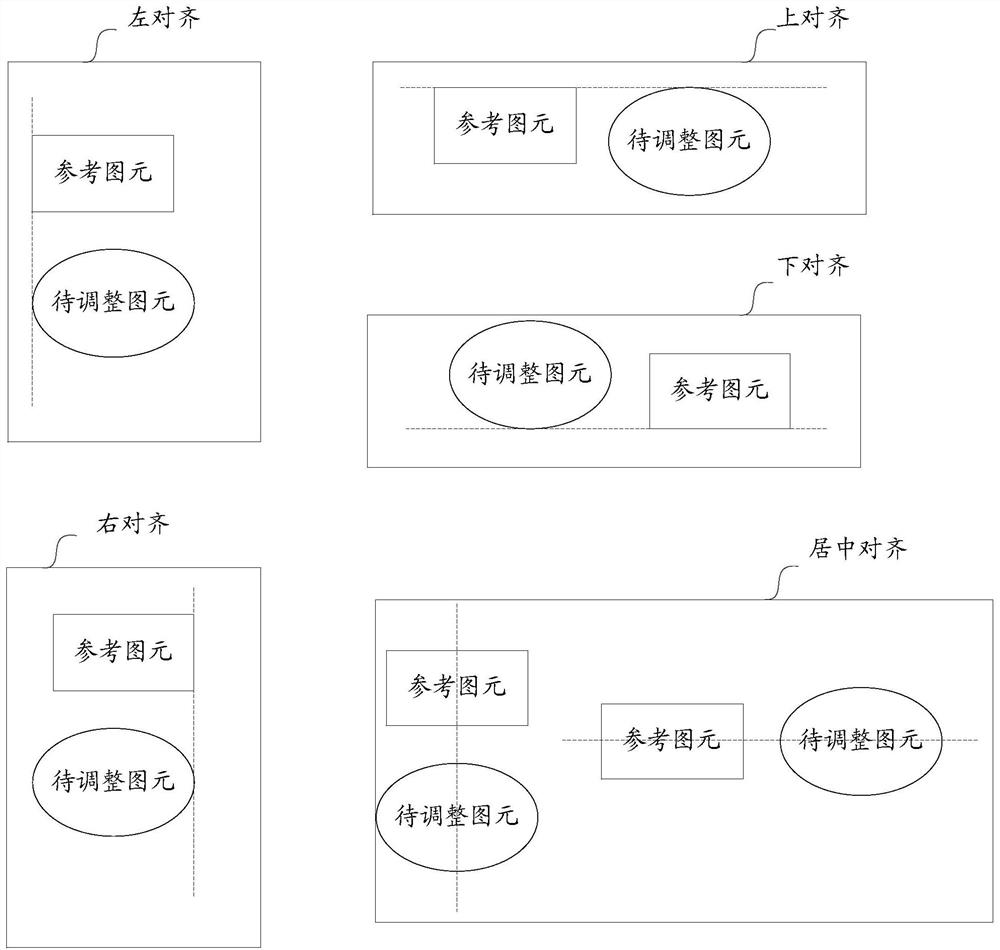

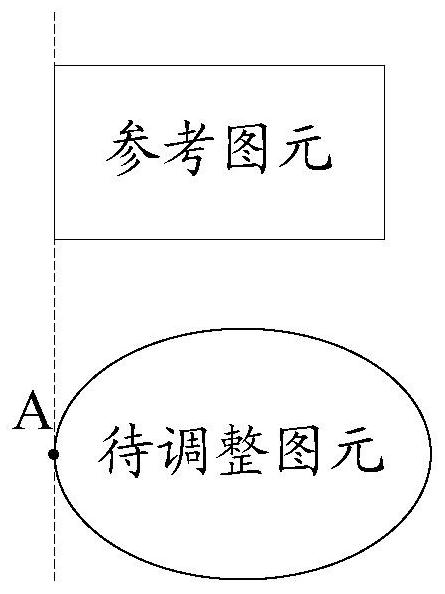

Figure automatic alignment method and apparatus

ActiveCN105787926AAchieve automatic alignmentImprove experienceImage enhancementImage analysisGraphicsComputer vision

The invention discloses a figure automatic alignment method and apparatus. The method comprises the following steps: determining a mobile figure and a firstly selected object figure to be aligned with the mobile figure, wherein the mobile figure and the firstly selected object figure are convex polygons; according to the firstly selected object figure, determining an external closely adjacent polygon and an internal closely adjacent polygon when the firstly selected object figure is aligned with the mobile figure; according to the external closely adjacent polygon and the internal closely adjacent polygon, determining an object alignment edge; according to the object alignment edge, determining a candidate alignment point; and according to a weight value of the candidate alignment point, determining an object alignment point. According to the figure automatic alignment method and apparatus provided by the invention, when an object figure and the mobile figure are aligned, the mobile figure moves around the object figure, and the locus of an original point of the mobile figure is modeled, and thus when a figure moves, the figure is automatically aligned with the object figure, and user experience is effectively improved.

Owner:广东国档科技有限公司

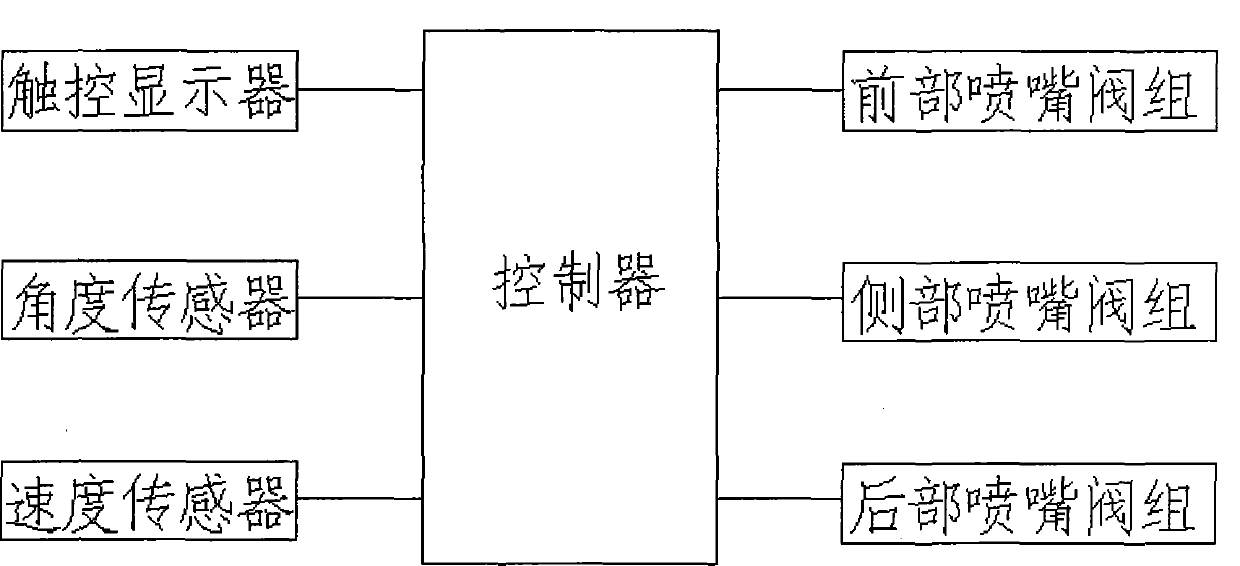

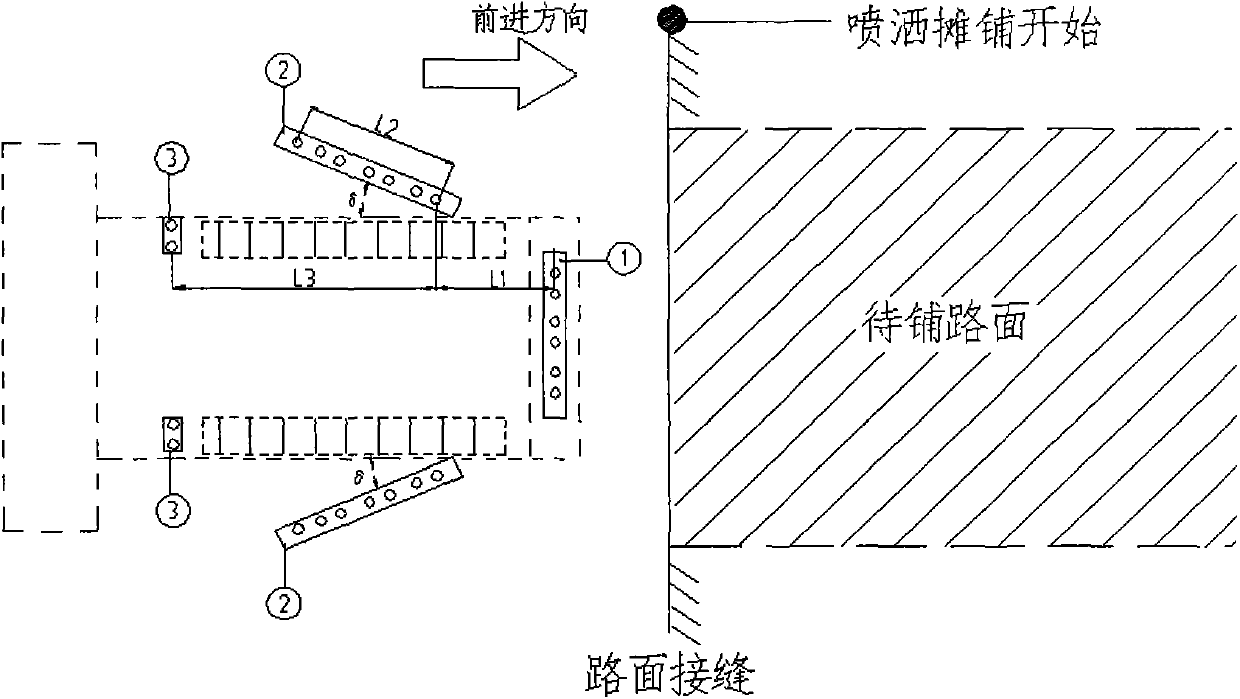

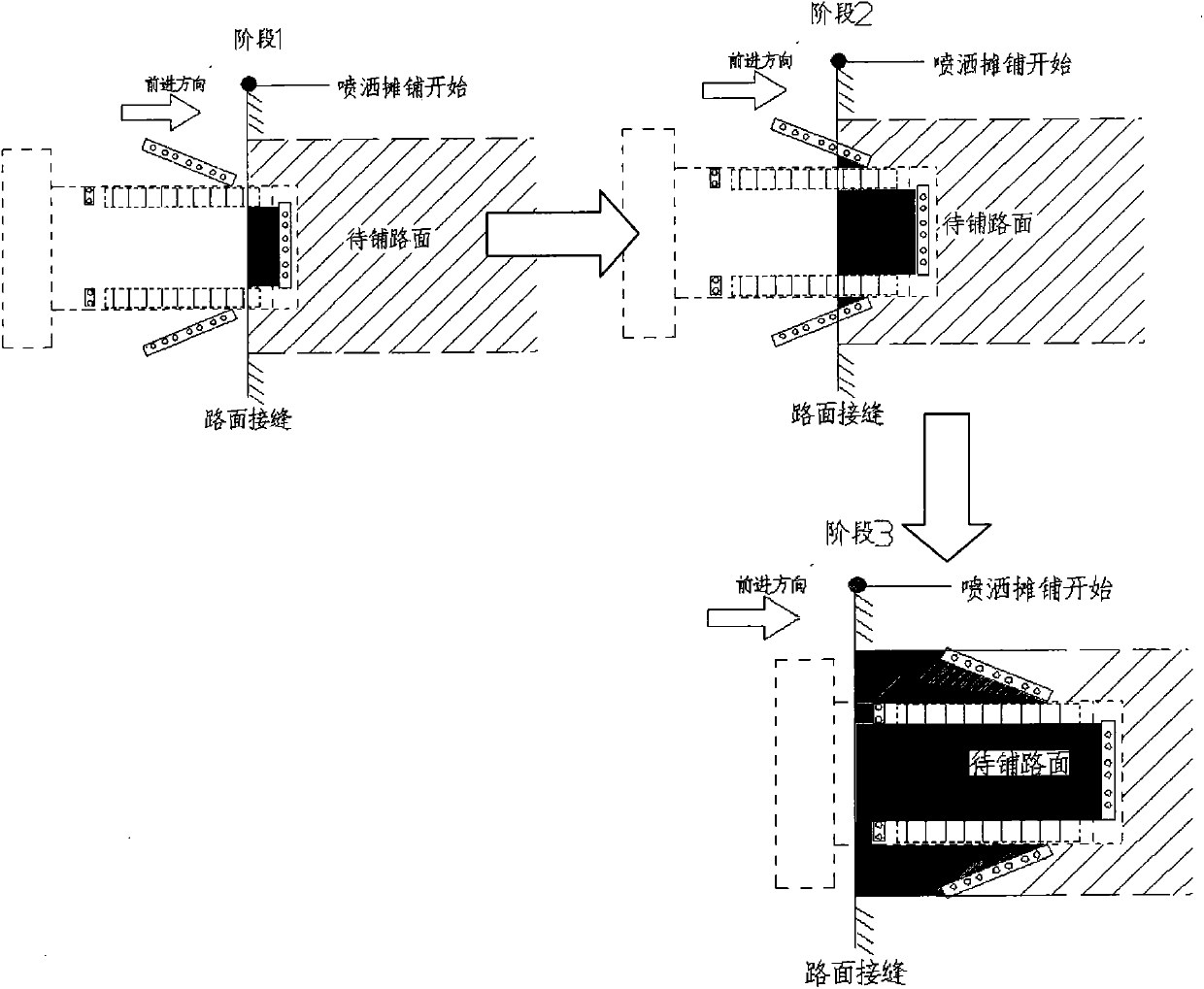

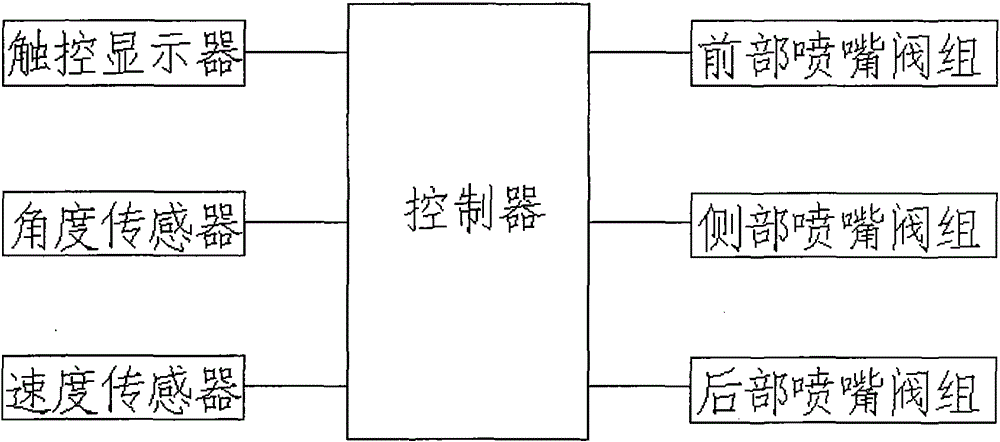

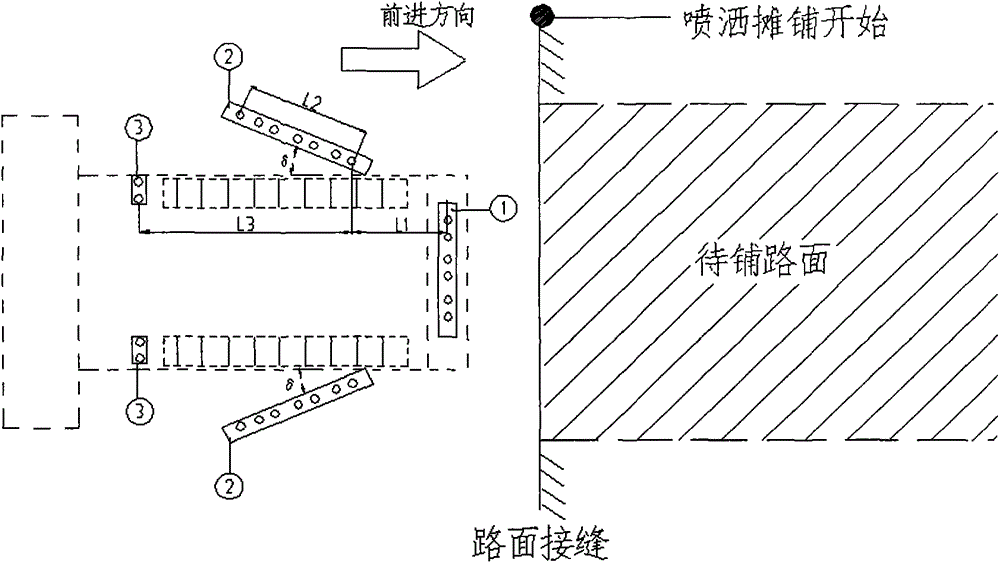

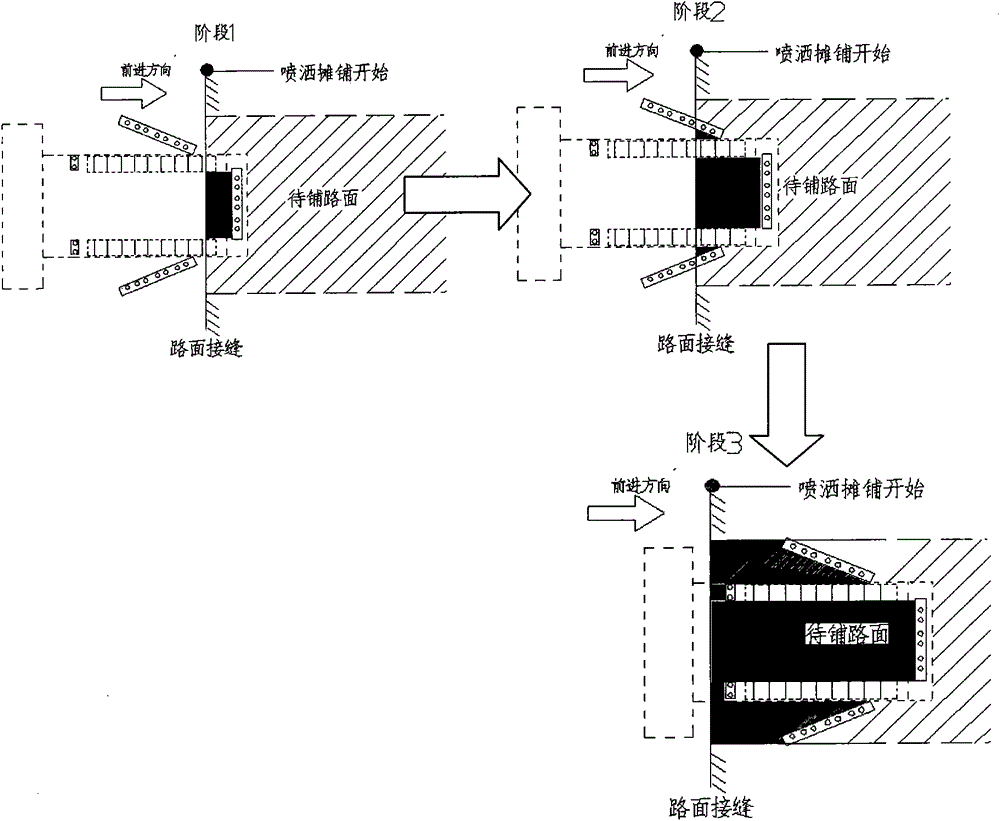

Automatic alignment control device and method of spraying joint of asphalt spraying paver

ActiveCN103526673AHigh degree of automationAchieve automatic alignmentRoads maintainenceTime delaysSpray nozzle

The invention discloses an automatic alignment control device and an automatic alignment control method of a spraying joint of an asphalt spraying paver. Automatic alignment of the spraying joint is achieved by program control and subsection time delay at the beginning stage and the stopping stage of spraying and paving aiming at the layout of a subsection spraying rod of the asphalt spraying paver. The control device comprises a controller, a touch display, a speed sensor, an angle sensor, a front nozzle valve bank, a lateral nozzle valve bank, and a rear nozzle valve bank. The control method comprises the following steps: (1) collecting an instruction and data; (2) calculating the delay time t1 from the front nozzle valve bank to the front end of the lateral nozzle valve bank; (3) calculating the delay time t2 of two adjacent nozzle valves in the lateral nozzle valve bank; (4) calculating the delay time t3 from the rear end of the lateral nozzle valve bank to the rear nozzle valve bank; (5) carrying out delay control by the controller at the beginning stage of spraying and paving; and (6) carrying out delay control by the controller at the finishing stage of spraying and paving. By adopting the delay control process, automatic alignment of the spraying edge at the joint of the pavement is perfectly achieved; material waste and pavement pollution are avoided.

Owner:XCMG CONSTR MACHINERY

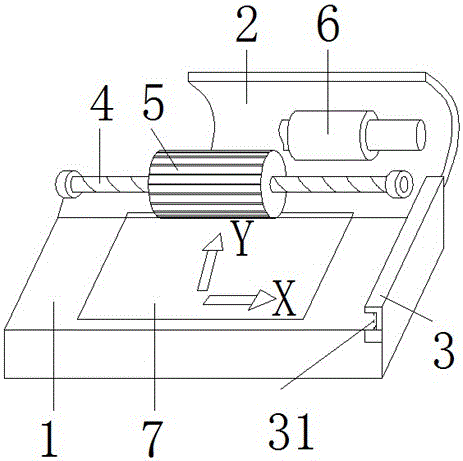

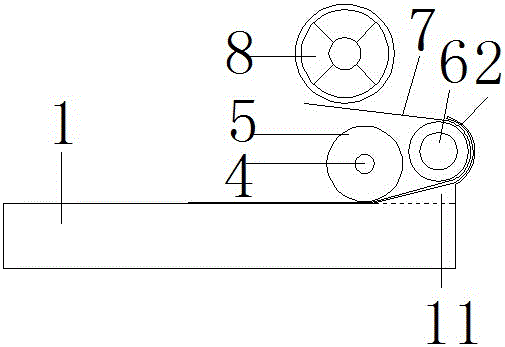

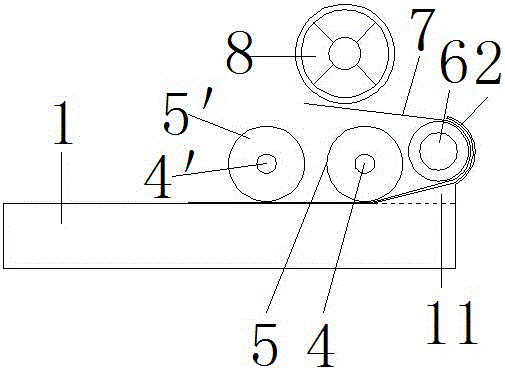

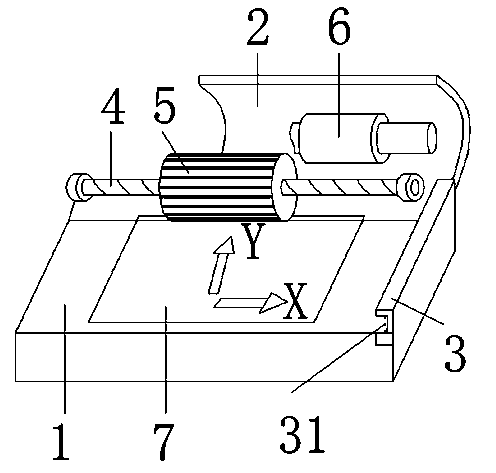

A kind of oblique type printer

ActiveCN104228357BAchieve alignmentAchieve automatic alignmentOther printing apparatusCardboardPulp and paper industry

The invention relates to an inclined entering type printer. The inclined entering type printer comprises a paper conveying table; a circular arc paper conveying plate is fixed to the paper outlet end of the paper conveying table; a baffle with an infrared facility is installed at the side edge of the paper conveying table; a screw capable of being controlled by a screw controller to lift is arranged at the paper outlet end of the paper conveying table; the axis of the screw is parallel to the edge of the paper outlet end of the paper conveying table; a pickup roller matched with threads of the screw is arranged on the screw in a sleeved mode; forward rotation and reverse rotation of the pickup roller are controlled by a main controller; a paper conveying roller matched with the paper conveying plate in radian is arranged at the position, tightly attached to the paper conveying plate, between the pickup roller and the paper conveying plate. The inclined entering type printer is simple in structure, paper can be effectively picked up, and meanwhile automatic alignment of the paper can be achieved.

Owner:茂名森源电子科技有限公司

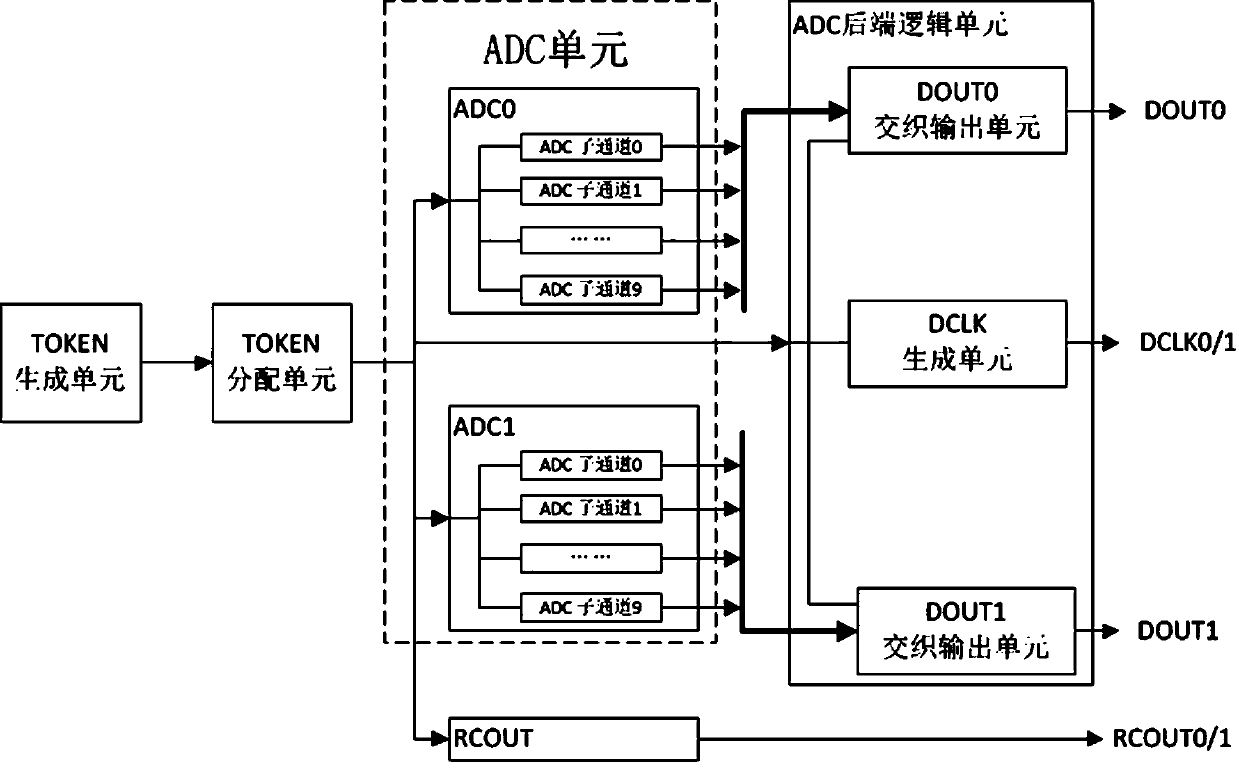

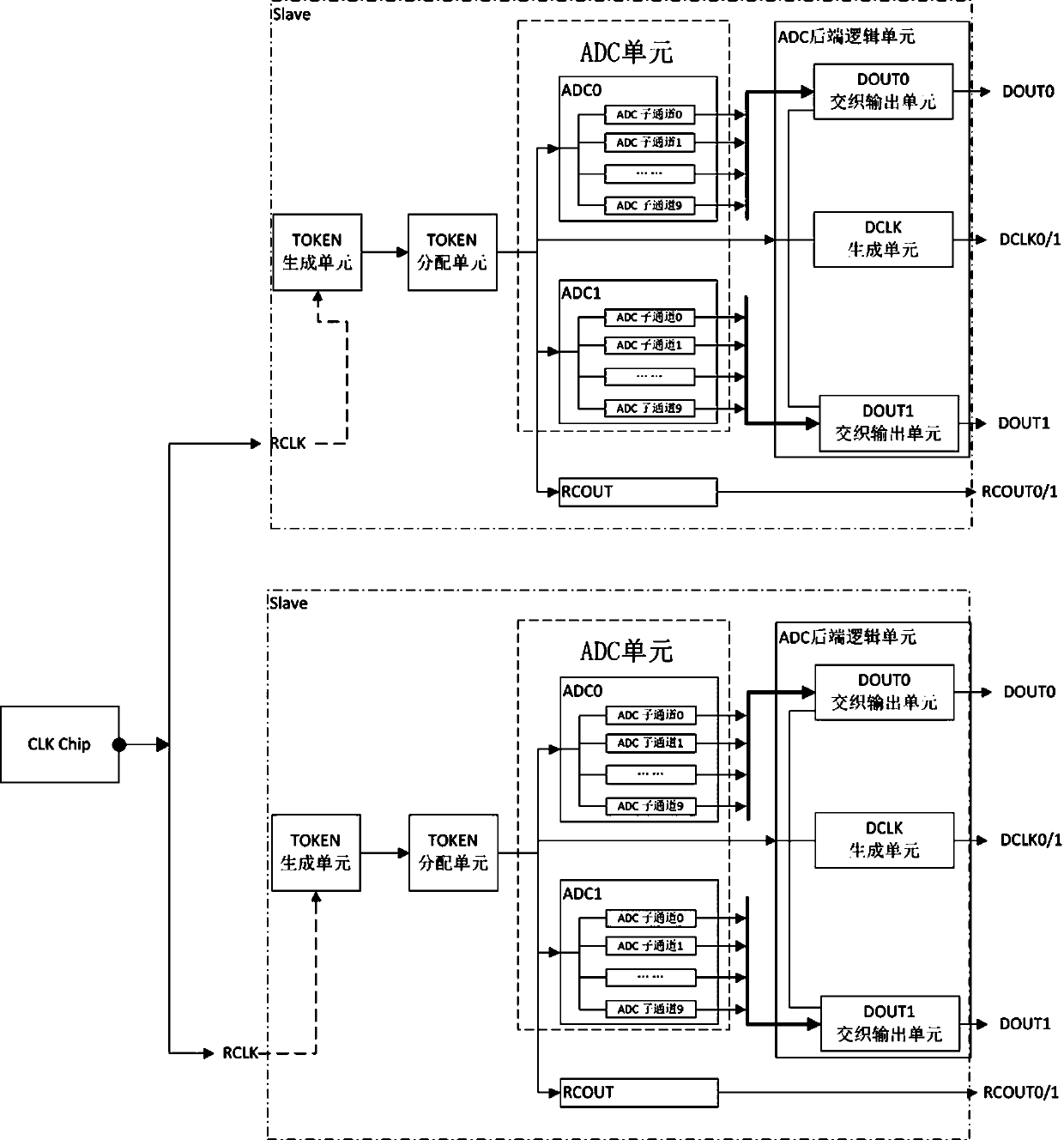

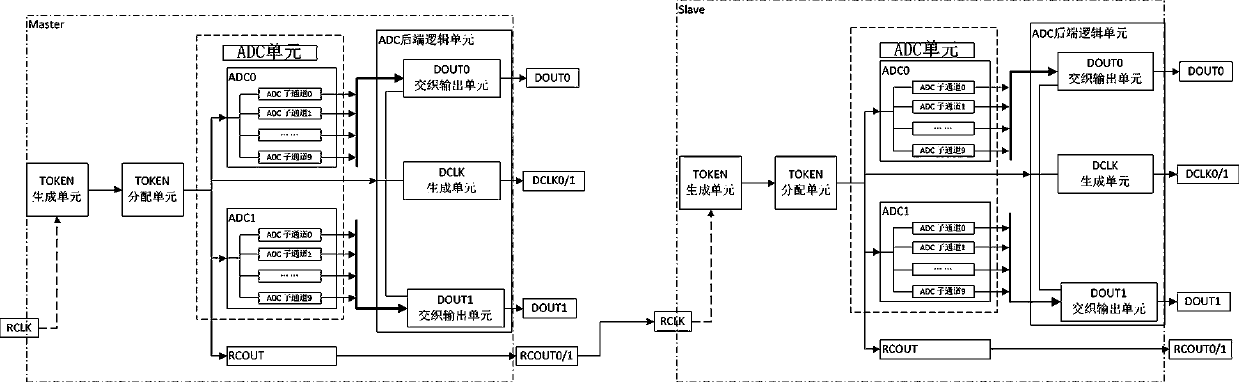

Multichannel ADC system synchronous sampling device and method

ActiveCN110350920AAchieve automatic alignmentNo external interventionAnalogue-digital convertersVIT signalsElectricity

The invention discloses a multichannel ADC system synchronous sampling device and method, and the device is provided with a TOKEN generation unit, a TOKEN distribution unit, an ADC unit, an ADC rear-end logic unit, an RCOUT, and a TOKEN generation unit, and a circulation factor TOKEN is generated based on a sampling clock CLK. The TOKEN distribution unit is used for distributing the circulation factor TOKEN to the ADC unit and the ADC rear-end logic unit; the ADC unit is used for sampling analog input of a corresponding channel and quantizing the analog input into a multi-bit digital signal, wherein the ADC back-end logic unit is used for generating aligned data clocks and realizing a data interleaving output function of a small channel in a large channel, the RCOUT is used for transmitting a cycle factor to a downstream ADC chip, the period of the RCOUT is equal to the period of the cycle factor, and the duty ratio of the RCOUT is 50%; the device can realize on-chip multi-channel dataalignment, and the method can also realize automatic alignment of data output DOUT0 and DOUT1 and clock output DCLK0 and DCLK1 after the device (chip) is powered on without software re-interference.

Owner:成都铭科思微电子技术有限责任公司

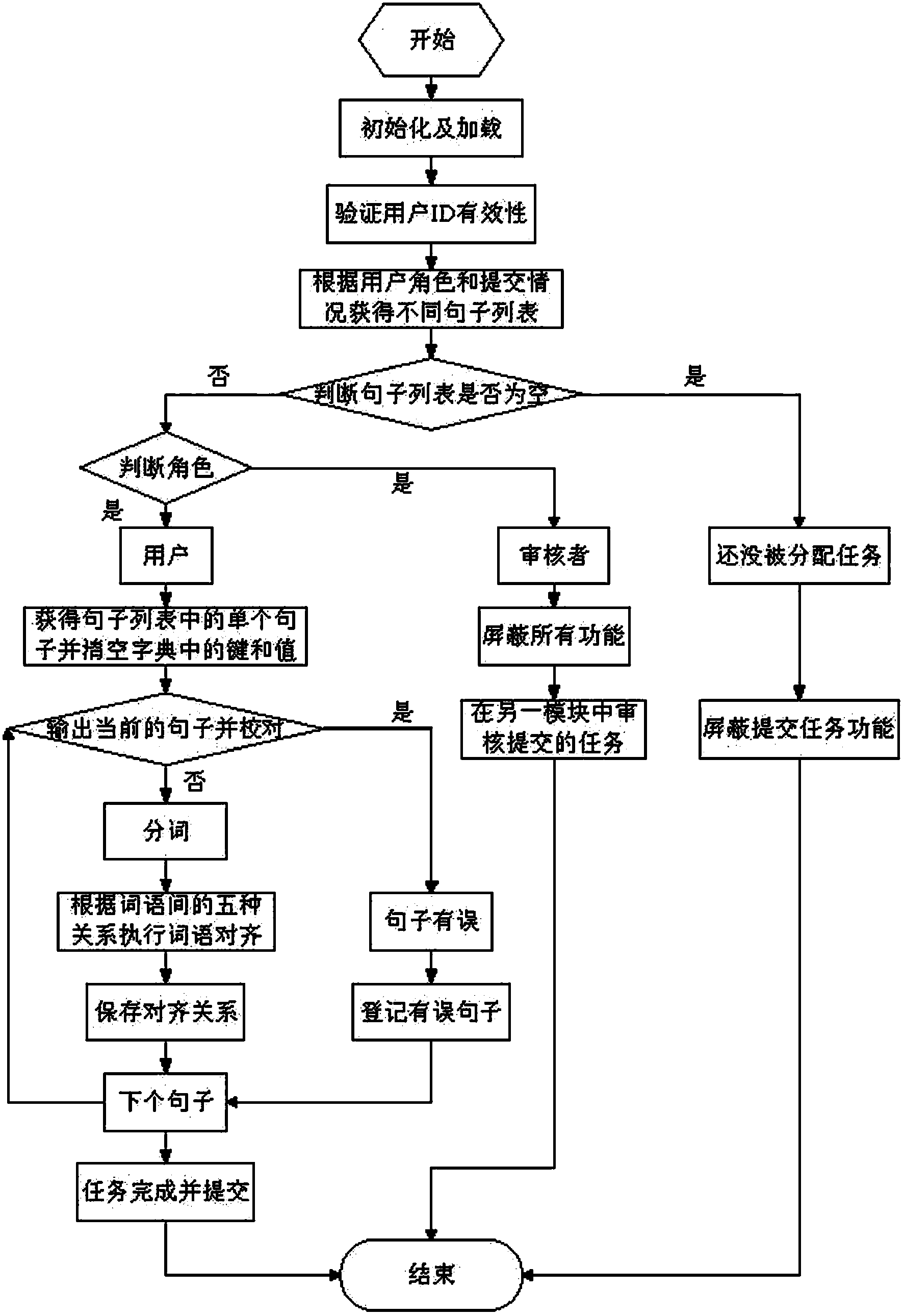

Uygur language word alignment method

InactiveCN103902528ARealize the mergerAchieve automatic alignmentSpecial data processing applicationsTerra firmaMachine translation system

The invention discloses a Uygur language word alignment method. The method includes that automatic alignment of Uygur language words is realized, and five alignment relationships between Uygur language words and Chinese words include one to one, one to multiple, multiple to one, multiple to multiple and one to none; manual alignment is performed on words which are wrong in automatic alignment, so that accuracy of a system to process Uygur language is improved; word splitting and merging of the Uygur language words is realized according to characteristics of the Uygur language. By the Uygur language word alignment method, automatic alignment of the Uygur language words is realized, assistance is provided for Chinese-Uygur machine translation and establishing of electronic Uygur language dictionaries, and a solid foundation is laid for development of electronic dictionaries for Uzbek, Kazak, Kyrgyz and Turkish and machine-aided translation systems.

Owner:新疆电力信息通信有限责任公司

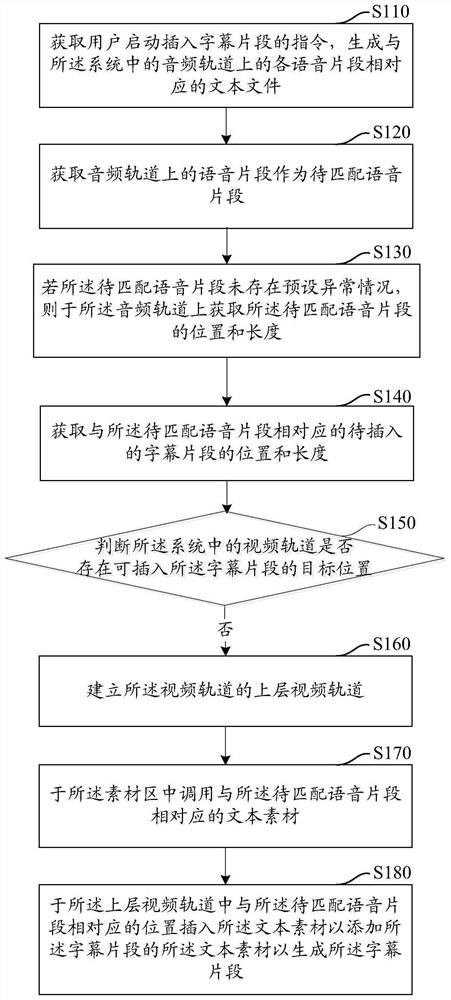

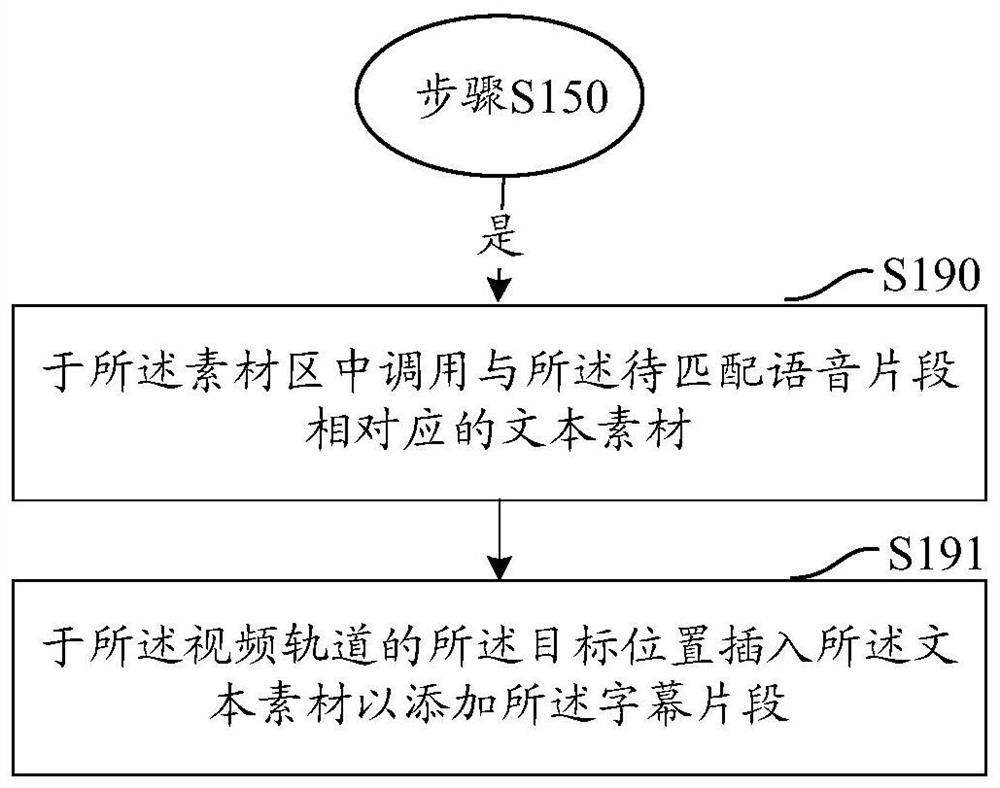

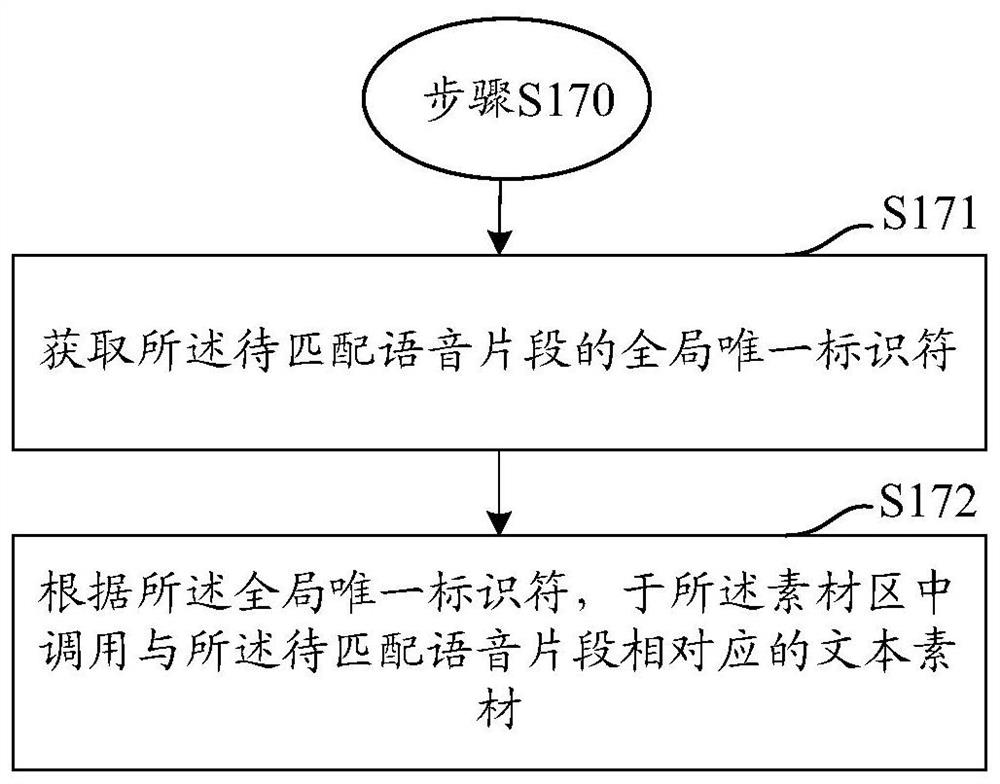

Method and device for automatically adding subtitle fragments and computer equipment

PendingCN112738563AAchieve automatic alignmentImprove experienceSelective content distributionComputer graphics (images)Subtitle

The embodiment of the invention discloses a method and system for automatically adding subtitle fragments, computer equipment and a storage medium, and relates to the technical field of multimedia. According to the method, the position and the length of a to-be-inserted subtitle segment are determined by collecting the position and the length of a to-be-matched voice segment on an audio track, and whether a target position where the subtitle segment can be inserted exists in a video track in a system or not is judged; and establishing an upper-layer video track of the video track, and generating subtitle fragments on the upper-layer video track. According to the embodiment of the invention, the method achieves the automatic matching of the plurality of to-be-matched voice segments with the corresponding subtitle segments, achieves the automatic alignment of the to-be-matched voice segments and the corresponding subtitle segments, improves the efficiency, and improves the user experience.

Owner:SHENZHEN WONDERSHARE SOFTWARE CO LTD

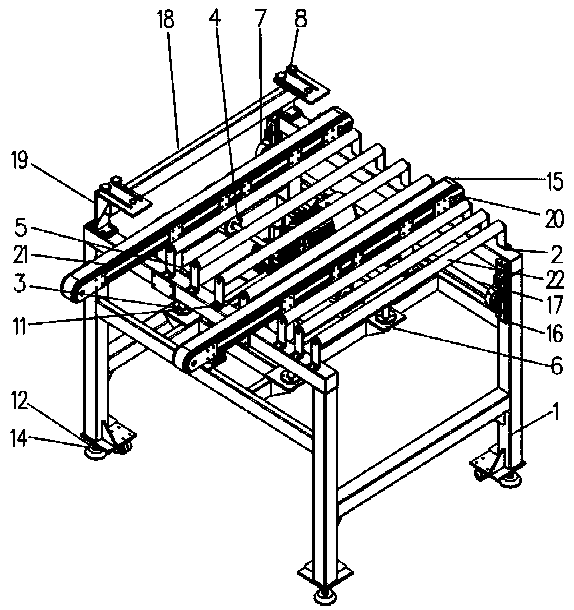

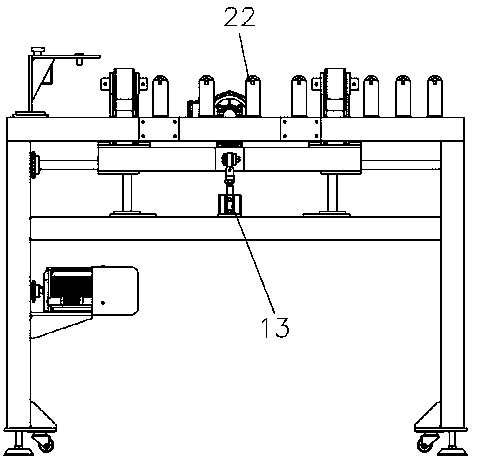

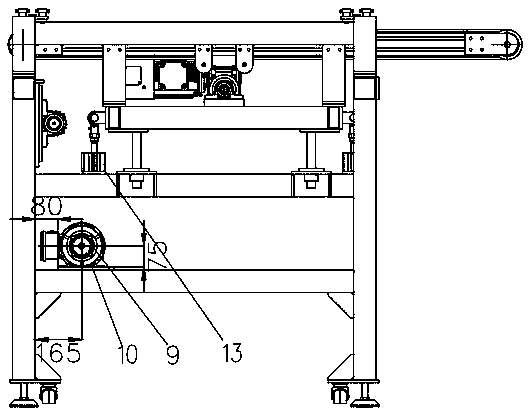

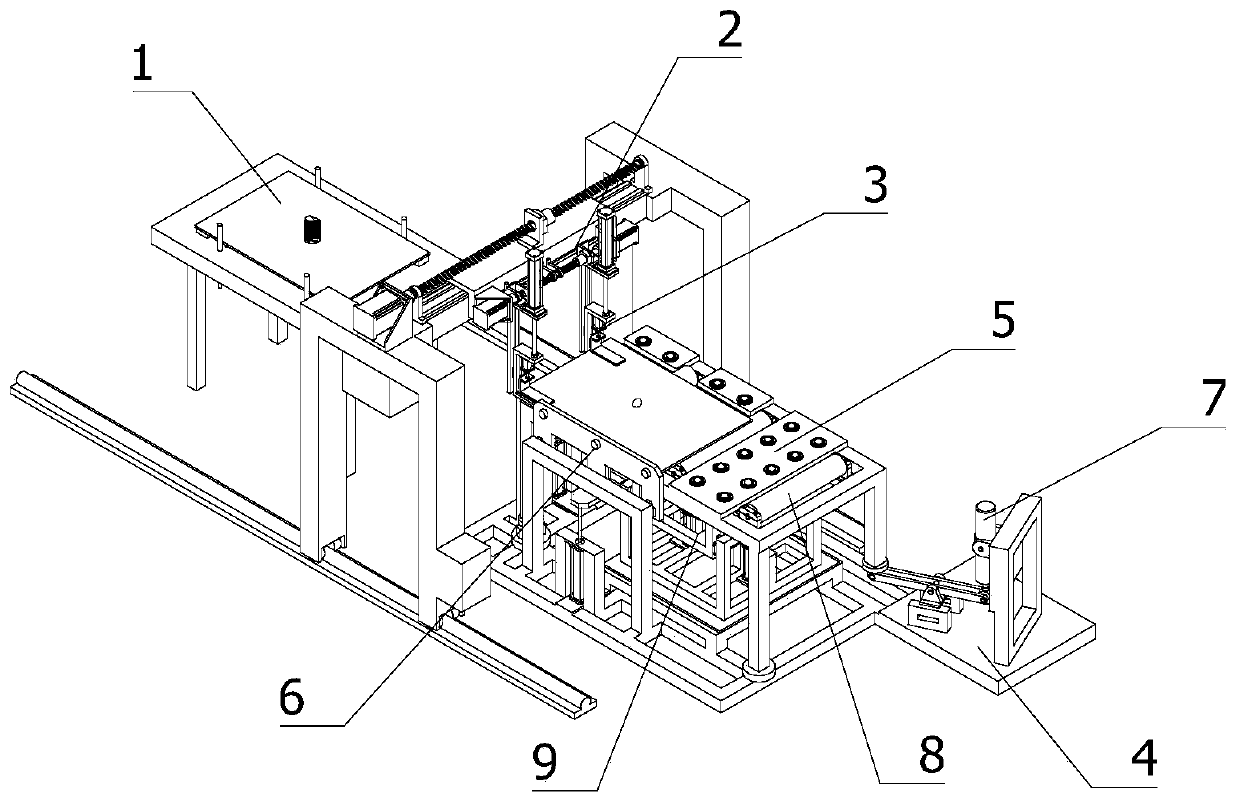

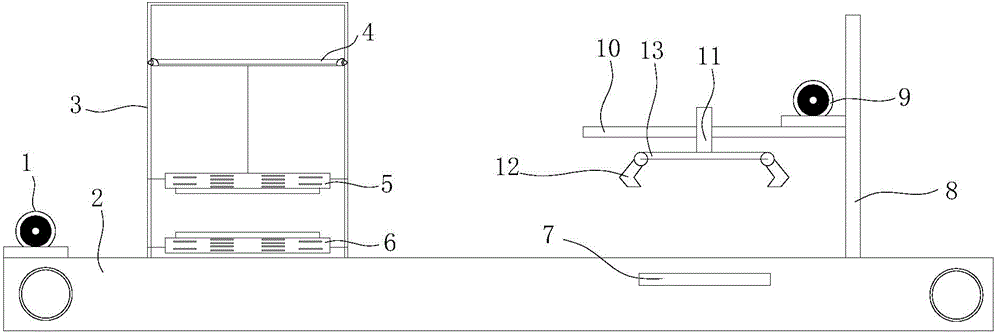

Composite floor turning conveying and gap feeding plate overturning device

PendingCN111483792AContinuous transmissionSimple structureConveyorsSupporting framesStructural engineeringIndustrial engineering

The invention discloses a composite floor turning conveying and gap feeding plate overturning device. The device comprises a conveying mechanism, a limiting mechanism, a lifting mechanism, a chute mechanism, a conveying chain mechanism and a blocking mechanism. The limiting mechanism is located at the front end of a roller assembly. Two parallel belt conveyors are mounted on a lifting rack assembly in the lifting mechanism, and the belt conveyors are arranged in the roller assembly in a staggered manner. The tail ends of the belt conveyors are located above a chute. The conveying chain mechanism comprises a pair of short-pitch conveying chains. Multiple square blocks separated at equal intercepts are arranged on the short-pitch conveying chains. The blocking mechanism is located below thechute mechanism. The device can cooperate with a former plate stamping procedure, next plate overturning continues to be carried out, the steps of manual turning and overturning are replaced, by meansof ingenious design, integrated work of reversing, aligning, overturning and separating of plates can be completed, a large quantity of manpower and financial resources are saved, the device works safely and reliably, and turning conveying and gap feeding can be efficiently completed.

Owner:CHINA UNIV OF MINING & TECH

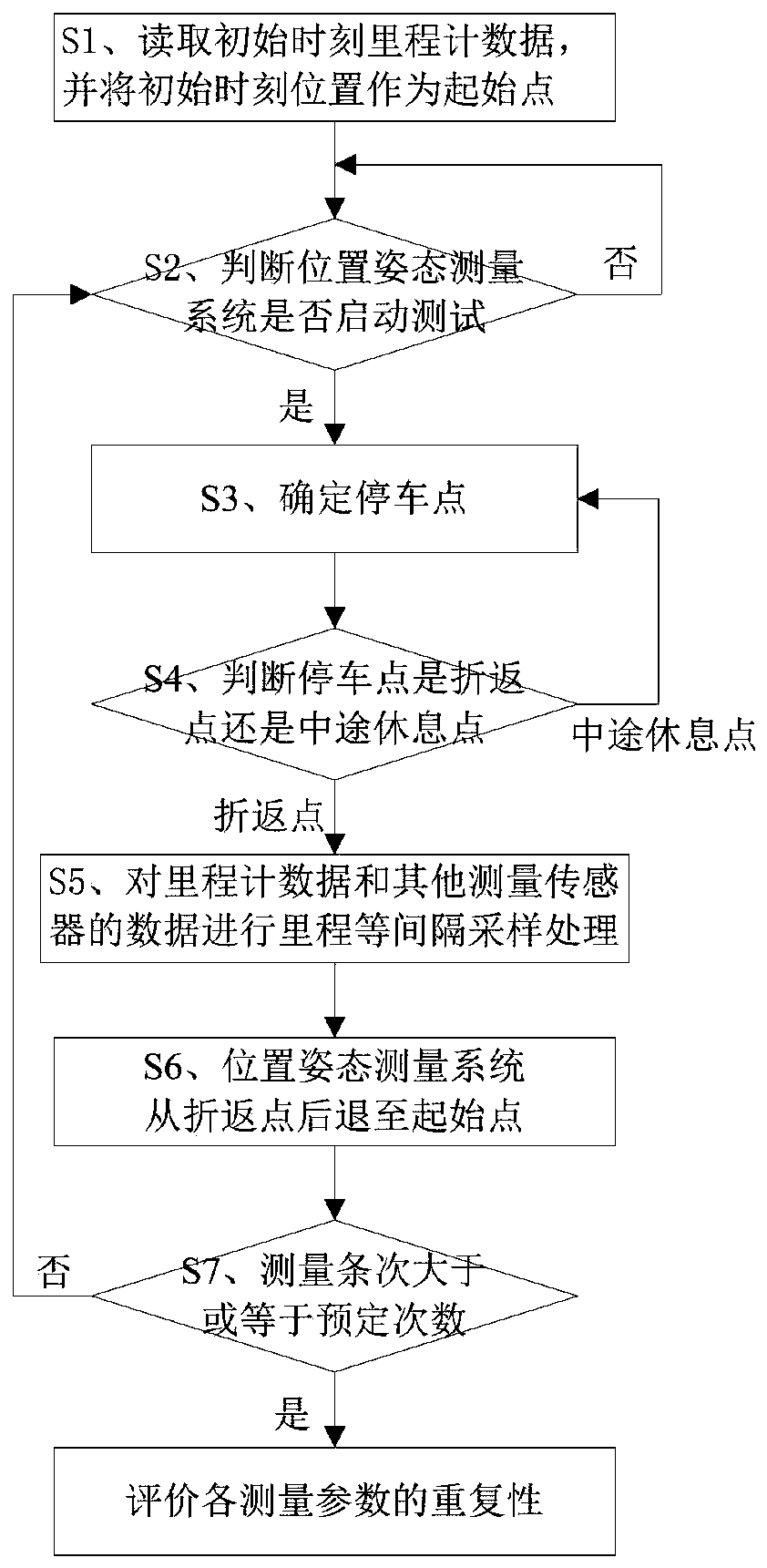

Odometer data processing method of position attitude measurement system

ActiveCN110440826AEasy to repeat calculationsImprove data processing efficiencyDistance measurementBreaking pointAutomatic processing

The invention provides an odometer data processing method of a position attitude measurement system. The method comprises the steps of: S1, reading odometer data at the initial time, and determining astart point; S2, judging whether testing is started or not, if testing is started, turning to the step S3, and otherwise, continuously executing the step S2; S3, judging a stop point; S4, judging whether the stop point in the step S3 is a return point or a break point, if the stop point in the step S3 is the return point, turning to the step S5, and if the stop point in the step S3 is the break point, turning to the step S3; S5, performing mileage equal-spaced sampling processing; S6, retreating the position attitude measurement system to the start point in the step S1 from the return point;and S7, judging whether the measurement time is greater than or equal to the predetermined time or not, if so, evaluating the repeatability of various measurement parameters, and otherwise, turning tothe step S2. By means of the odometer data processing method of the position attitude measurement system in the invention, accurate judgement on all kinds of states of the position attitude measurement system and rapid and automatic processing on measurement results for many times can be realized; and the data post-processing efficiency can be increased.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Simple perforating device for note finishing

PendingCN106881750AAchieve automatic alignmentEasy to operateMetal working apparatusEngineeringPressure sensor

The invention discloses a simple punching device for note sorting, comprising a working base, a controller, an L-shaped baffle, and a punching knife. A support plate is installed in the middle of the working base, and a rocker is installed in the middle of the support plate. A pressure plate is installed on one end of the rocker, the punching knife is installed on the lower end of the pressure plate, the L-shaped baffle is installed on one side of the middle of the working base, and a horizontal adjustment cylinder is installed on the other side of the working base. A horizontal adjustment plate is installed at the end of the horizontal adjustment cylinder, a second pressure sensor is installed in the middle of the horizontal adjustment plate, the controller is installed on the lower side of the working base, and a longitudinal pressure sensor is installed on the upper side of the working base. Adjusting the cylinder, the longitudinal adjustment plate is installed at the end of the longitudinal adjustment cylinder, and the first pressure sensor is installed in the middle of the longitudinal adjustment plate. The beneficial effect lies in that it can realize automatic alignment and automatic punching, can detect, control and adjust pressure, has simple operation and good punching effect.

Owner:朱石明

Inclined entering type printer

ActiveCN104228357AAchieve alignmentAchieve automatic alignmentOther printing apparatusComputer printingPaperboard

The invention relates to an inclined entering type printer. The inclined entering type printer comprises a paper conveying table; a circular arc paper conveying plate is fixed to the paper outlet end of the paper conveying table; a baffle with an infrared facility is installed at the side edge of the paper conveying table; a screw capable of being controlled by a screw controller to lift is arranged at the paper outlet end of the paper conveying table; the axis of the screw is parallel to the edge of the paper outlet end of the paper conveying table; a pickup roller matched with threads of the screw is arranged on the screw in a sleeved mode; forward rotation and reverse rotation of the pickup roller are controlled by a main controller; a paper conveying roller matched with the paper conveying plate in radian is arranged at the position, tightly attached to the paper conveying plate, between the pickup roller and the paper conveying plate. The inclined entering type printer is simple in structure, paper can be effectively picked up, and meanwhile automatic alignment of the paper can be achieved.

Owner:茂名森源电子科技有限公司

Automatic feeding platform for automatic assembling equipment for leaf springs

ActiveCN110860883AEasy to take outRealize automatic feeding processMetal working apparatusManipulatorIndustrial engineering

The invention relates to the field of assembling equipment for leaf springs, in particular to an automatic feeding platform for automatic assembling equipment for the leaf springs. The automatic feeding platform comprises a rack and a ball platform; the rack is arranged on the ground; the ball platform is movably connected with the rack; a lifting mechanism for driving the ball platform to tilt towards one corner is arranged on one side of the ball platform; lifting baffles are arranged on two sides, adjacent to the tilting corner, of the ball platform; working surfaces of the lifting bafflesare vertically arranged and are closely attached to the edges of the ball platform; a roller platform is mounted on the platform surface of the ball platform in an embedded manner; and a hoisting mechanism for driving the roller platform to penetrate through the platform surface of the ball platform vertically upwards is arranged at the bottom end of the roller platform. By the aid of the feedingplatform, automatic feeding and automatic alignment can be realized, and a manipulator can take materials conveniently.

Owner:蒙阴县鑫沃机械科技有限公司

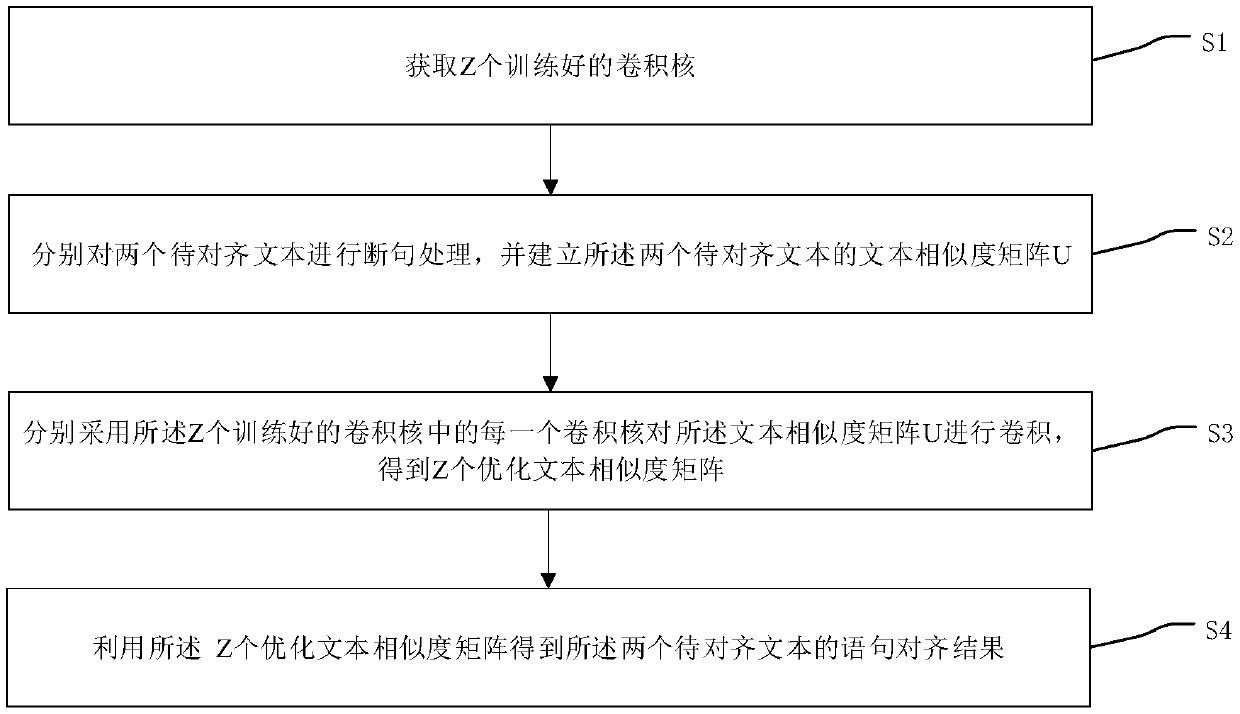

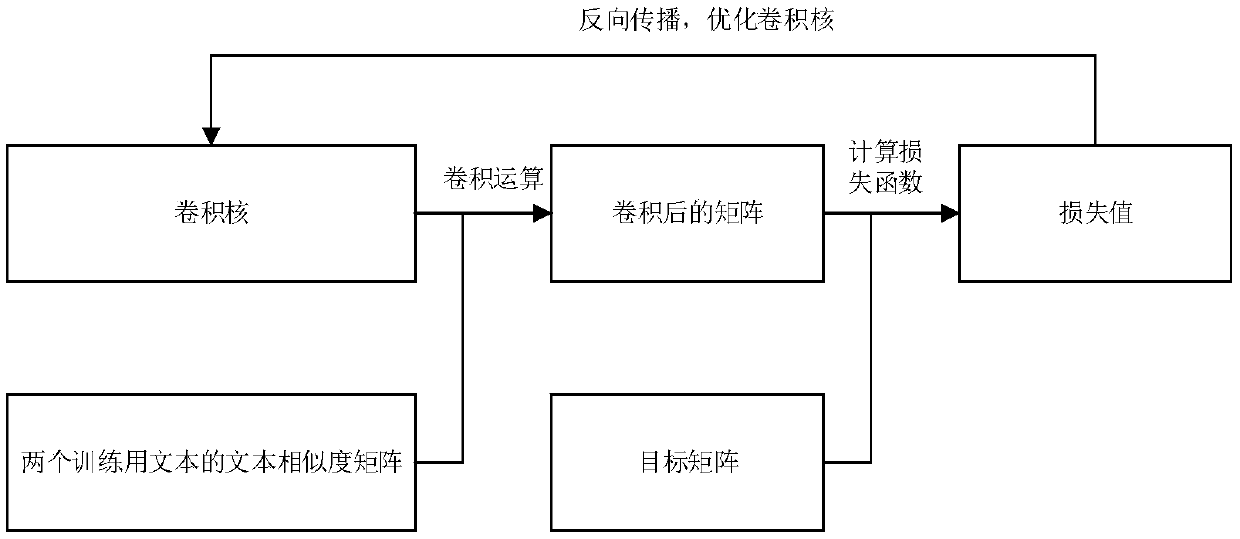

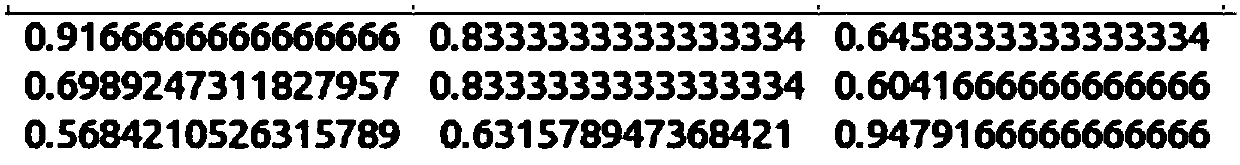

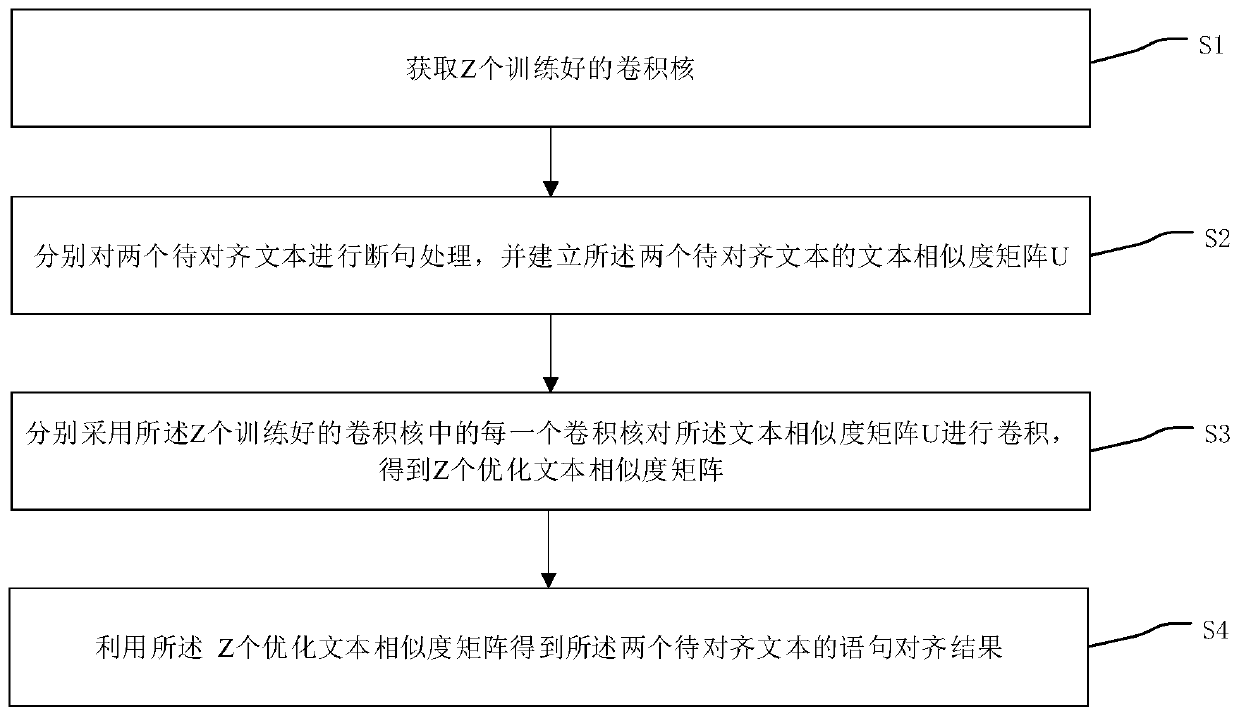

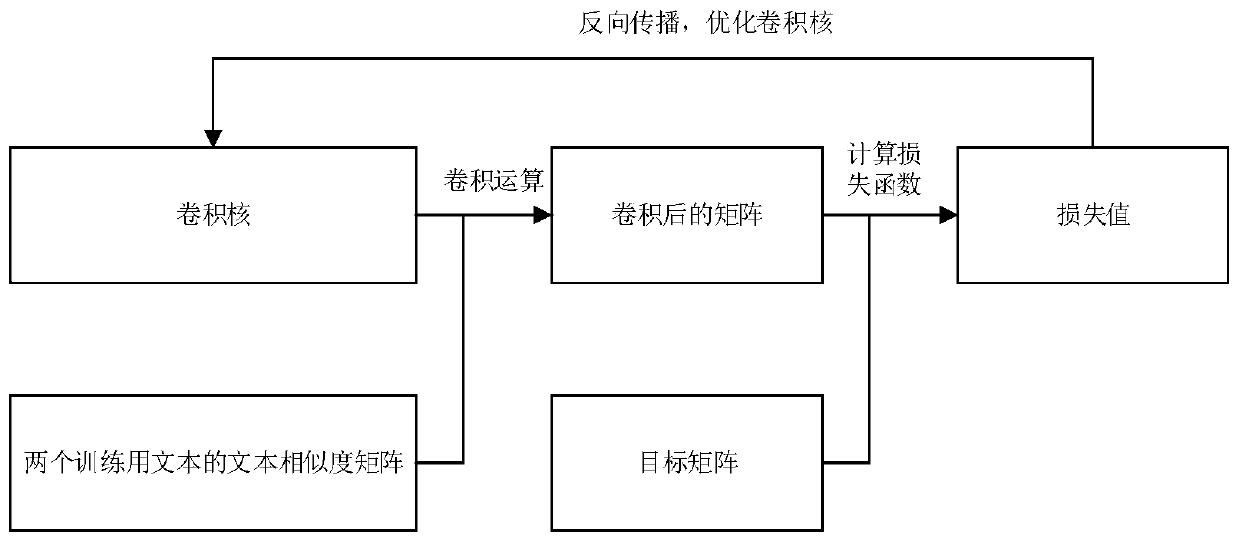

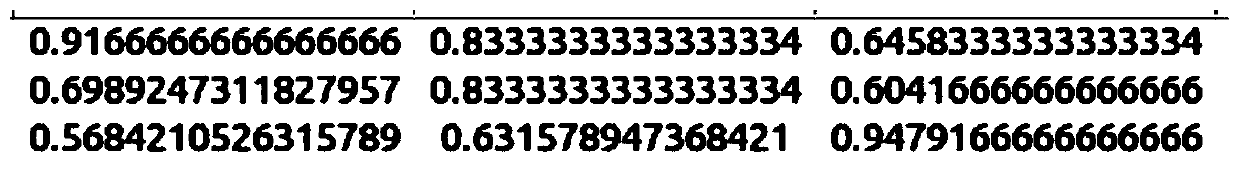

Sentence-level bilingual alignment method and device and computer readable storage medium

ActiveCN109670178AAchieve automatic alignmentReduce manual involvementNatural language data processingSpecial data processing applicationsSentence segmentationSpeech recognition

The invention discloses a sentence-level bilingual alignment method and device and a computer readable storage medium, and the method comprises the steps of S1, obtaining Z trained convolution kernels, where Z is an integer greater than or equal to 1; S2, carrying out sentence segmentation processing on the two to-be-aligned texts respectively, and establishing a text similarity matrix U of the two to-be-aligned texts; S3, carrying out convolution on the text similarity matrix U by adopting each convolution in the Z trained convolution kernels to obtain Z optimized text similarity matrixes; and S4, obtaining statement alignment results of the two to-be-aligned texts by utilizing the Z optimized text similarity matrixes. The method and the device are beneficial to improving the text statement alignment efficiency.

Owner:龙马智芯(珠海横琴)科技有限公司

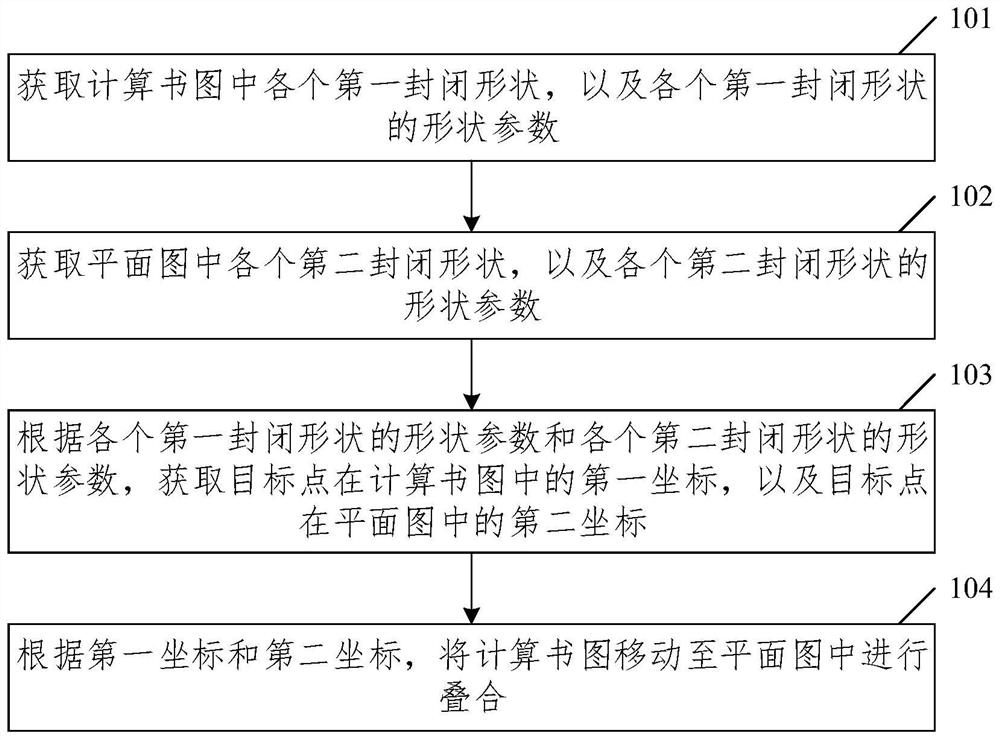

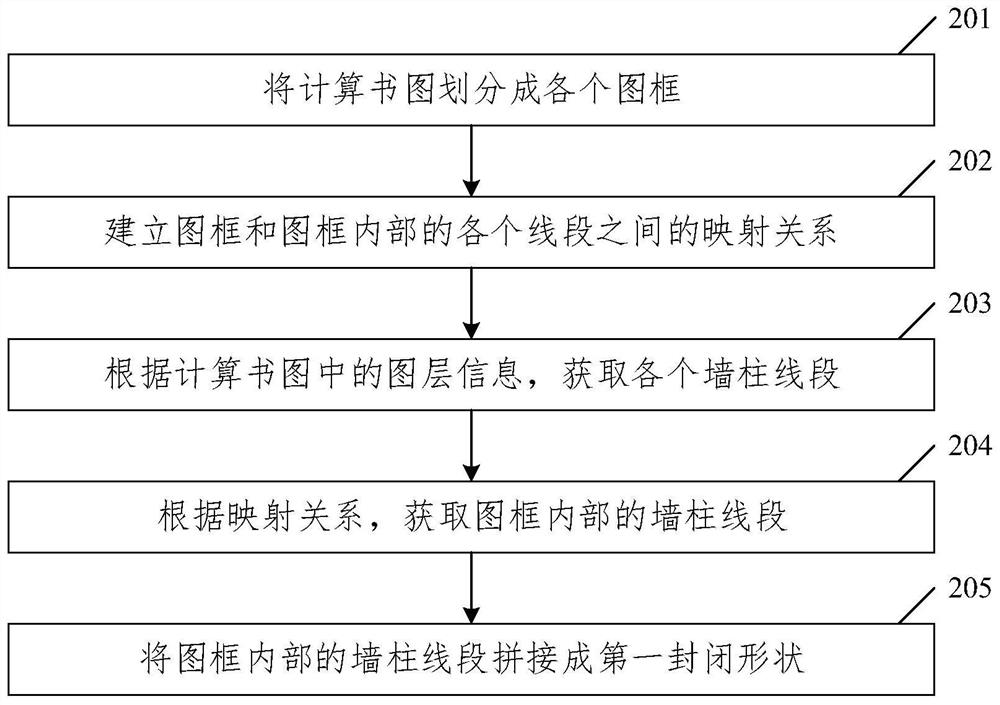

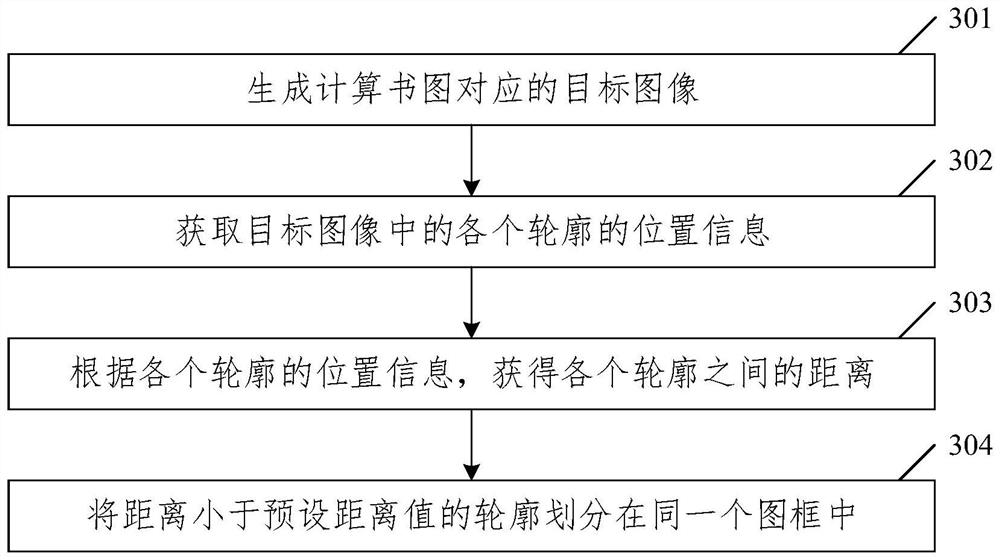

Computing book graph and planar graph superposition method and device, equipment and storage medium

PendingCN114549376AAchieve automatic alignmentSolve the cumbersome operationImage enhancementImage analysisAlgorithmTheoretical computer science

The invention relates to a superposition method and device for calculating a book graph and a plane graph, equipment and a storage medium, and relates to the field of drawing auditing. The superposition method of the calculation book graph and the planar graph comprises the steps of obtaining each first closed shape in the calculation book graph and a shape parameter of each first closed shape; obtaining each second closed shape in the planar graph and a shape parameter of each second closed shape; according to the shape parameter of each first closed shape and the shape parameter of each second closed shape, obtaining a first coordinate of the target point in the calculation book graph and a second coordinate of the target point in the planar graph; and according to the first coordinate and the second coordinate, moving the calculation book graph to the planar graph for superposition. The method is used for solving the problem that when a planar graph is audited according to a calculation book graph, the calculation book graph and the planar graph need to be manually aligned, and operation is tedious.

Owner:深圳市万翼数字技术有限公司

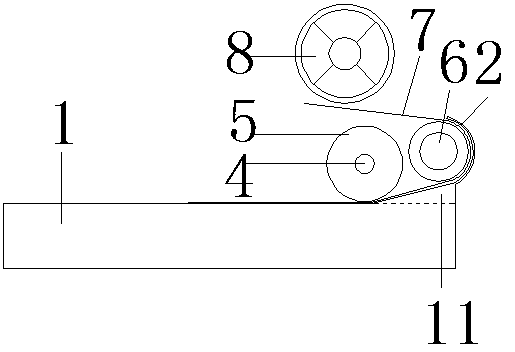

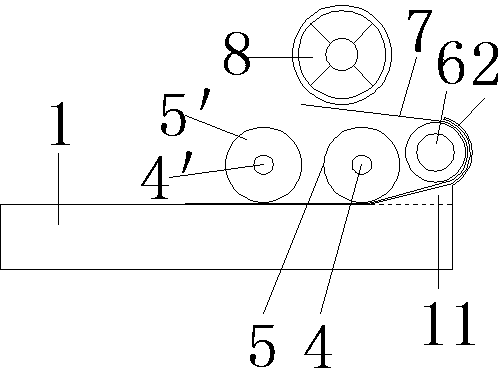

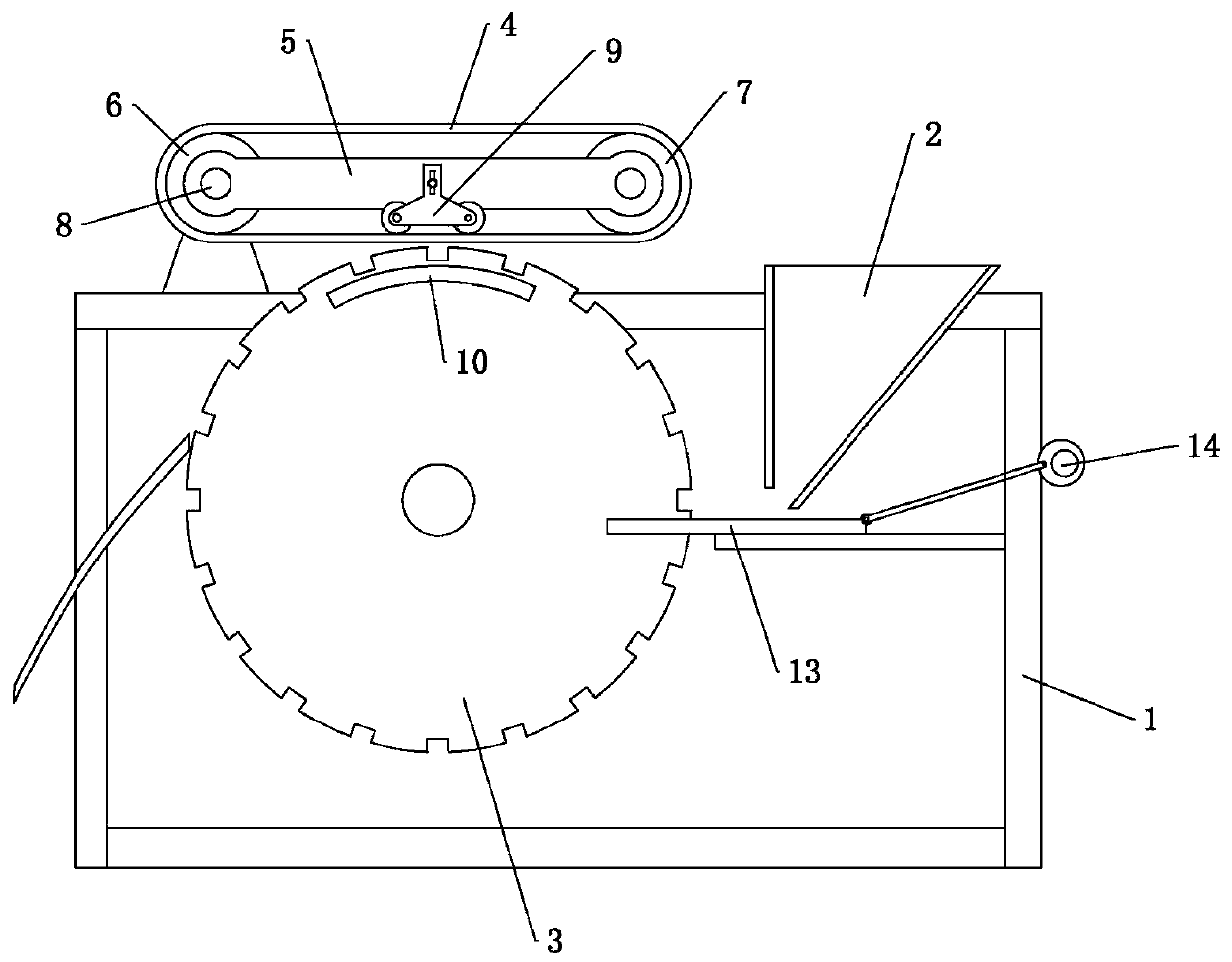

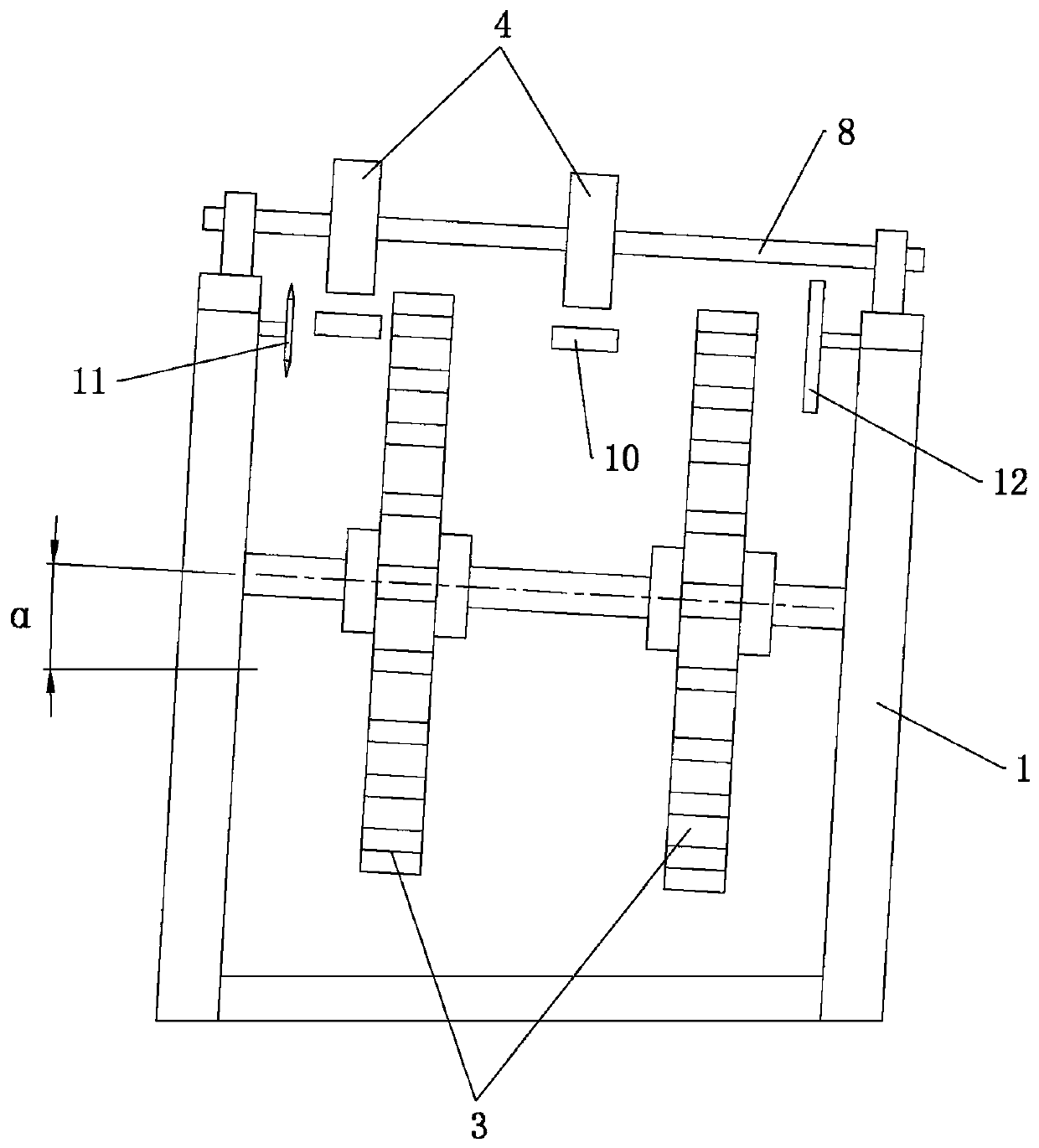

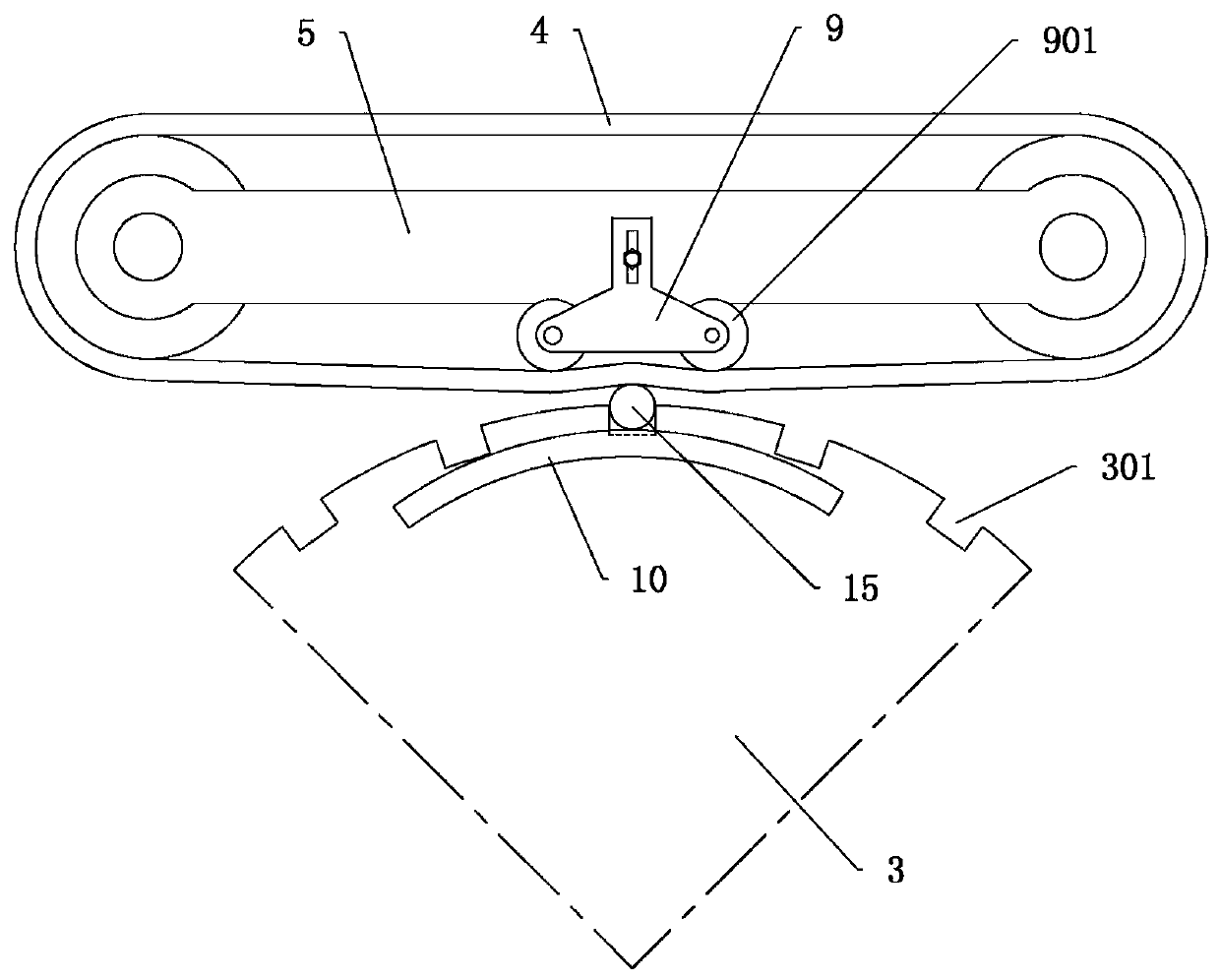

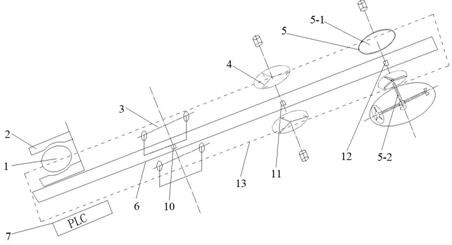

Full-automatic chopstick sawing machine

InactiveCN110126024AIncrease productivityAchieve automatic alignmentWooden sticks manufactureFeeding devicesAutomatic processingTransfer mechanism

The invention relates to a full-automatic chopstick sawing machine comprising a rack, a discharging mechanism, a transferring mechanism and a rotary cutting mechanism; the transferring mechanism comprises transferring pieces and friction belts; the friction belts are arranged above the transferring pieces respectively; at least one belt surface of each friction belt is used for downwards leaning against a chopstick positioned on the corresponding transferring piece; the transferring pieces are obliquely arranged in a longitudinal direction of the chopstick up and down, and the height of one transferring piece is higher than the height of the other transferring piece; and the rotary cutting mechanism is arranged on one side of the transferring piece at the higher position, and a limiting baffle plate for limiting longitudinal movement of the chopstick is arranged on one side of the transferring piece arranged at the lower position. By adopting the full-automatic chopstick sawing machine, the obliquely arranged transferring pieces enable the chopstick to move towards the inclined side under the action of dead weight when the chopstick is transferred, so that one end of the chopstickcan be automatically abutted against the limiting baffle plate to realize automatic alignment of the chopsticks, the other end of the chopstick is sawn by the rotary cutting mechanism to realize automatic processing of the chopsticks, and the production efficiency is improved.

Owner:FUJIAN FUZHOU WEST HONEST ARTS & CRAFTS

Palletizing machine

InactiveCN104609193ASimple structureReduce maintenance costsStacking articlesEngineeringMechanical engineering

The invention provides a palletizing machine. The palletizing machine comprises a horizontal conveying belt horizontally arranged on a base station, the horizontal conveying belt moves by linkage with a gear motor, a lifting machine frame is arranged on the upper side of the horizontal conveying belt, a hoisting mechanism is arranged on the lifting machine frame, a palletizing guiding platform and a palletizing workbench which are matched with each other in the vertical direction are correspondingly arranged on the lower side of the hoisting mechanism, a turning machine frame is arranged on the lower side of the horizontal conveying belt, a hanging beam with a horizontally supporting effect is arranged on the turning machine frame, a turning supporting shaft which is in linkage with a stepping motor and capable of stepping and rotating is arranged on the hanging beam, positioning tongs of a positioning arm machine are arranged on the lower side of the turning supporting shaft, and a discharging conveying outlet for stacking and storing materials is correspondingly arranged under the positioning arm. The palletizing machine is simple in structure, low in manufacturing cost, and low in maintenance cost, can realize the automatic stacking of laying blocks, largely saves the labor force and increases the product yield rate at the same time.

Owner:天津市坤奥建筑机械有限公司

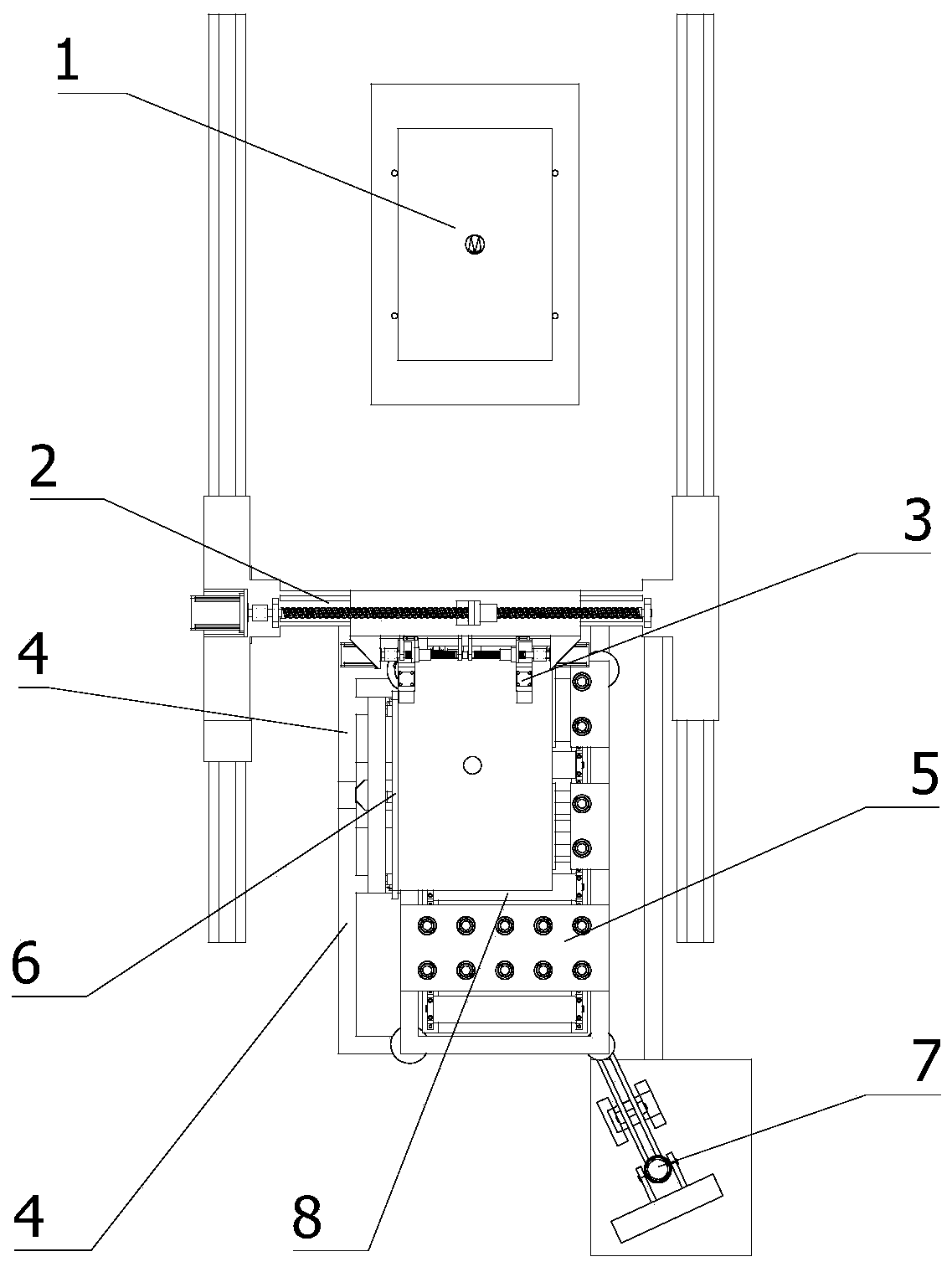

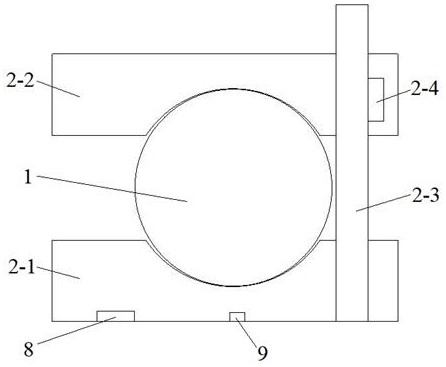

Automatic original soil sample preparation production line and production method

PendingCN112729906AReduce labor intensityReduce pollutionWithdrawing sample devicesEarth material testingSoil scienceAgricultural engineering

The invention discloses an automatic original soil sample preparation production line and a production method, and provides a production line capable of automatically controlling key actions such as aligning, clamping, uncovering, end surface soil cutting, sample cutting and ring-mounting sampling on a sample preparation box, so that the traditional complex and low-efficiency manual original soil sample preparation process in a laboratory is replaced. Automatic alignment, clamping, cover dismounting, automatic end face soil cutting, sample cutting and ring mounting sampling are achieved, manual intervention is reduced, automation of the original soil sample preparation process is achieved, a good foundation is laid for subsequent operation, compared with manual sample preparation, the efficiency is improved by 100%, the labor intensity of experimenters and environmental pollution are reduced, and the sample preparation efficiency of original soil samples is greatly improved.

Owner:XIAN CHANGQING TECH ENG +1

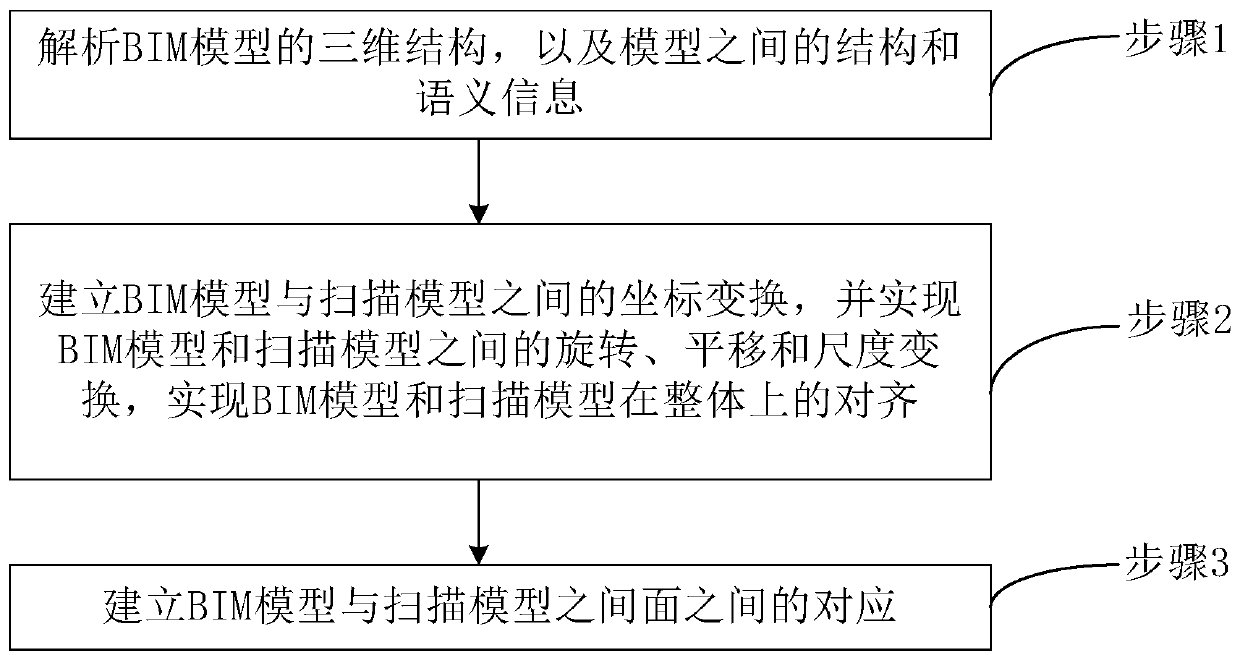

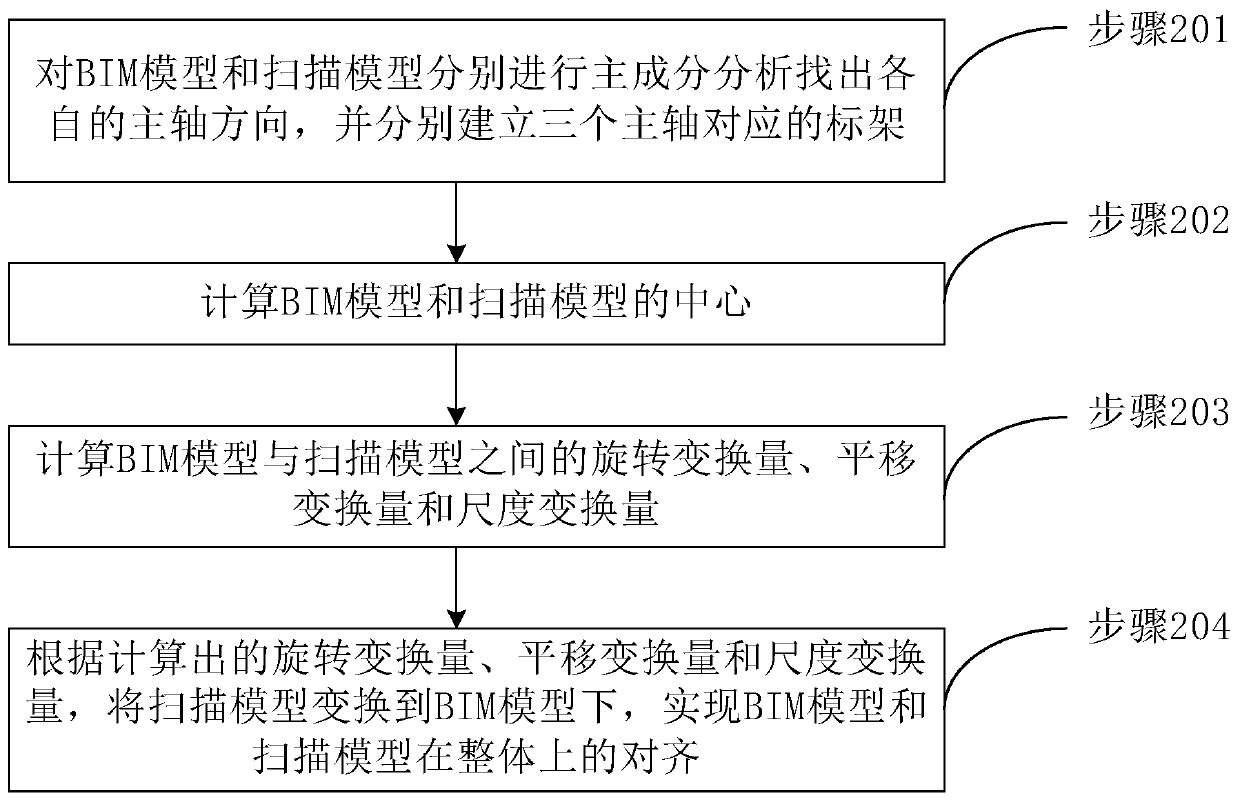

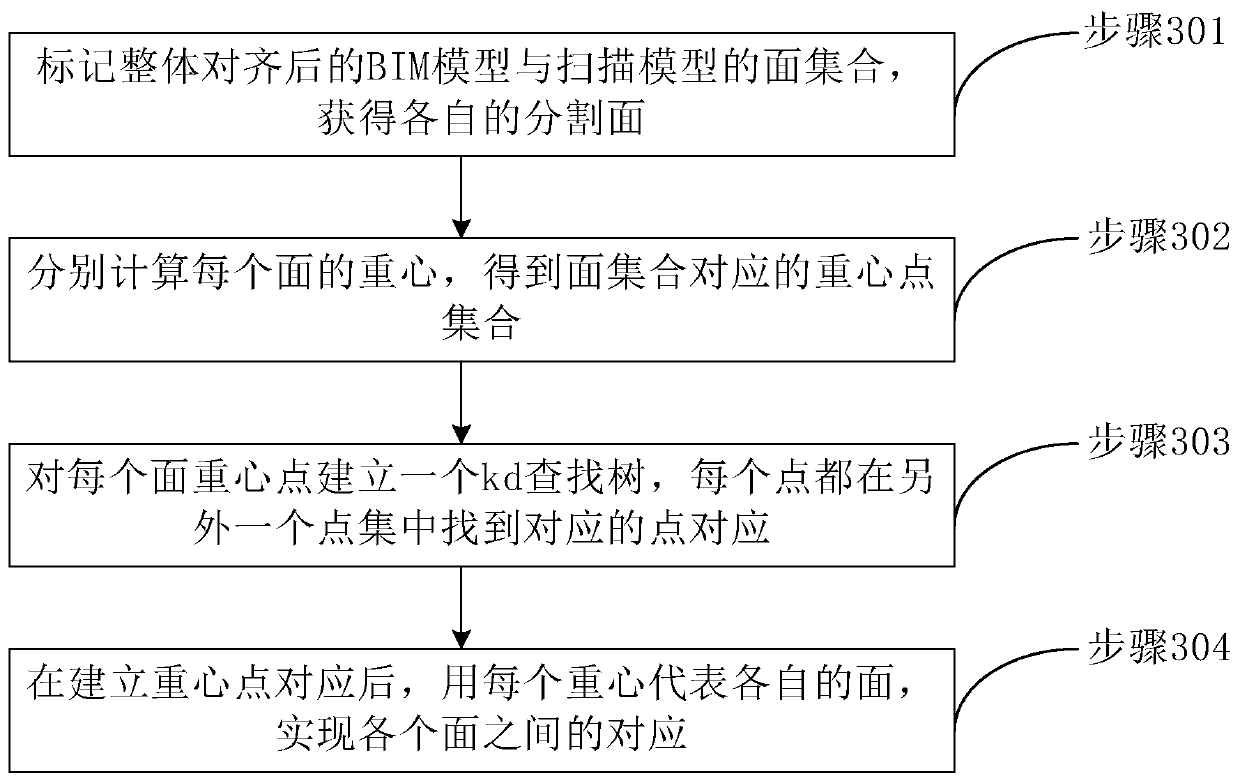

Method and system for establishing mapping between BIM model and three-dimensional cloud model

InactiveCN110929322AAchieve automatic alignmentAchieve alignmentGeometric CAD3D modellingData miningData science

The invention provides a method for establishing mapping between a BIM model and a three-dimensional cloud model, which comprises the following steps: step 1, analyzing a three-dimensional structure in the BIM model, and analyzing and exporting structure and semantic information between models in the BIM model at the same time; 2, coordinate transformation between the BIM model and the scanning model is established, rotation, translation and scale transformation between the BIM model and the scanning model are achieved, and alignment of the BIM model and the scanning model on the whole is achieved. The invention further provides a system for establishing the mapping between the BIM model and the three-dimensional cloud model. According to the method, the problem of overall alignment of theBIM model and the three-dimensional building scanning model in scale, rotation and translation can be solved, the BIM model corresponds to the scanning model, and guidance is provided for building high-precision measurement and guiding operation of other indoor robots.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

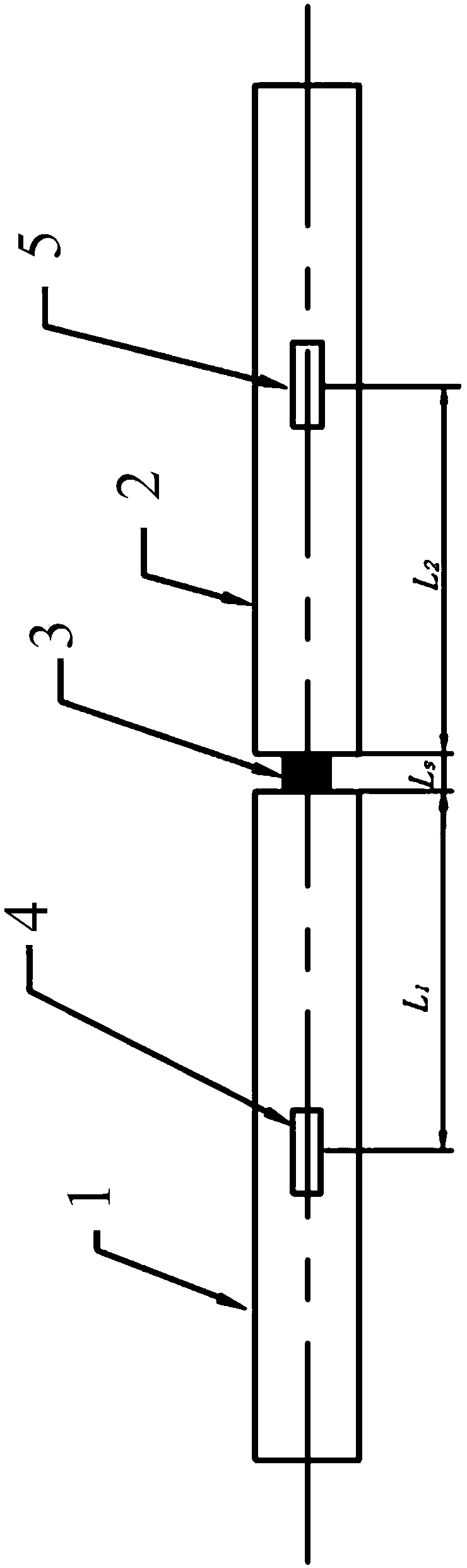

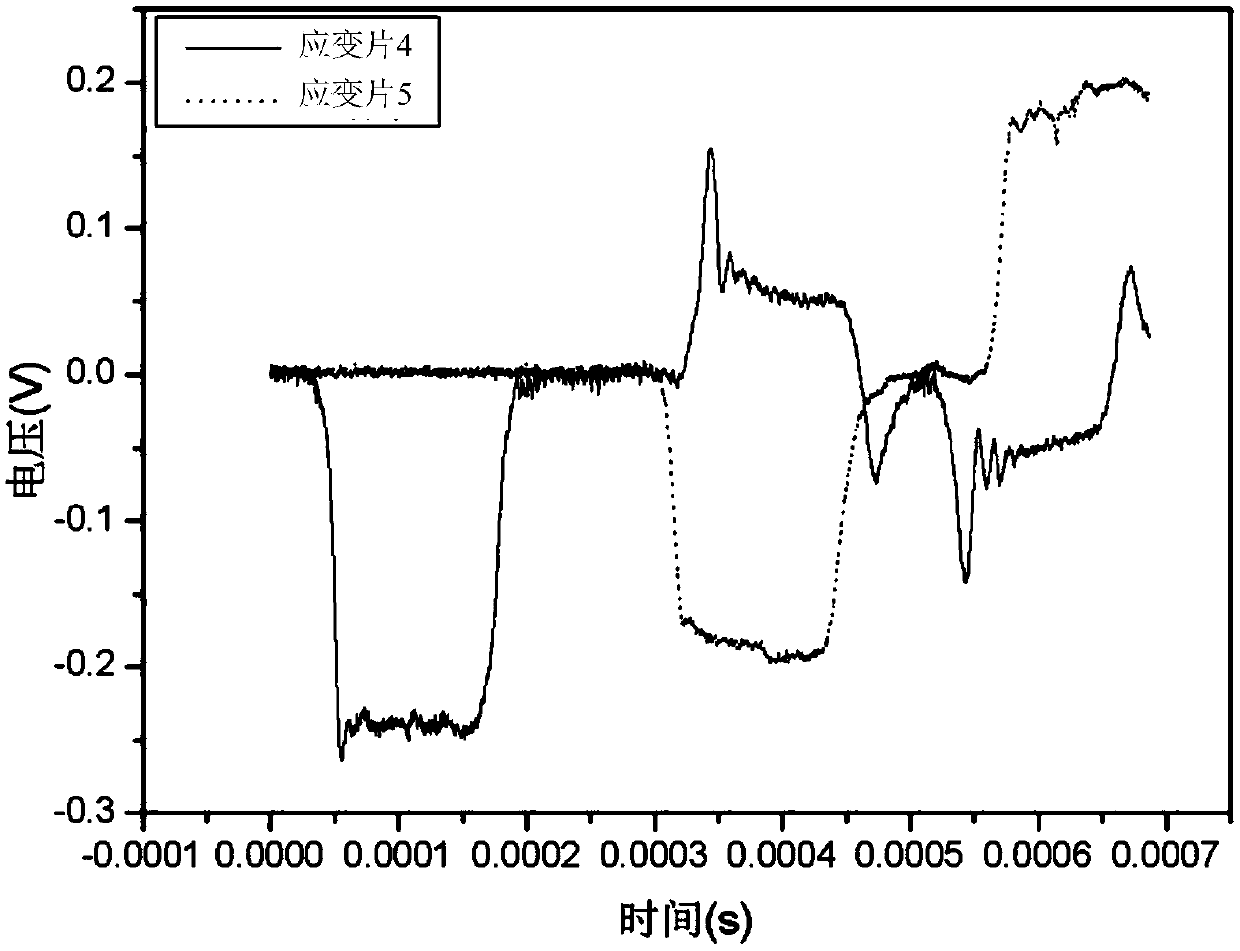

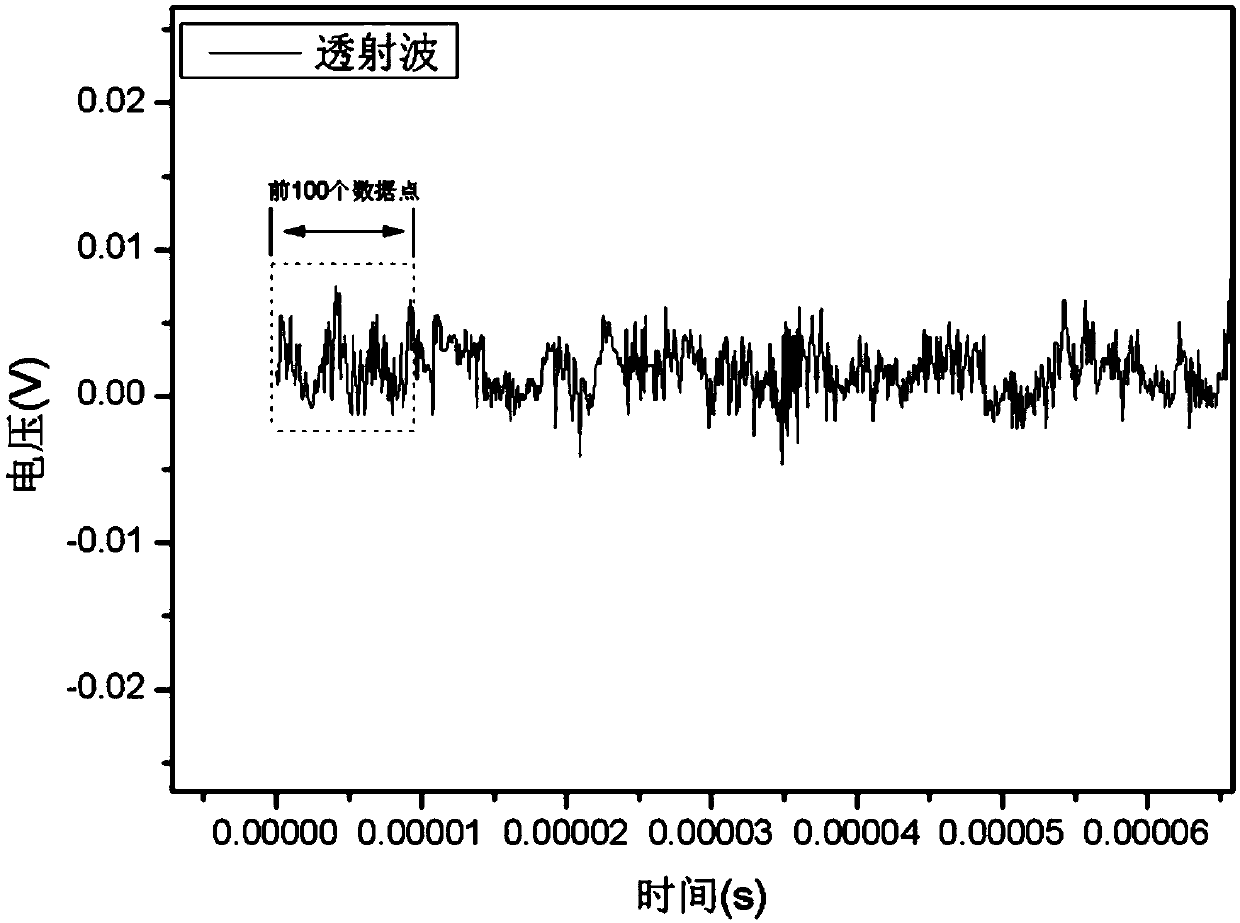

Data processing method and data processing system for split Hopkinson bar experiment

ActiveCN110967246AAchieve alignmentStress-strain curve results are reliableStrength propertiesData processing systemReflected waves

The invention relates to a data processing method and a data processing system for a split Hopkinson bar experiment. The data processing method comprises the steps of (a) setting a starting point interval which is symmetrical relative to a baseline according to the baseline of an incident wave waveform, and selecting a first intersection point of the incident wave waveform and an upper boundary ora lower boundary of the starting point interval as an incident wave starting point; and (b) obtaining a transmitted wave starting point and a reflected wave starting point according to the incident wave starting point obtained in the step (a), and aligning the incident wave starting point, the transmitted wave starting point and the reflected wave starting point to obtain stress and strain at thesame moment. The data processing method and the data processing system at least have the advantages of simple data processing process, reliable result and the like.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

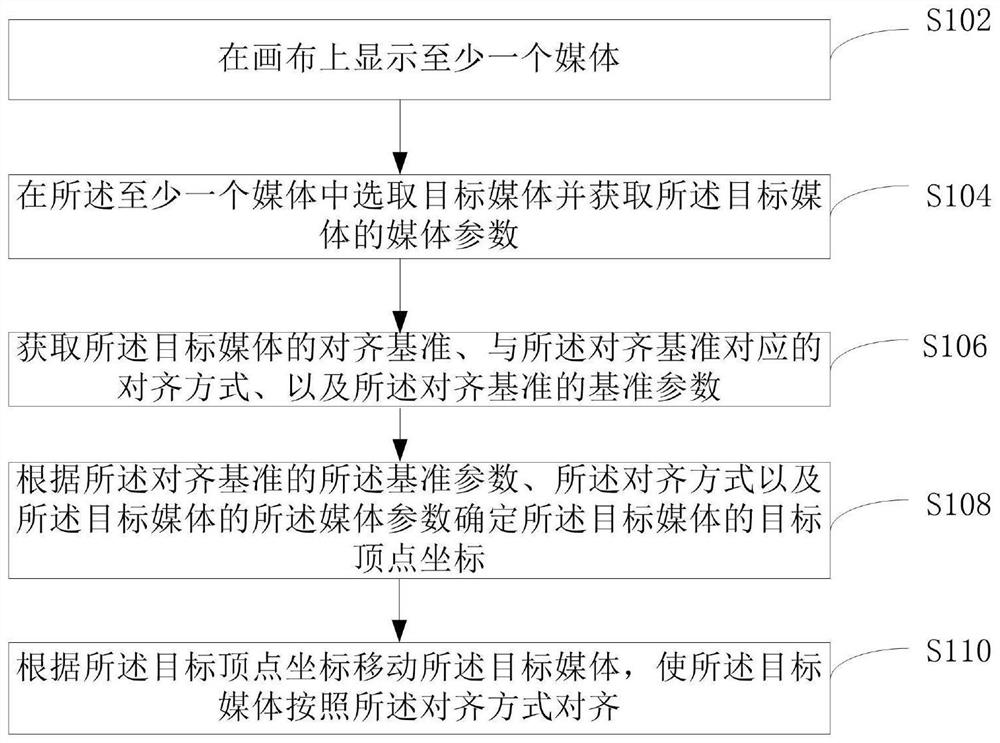

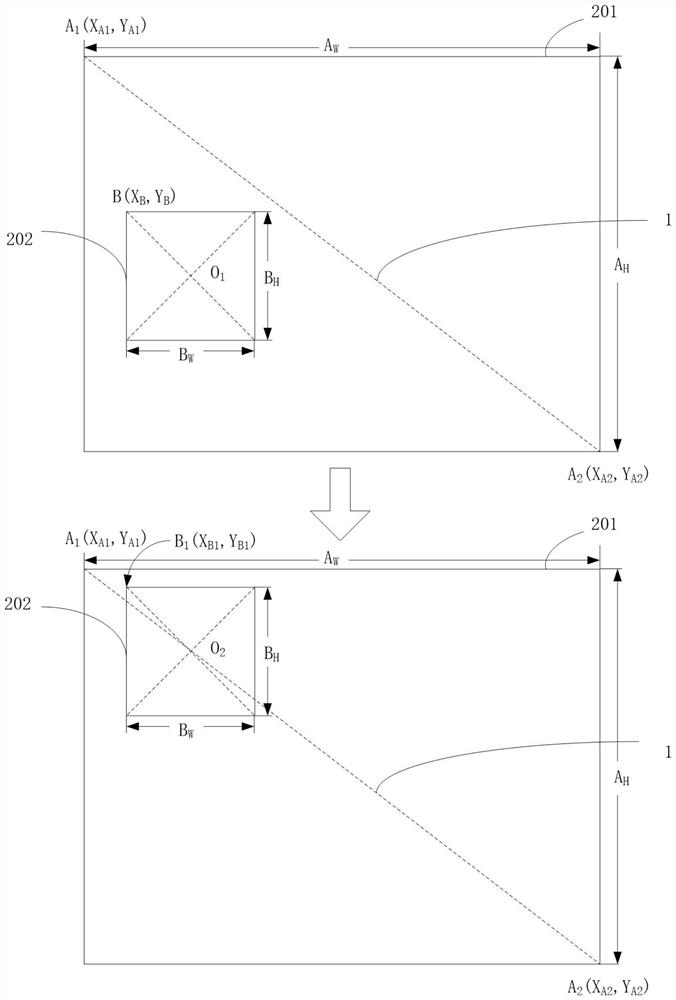

Media alignment method and media alignment device

InactiveCN112702655AAchieve automatic alignmentSteps to Simplify AlignmentSelective content distributionComputer graphics (images)Theoretical computer science

Owner:XIAN NOVASTAR TECH

3D grating bonding process for led display

The invention belongs to the technical field of LED display screens, and aims to provide a 3D (three-dimensional) grating laminating process of an LED display screen. The process includes the steps: providing a transparent substrate and a grating film with identification points, and a transparent optical adhesive; according to different transparent optical adhesives, flatly arranging two kinds of the raw materials on table tops of two working tables respectively, using cameras on the working tables for respectively capturing the identification points of the raw materials, and displaying related information on a display, using application software for calculating the position where the first workbench needs to be turned over and the distance by which the second workbench needs to be translated; performing edge sealing and ensuring that the raw materials flatly placed on the two workbenches are incapable of adhering to each other; performing turnover and lamination; finally, selectively subjecting a 3D grating sample to aftertreatment. Thus, a 3D grating is positioned without depending on human eyes, precision and slope of lamination are ensured, the edges are free of folds, product scrap rate is low, and requirements and dependency on operators are lowered.

Owner:SHENZHEN AOTO ELECTRONICS

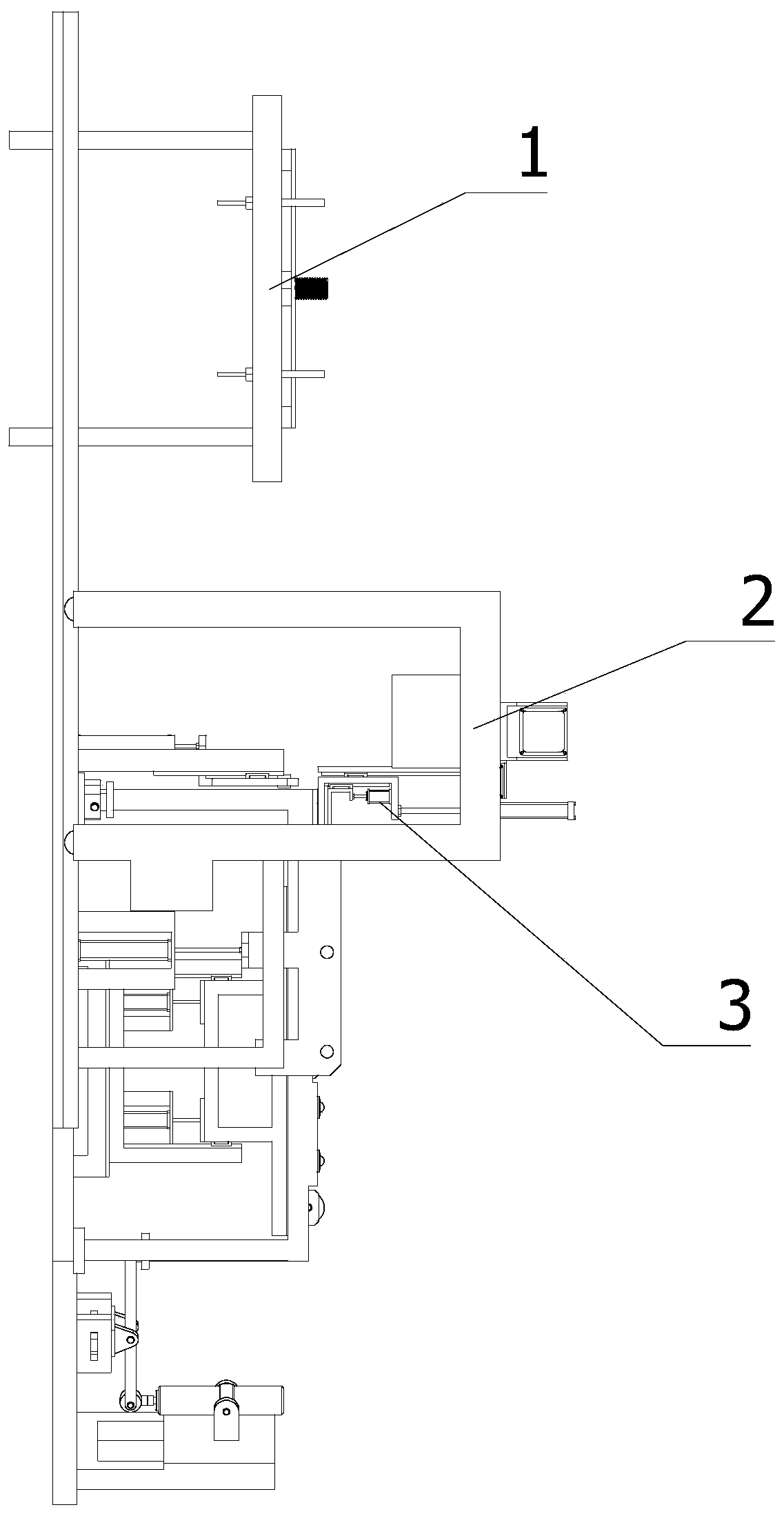

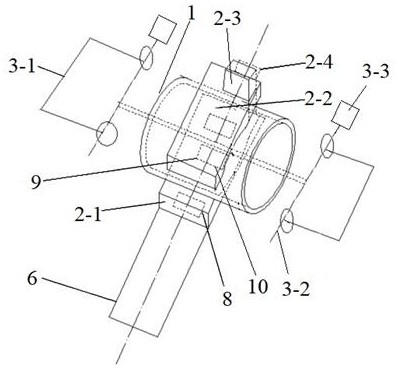

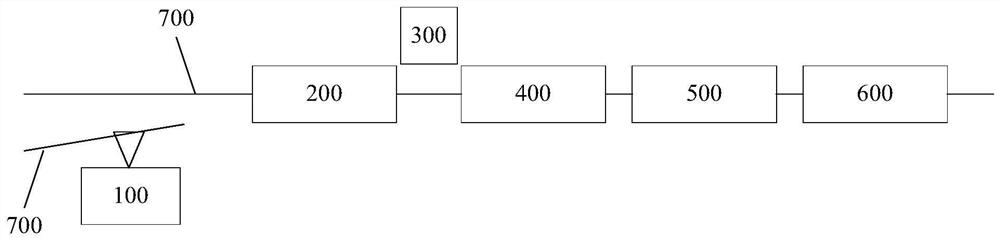

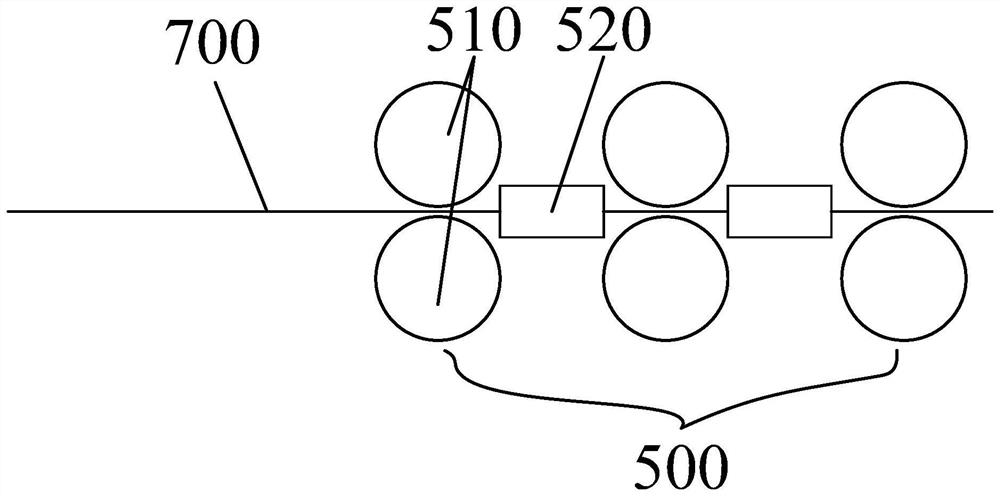

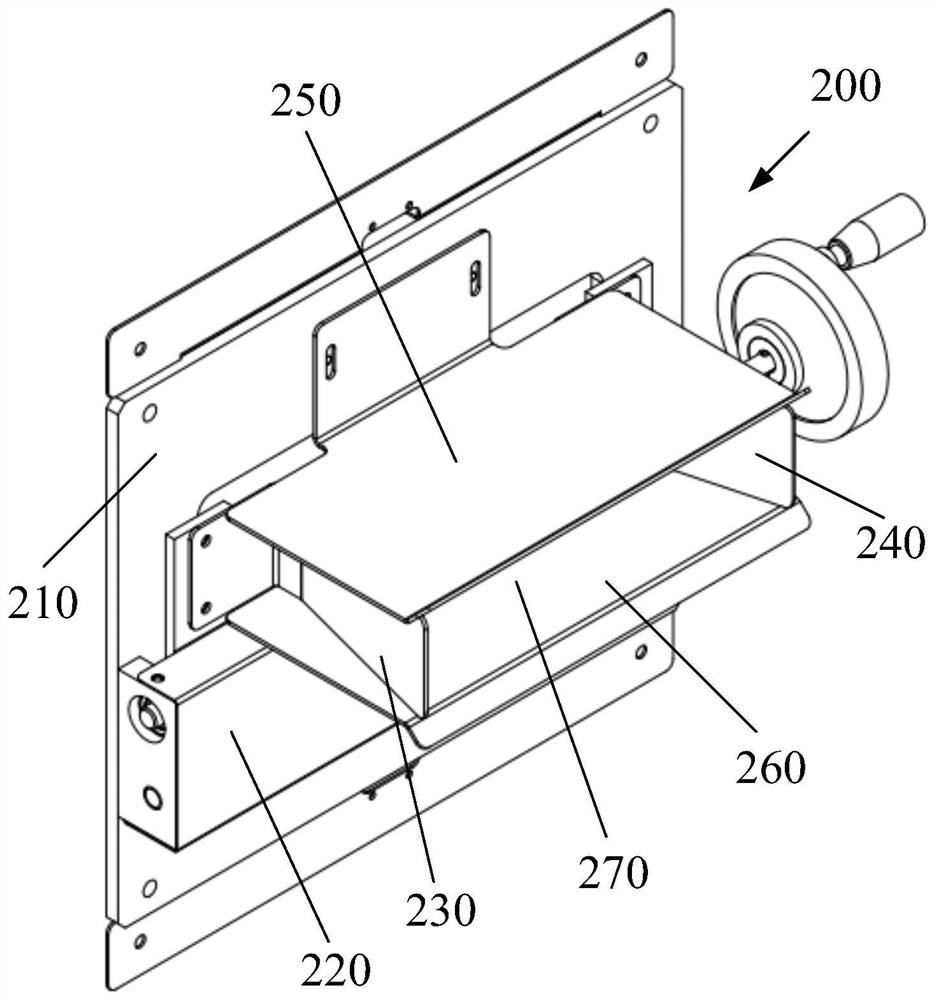

Belt head adjusting mechanism for metal belts and continuous conveying equipment for metal belts

PendingCN113369729AAchieve automatic alignmentWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention provides a belt head adjusting mechanism for metal belts and continuous conveying equipment for the metal belts. The belt head adjusting mechanism comprises multiple belt pressing roller sets which are arranged front and back at intervals and first guide channels arranged between the adjacent belt pressing roller sets. According to the belt head adjusting mechanism, the rear-side metal belt is conveyed forwards through the multiple belt pressing roller sets and the first guide channels, and the multiple belt pressing roller sets press the belt head of the rear-side metal belt to adjust the bending direction of the belt head of the rear-side metal belt, so that the belt head of the rear-side metal belt is pressed by the multiple belt pressing roller sets, then extends out of the multiple belt pressing roller sets in the set direction and stops at the belt tail of the front-side metal belt, and automatic alignment of the belt head of the rear-side metal belt and the belt tail of the front-side metal belt is achieved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

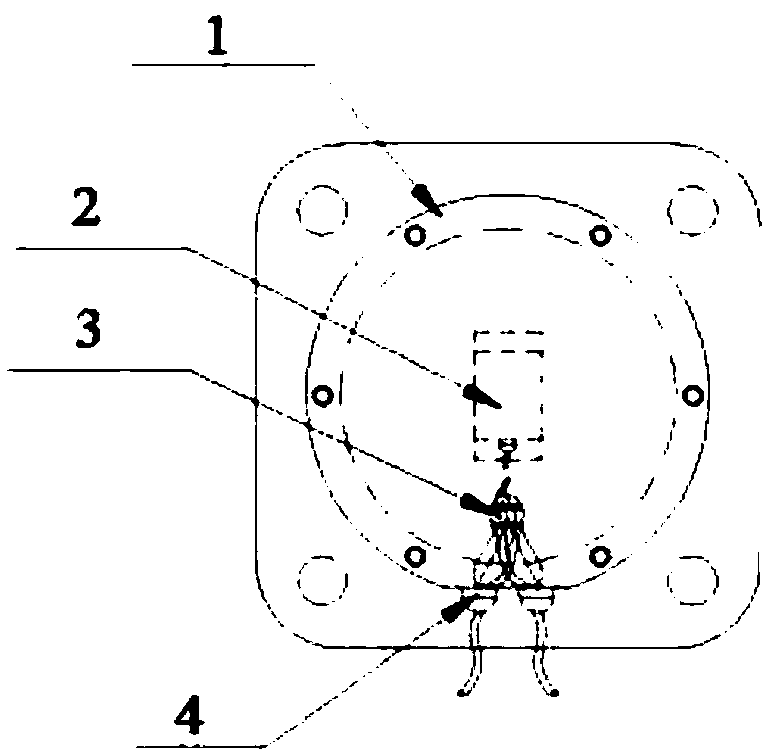

Hydraulic dam gate angle detection device and application thereof

PendingCN109307498ARealize automatic shutdown functionAchieve automatic alignmentMeasurement devicesElectricityEngineering

The invention discloses a hydraulic dam gate angle detection device and an application thereof. The hydraulic dam gate angle detection device comprises at least one group of angle detection devices, wherein each angle detection device is installed on each gate of a hydraulic dam; each angle detection device comprises a waterproof base, an inclination angle sensor, a wiring terminal strip, a waterproof cable and a control system, wherein the waterproof base is arranged on a steel dam gate; the inclination angle sensor is arranged in the waterproof base, and the inclination angle sensor is parallel to the center line of the steel dam gate; the wiring terminal strip is electrically connected with the inclination angle sensor; and the wiring terminal strip is connected with the control systemthrough the waterproof cable. The top elevation of the gate can be calculated according to the included angle between the gate of the current hydraulic dam and the horizontal plane. Therefore, the water level control and automatic alignment of multiple hydraulic dam gates at any positions can be realized.

Owner:YANGZHOU CITY FIDELITY HYDRAULIC MACHINERY

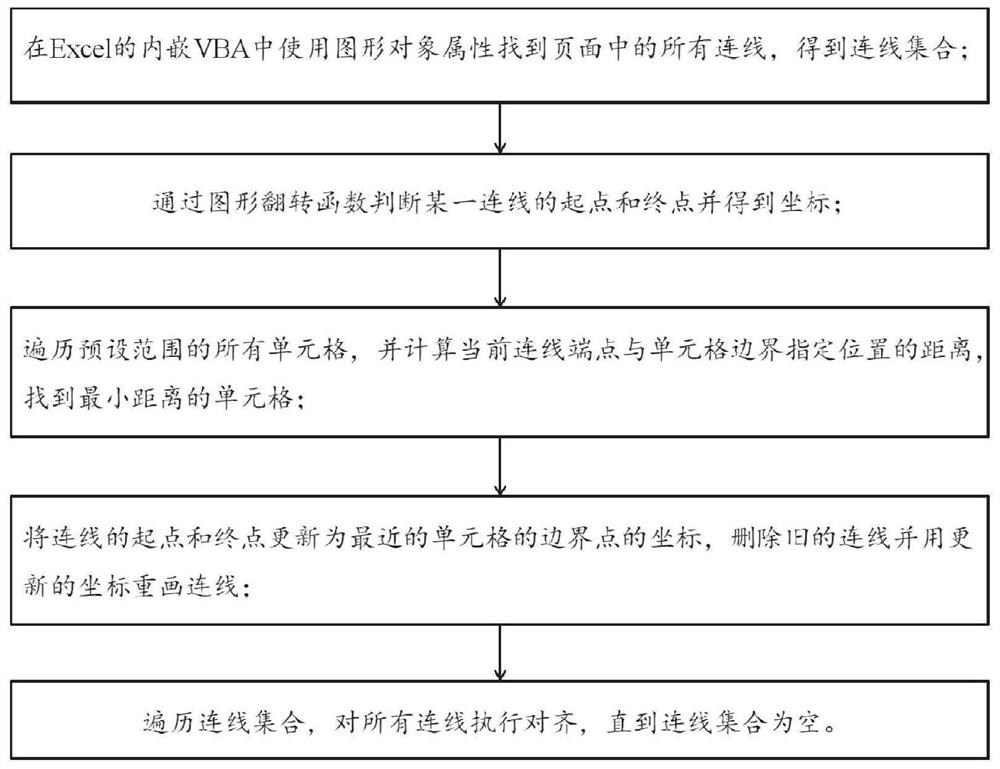

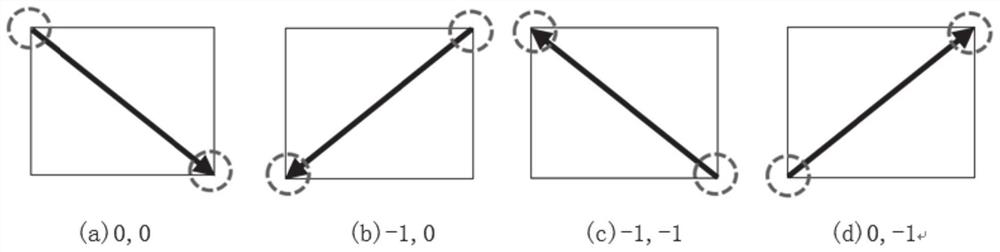

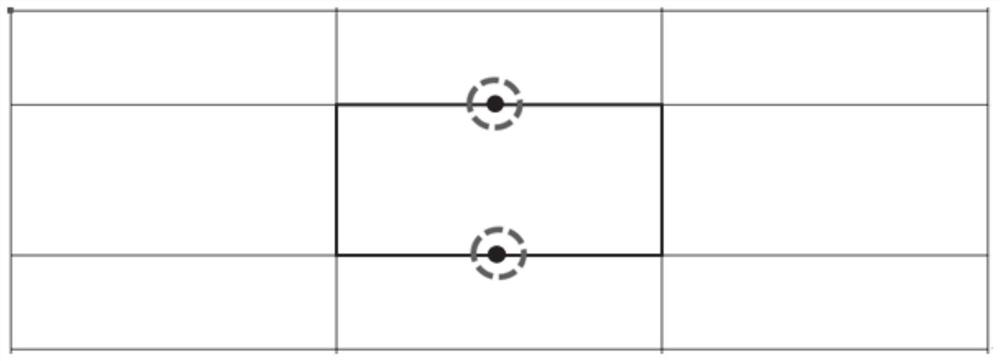

Excel connection endpoint automatic alignment method and device

PendingCN112364615AAchieve automatic alignmentImprove drawing efficiencyVisual data miningStructured data browsingGraphicsAlgorithm

The invention provides an Excel connecting line endpoint automatic alignment method and device, and the method comprises the following steps: finding all connecting lines in a page in an embedded VBAof Excel through employing the attributes of a graphic object, and obtaining a connecting line set; judging a starting point and an ending point of a certain connecting line through a graph overturning function and obtaining coordinates; traversing all cells in a preset range, calculating the distance between the current connection endpoint and the specified position of the boundary of the cells,and finding the cell with the minimum distance; updating the starting point and the ending point of the connecting line to be coordinates of the boundary point of the nearest cell, deleting the old connecting line and redrawing the connecting line by using the updated coordinates; traversing the connection line set, and aligning all the connection lines until the connection line set is empty; by traversing the connecting lines and the cells and judging the starting point and the terminal point, redrawing of the existing connecting lines is achieved, and automatic alignment of the connecting lines is achieved.

Owner:SHANDONG NORMAL UNIV

Pixel alignment method, device and equipment

Owner:天翼安全科技有限公司

Sentence-level bilingual alignment method and device, and computer-readable storage medium

ActiveCN109670178BAchieve automatic alignmentReduce manual involvementNatural language data processingSpecial data processing applicationsSentence segmentationSimilarity matrix

The invention discloses a sentence-level bilingual alignment method and device and a computer readable storage medium, and the method comprises the steps of S1, obtaining Z trained convolution kernels, where Z is an integer greater than or equal to 1; S2, carrying out sentence segmentation processing on the two to-be-aligned texts respectively, and establishing a text similarity matrix U of the two to-be-aligned texts; S3, carrying out convolution on the text similarity matrix U by adopting each convolution in the Z trained convolution kernels to obtain Z optimized text similarity matrixes; and S4, obtaining statement alignment results of the two to-be-aligned texts by utilizing the Z optimized text similarity matrixes. The method and the device are beneficial to improving the text statement alignment efficiency.

Owner:龙马智芯(珠海横琴)科技有限公司

Control method of automatic alignment control device for spraying joints of asphalt spreading paver

ActiveCN103526673BHigh degree of automationAchieve automatic alignmentRoads maintainenceDistribution controlDisplay device

A control method for an automatic alignment control device for spraying seams of an asphalt spreading paver, the control device includes a controller, a touch display, a speed sensor, an angle sensor, a front nozzle valve group, a side nozzle valve group and a rear nozzle valve group Nozzle manifold. The control method is: (1) collect instructions and data; (2) calculate the delay time t from the front nozzle valve group to the front end of the side nozzle valve group 1 ; (3) Calculate the delay time t of two adjacent nozzle valves in the side nozzle valve group 2 ; (4) Calculate the delay time t from the rear end of the side nozzle valve group to the rear nozzle valve group 3 ; (5) In the beginning stage of spraying and paving, the controller delays the control; (6) In the end stage of spraying and paving, the controller delays the control. Through the above delay control process, the automatic alignment of the spraying edge at the joint of the road surface is perfectly realized, avoiding material waste and road surface pollution.

Owner:XCMG CONSTR MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com