Real leather or leather processing technology

A processing technology, leather technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of uneven appearance, inaccurate cutting of genuine leather or leather, etc., and achieve good invention effect, convenient surface and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

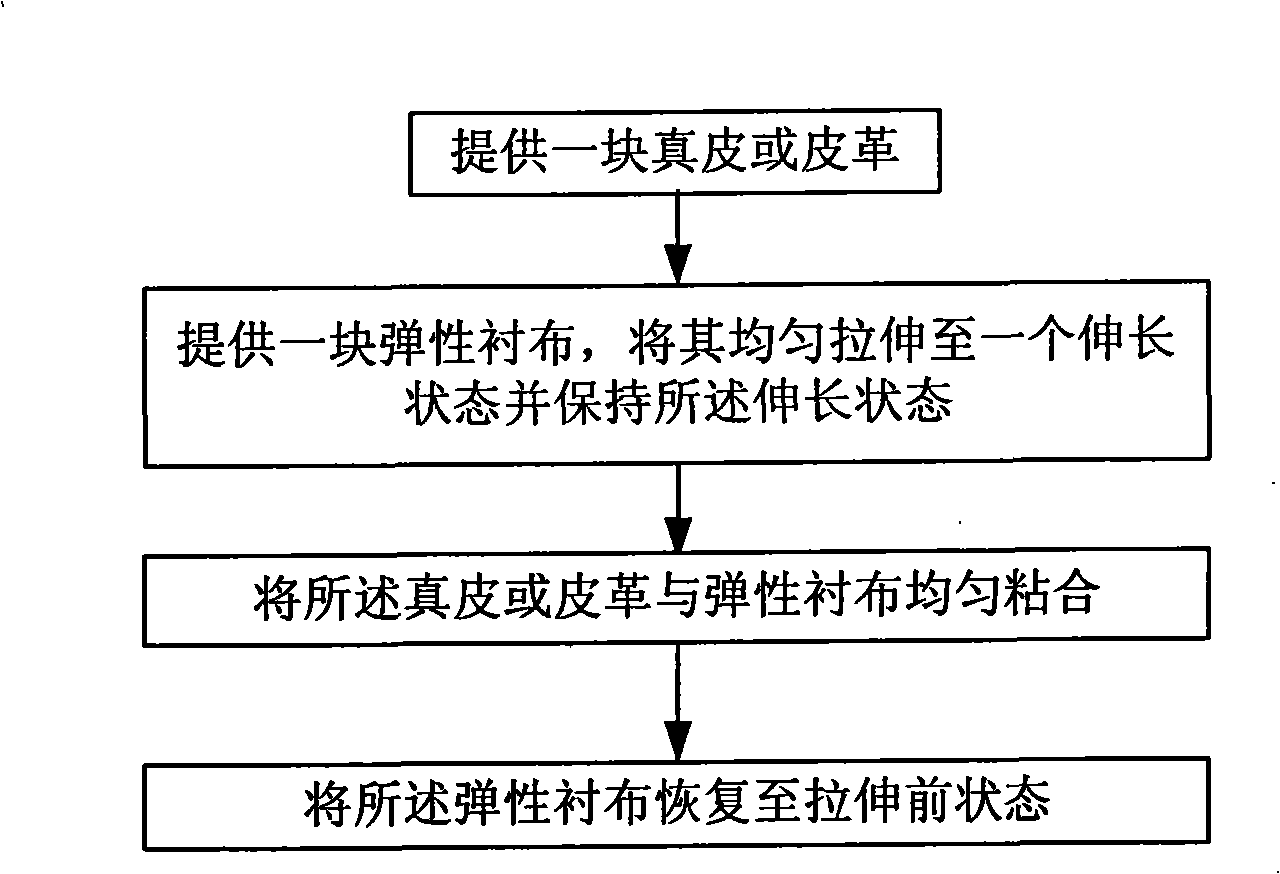

[0029] see figure 1 , is a flow chart of the leather or leather processing process of the first embodiment of the present invention.

[0030] Described corium or leather processing technology comprises the following steps:

[0031] A. Providing a piece of genuine leather or leather on which a layer of adhesive is formed;

[0032] Preferably, the thickness of the genuine leather or leather is between 0.25mm and 0.35mm. The genuine leather or leather can be obtained by thinning the genuine leather or leather raw material to a thickness between 0.25mm and 0.35mm by adopting the thinning process in the prior art.

[0033] The method for forming a layer of adhesive is coating a layer of adhesive.

[0034] B. Provide an elastic interlining, stretch it evenly to an elongated state and maintain the elongated state, and form a layer of adhesive on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com