Device and method for assembling chain integrally

An assembly equipment and strip forming technology, applied in the direction of metal chains, etc., can solve the problems of poor uniformity of the gap between the pin shaft and the outer chain plate of the small hole, roughening of the pin shaft, and reduced service life of the chain, so as to reduce labor intensity and the probability of finger injury accidents , Avoid trimming burrs and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

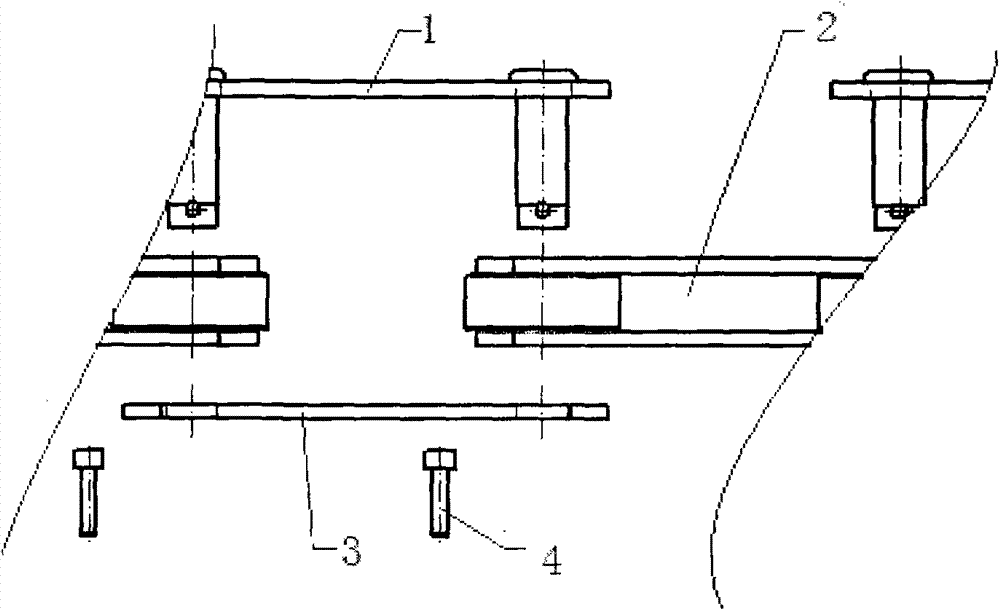

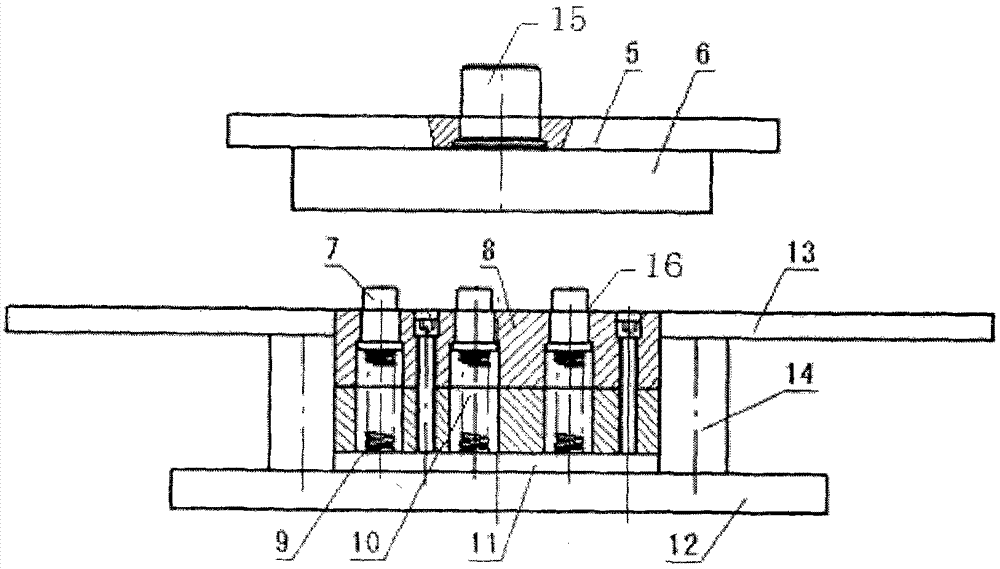

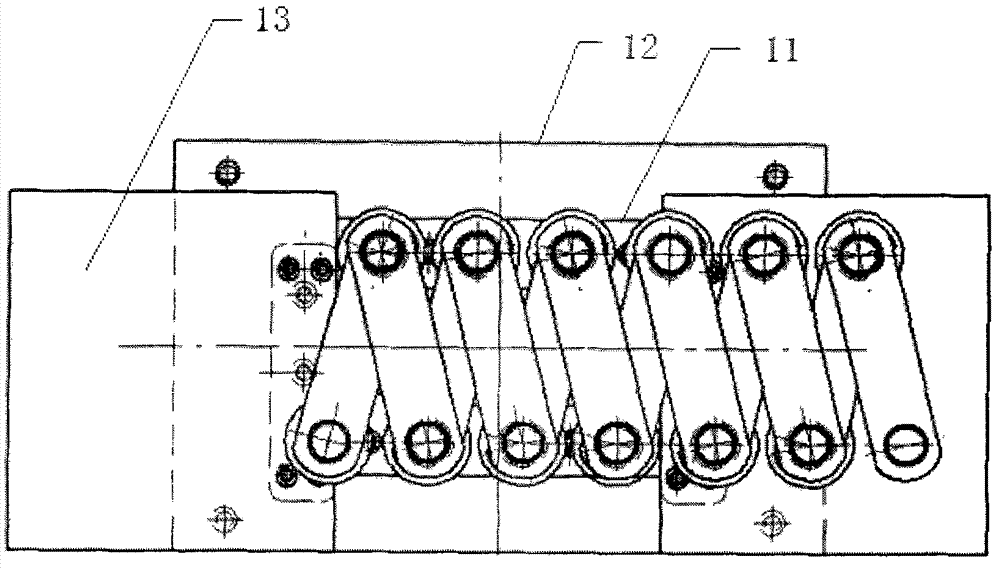

[0024] Such as Figure 1 to Figure 5 As shown, the chain assembly equipment of the present invention includes a hydraulic press (not shown), a hydraulic press panel (not shown), an upper template 5, an upper mold 6 and a bottom plate 12, and the top surface of the upper template 5 is fixed on the hydraulic press The bottom of the hydraulic rod 15, the bottom of which is fixed with the upper mold 6; the top of the working panel of the hydraulic machine is fixed with the base plate 12; the bottom plate 11 is installed above the base plate 12; 12 left and right supporting block pads 14 and left and right supporting blocks 13; core base 8 is installed in the middle of the left and right supporting block pads 14; a plurality of positioning holes 16 are arranged at intervals on the core base 8; inside the positioning holes 16 A core block 9 and a spring 10 are provided; a mandrel 7 is installed on the top of the spring 10 .

[0025] The top surfaces of the left and right supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com