A dual-melting electrode transfer arc compound welding power supply device

A technology of transferred arc and composite welding, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc. It can solve the problems of large heat input and large heat production, and achieve the effects of small heat input, improved welding efficiency, and increased quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

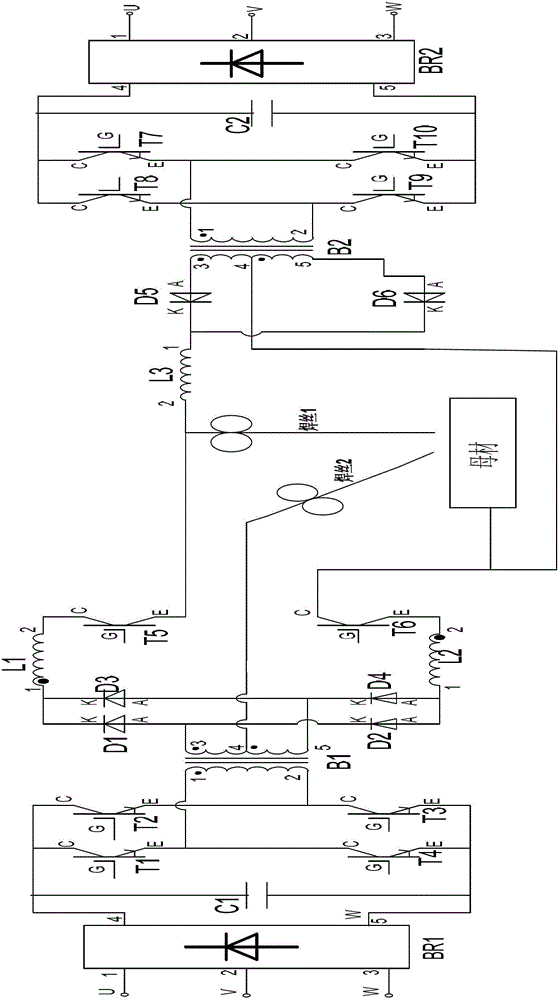

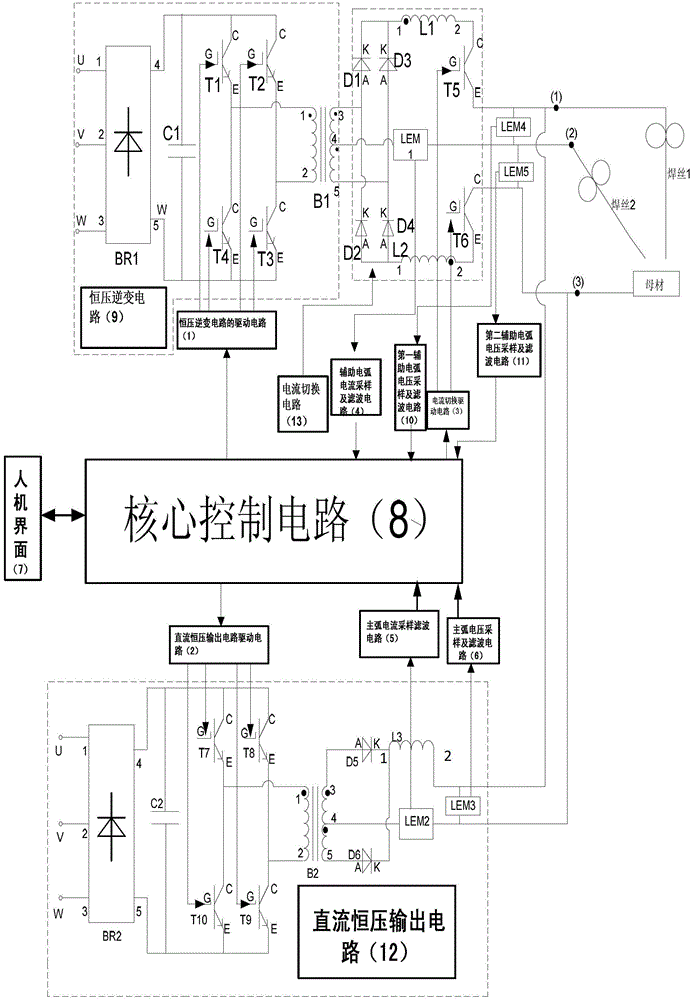

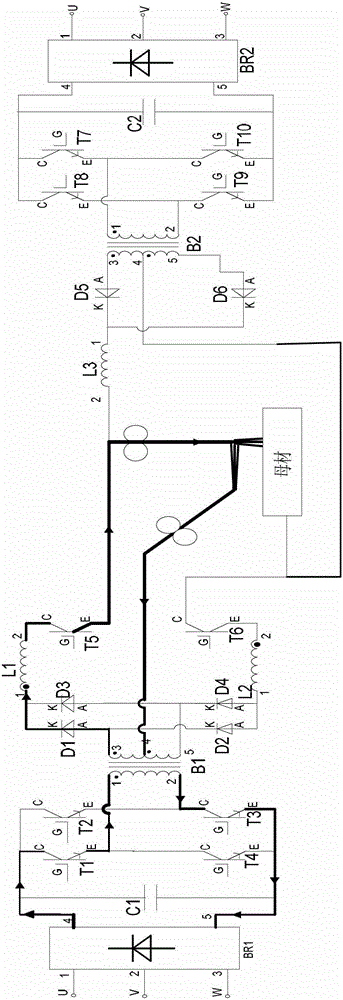

[0036] The present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments: In the present invention, the constant voltage inverter circuit drive circuit (1), the DC constant voltage output circuit drive circuit (2), the core control circuit (8), the auxiliary Arc current sampling filter circuit (4), main arc current sampling filter circuit (5), main arc voltage sampling filter circuit (6), first auxiliary arc voltage sampling filter circuit (10), second auxiliary arc voltage sampling filter circuit ( 11) The current switching drive circuit (13) belongs to the prior art, wherein the constant voltage inverter circuit drive circuit (1) is composed of an IGBT dedicated drive chip M57962, and the DC constant voltage output circuit drive circuit (2) is composed of an IGBT dedicated drive chip M57962 The core control circuit (8) is composed of PIC30f2020, the auxiliary arc current sampling filter circuit (4) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com