Argon tungsten-arc repair welding method based on activated flux

A technology of argon tungsten arc welding and active flux, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low repair welding efficiency, large workpiece deformation, etc., and achieves simple and convenient operation. The effect of small repair welding deformation and improving arc energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

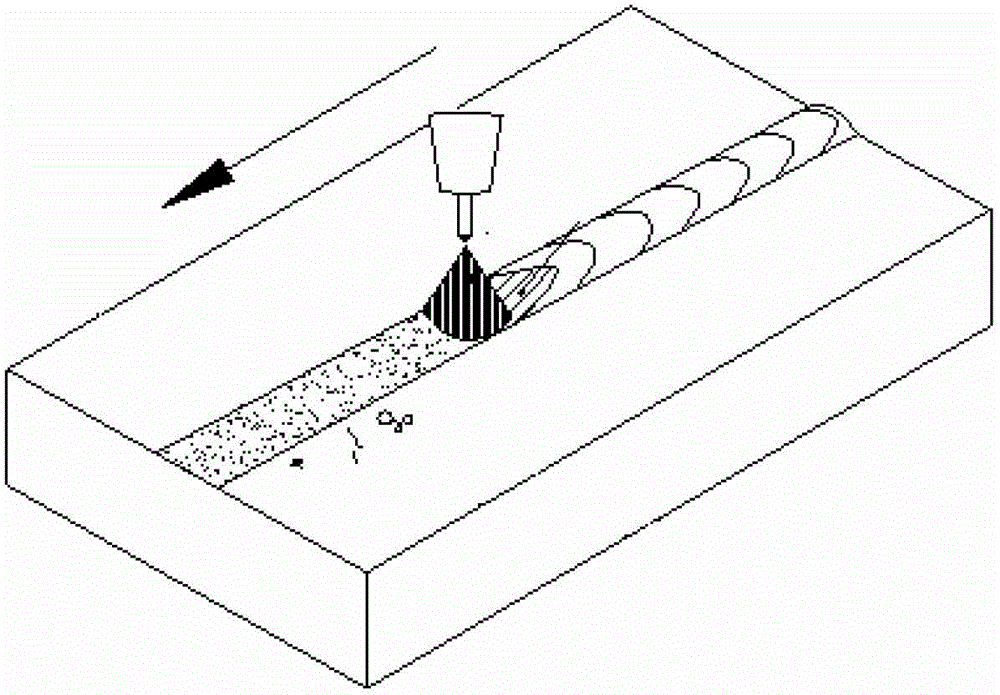

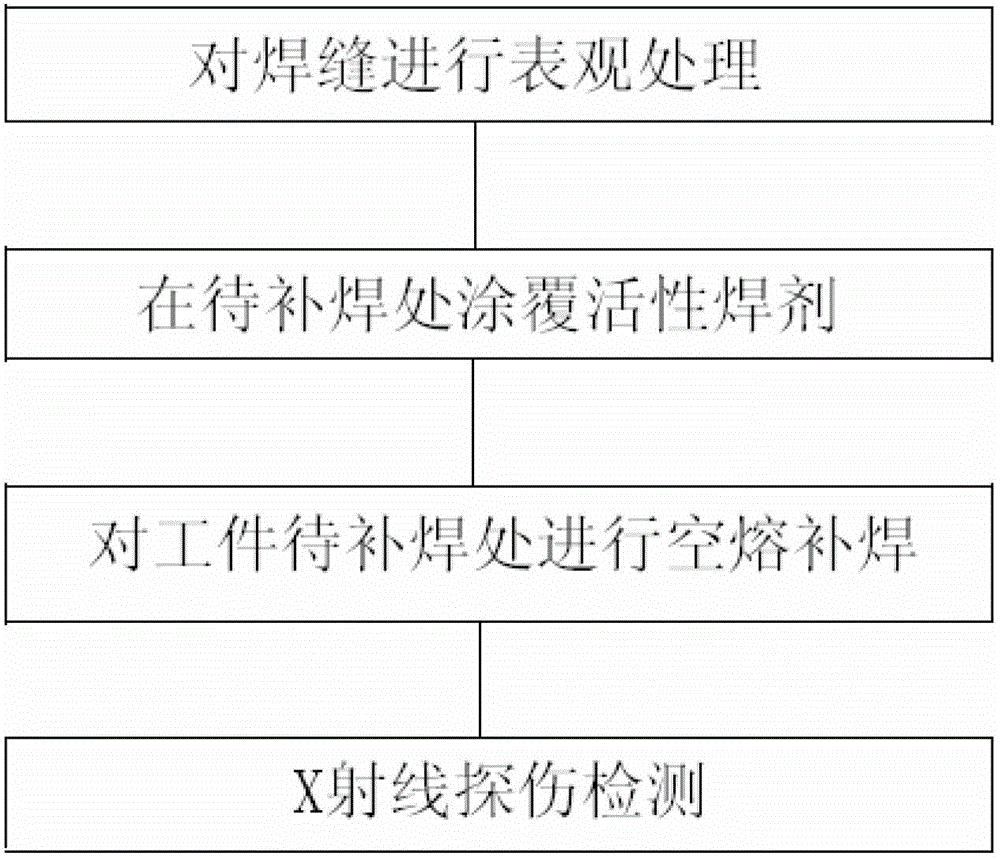

[0016] This embodiment is an active flux-based repair welding method for a low-alloy high-strength steel pressure vessel by argon tungsten arc welding.

[0017] In this embodiment, the workpiece to be repaired is a low-alloy high-strength steel pressure vessel with a diameter of φ1200 mm, a wall thickness of 3.2 mm, and a material of 30CrMnSiA high-strength steel with a material strength level of 1000 MPa. After argon tungsten arc welding was adopted, many cracks were found in the girth weld by X-ray inspection. The active flux used is low-carbon steel argon tungsten arc welding active flux produced by Xi'an Aerospace Power Machinery Factory, and the gas hole defects in the weld seam of the low-alloy high-strength steel pressure vessel are repaired by argon tungsten arc welding , the specific repair welding steps are:

[0018] Step 1, perform appearance treatment on the weld seam. The conventional method is used to clean the defect parts in the weld seam of low-alloy high-st...

Embodiment 2

[0023] This embodiment is an active flux-based repair welding method for a low-alloy high-strength steel pressure vessel by argon tungsten arc welding.

[0024] In this embodiment, the workpiece to be repaired is a low-alloy high-strength steel pressure vessel with a diameter of φ1400 mm, a wall thickness of 4.5 mm, and a material of 30CrMnSiA high-strength steel with a material strength level of 1000 MPa. After argon tungsten arc welding was adopted, X-ray flaw detection found that there were clusters of air hole defects with a diameter of about φ1.0mm scattered in the girth weld in a length of about 500mm. The active flux used is low-carbon steel argon tungsten arc welding active flux produced by Xi'an Aerospace Power Machinery Factory, and the gas hole defects in the weld seam of the low-alloy high-strength steel pressure vessel are repaired by argon tungsten arc welding , the specific repair welding steps are:

[0025] Step 1, perform appearance treatment on the weld seam...

Embodiment 3

[0030] This embodiment is an active flux-based repair welding method for a low-alloy ultra-high-strength steel pressure vessel by argon tungsten arc welding.

[0031] In this embodiment, the workpiece to be repaired is a low-alloy ultra-high-strength steel pressure vessel with a diameter of φ2000mm and a wall thickness of 6.5mm. The material is 31Si2MnCrMoVE ultra-high-strength steel, and the material strength level is 1700MPa. After adopting automatic argon tungsten arc welding, X-ray flaw detection found that there were many incomplete penetration at the root of the girth weld. Due to the limitation of the product structure, root cleaning and repair welding cannot be performed directly from the back of the weld. Manual argon tungsten arc welding based on active flux is used to repair the above-mentioned incomplete penetration defect at the root of the weld from the front of the weld. The active flux used is low-carbon steel argon tungsten arc welding active flux produced by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com