Welding device for compounding ultrasonic focusing sound field with molten pole arc welding

A melting electrode welding and arc welding technology, which is applied in the direction of arc welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of reduced sound field energy density, unstable wire feeding speed, unfavorable welding process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

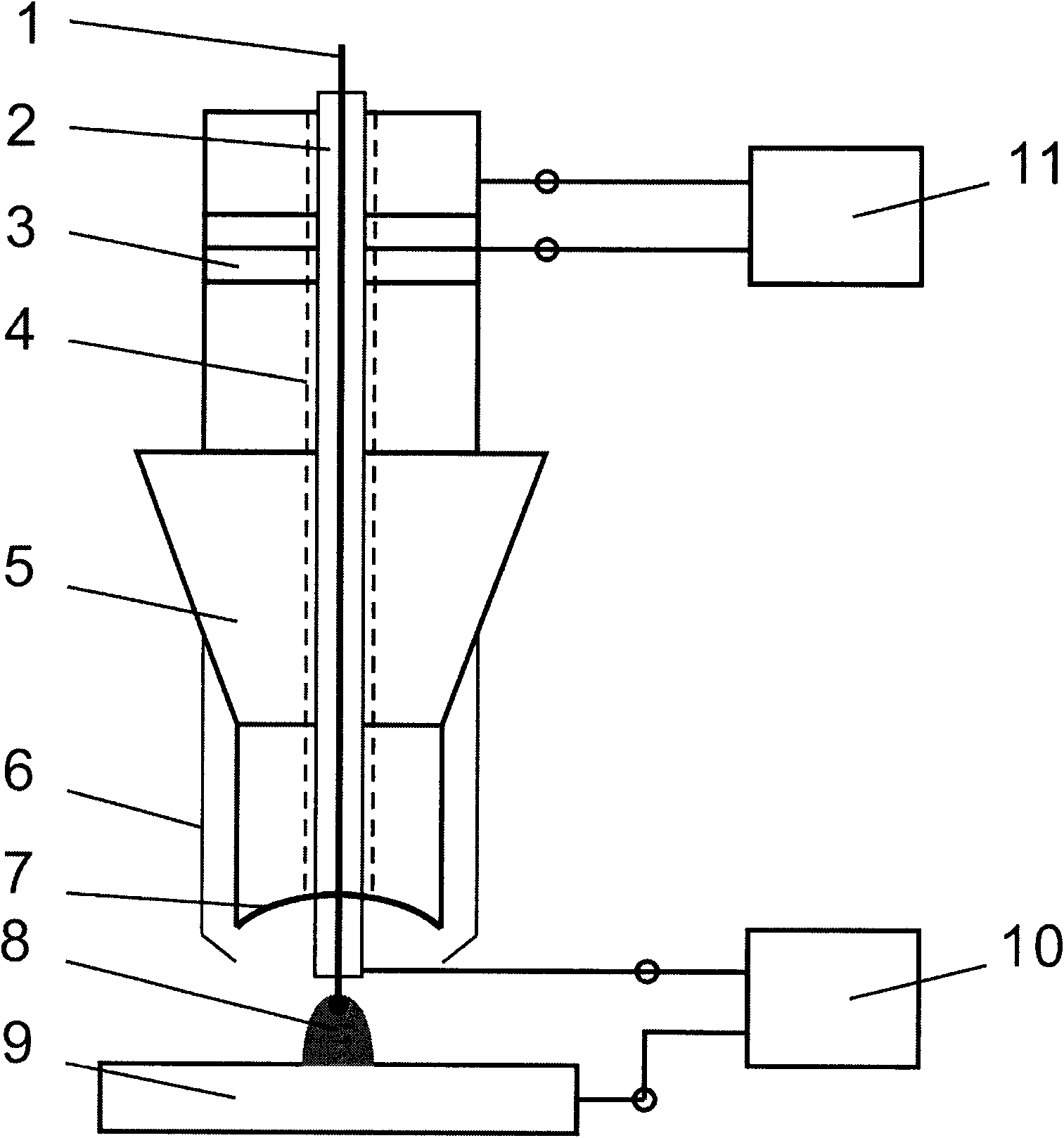

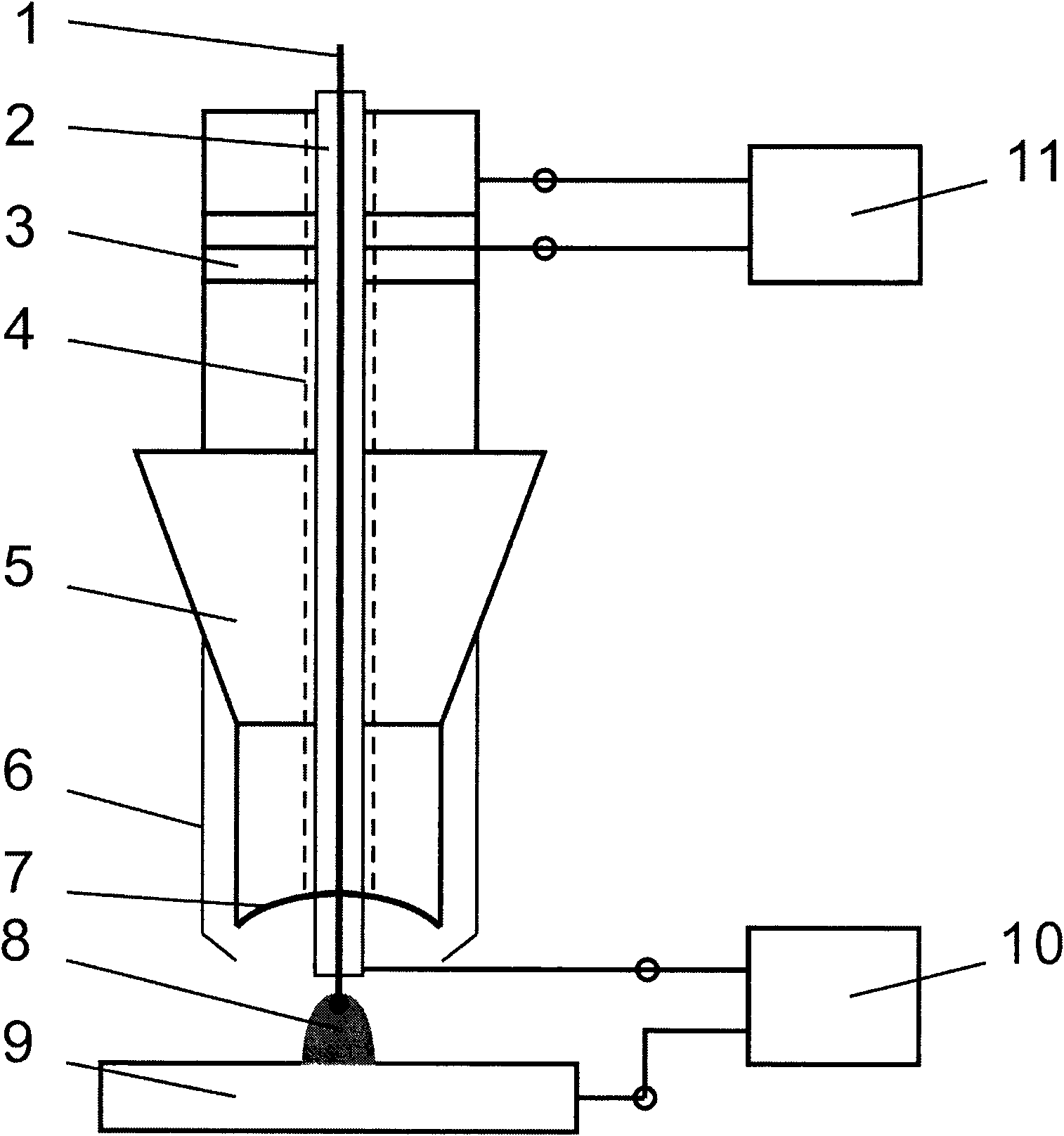

[0008] Example 1: Combining figure 1 , the present invention is a welding device combined with ultrasonic focused sound field and melting electrode arc welding, which is composed of melting electrode welding wire (1), conductive rod (2), ultrasonic transducer (3), axial through hole (4) ultrasonic Composed of horn (5), welding nozzle (6), focusing plane (7), welding arc (8), workpiece to be welded (9), welding power source (10) and ultrasonic power source (11), the melting electrode welding wire ( 1) Pass through the conductive rod (2) and maintain a sliding contact state with it, and the conductive rod (2) surrounding the melting electrode wire (1) passes through the axis of the ultrasonic transducer (3) and ultrasonic horn (5) The through hole (4) makes the end of the melting electrode wire (1) in the ultrasonic propagation space radiated by the focusing plane (7), and the diameter of the axial through hole (4) is greater than the diameter of the conductive rod (2), so that ...

Embodiment 2

[0009] Embodiment 2: The present invention generates and amplifies ultrasonic vibrations through an ultrasonic transducer and a horn, and utilizes a special-shaped focusing surface processed on the end face of the horn to realize ultrasonic radiation convergence. The concentrated ultrasonic energy is further improved, and the ultrasonic wave is radiated through the focusing surface and the welding arc is directly compounded to achieve the purpose of improving welding efficiency and welding quality.

[0010] The main technical steps of the present invention are as follows:

[0011] (1) The ultrasonic generator is connected to the ultrasonic transducer through the electrode, and converts the electrical signal of the ultrasonic frequency into mechanical vibration of the ultrasonic frequency;

[0012] (2) The ultrasonic transducer is closely connected with the ultrasonic horn to amplify the ultrasonic vibration amplitude output by the ultrasonic transducer;

[0013] (3) The end f...

Embodiment 3

[0026] Example 3: Binding figure 1, the working process of the present invention is as follows: at first the workpiece (8) to be welded is fixed on the welding platform by the clamp. The ultrasonic power supply (11) is connected with the ultrasonic transducer (3), and the ultrasonic power is adjusted within the range of 1-5000W through the ultrasonic power supply (11). Utilize the ultrasonic transducer (3) to convert the ultrasonic frequency electric signal generated by the ultrasonic power supply (11) into ultrasonic vibration with a frequency between 15-100 kHz, and then amplify the amplitude to 10-150 μm through the ultrasonic horn (5) . The focusing surface (7) at the end of the ultrasonic horn (5) converges the ultrasonic radiation energy and directly radiates and outputs it to form an ultrasonic focused sound field. The conductive rod (2) and the melting pole welding wire (1) are fed through the axial through hole (4), and the end of the melting pole welding wire (1) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com