Fixed-size saw cutting device for plastic-steel composite pressure pipe

A steel-plastic composite and pressure tube technology, which is applied in the field of pipe online fixed-length sawing device and improved steel-plastic composite pressure tube on-line fixed-length sawing device to ensure flatness, improve accuracy and stability, and reduce relative sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment the present invention is described in further detail:

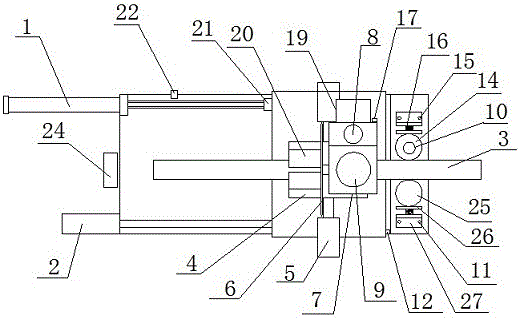

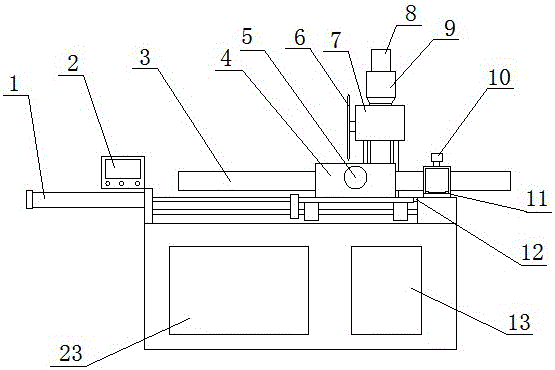

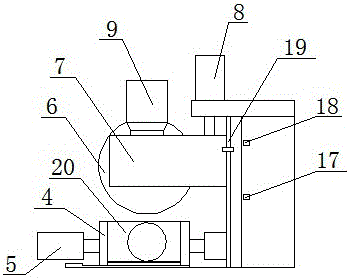

[0037]Before using the improved steel-plastic composite pressure pipe fixed-length sawing device of the present invention, at first, according to the steel-plastic composite pressure pipe 3 specifications produced, by adjusting the adjustment bolt I11 on the "L" shape adjustment plate 27 of the roller adjustment mechanism and Adjust the tightness of the bolt II15 to control the compression of the elastic component 16, so that the veneer 26 can be circumscribed with the counting roller 14 and the adjustment roller 25, and control the distance between the two rollers to adjust to the corresponding position, according to the steel-plastic composite pressure Replace the clamp block 20 with the corresponding specifications of the pipe 3, adjust the height position, and then adjust the position of the photoelectric limit I17 and the photoelectric limit II18 to control the position rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com