Automatic alignment control device and method of spraying joint of asphalt spraying paver

A control device and automatic alignment technology, applied in roads, road repairs, roads, etc., can solve the problems of misalignment of spraying edges and waste of materials, and achieve the effects of avoiding road surface pollution, perfect spraying effect, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

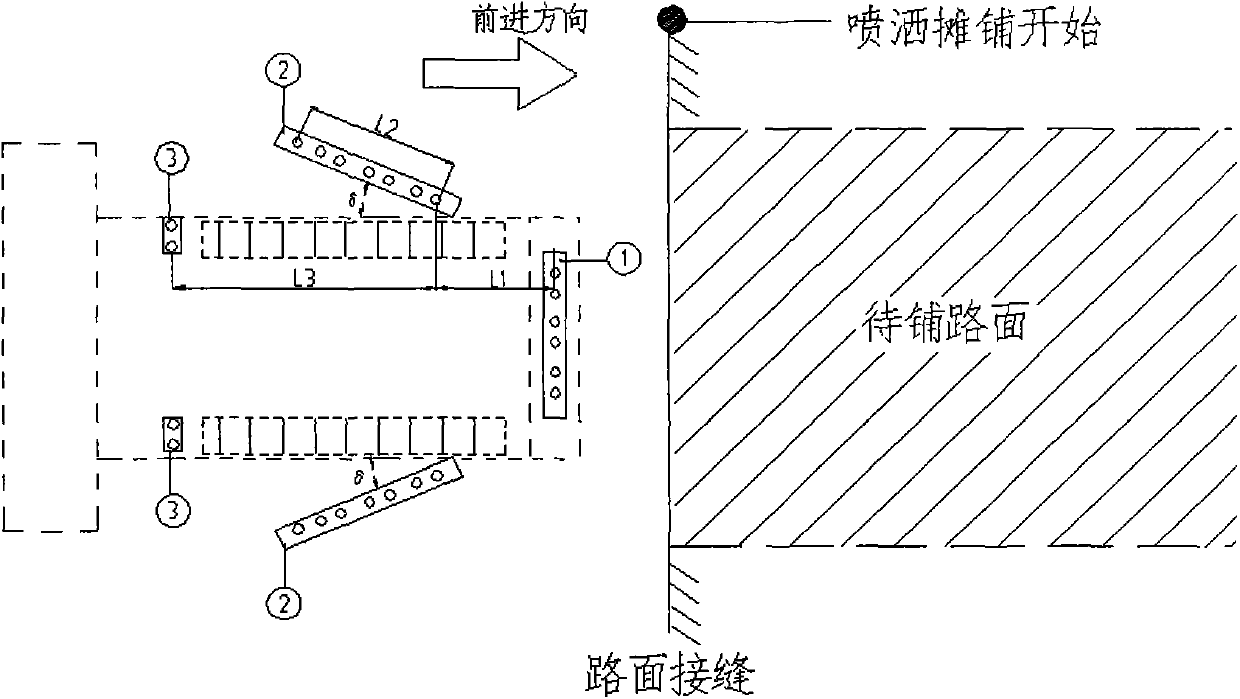

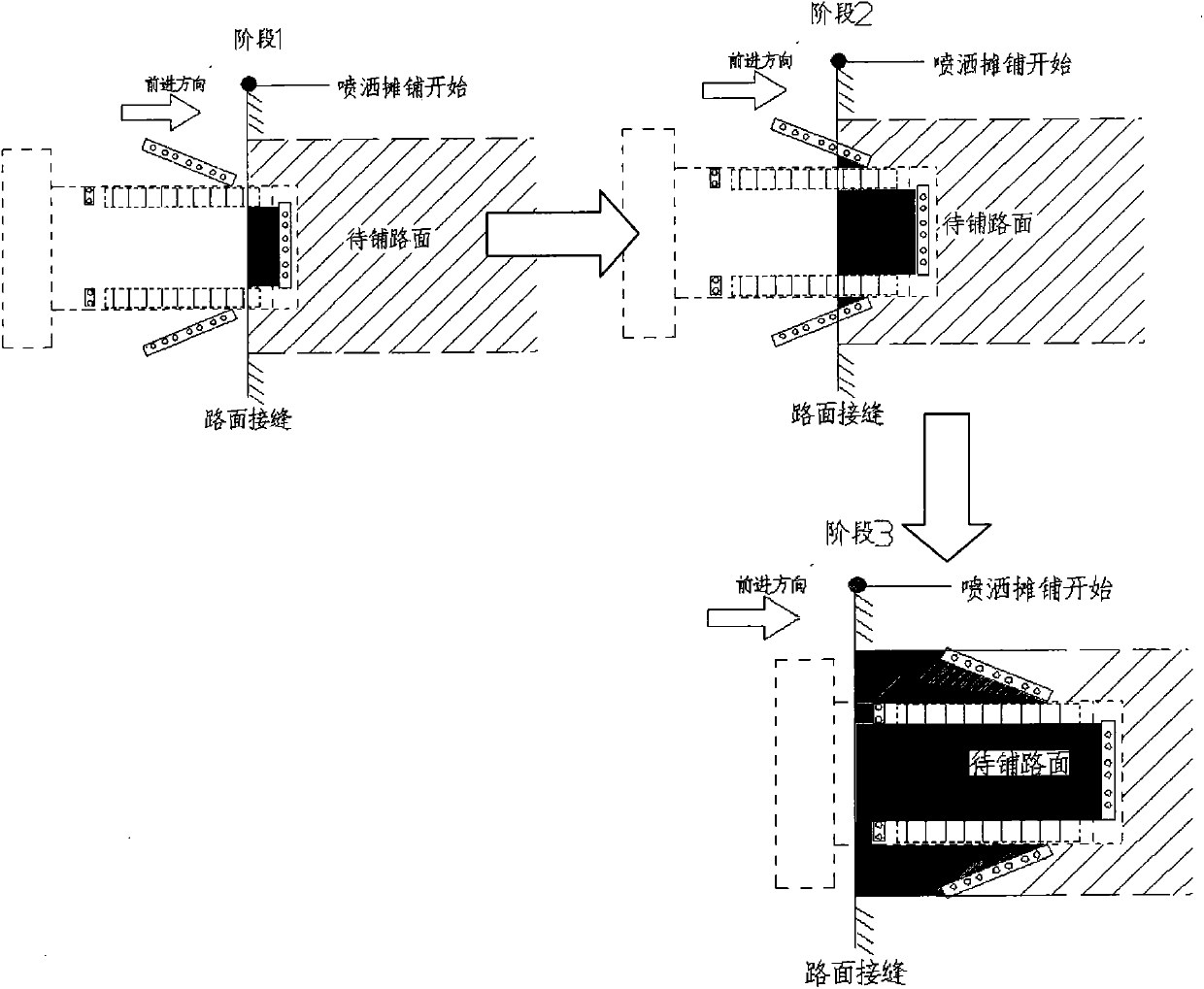

[0033] An automatic alignment control device and method for the spraying joints of an asphalt spreading paver, aiming at the segmented spray bar layout of the asphalt spreading paver, during the start and stop stages of spraying and paving, each group of nozzle valves The program control and segmental delay realize the automatic alignment of the spraying edge at the joint of the road surface. The present invention will be described in further detail below in conjunction with the accompanying drawings.

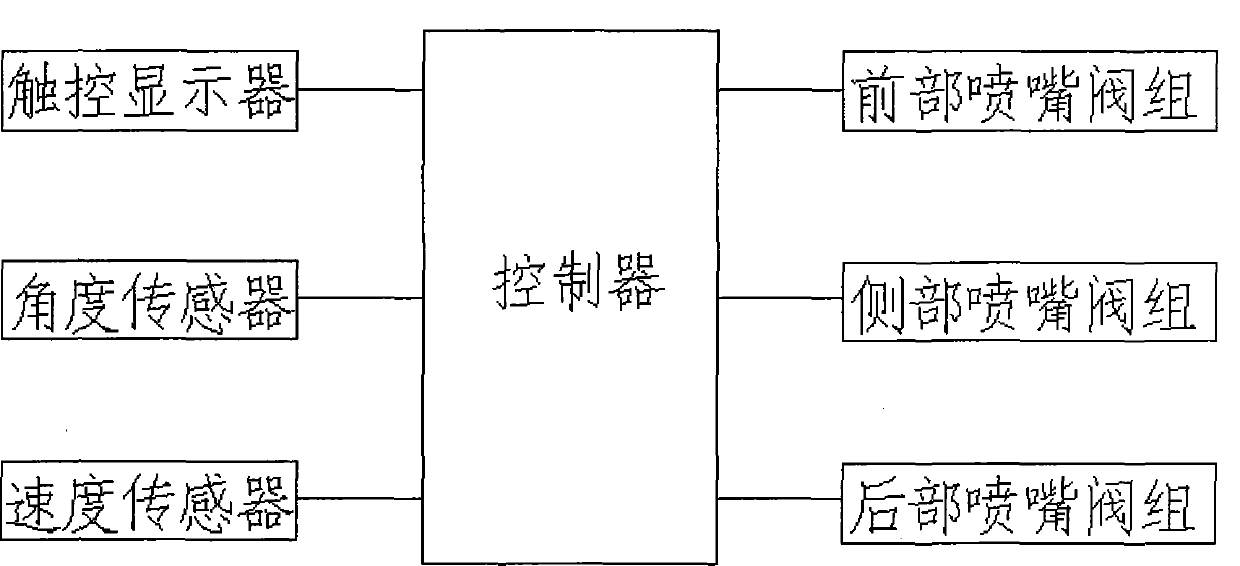

[0034] Such as figure 1 As shown, the spray seam automatic alignment control device includes a controller, a touch display, a speed sensor, an angle sensor, a front nozzle valve group, a side nozzle valve group and a rear nozzle valve group; the touch display is connected to the controller , the touch display sends a "spraying and paving start" or "spraying and paving end" command to the controller; the controller communicates with the speed sensor, angle sensor, front nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com