Double arc hybrid welding power supply device

A hybrid welding and power supply technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of reducing the minimum working current, reducing the minimum welding heat input, etc., to achieve high-speed switching, improve the effect of adapting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

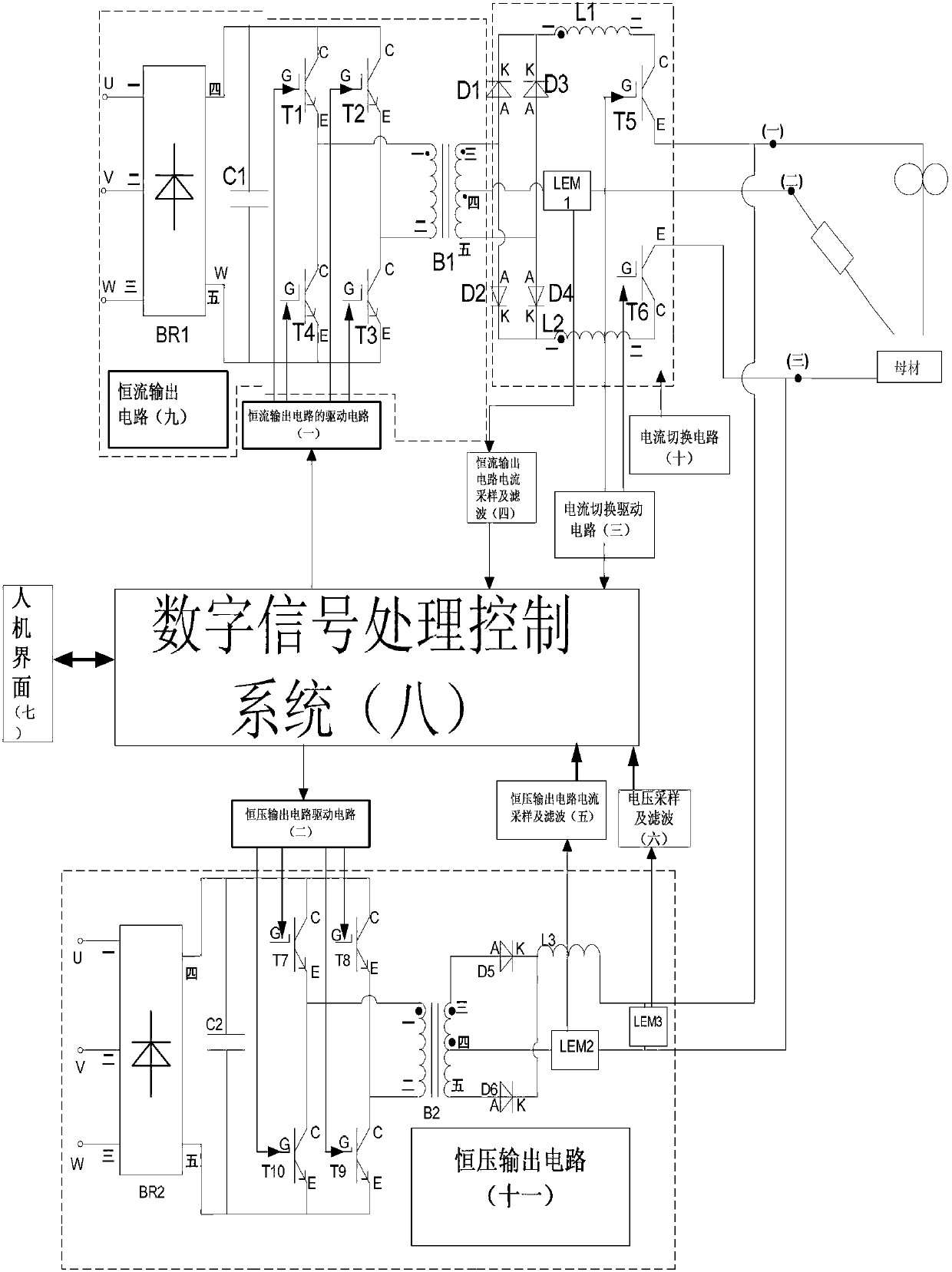

[0024] Below in conjunction with accompanying drawing description and specific embodiment, the present invention is described in further detail:

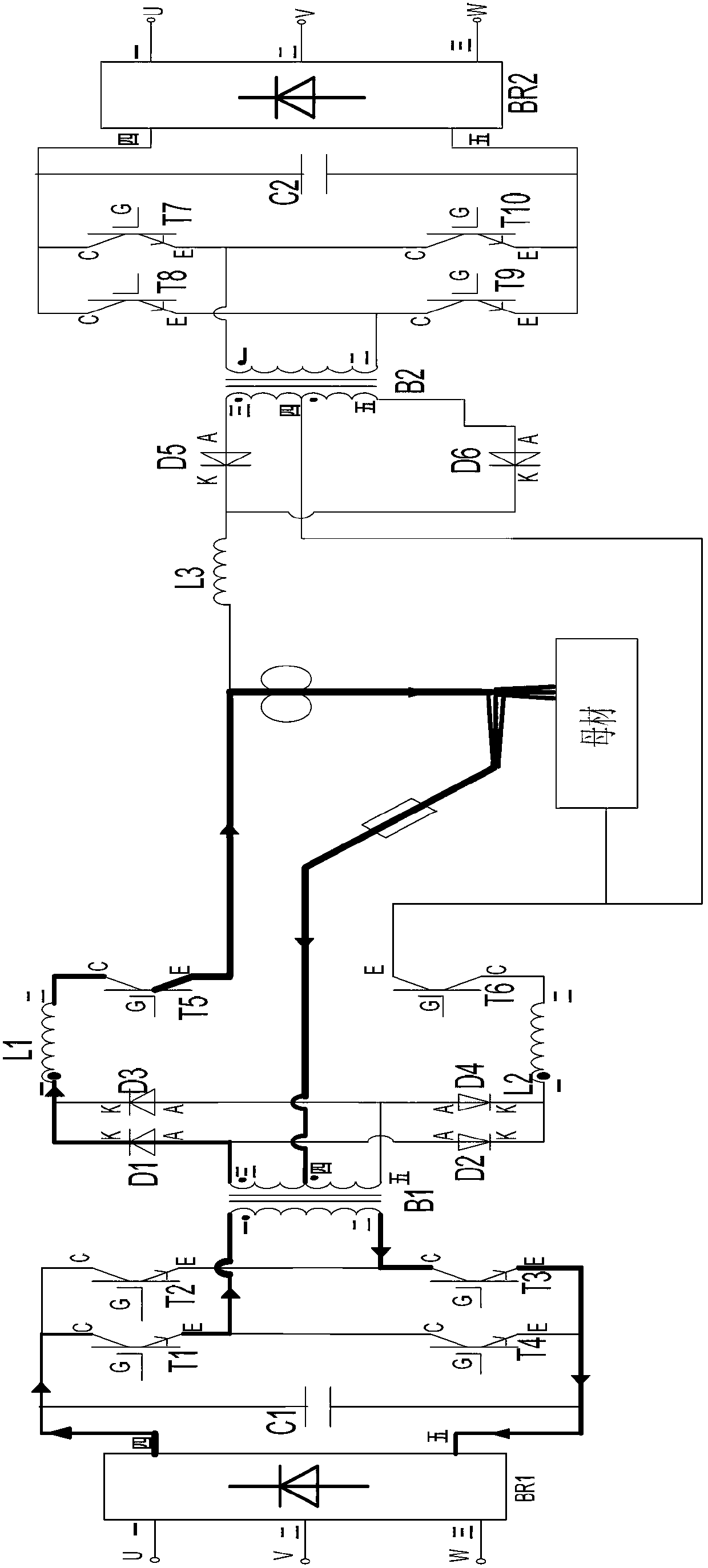

[0025] The system consists of a melting electrode arc as the main arc, and a non-melting electrode arc as the auxiliary arc. The auxiliary arc can be alternately conducted between the base metal and the welding wire. When the auxiliary arc exists between the tungsten electrode and the base metal, a similar The temperature field of twin-wire welding, when the auxiliary arc exists between the tungsten electrode and the welding wire, can increase the deposition speed, because the tungsten arc can work stably at a very low current, so this process is compared with the double melting electrode Welding can reduce the minimum working current and the minimum welding heat input, so it can be applied to the high-speed welding process problems of ultra-thin plates that cannot be solved by conventional twin-wire welding.

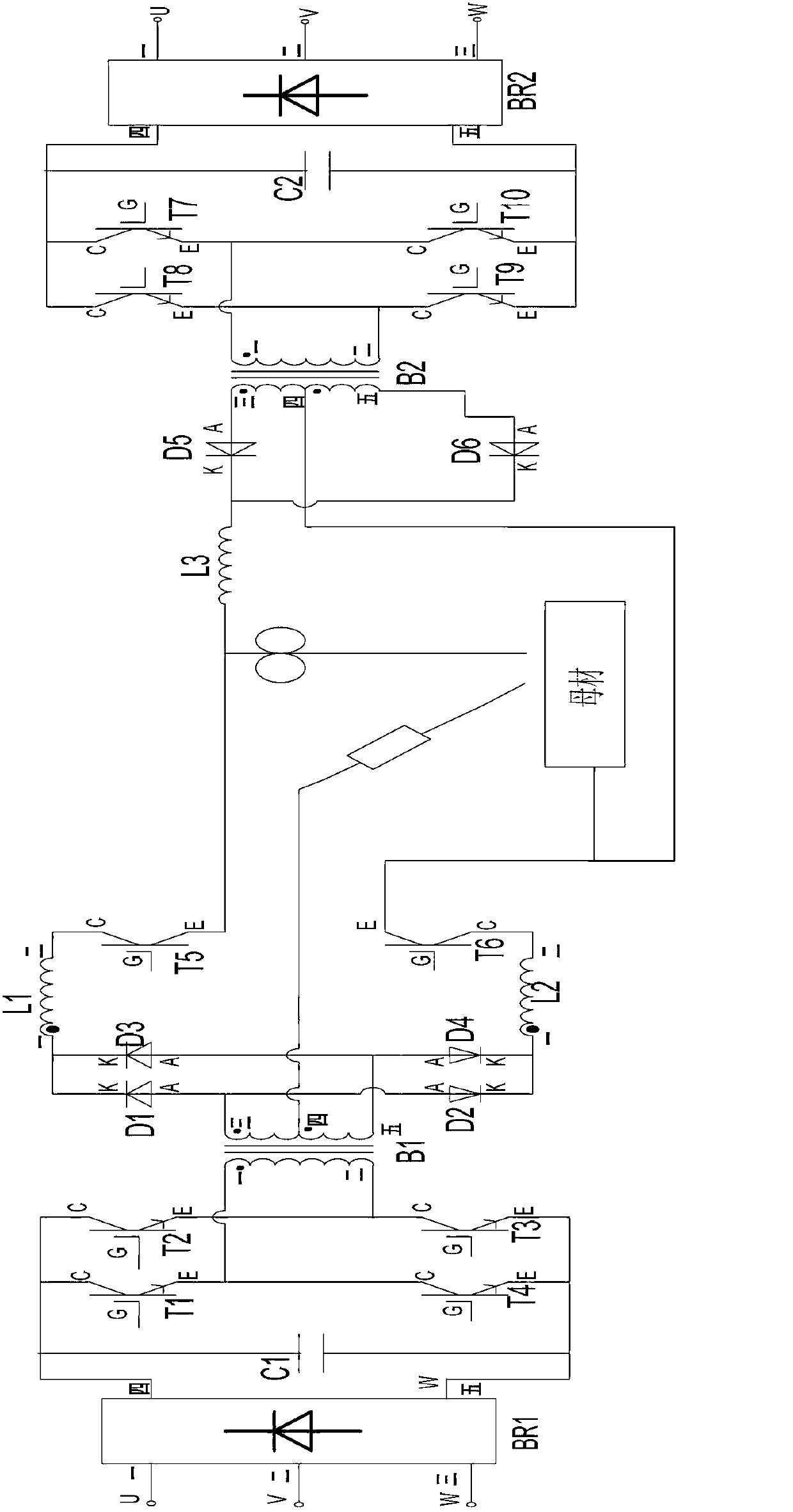

[0026] see figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com