A kind of oblique type printer

A printer, oblique entry technology, applied in the direction of printing device, printing, etc., can solve the problems of manual alignment, inconvenient printing of paper in batches, complex structure, etc., and achieve the effect of automatic alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

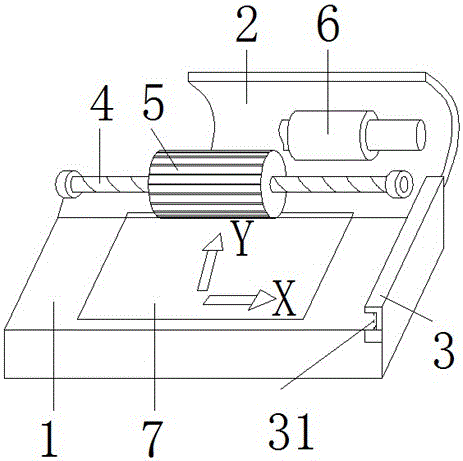

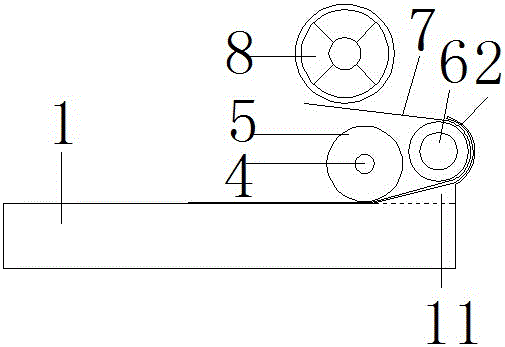

[0015] exist figure 1 , figure 2 In the first embodiment, the oblique entry pile driver includes a paper conveying table 1; a wedge-shaped protrusion 11 is provided at the paper output end of the paper conveying table 1; A smooth paper feeding board 2; a baffle plate 3 with an infrared device is installed on the side of the paper transport table 1; a screw 4 controlled by a screw controller to lift is installed at the paper output end of the paper transport table 1; The axis of the screw 4 is parallel to the edge of the paper delivery end of the paper transport platform 1; matching; the forward and reverse rotation of the pickup wheel 5 is controlled by the main controller (not shown); between the pickup roller 5 and the paper feeder 2, one device that is close to the paper feeder 2 and the paper feeder 2 The paper feed roller 6 is driven by a paper feed motor (not shown) with matching radians.

[0016] Put the paper 7 into the paper conveying table 1, and the edge of the ...

Embodiment 2

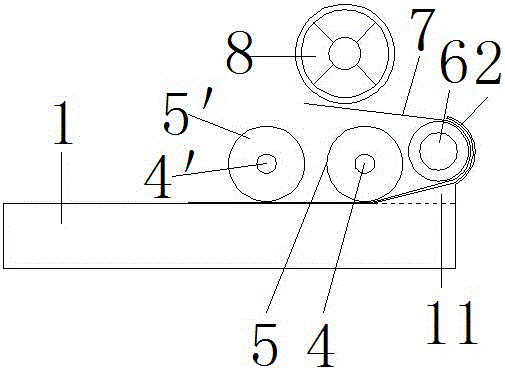

[0018] exist image 3 In the shown embodiment two, the difference from the first embodiment is that on the paper transport platform 1, a set of attached screw rod 4' and attached pickup wheel 5' are arranged side by side with the screw 4 and the pick-up wheel 5, The two sets of screw rods and the paper pickup wheels move synchronously; when the printer with this structure transports the paper, there are two parallel friction forces to drive the paper to move, which can effectively prevent the paper from skewing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com