Chip fuse and its making method

A fuse and chip-type technology, applied in the manufacture of fuses, emergency protection devices, electrical components, etc., can solve the problems of thermal stress and protective layer damage, high manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

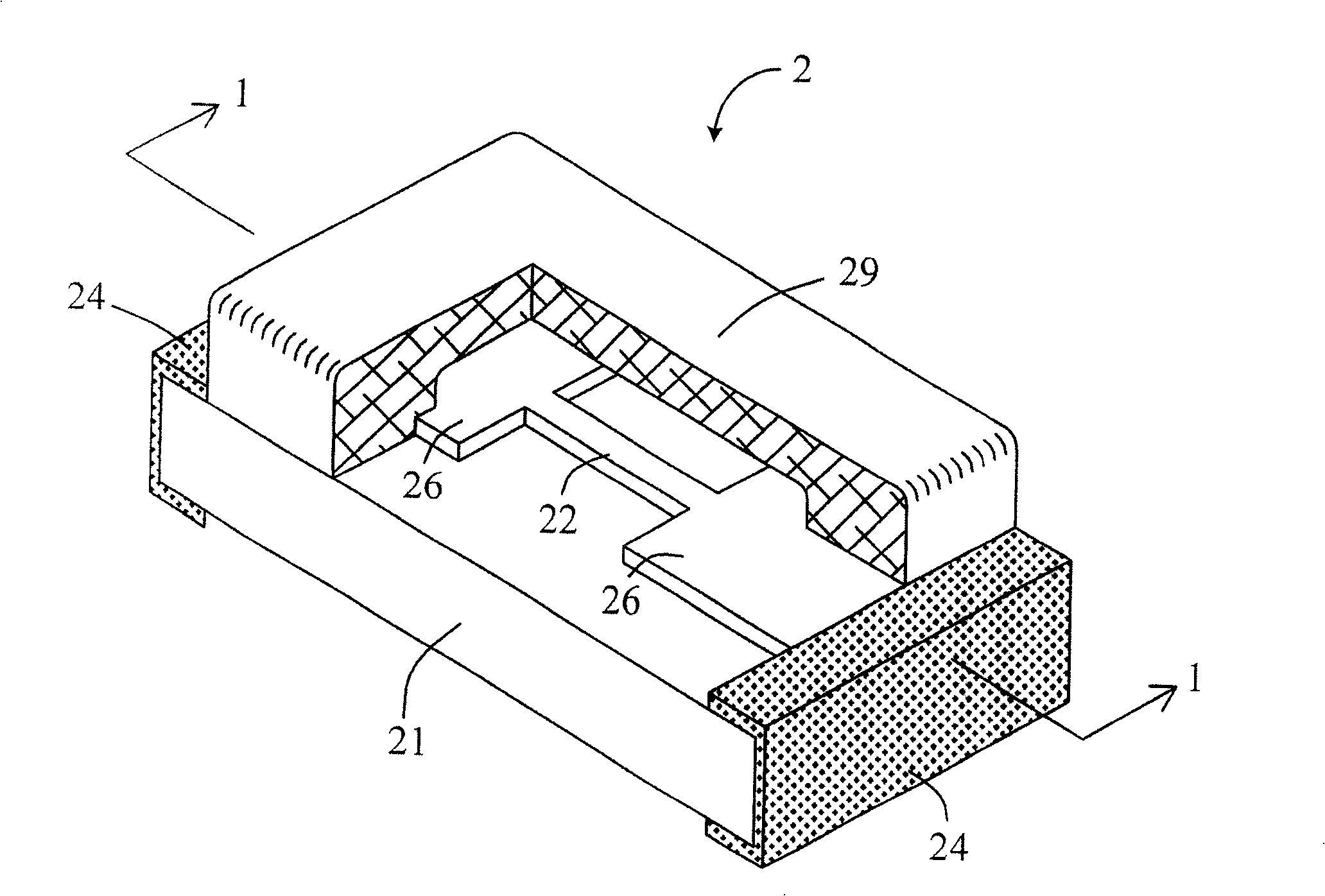

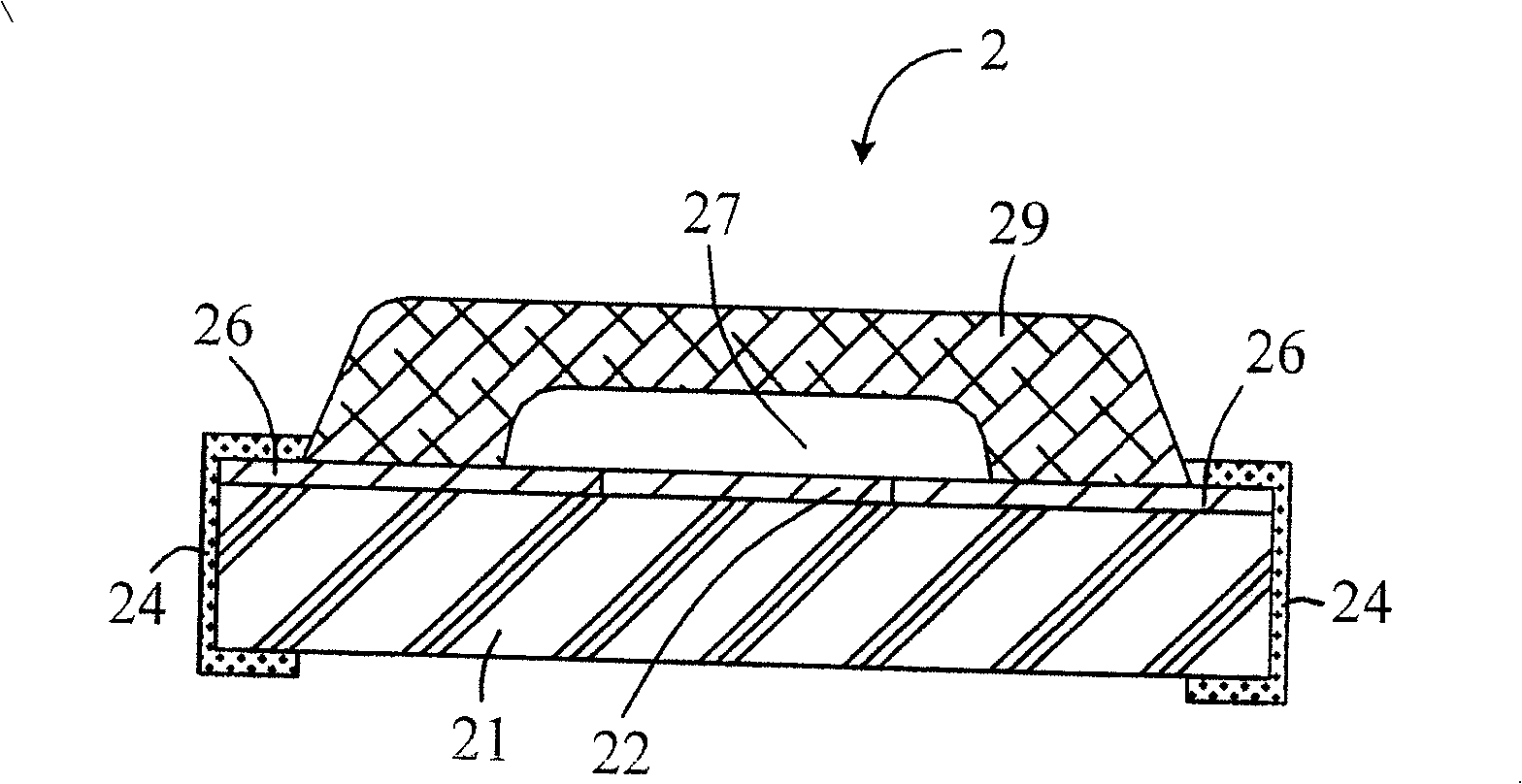

[0060] see figure 2 , figure 2 A perspective view of the chip fuse 2 according to the first preferred embodiment of the present invention is shown. The protective layer 29 is partially cut in the length direction and the width direction to clearly show the internal structure. image 3 for figure 2 Sectional view cut along the width centerline (1-1 line). The chip fuse 2 includes a substrate 21 , a fuse 22 , a cavity 27 , a protective layer 29 , two terminal electrodes 24 and two terminal pads 26 .

[0061] The substrate 21 is electrically insulating, and its material is alumina with a purity of more than 90%, glass, or other electrically insulating ceramic materials, wherein alumina with a purity of 96% is the most suitable, and its thickness is about 0.2 to 1.0 millimeters (mm).

[0062] Fuse 22 is a layer of conductive film, its composition is gold, silver, aluminum, copper, platinum and other pure metal or alloy, also can be silver and glass composite conductor, made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com