The material baffle assembly that quickly realizes the left and right fine adjustment of the baffle

A material baffle and component technology, which is applied to sawing components, wood processing appliances, manufacturing tools, etc., can solve the problems of difficult operation for ordinary users, inability to fine-tune the saw blade left and right, and difficulty in straight line cutting, and improve sawing accuracy. , Improve the accuracy of linear cutting and save raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further illustrate the present invention below in conjunction with accompanying drawing.

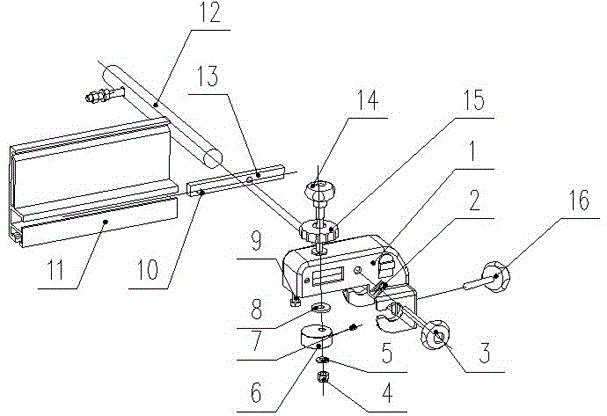

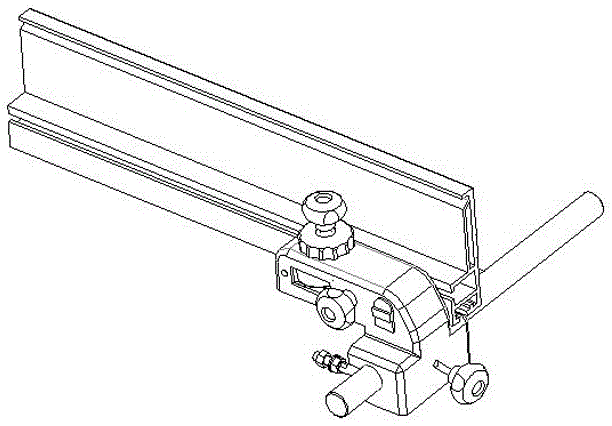

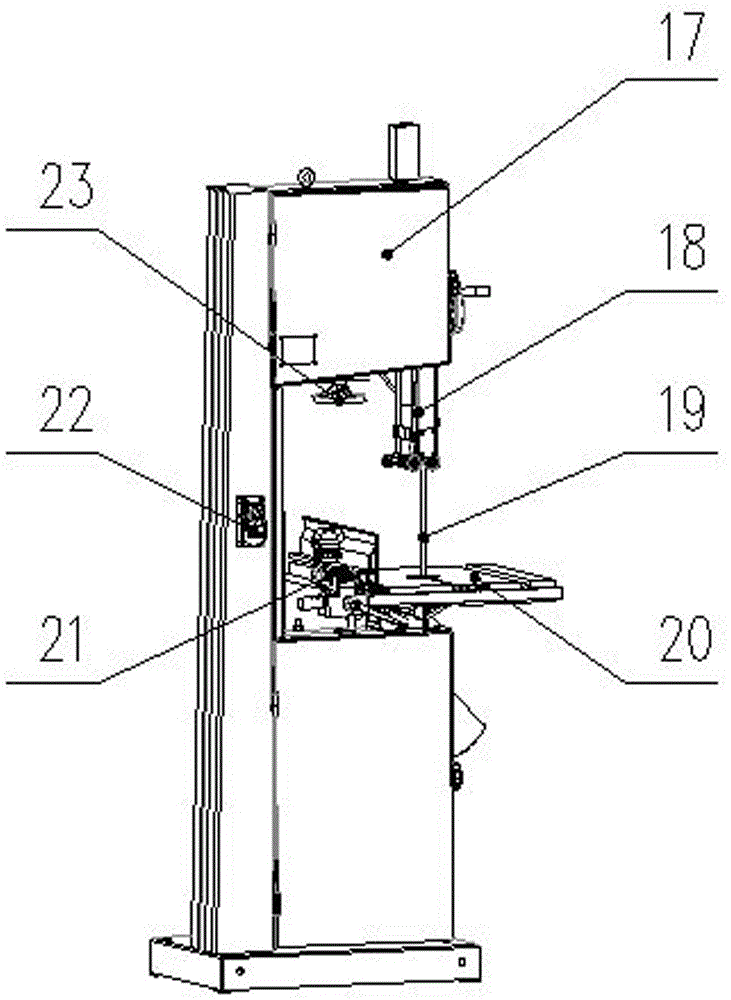

[0019] like figure 1 , figure 2 The shown material baffle assembly 21 for quickly realizing left and right fine-tuning of the baffle is characterized in that it includes a baffle seat 1, a compression spring 2, a locking handle 3, a self-locking nut 4, a washer, a cam 6, a washer, and a set screw 7 , nylon screw 9, rolling pin 10, material baffle 11, guide rail assembly 12, slide block 13, adjustment handle 14, adjustable handle 16 and straight grain handle 15, said adjustment handle 14 is installed on the baffle plate by straight grain handle 15 In the screw hole on the seat 1, the other end of the adjustment handle 14 is installed with the washer 2 8, the cam 6, and the washer 1 5 in sequence, and is locked by the self-locking nut 4, and the straight grain handle 15 is adjusted to fix the adjustment handle 14 and the cam 6 on the stopper. on the plate base 1; the rolling pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com