Vibratory stress relief apparatus for medium frequency and low frequency shaft type parts, and use method thereof

A technology of shaft parts and vibration aging, which is applied in the direction of furnace types, furnaces, heat treatment equipment, etc., can solve problems such as poor effect, inability to obtain dynamic stress for rolls, and difficulty in reducing residual stress, so as to achieve deformation guarantee and dynamic stress distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

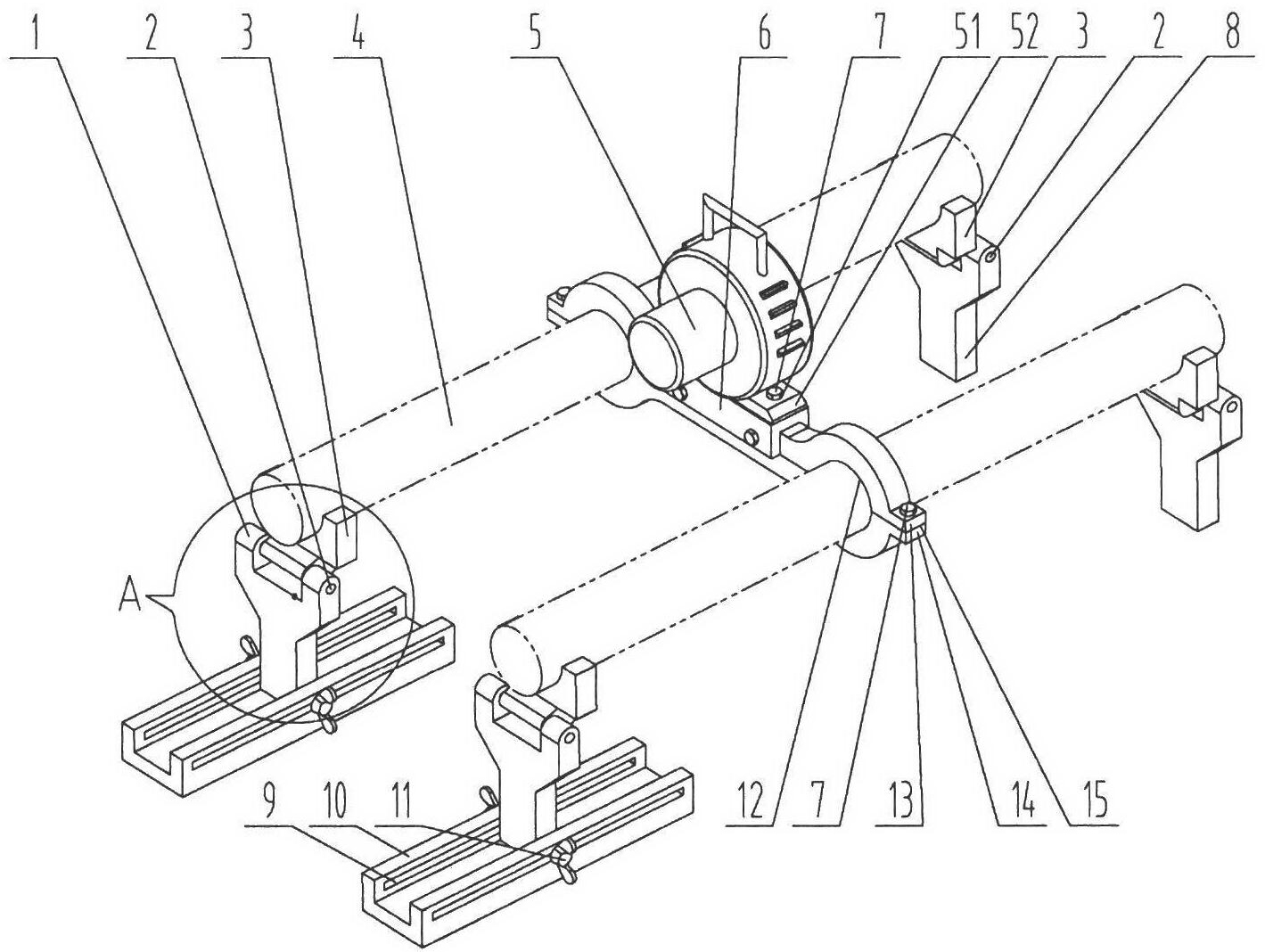

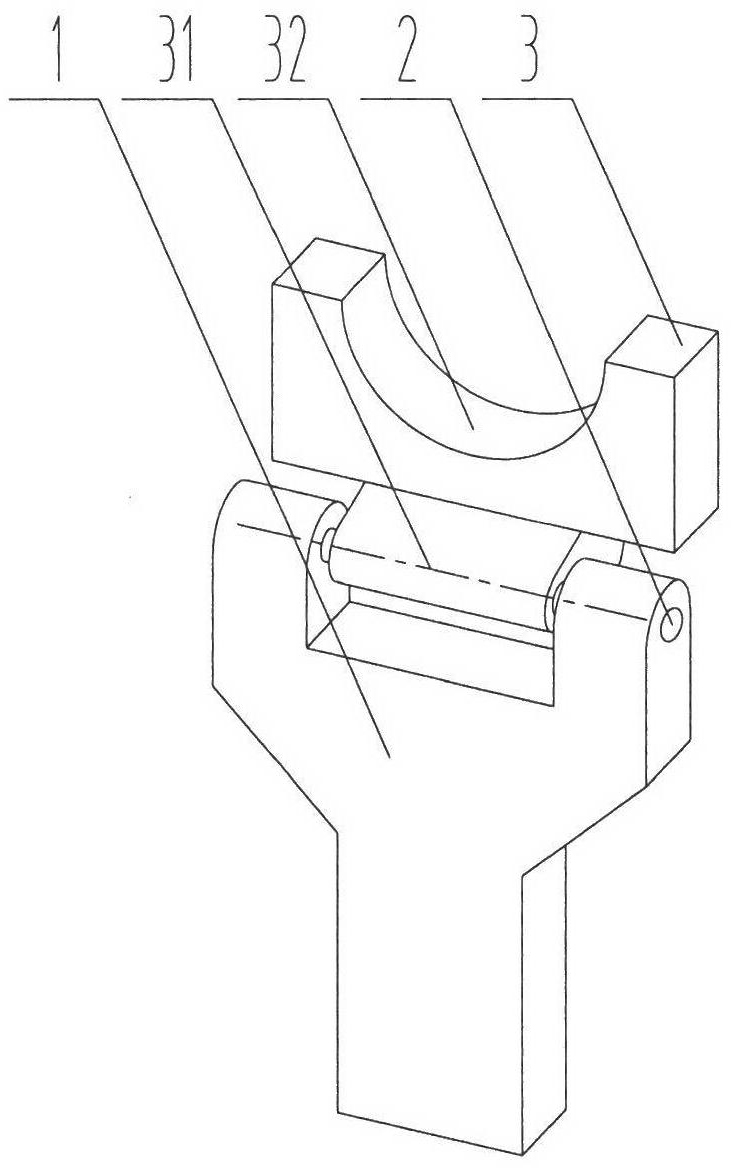

[0029] like figure 1 As shown, the vibration aging device for shaft parts according to the present invention is composed of a vibrator 5, an exciter base, a clamping block 3 and a supporting mechanism.

[0030] The bottom end of the exciter 5 is provided with a connection plate 52, and two connection holes 51 are opened on the connection plate 52. There are two screw holes corresponding to the hole 51, screw the bolt 7 through the connecting hole 51 on the connecting plate 52 into the screw hole of the upper bottom cover, and then the vibrator 5 can be fixed on the middle position of the upper bottom cover 13 , the two ends of the upper bottom cover 13 are arc-shaped notches 12, the edge of the notch 12 is provided with a protruding flat plate 15, and a through hole is opened on the flat plate 15, and the structure of the lower bottom plate 14 is similar to that of the upper bottom cover 13. The upper bottom cover 13 and the lower bottom plate 14 are combined with the upper b...

Embodiment 2

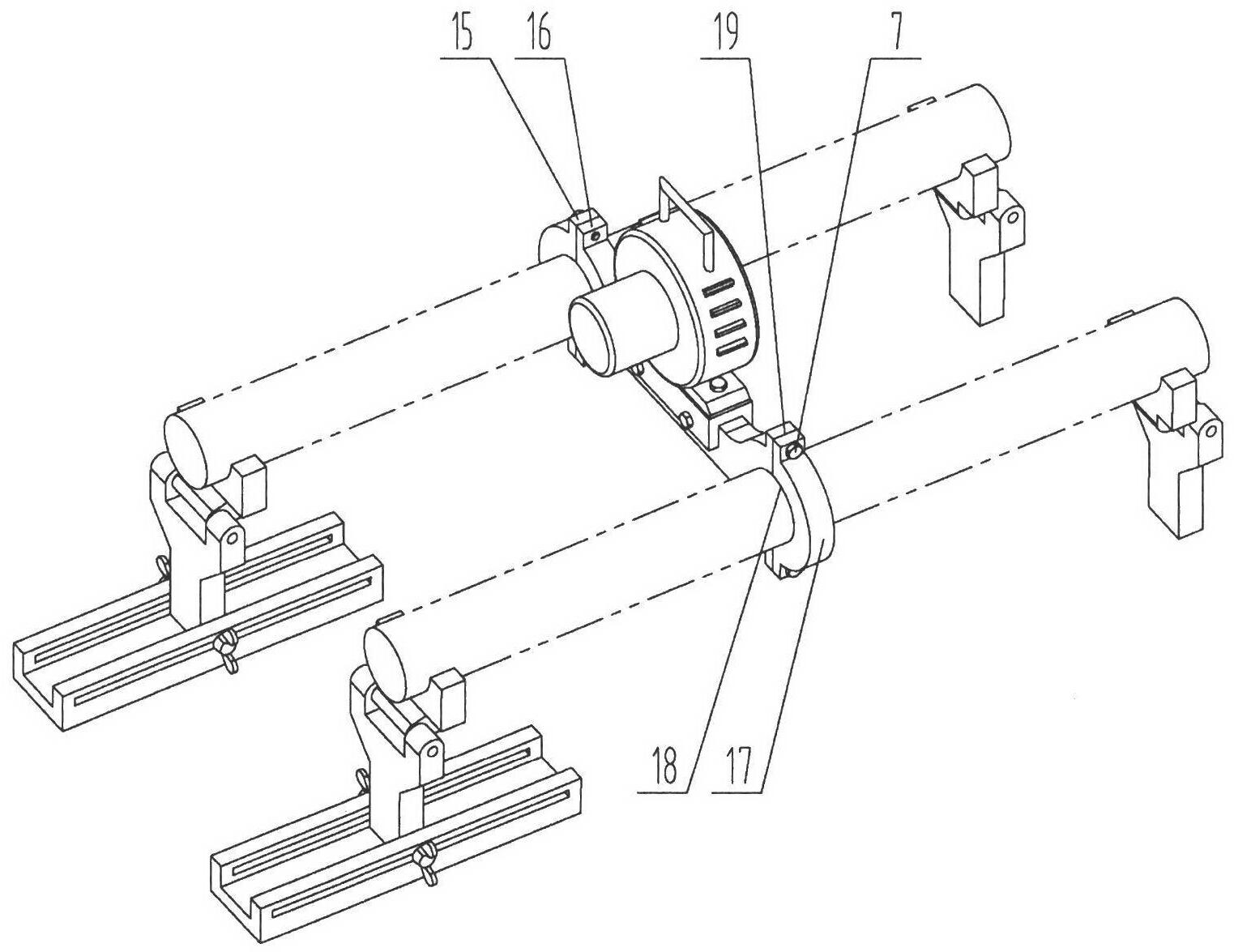

[0034] like image 3 As shown, the specific structure of another embodiment of the present invention, this embodiment is different from Embodiment 1 in that the main exciter bottom 6 includes a fork bar 16, a left end cover 15, and a right end cover 17, and the fork bar 16 is open at both ends. There is an arc-shaped fork 18 (from the figure, the position of the lead wire of 18 should be moved into the fork), the two ends of the fork 18 have radially outwardly protruding extensions 19, and there are through holes on the extension plate 19 , the left end cap 15 and the right end cap 17 are arc-shaped, and the openings are also arc-shaped to match the fork 18. The two ends of the left end cap 15 and the right end cap 17 are also provided with radially outwardly protruding extensions. The plate 19 and the extension plate 19 have through holes, and the left end cover 15 and the right end cover 17 are fixed on the fork bar 16 by bolts, and the fork bar 16 can be fixed on the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com