Silicone master batch with long-lasting scratch resistance, and preparation method thereof

A silicone and scratch-resistant technology, which is applied in the field of plastic modification additives, can solve the problems of unstable scratch resistance, affecting the mechanical properties of the substrate, and the decline of scratch resistance, so as to improve the plastic processing performance and durable Effective scratch resistance and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation Examples and Comparative Examples of Durable Scratch-resistant Silicone Masterbatch

[0032] See Table 1 for the silicone masterbatch components and the mass parts of the components in the examples and comparative examples of the present invention.

[0033] Table 1 Silicone Masterbatch Components and Component Mass Parts

[0034]

[0035] In the above examples and comparative examples, common silicone refers to methyl vinyl silicone rubber.

[0036] The polypropylene used is a homopolypropylene with a melt flow rate of 25g / 10min; the reinforcing agent used is fumed silica with an average particle size of 20nm; The deodorant is a commercially available product.

Embodiment 1

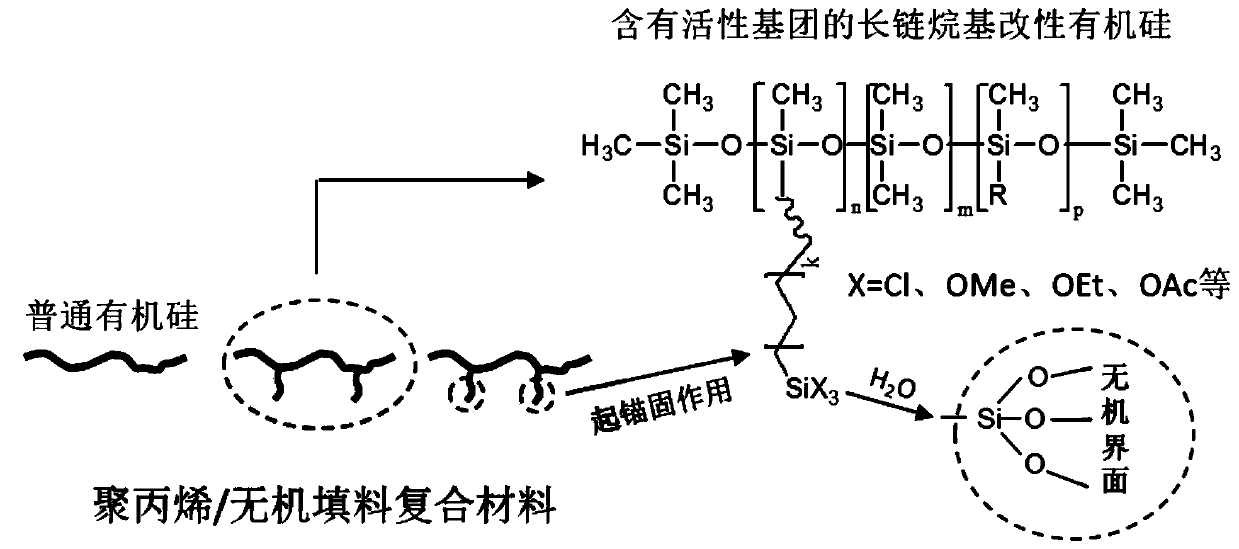

[0037] The modified silicones used in Examples 1-5 are modified polysiloxane alkyl groups with side long chains of different structures, and the molecular chain structure and anchoring mechanism of the modified silicones are shown in figure 2 As shown; the common silicone used in the comparative example is methyl vinyl silicone rubber, and the average molecular weight is similar to that of the modified silicone used in Example 1.

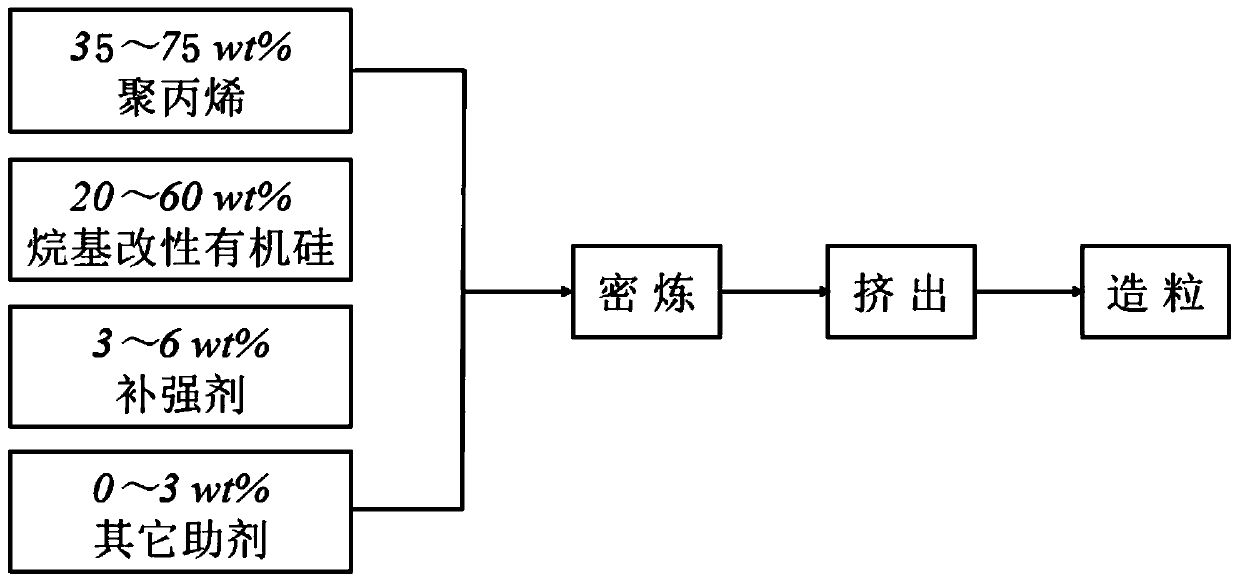

[0038] The organosilicon masterbatch preparation process route in each above-mentioned embodiment and comparative example sees figure 1 : Add the measured polypropylene, modified silicone, reinforcing agent, anti-aging agent and deodorant to a pressurized internal mixer for melt mixing. The temperature of the internal mixer is 210°C, and the internal mixer is mixed for 15 minutes; mixing The good material is transported to the twin-screw extruder equipped with forced feeding device for extrusion and granulation. The screw feeding section of the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com