Automatic wire arranging device and method

An automatic wire and cable technology, applied in the field of cable manufacturing, can solve problems such as high labor intensity, potential safety hazards, gapped wires, jumper wires, etc., and achieve the effect of reducing labor intensity and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings of the description.

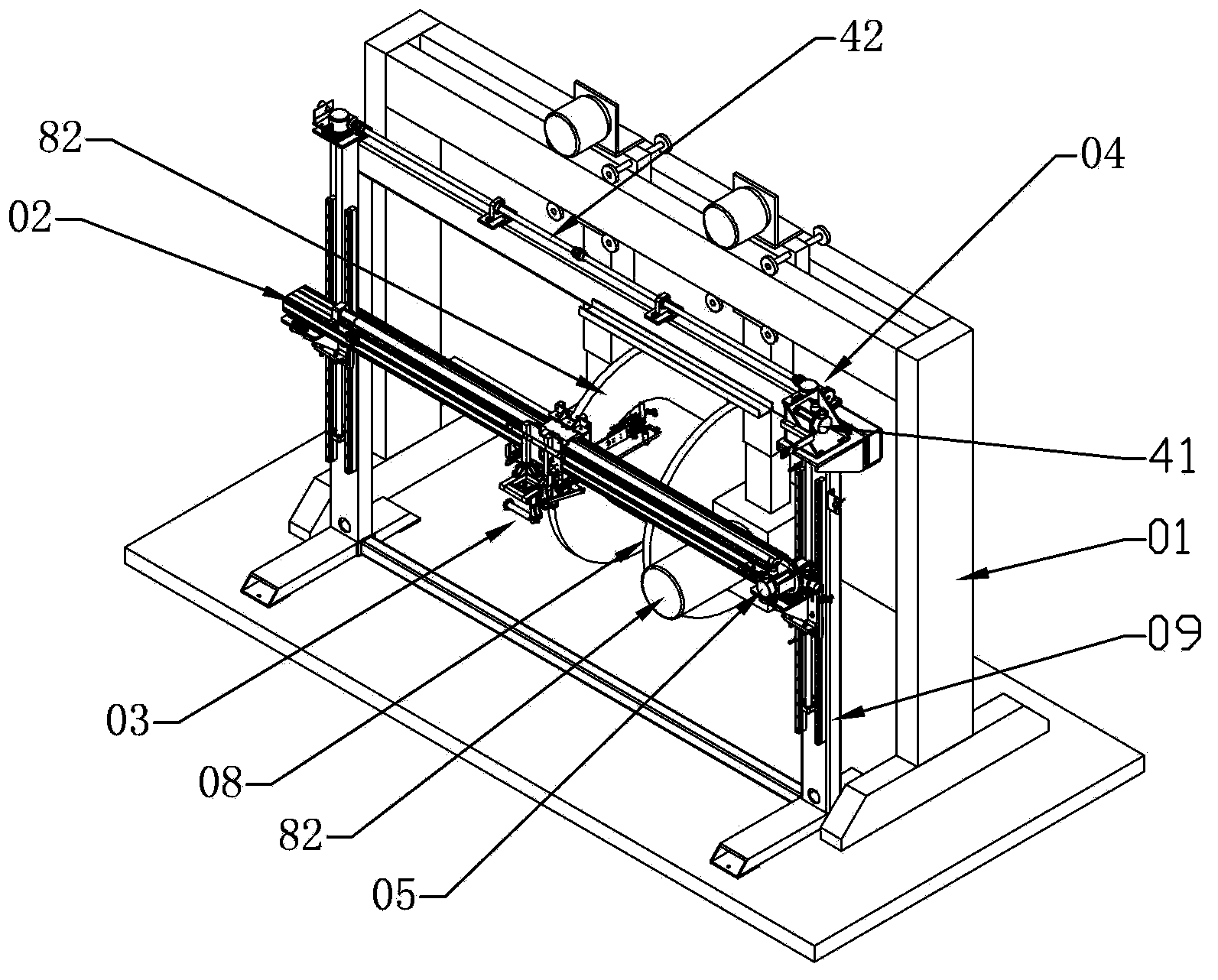

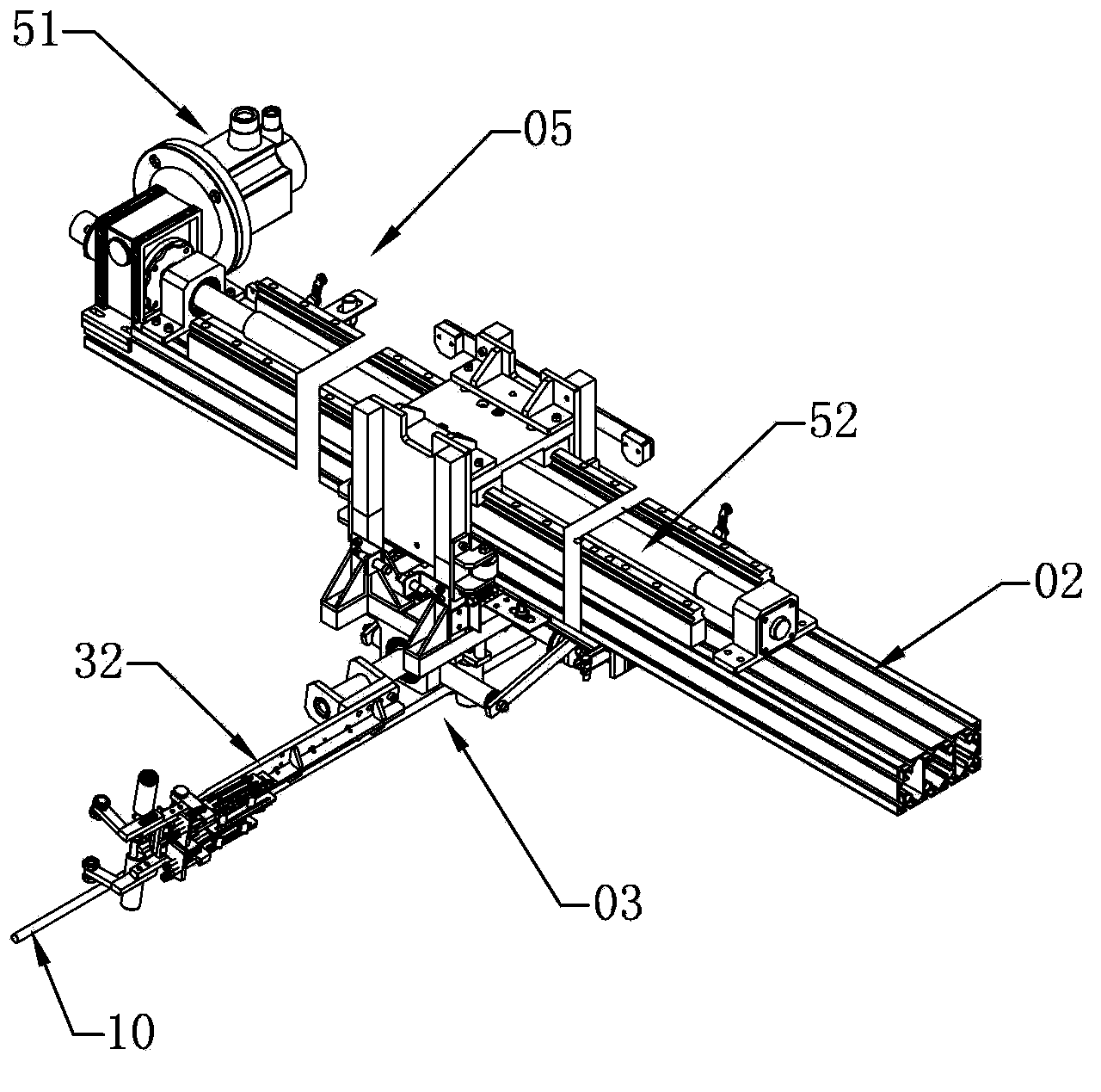

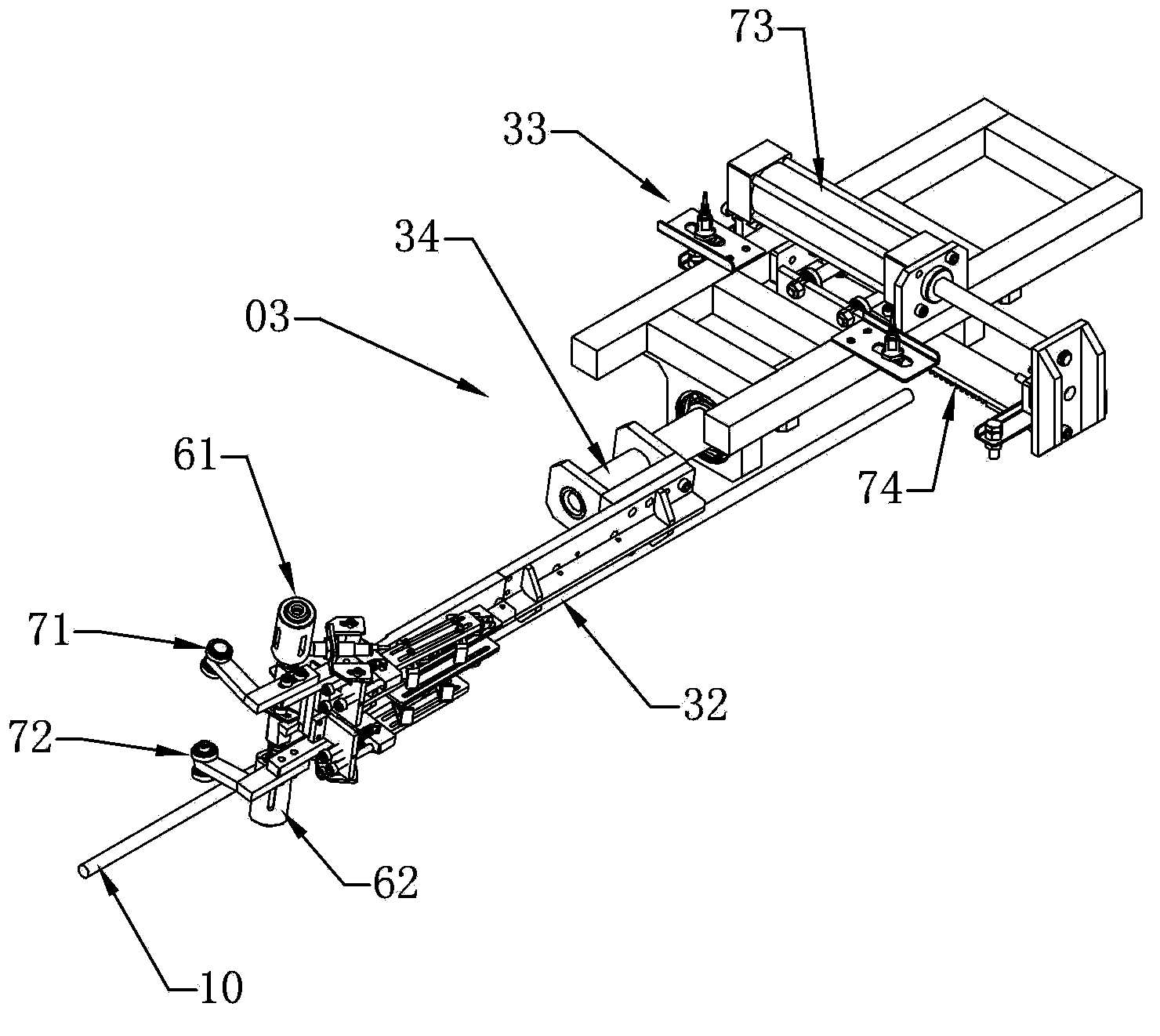

[0048] The automatic wiring device of the present invention, such as Figure 1-4 As shown, it includes a gantry frame 01, a traverse platform 02, a manipulator 03, a lifting mechanism 04, a horizontal movement mechanism 05, a dynamic compensation mechanism 06, an automatic reversing mechanism 07, a wire take-up mechanism 08, a gantry auxiliary frame 09, a controller, Encoder:

[0049] The gantry auxiliary frame 09 is located on the front side of the gantry frame 01;

[0050] The take-up mechanism 08 is arranged on the gantry 01, which includes a take-up motor 81 and a cable reel 82 driven by the take-up motor 81;

[0051] The traversing platform 02 is set up and down on the gantry auxiliary frame 09 and is located on the front side of the cable reel 82, and is driven up and down by the lifting mechanism 04;

[0052] The lifting mechanism 04 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com