3D grating bonding process for led display

A display and 3D technology, applied in optics, optical components, lamination devices, etc., can solve problems such as unevenness, high product scrap rate, edge wrinkles of grating film and transparent substrate, and reduce requirements and dependencies Sexuality, easy mass production, and the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

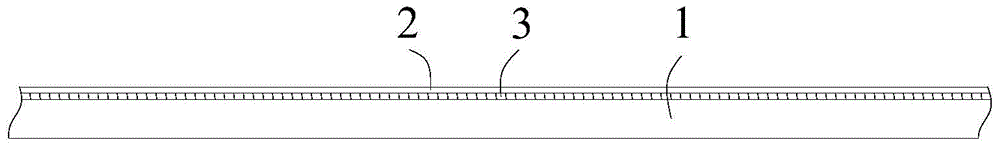

[0048] Embodiment one Transparent optical adhesive 3 is selected as OCA double-sided adhesive

[0049] In this embodiment, the transparent optical adhesive 3 provided in step S1 is selected as the OCA double-sided adhesive, then in step S1, in addition to marking the transparent substrate 1 and the grating film 2 with marking points, the OCA double-sided adhesive should also be marked Identify points.

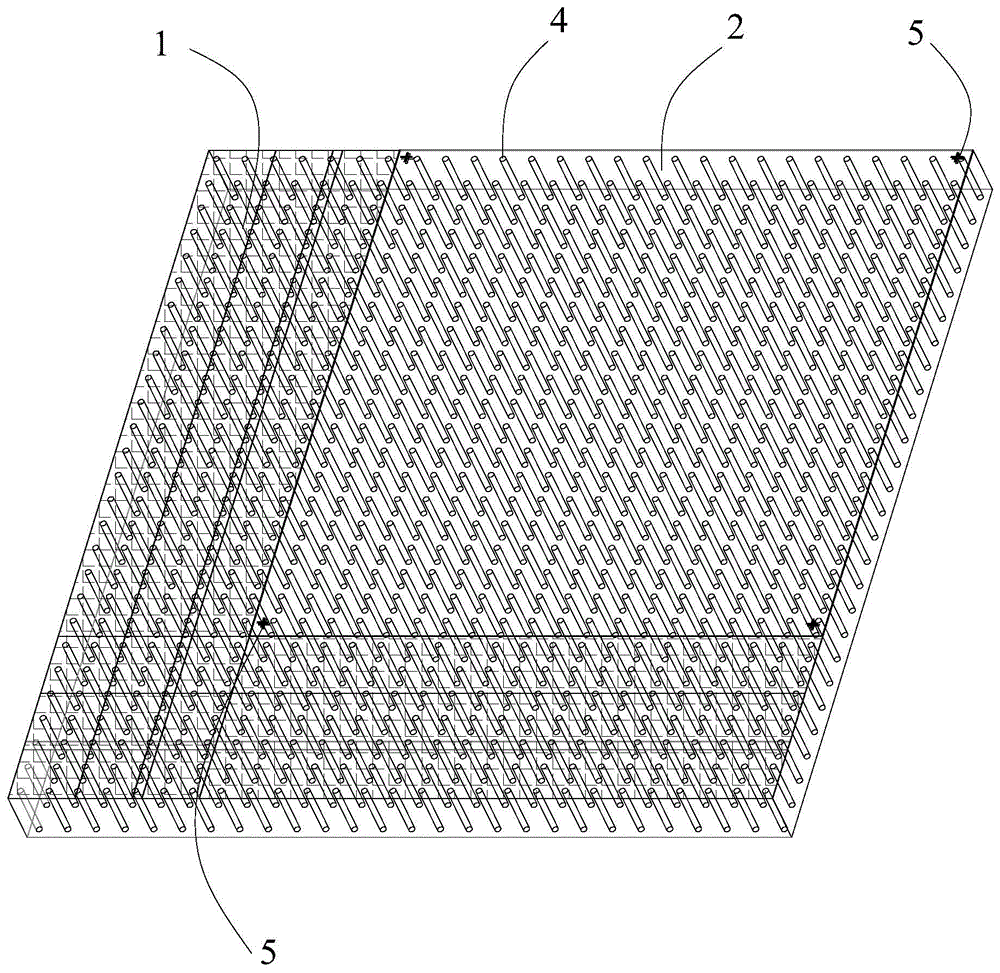

[0050] Further, in this embodiment, the raw materials placed on the first workbench 7 and the raw materials placed on the second workbench 7 in step S2 should first be OCA double-sided adhesive tape and grating film 2 respectively. , that is, the OCA double-sided tape should be laid flat on the first workbench 7 , and the grating film 2 should be laid flat on the second workbench 8 .

[0051] Further, as figure 2 and image 3 As shown, in order to facilitate the OCA double-sided adhesive tape and the grating film 2 to be respectively arranged on the table tops of the fir...

Embodiment 2

[0057] Embodiment two Transparent optical glue 3 is selected as LOCA glue

[0058] The main technical features of this embodiment are generally the same as those of Embodiment 1, and will not be repeated here. The difference between it and Embodiment 1 is:

[0059] 1) In the above step S1, the 3 layers of transparent optical glue are selected as LOCA glue. Because LOCA glue is liquid, it is not necessary to mark it in the above step S1, but to avoid the subsequent lamination process. , because the LOCA glue is doped with air bubbles, resulting in air bubbles in the bonded sample, in this embodiment, the air bubbles inside the LOCA glue should be eliminated in step S1, which is usually carried out in a vacuum environment.

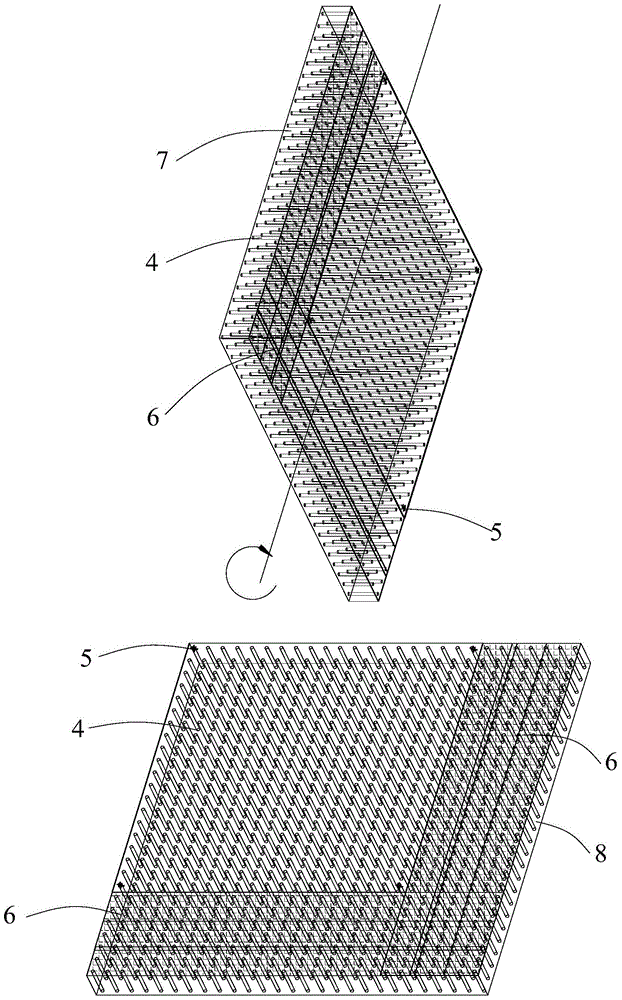

[0060]2) Because the transparent optical glue 3 is selected as LOCA glue, another difference between this embodiment and the first embodiment is that the raw material arranged on the table top of the first workbench 7 in this embodiment is the grating fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com