Door frame clamping device

A technology of clamping device and door frame, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems that the clamping device is not competent, and achieve the effect of firm and stable clamping, high sawing operation efficiency, and guaranteed sawing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

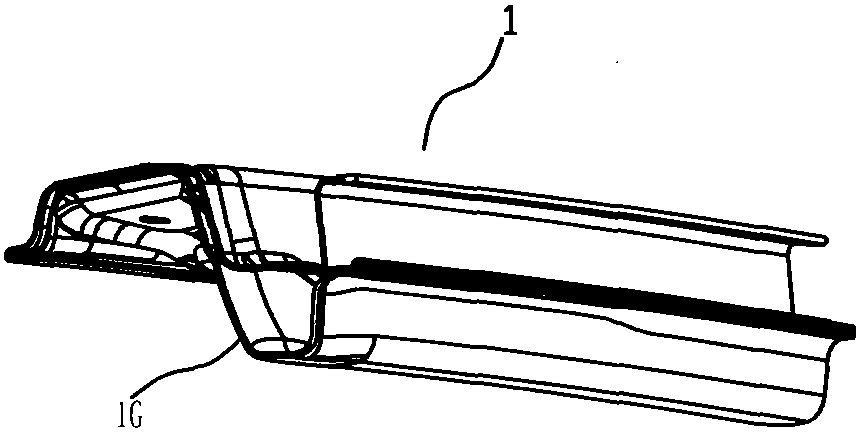

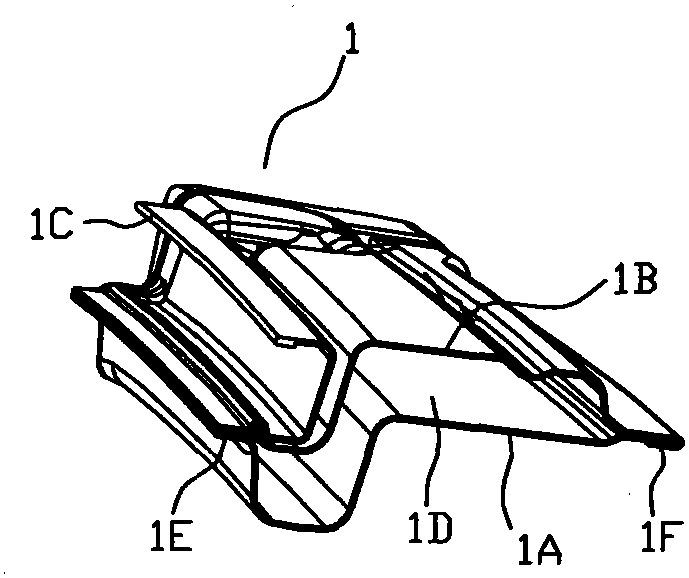

[0021] like figure 2 , image 3 The door frame column 1 shown is assembled and welded by stamping parts 1A, 1B and rolling part 1C. Stamping parts 1A, 1B and rolling part 1C are made of thin metal strips. After assembly and welding, stamping parts 1A and 1B A hollow part 1D with a large space is formed between them, and thick-walled regions 1E and 1F are formed on both sides thereof, one end of which is the end 1G to be cut; implementation.

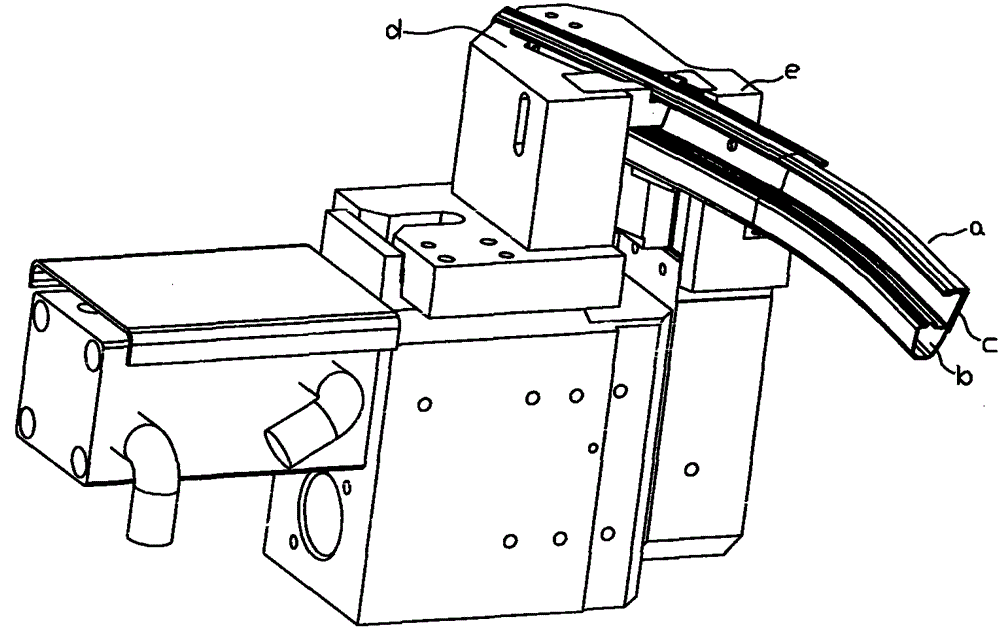

[0022] A door frame column clamping device used for sawing automobile door frame column 1, such as Figure 4 to Figure 10 As shown, it includes a base 2 suitable for fixed installation to the door frame column sawing machine. Specifically, two mounting holes can be provided under the base 2, so that it can be fixed and installed to the general saw wheel sawing machine with bolts. On the frame of the machine; one side of the base 2 is provided with a hydraulic cylinder 3, the hydraulic cylinder 3 can also be replaced by a cylinder, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com