Welding machine with adjustable electric arc energy density

A technology of arc energy and density, applied in the direction of arc welding equipment, electrode characteristics, welding equipment, etc., can solve the problems of complex structure, insufficient cooling water circulation, uneven gas film protection, etc., and achieve lower skill requirements and reasonable welding operation. Convenience, easy maintenance and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

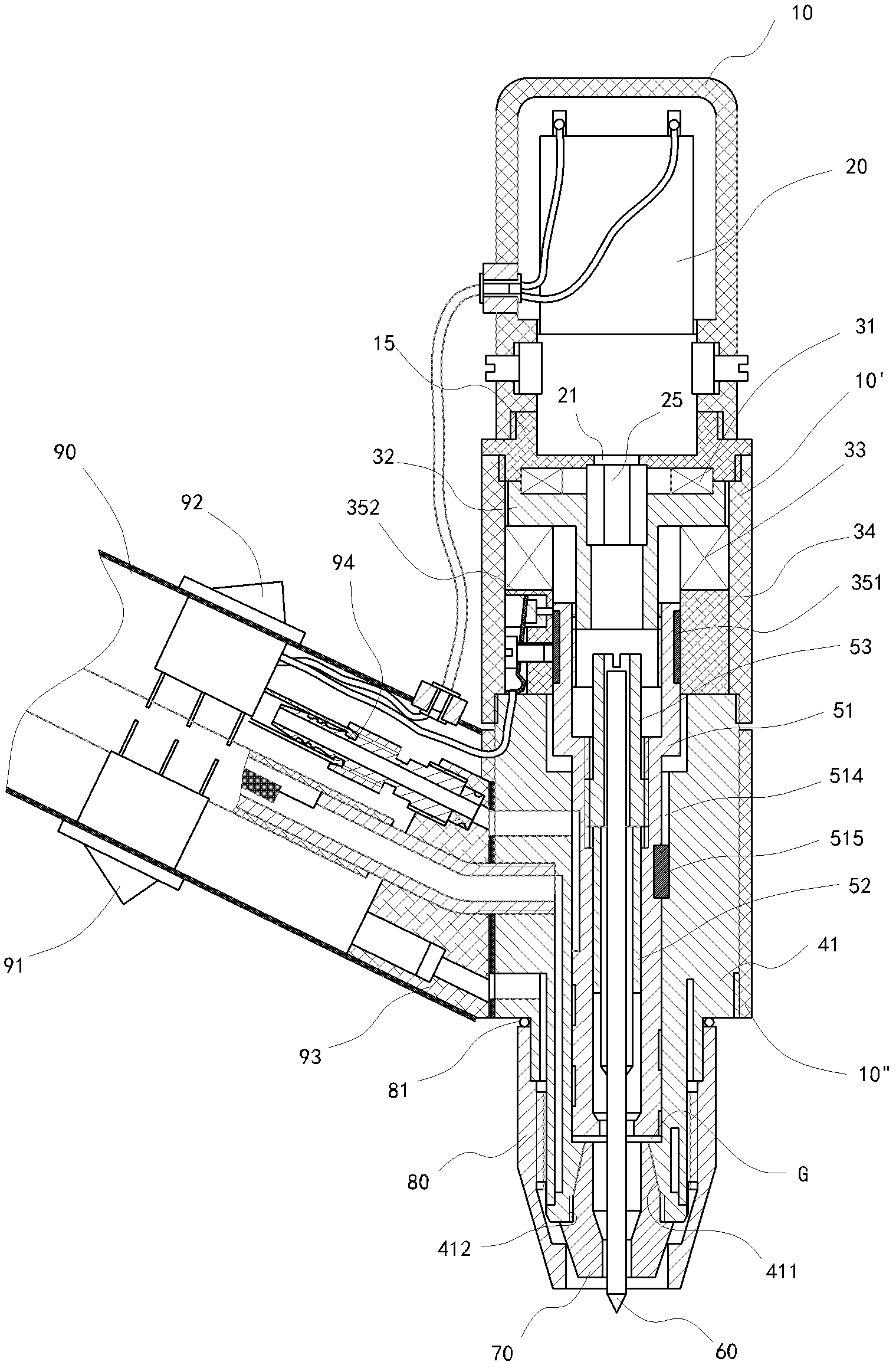

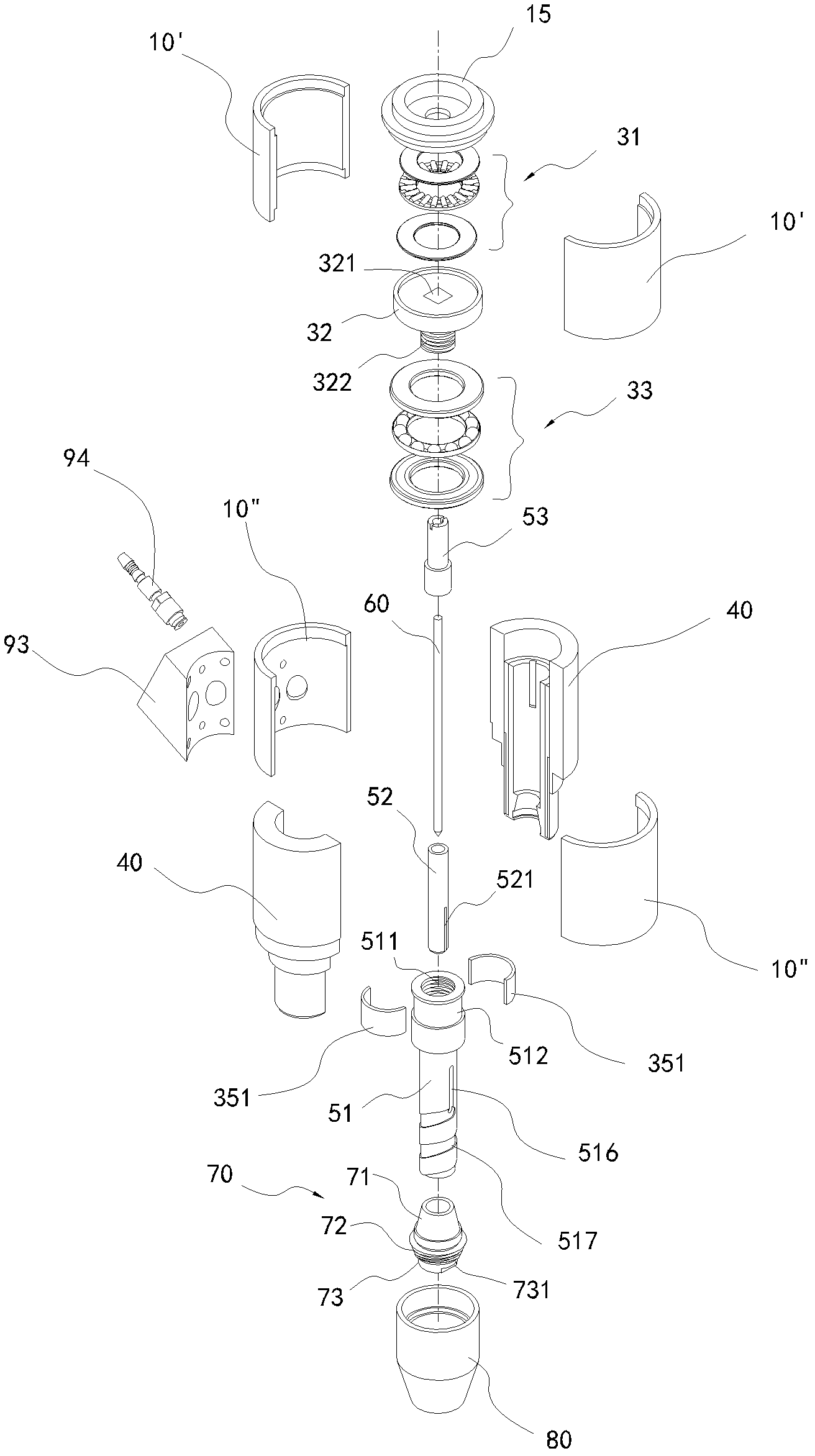

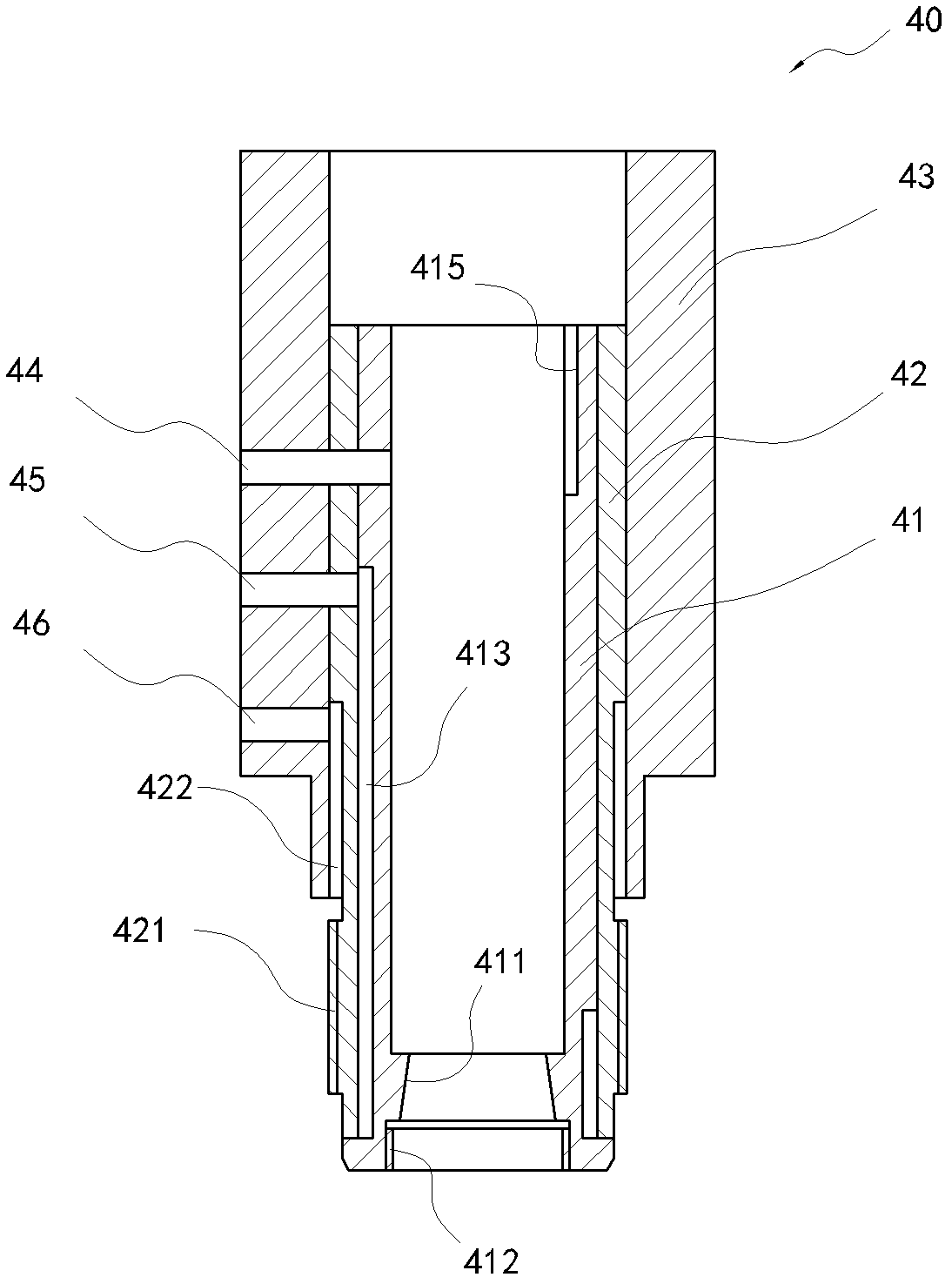

[0037] The argon arc welding inverter welding equipment involved in the present invention is mainly composed of a TIG welding host, a gas supply system, a cooling water circulation system, and a welding gun capable of adjusting arc energy. The improvement of the present invention mainly lies in the structure of the tungsten rod adjustment device inside the welding torch, the cooling water circulation circuit, the compressed gas and shielding gas channels, the arc nozzle and the shielding gas nozzle.

[0038] First, combine the reference figure 1 with figure 2As shown, the welding torch structure of the arc energy adjustable welding machine according to the principle of the present invention mainly includes from top to bottom: upper, middle and lower insulating jackets 10, 10', 10", driving source 20, tungsten rod adjustment device (not shown in the figure) label), cooling water jacket 40, tungsten rod jacket 50, tungsten rod 60, arc nozzle 70, shielding gas nozzle 80, operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com