Material breakage constraint-based continuum structure topology design modeling and optimization design method

An optimized design and continuum technology, applied in calculation, special data processing applications, instruments, etc., can solve problems such as small structure scale, large amount of analysis and calculation, unsuitable for engineering applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

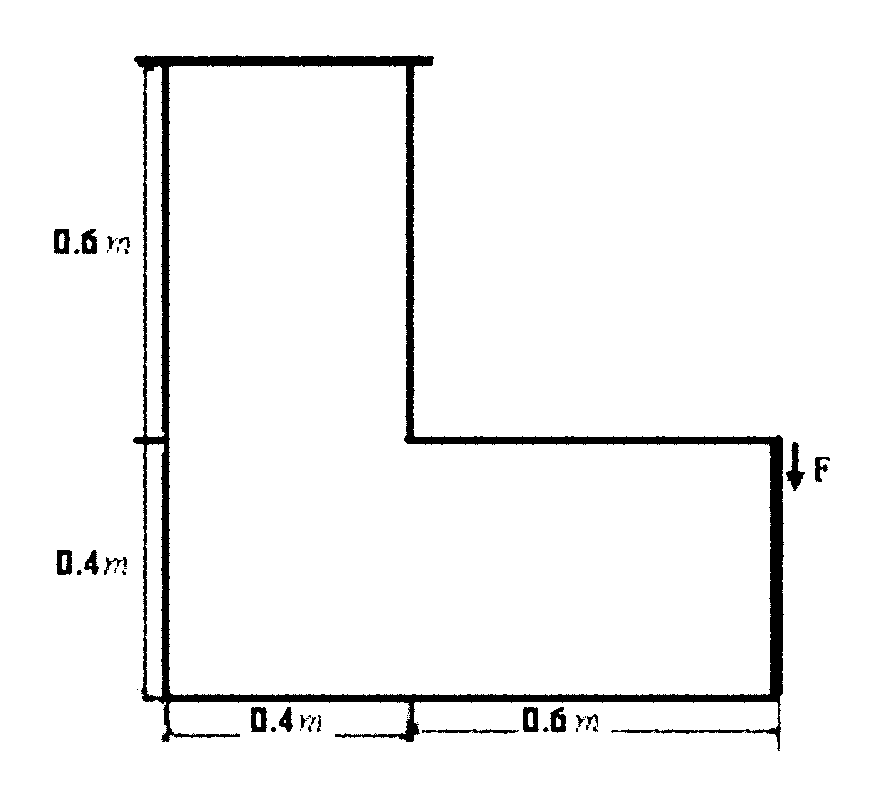

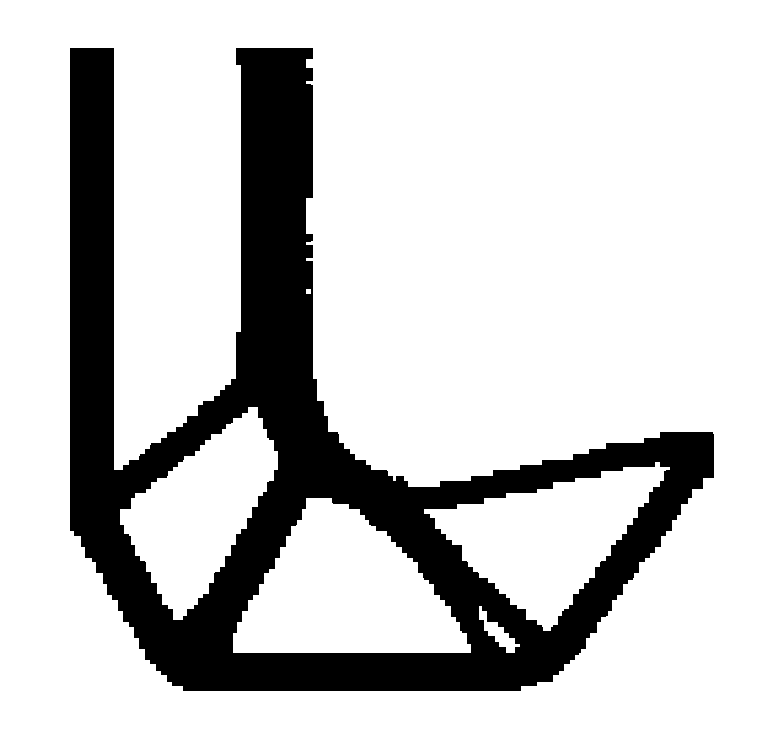

[0111] Example: Topology Optimization of an L-Beam Structure

[0112] An L-shaped beam with a length of 1 meter, a height of 1 meter, and a thickness of 0.01 meter is shown in figure 2 , whose upper end face is fixed. A vertical load F=55.kN acts uniformly in the uppermost 0.04167m area of the right vertical end, without considering the effect of gravity. The failure stress of the beam is σ Y =355Mpa, its Young's modulus is E=210GPa, Poisson's ratio v=0.3, mass density is ρ 0 =7800kg / m 3 ; The largest design area structure is used as the initial structure for design, and the initial structure volume is 0.0064m 3 .

[0113] Optimum design goals: the smallest volume, the maximum Von Mises stress is less than the failure stress. The maximum design domain is divided into 9216 identical quadrilateral plane stress elements.

[0114] The optimization steps are as follows:

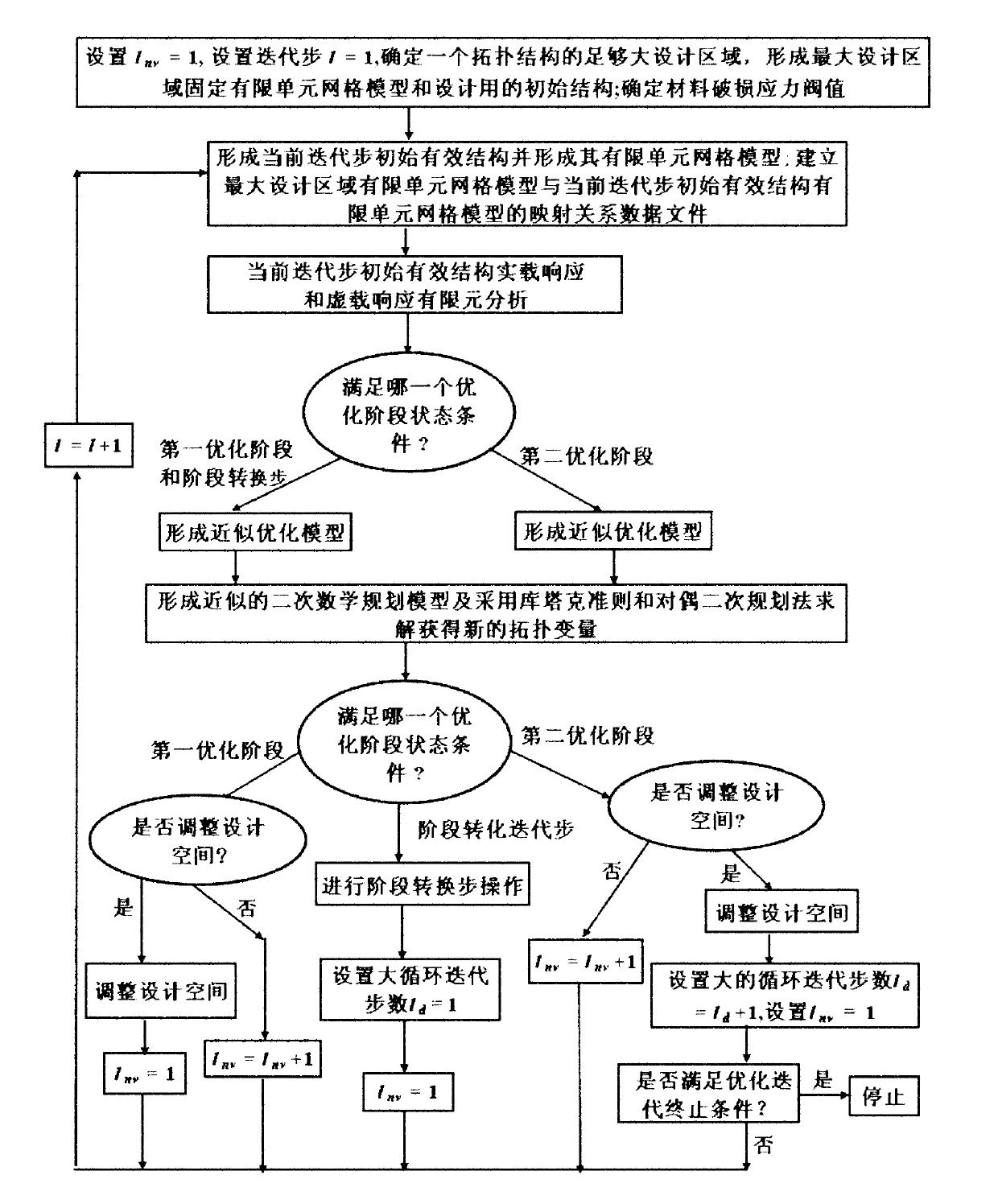

[0115] 1. According to the service requirements of the continuum structure to be designed, the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com