Wide-temperature range thermoelectric generation device with multi-segmented structure and preparation method

A technology of thermoelectric power generation and segment structure, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric devices, and thermoelectric devices that only use the Peltier or Seebeck effect, etc. It can solve the problems of interface thermal resistance and resistance increase, device reliability reduction, and thermal stress Concentration and other issues to achieve maximum energy conversion efficiency, high thermoelectric conversion efficiency, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

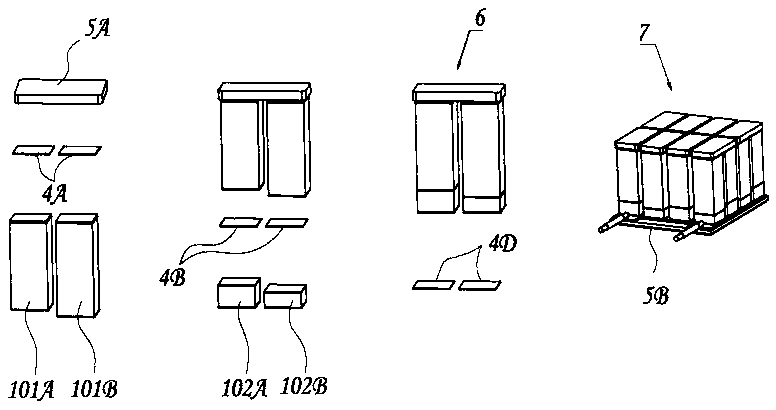

[0077] refer to Image 6 It can be seen that Embodiment 1 according to the present invention will be described in detail. Choose CoSb in the middle temperature zone 3 The base skutterudite thermoelectric material, specifically, the P-type thermoelectric unit element 101A selects CeFe 3.9 mn 0.1 Sb 12 , N-type thermoelectric cell element 101B selects Yb 0.3 co 4 Sb 12 , and select the bismuth telluride thermoelectric material in the low temperature region, specifically, the P-type thermoelectric element 102A selects Bi 1.9 Sb 0.1 Te, N-type thermoelectric cell element 102B chooses Bi 2 Te 2.85 Se 0.05 , thus forming a thermoelectric power generation device 7 with a two-stage structure.

[0078] refer to Figure 5A with Figure 5B It can be seen that the high temperature end temperature is determined to be 850K according to the material properties, and the P-type CoSb 3 The temperature of the interface between the base cobalt ore thermoelectric cell element 101A an...

Embodiment 2

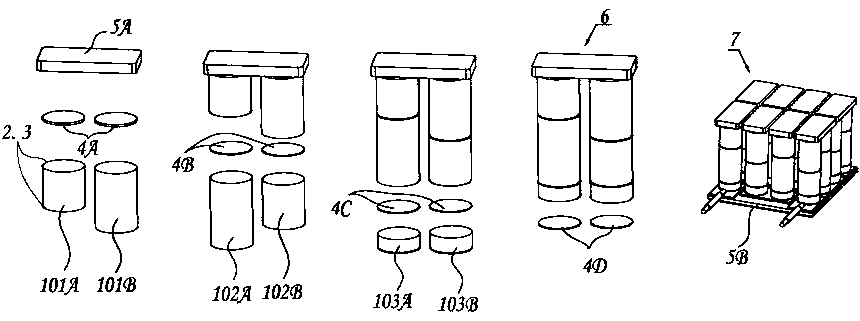

[0083] refer to Figure 9 It can be seen that Embodiment 2 according to the present invention will be described in detail. The Half-Heusler alloy material in the medium and high temperature area is selected, specifically, the P-type thermoelectric element 101A is selected from FeNb 0.8 Ti 0.2 Sb, N-type thermoelectric unit element 101B selects Hf 0.3 Zr 0.7 NiSn, choose CoSb in the middle temperature zone 3 The base skutterudite thermoelectric material, specifically, the P-type thermoelectric unit element 102A selects CeFe 3.9 mn 0.1 Sb 12 , N-type thermoelectric cell element 102B selects Yb 0.3 co 4 Sb 12 , select the bismuth telluride thermoelectric material in the low temperature region, specifically, the P-type thermoelectric element 103A selects Bi 1.9 Sb 0.1 Te 3 , N-type thermoelectric cell element 103B selects Bi 2 Te 2.85 Se 0.05 , thus forming a thermoelectric power generation device 7 with a three-stage structure.

[0084] refer to Figure 8A with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com