Formaldehyde-free paint-free water-based fiberboard and preparation process thereof

A preparation process, water-based technology, applied in the field of formaldehyde-free paint-free water-based wood fragrance board and its preparation process, can solve the problems of small log diameter, short production cycle, and inability to produce thick core veneer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

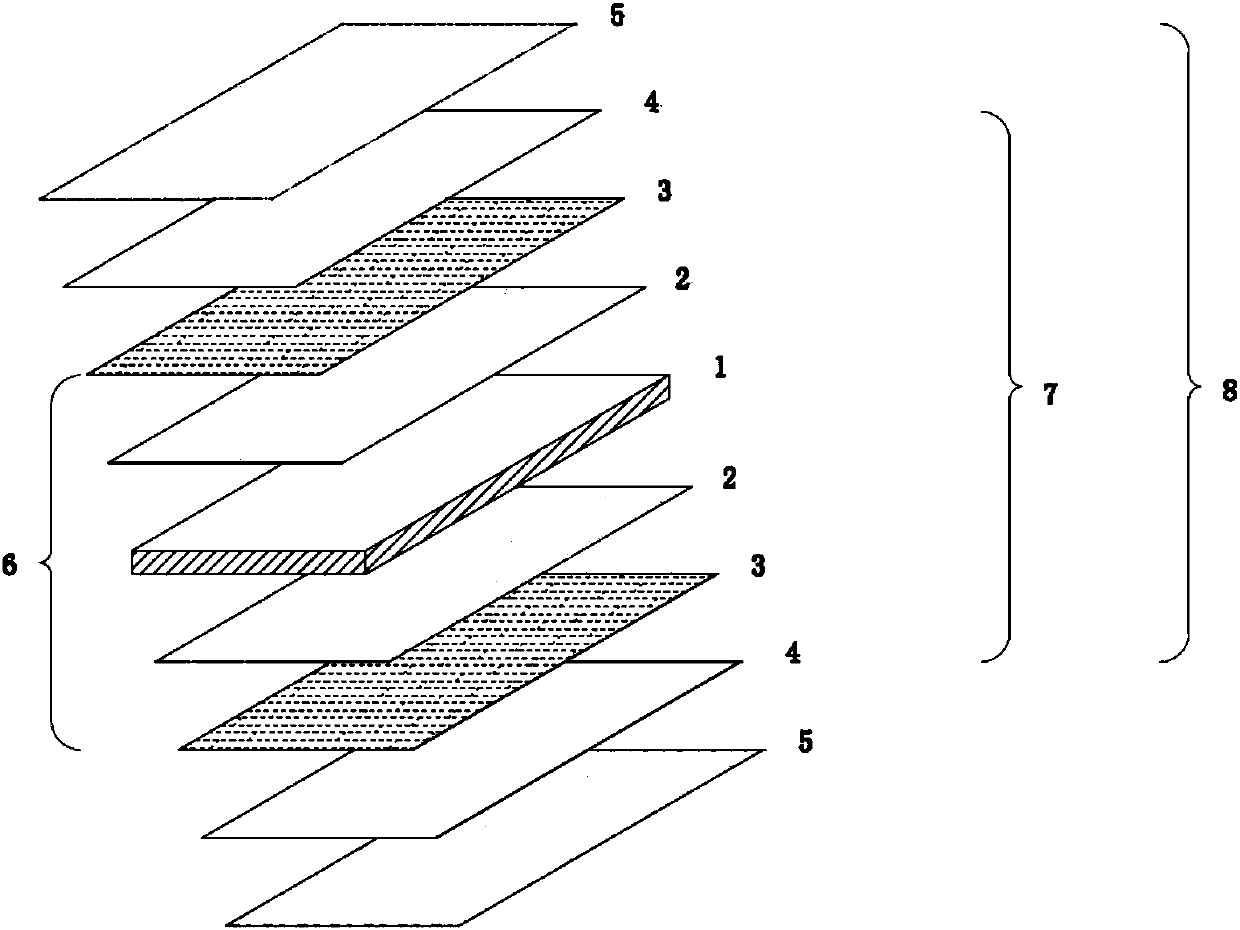

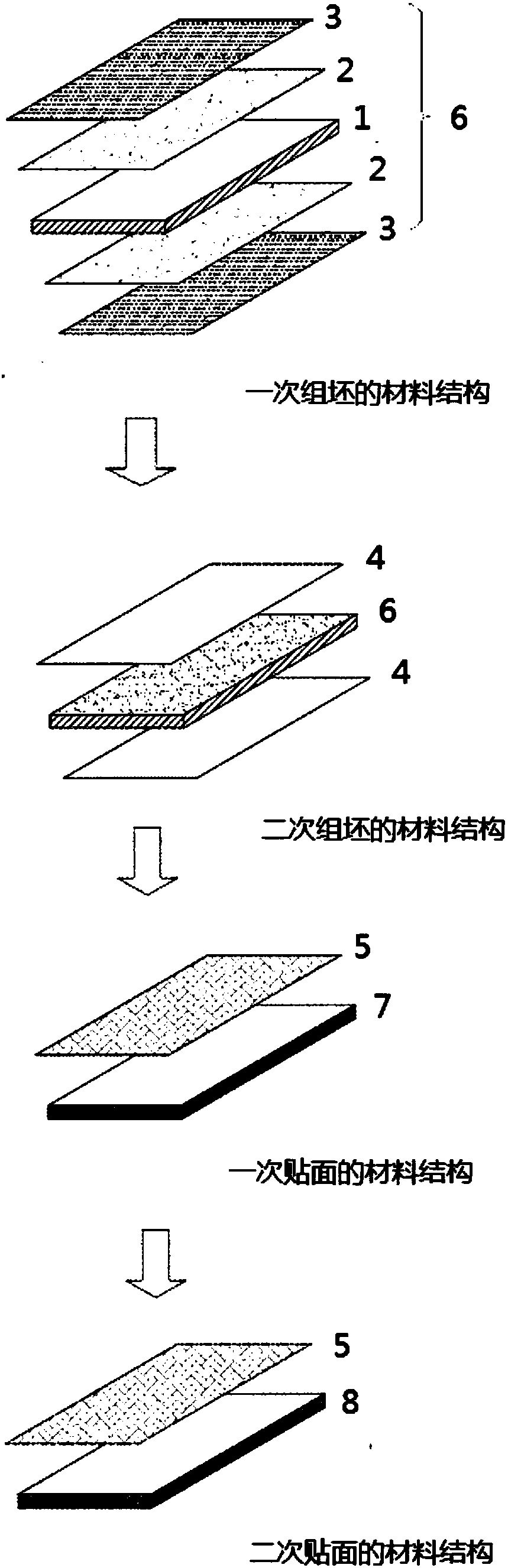

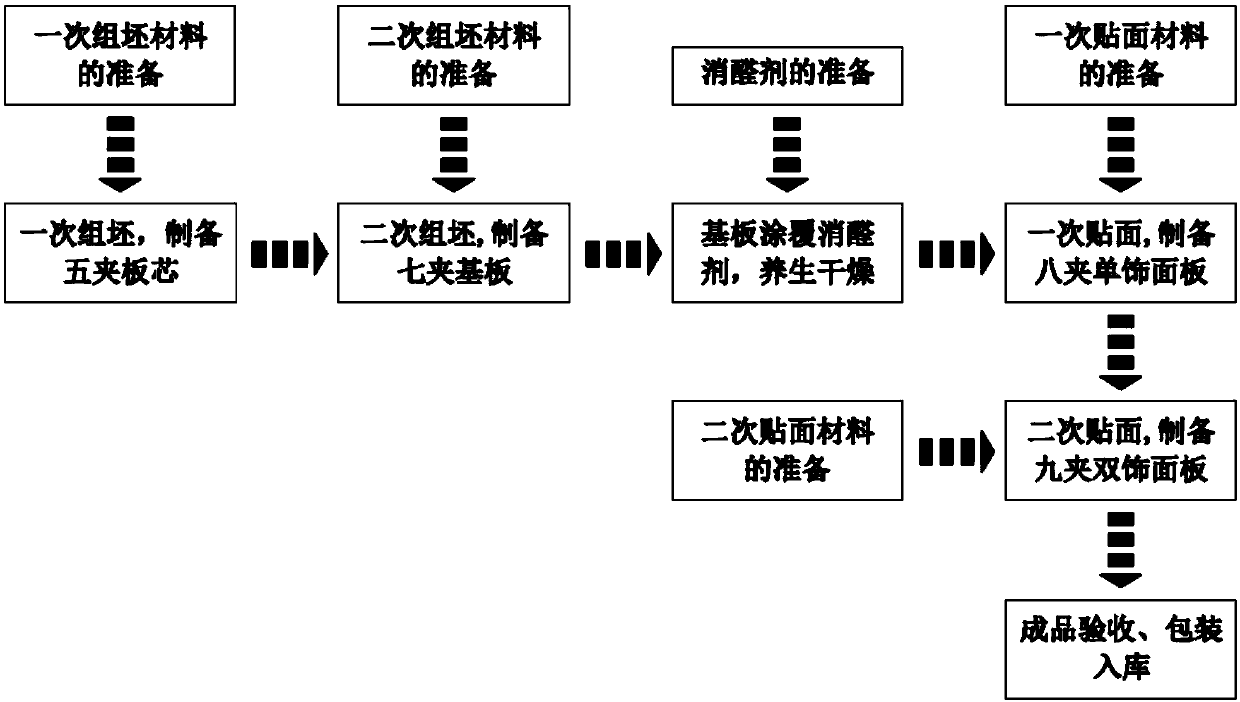

[0111] Example 1: The preparation process of the 17mm New Zealand bulky core structure formaldehyde-free paint-free water-based wood fragrance board (Type A) (1) Preparation of the primary blank material

[0112] ①The wood species is New Zealand pine, the size specification is 2520×1270×7.0mm, the moisture content is 10%, and the appearance quality level of the board surface is above the first grade (standard, smooth, no bark, no hole, no obvious non-closed cracks) as the center layer 1.

[0113] ②The wood species is poplar, the size specification is 1270×1270×2.2mm, the moisture content is 14%, and the appearance quality level of the board surface is above the first grade (standard, smooth, no bark, no holes, no obvious irregularities) The long mid-slab is formed into the long mid-slab layer 2 by two splicing butt joint machines for closing the cracks.

[0114] ③Take the wood species as poplar, the size specification is 2500×1270×3.0mm, the moisture content is 13%, and the a...

Embodiment 2

[0177] Example 2: The preparation process of the 17mm New Zealand bulky core structure formaldehyde-free paint-free water-based wood fragrance board (Type B) (1) Preparation of primary blank materials

[0178] ①The wood species is New Zealand pine, the size specification is 2520×1270×7.0mm, the moisture content is 10%, and the appearance quality level of the board surface is above the first grade (standard, smooth, no bark, no hole, no obvious non-closed cracks) as the center layer 1.

[0179] ②The wood species is eucalyptus, the size specification is 1270×1270×2.0mm, the moisture content is 14%, and the appearance quality level of the board surface is above the first grade (standard, smooth, no bark, no holes, no obvious irregularities) The long mid-slab is formed into the long mid-slab layer 2 by two splicing butt joint machines for closing the cracks.

[0180] ③The wood species is eucalyptus, the size specification is 2500×1270×3.2mm, the moisture content is 14%, and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com