Full-automatic chopstick sawing machine

A fully automatic, chopsticks technology, applied in circular saws, sawing components, sawing equipment, etc., can solve the problem that the ends of chopsticks cannot be automatically aligned, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

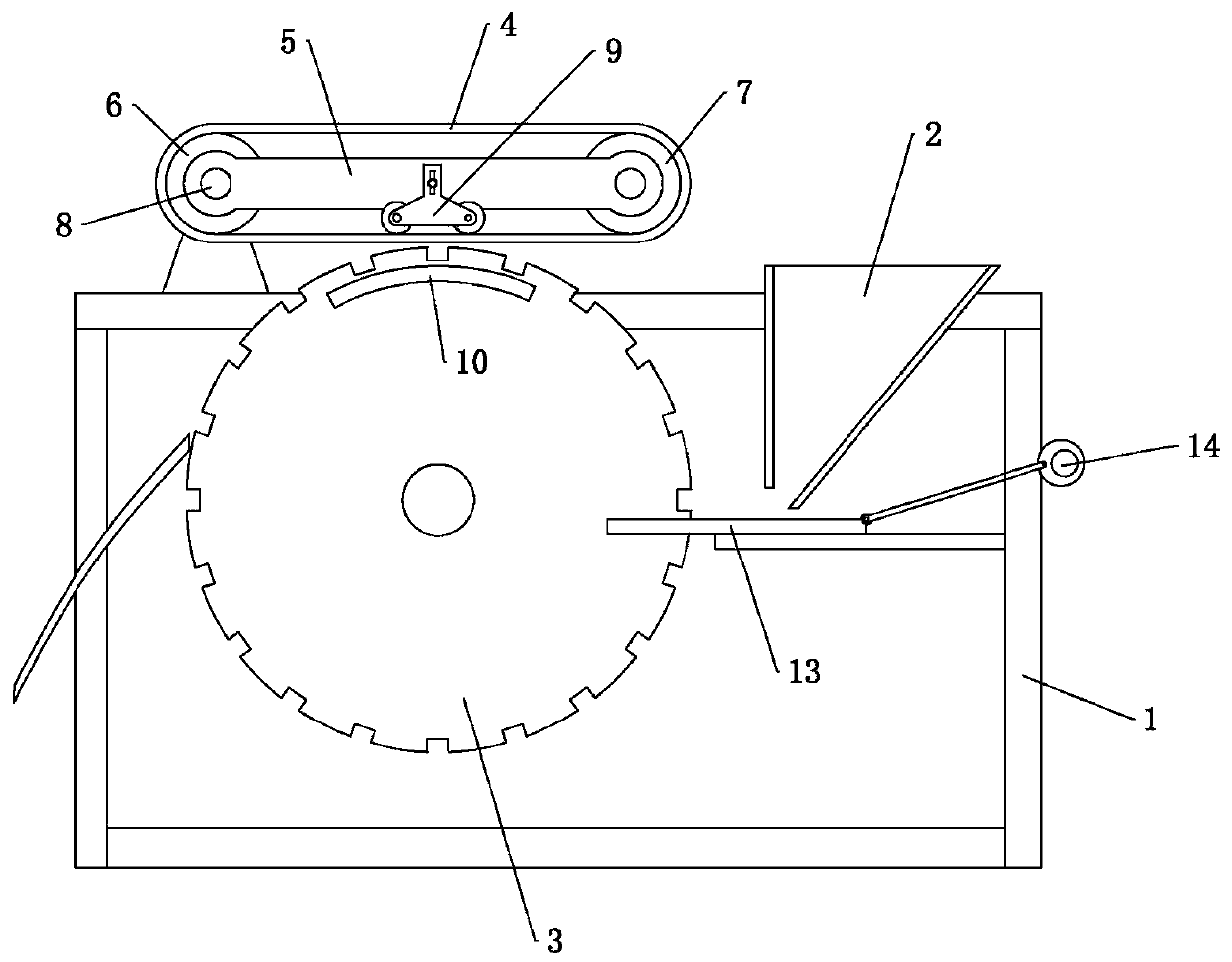

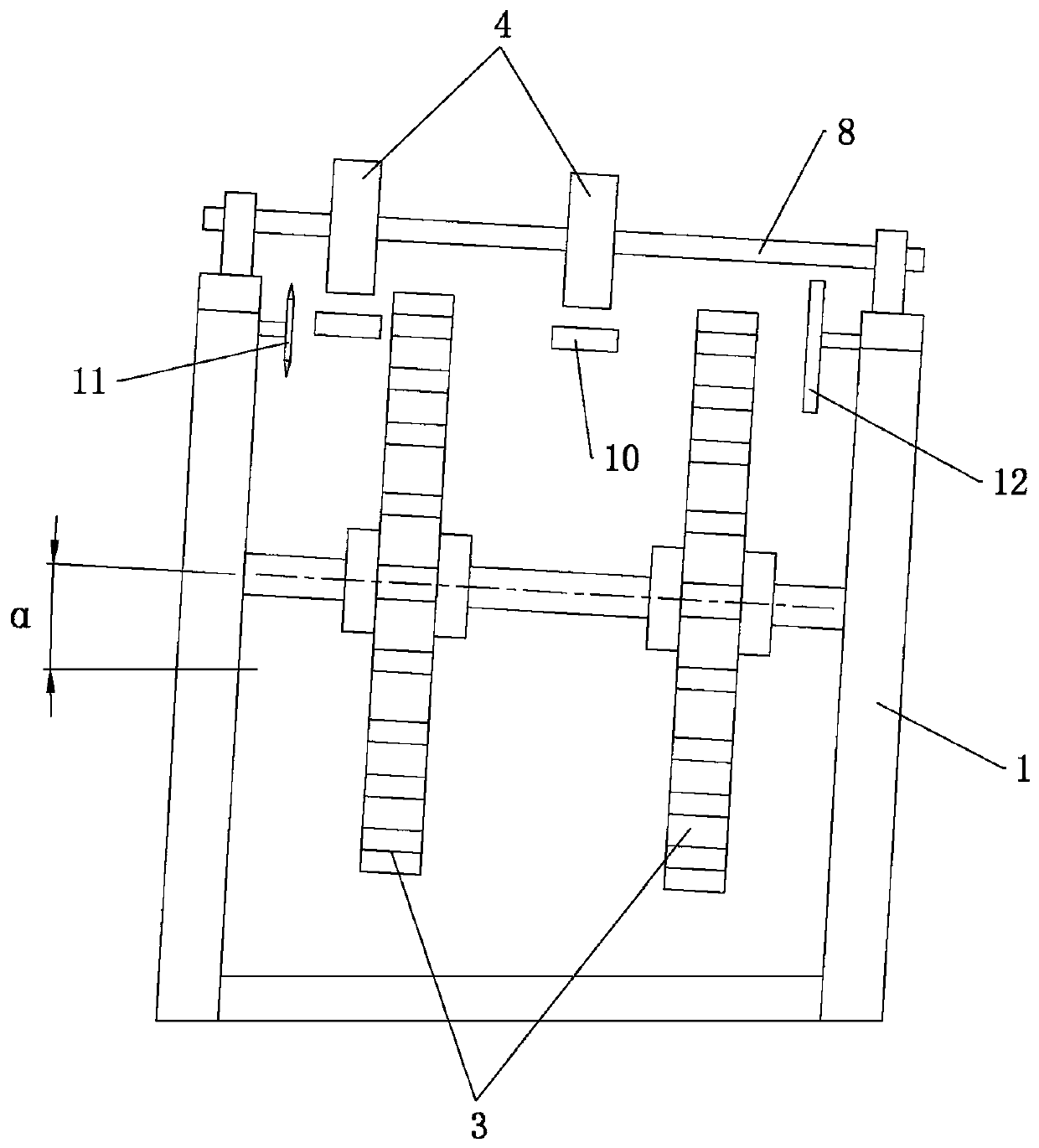

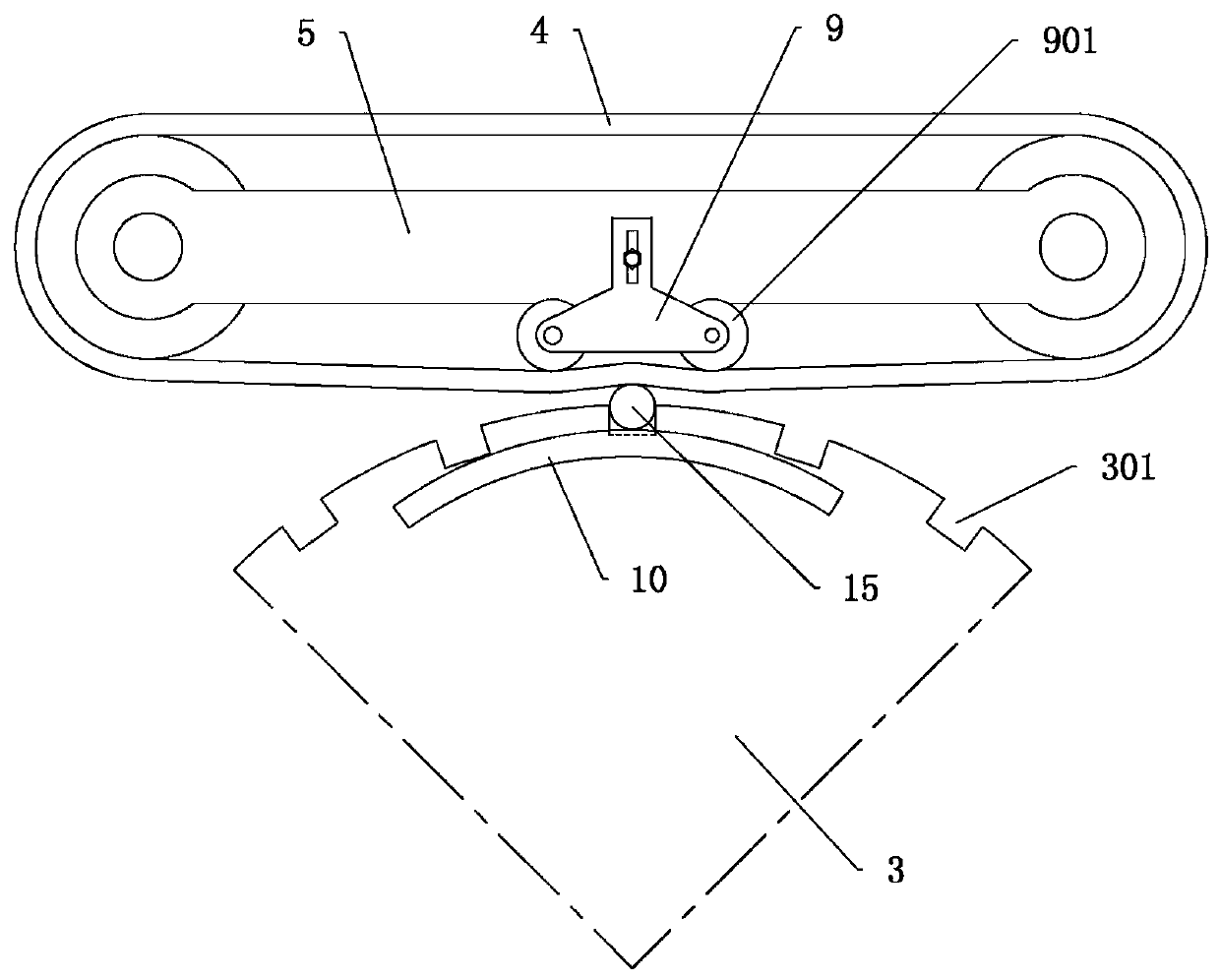

[0029] Example: such as figure 1 and figure 2 As shown, the fully automatic chopsticks sawing machine includes a frame 1, a feeding mechanism, a transfer mechanism and a rotary cutting mechanism 11. The transfer mechanism includes a transfer member 3 and a friction belt 4. The transfer member 3 is arranged at the outlet of the discharge mechanism, and The horizontal chopsticks are driven to move from front to back, and the friction belt 4 is arranged on the top of the transfer member 3 and is driven by two front and rear pulleys to move.

[0030] The transfer member 3 is an unpowered transfer wheel, which is freely rotatably installed on the frame 1 . The wheel surface of the transfer wheel is provided with transfer grooves 301 axially penetrating, and the transfer grooves 301 are distributed on the wheel surface of the transfer wheel. There are multiple transfer parts 3, two in this embodiment, and the two are arranged coaxially, located at both ends of the chopsticks in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com