Patents

Literature

63results about How to "Reduce arc energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

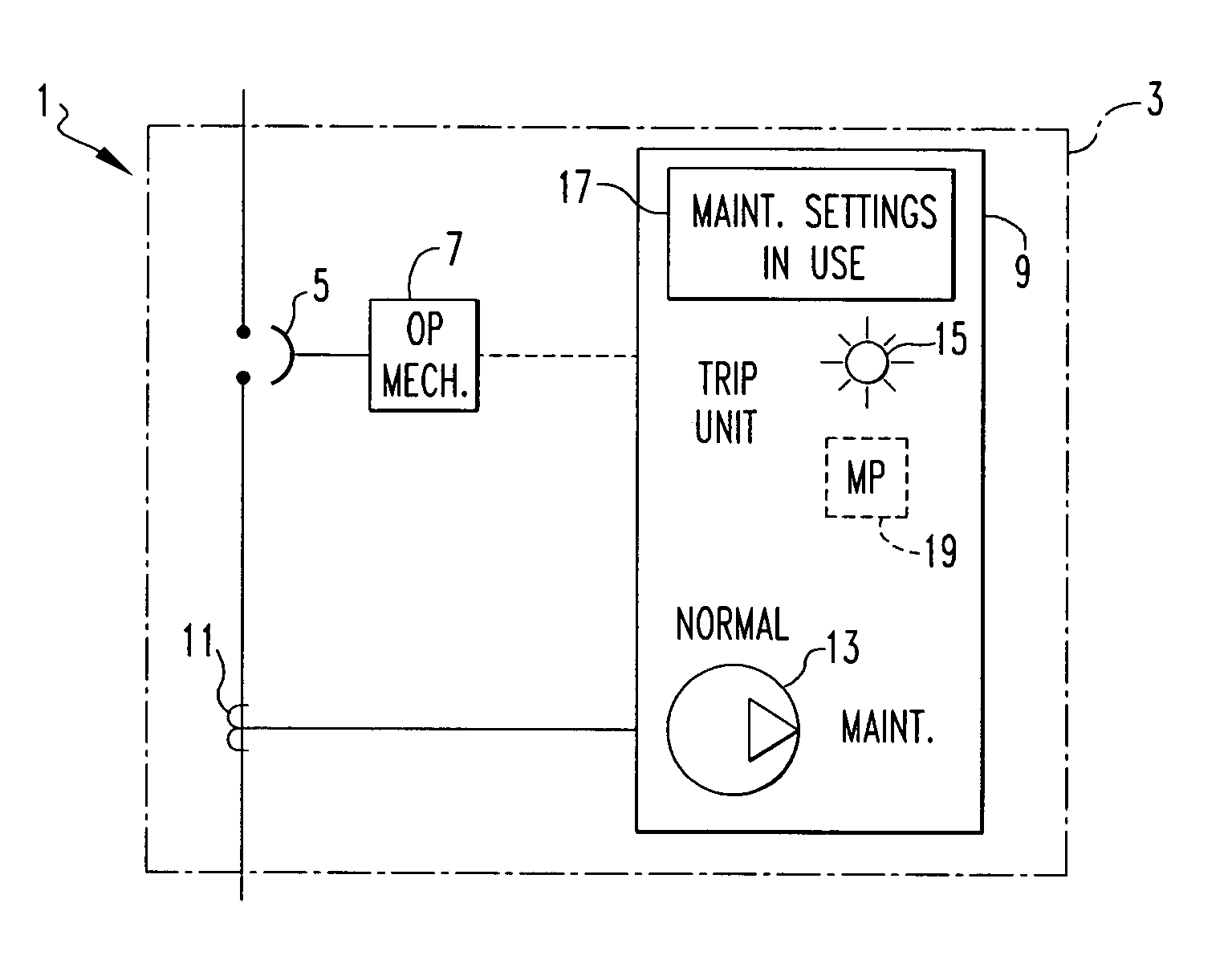

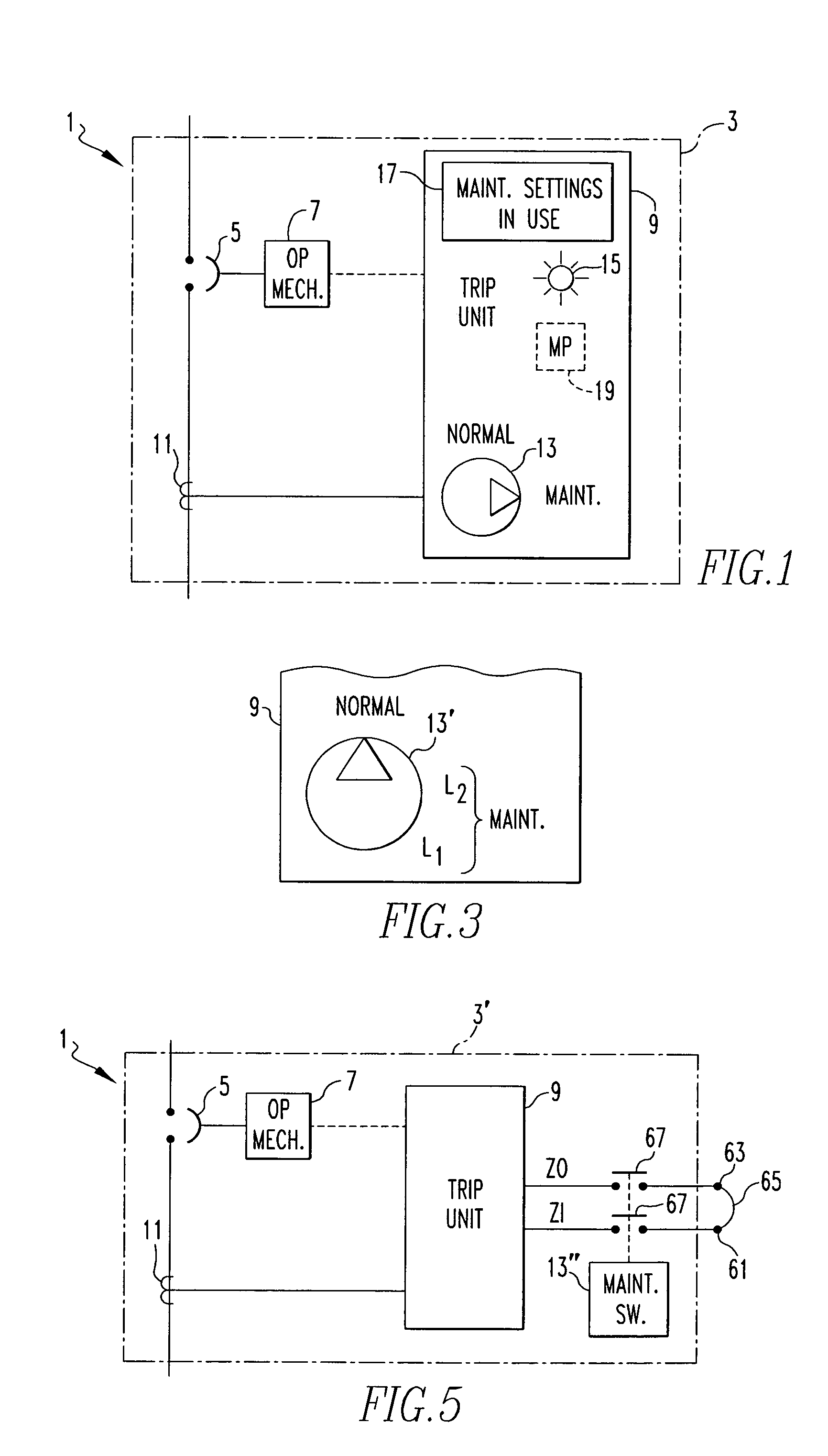

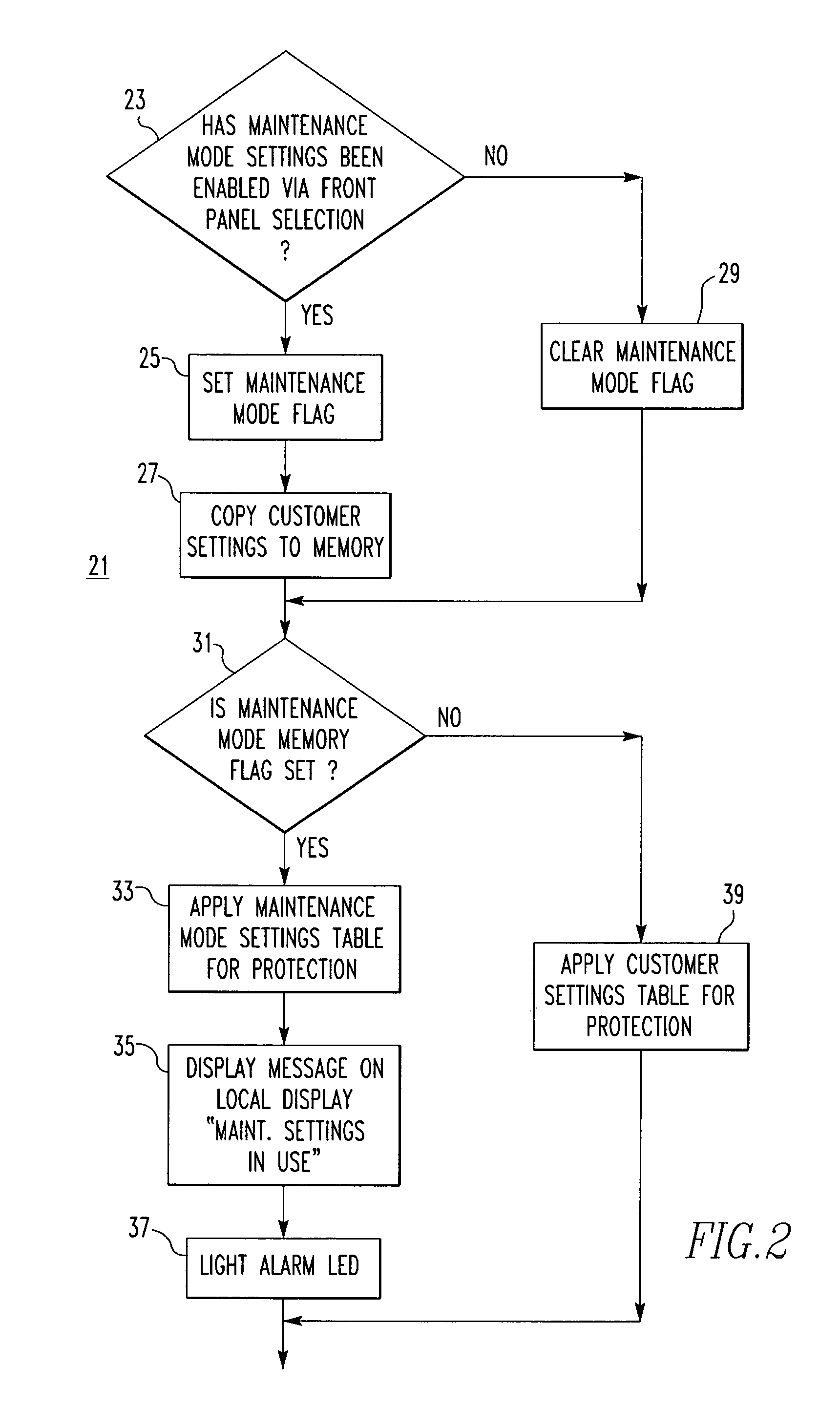

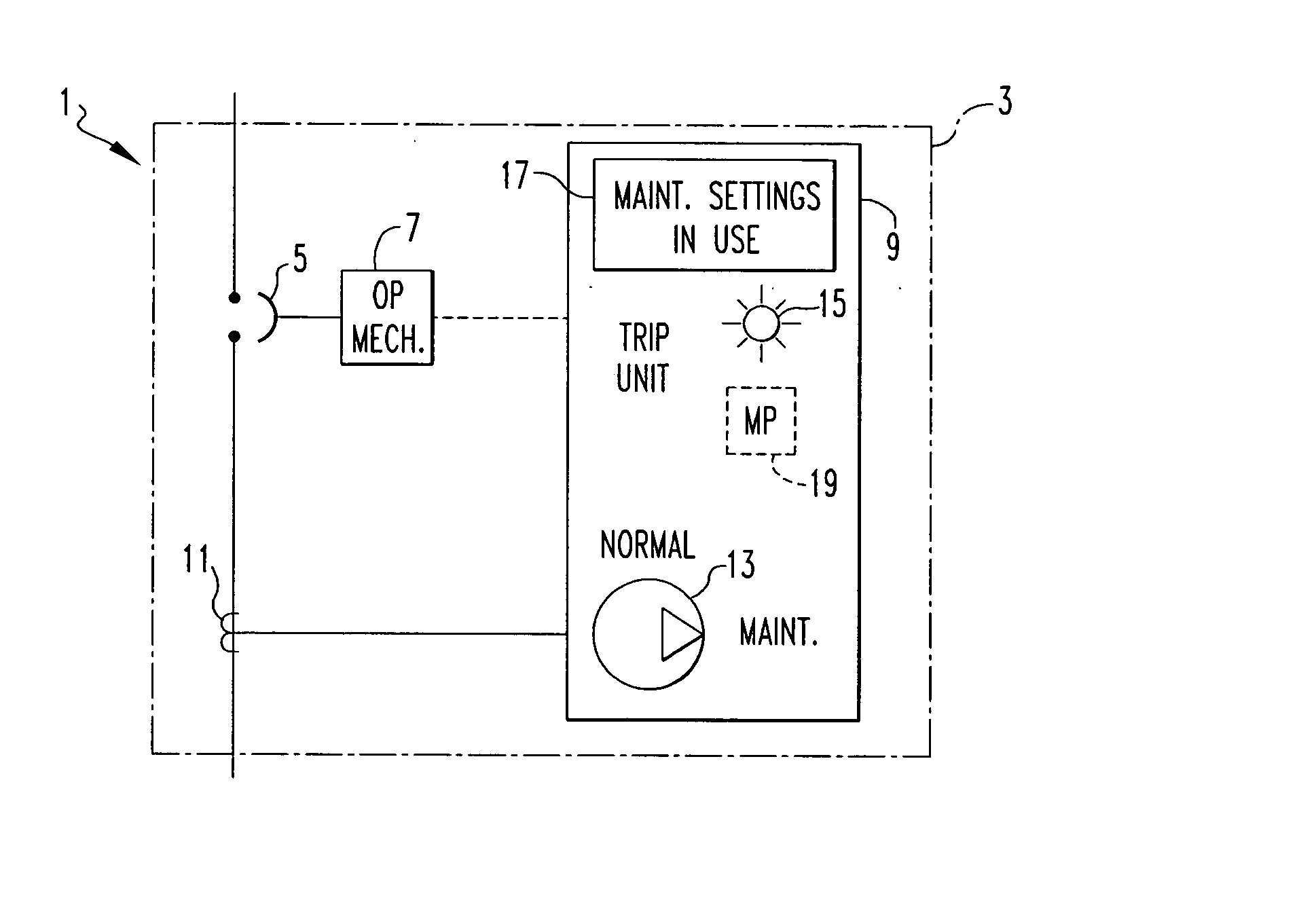

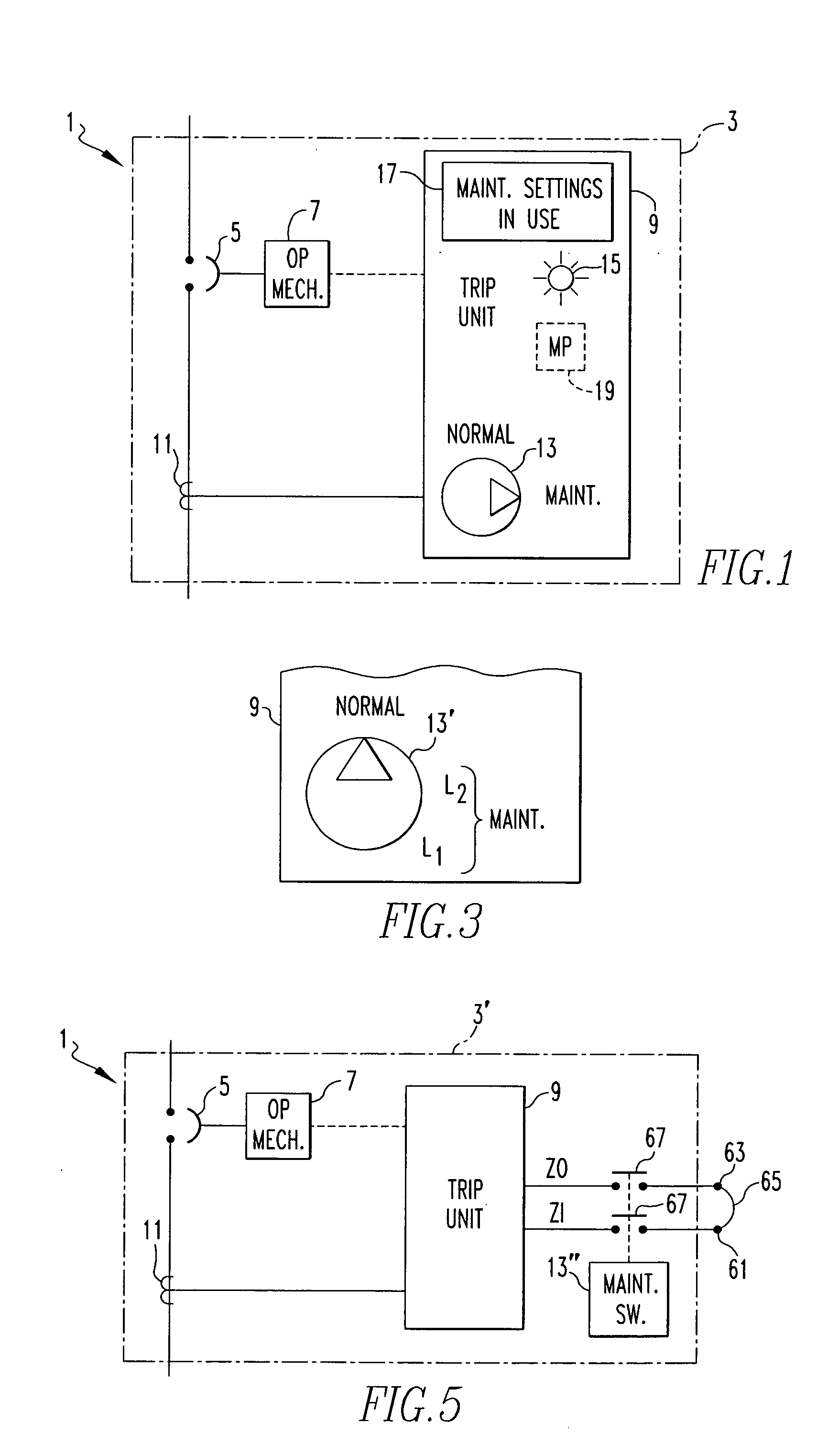

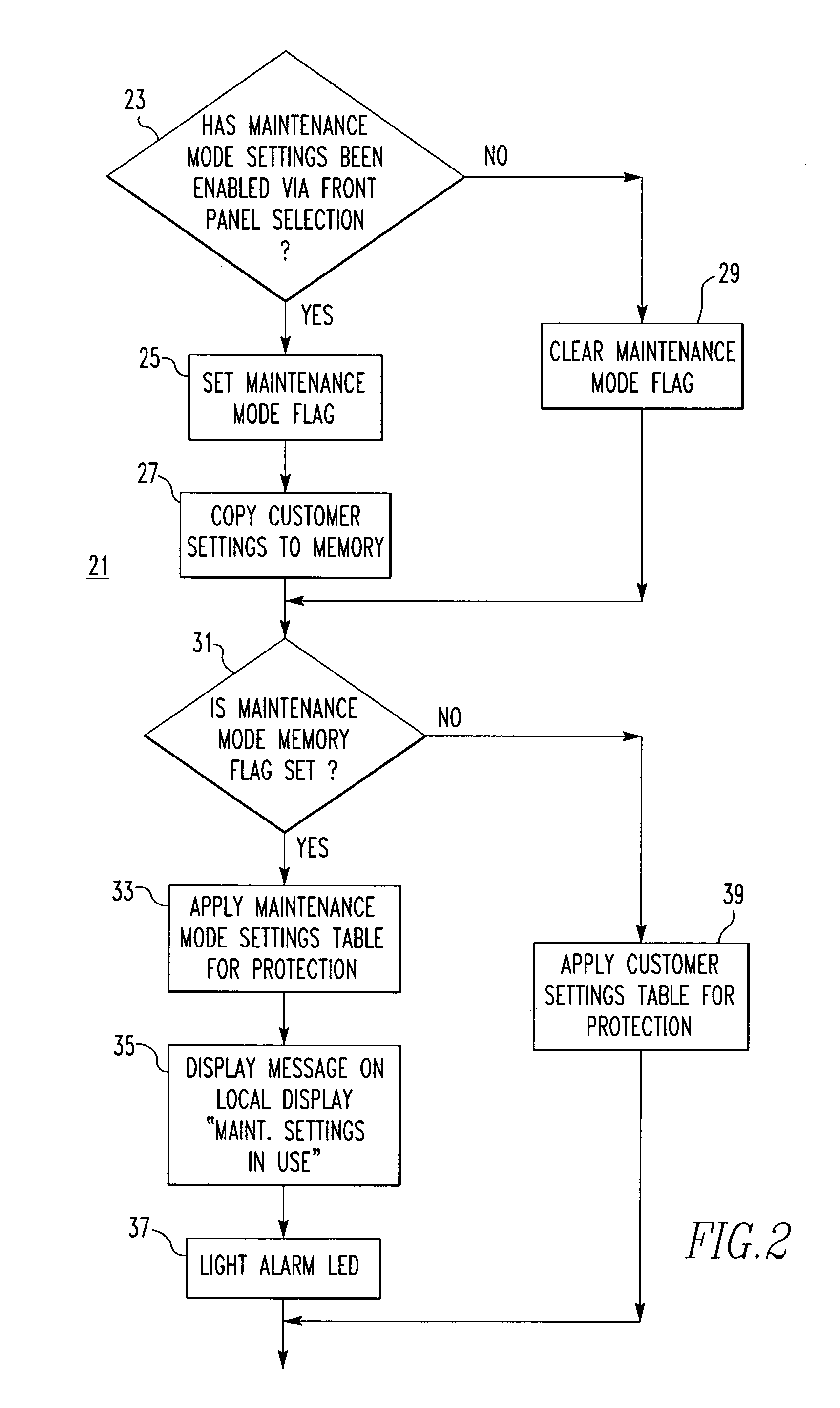

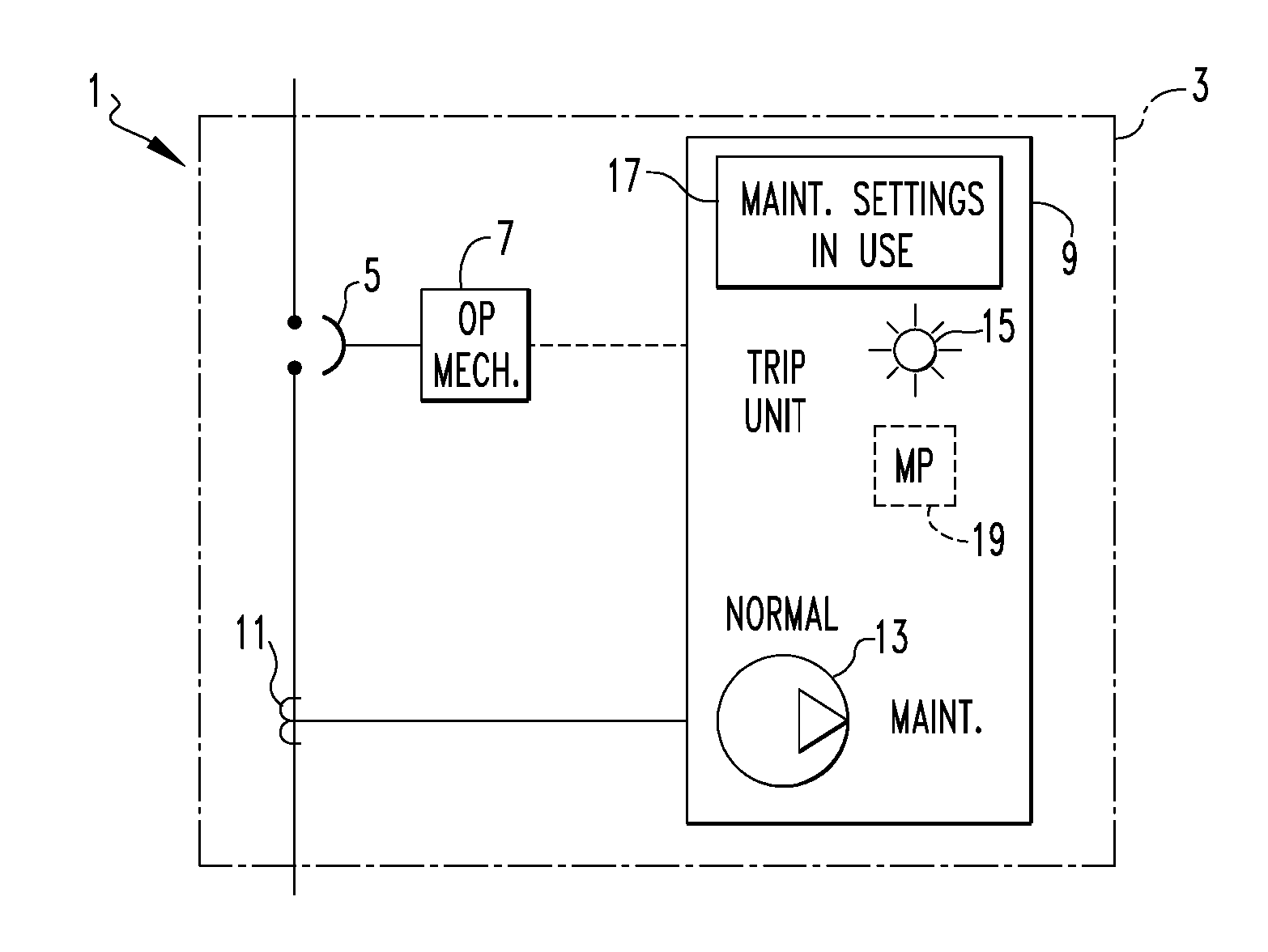

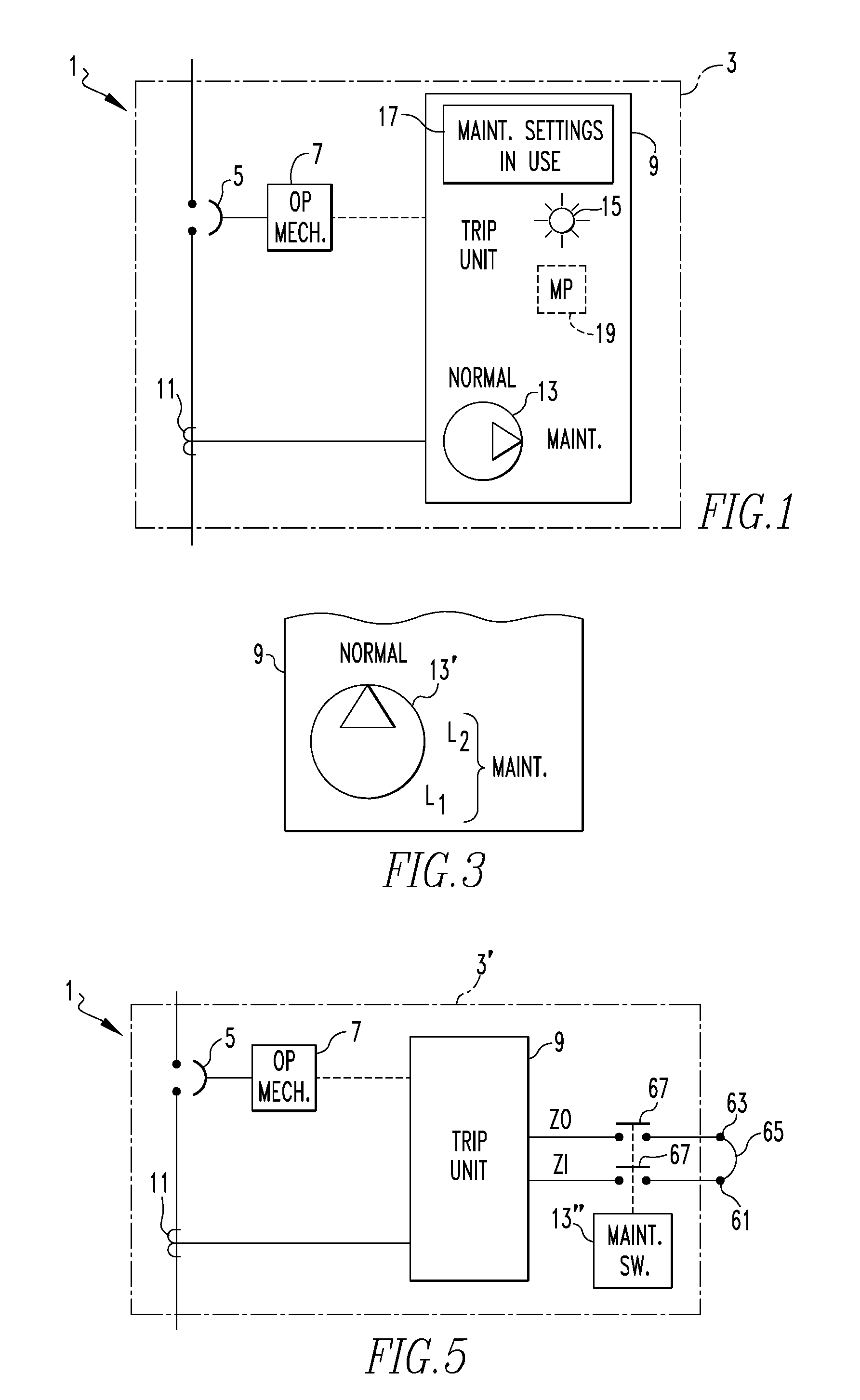

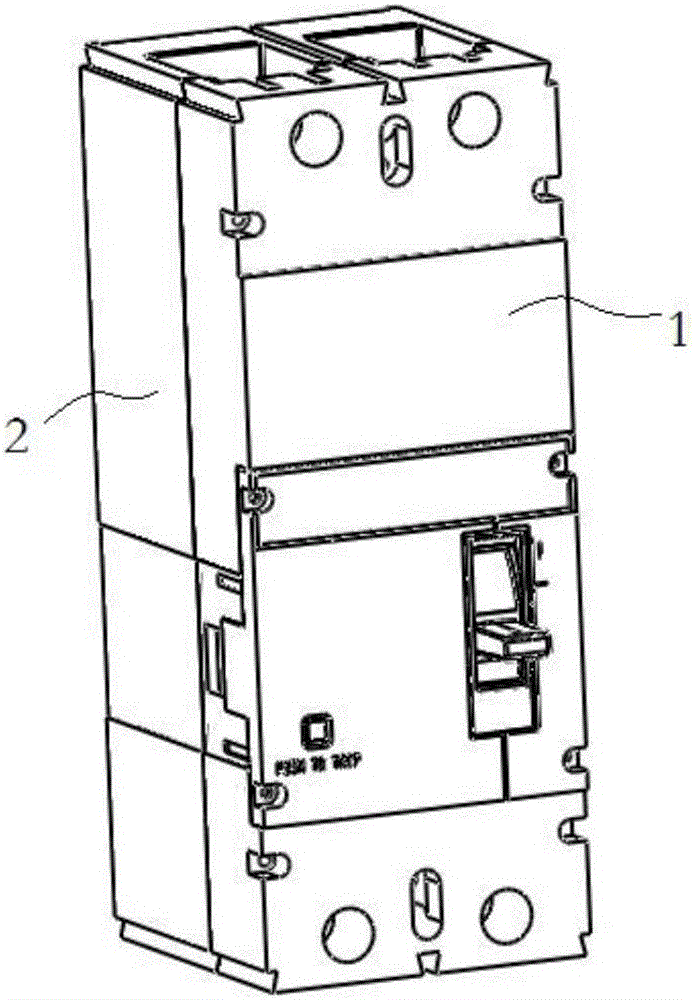

Method and circuit breaker for reducing arc flash during maintenance in a low voltage power circuit

ActiveUS7203040B2Low levelReduce arc energyParameter calibration/settingProvisions for user interfaceLow voltage circuitsArc flash

Owner:EATON INTELLIGENT POWER LTD

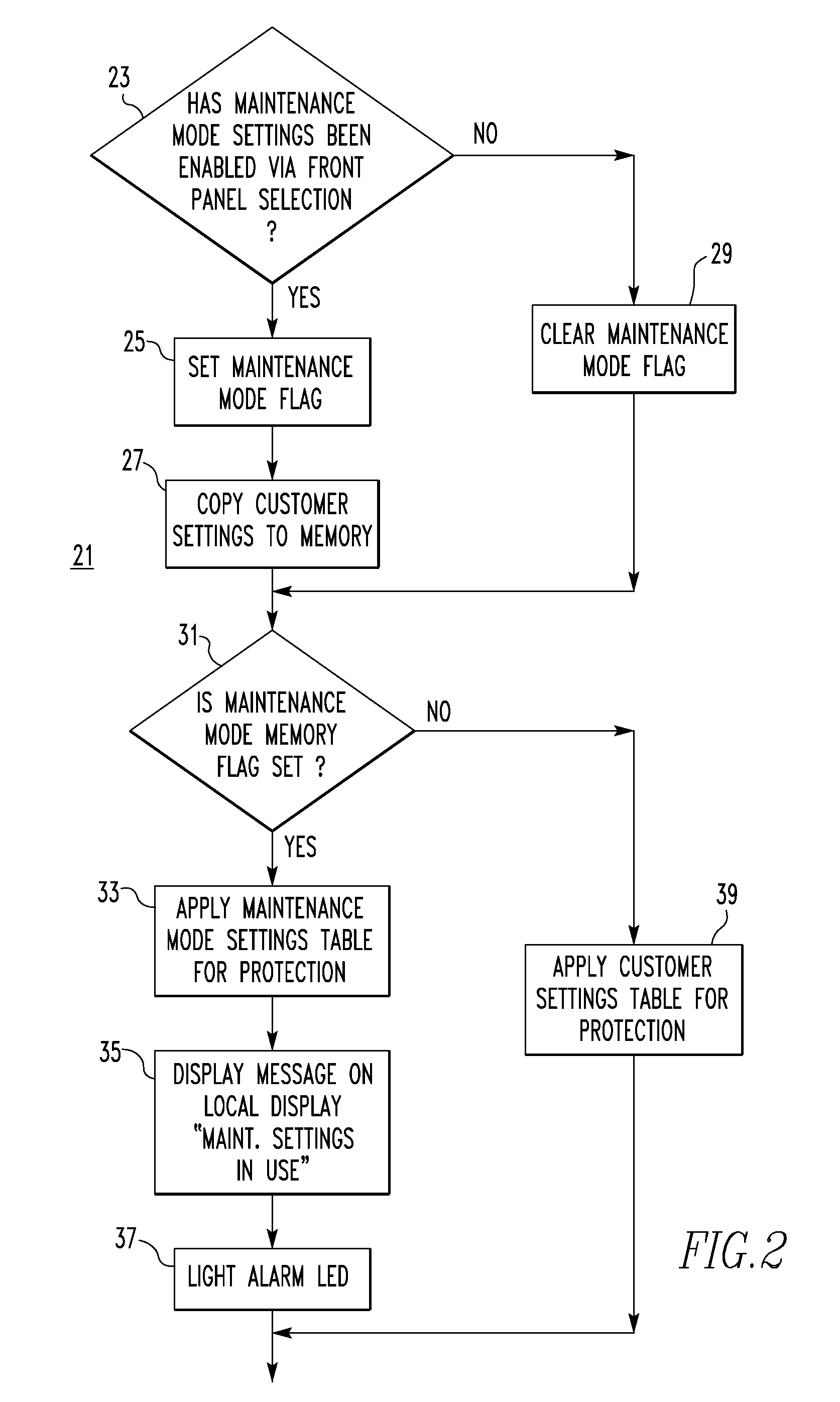

Method and circuit breaker for reducing arc flash during maintenance in a low voltage power circuit

ActiveUS20050219775A1Eliminate delaysLow levelParameter calibration/settingProvisions for user interfaceArc flashLow voltage circuits

Maintenance trip functions override the normal or specified trip functions of a low voltage circuit breaker to reduce pickup currents and / or time delays to effect faster trips, which reduces arc energy produced by faults during maintenance or testing on a live circuit breaker.

Owner:EATON INTELLIGENT POWER LIMITED

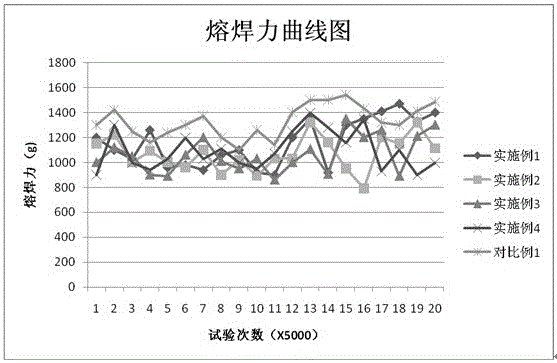

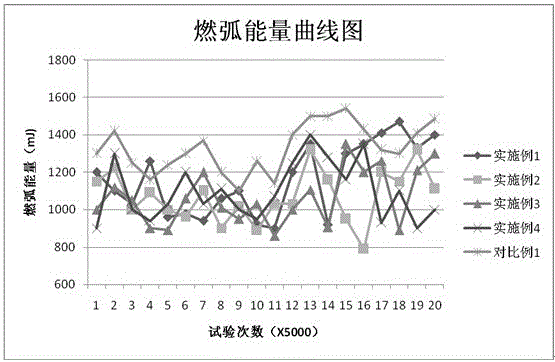

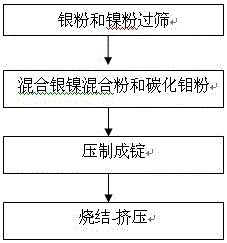

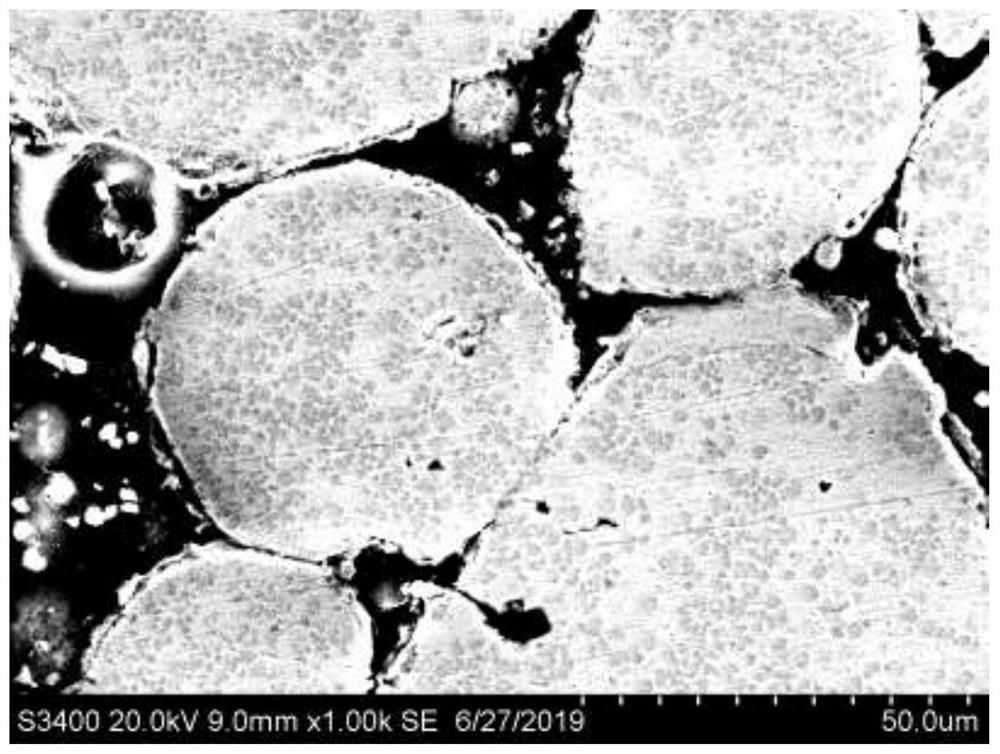

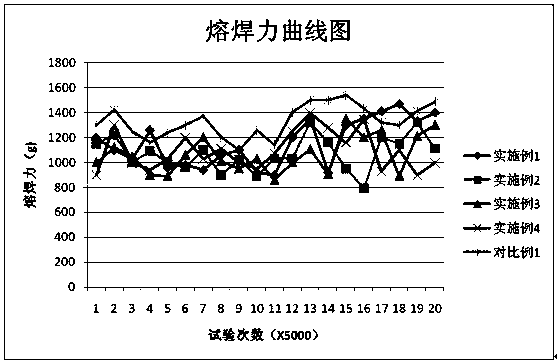

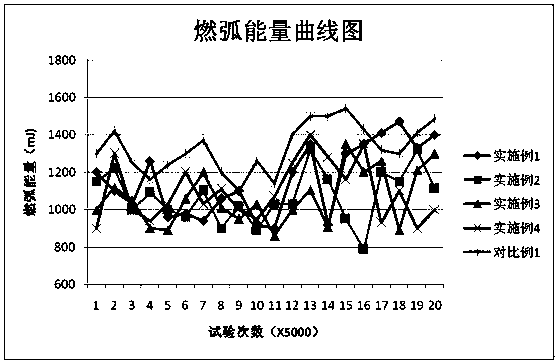

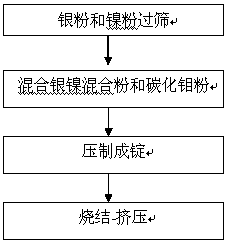

Silver-nickel electric contact material and preparing method thereof

ActiveCN106282640AImprove welding resistanceGuaranteed uniformityContactsElectricityHigh volume manufacturing

The invention relates to the field of electric contact materials, in particular to a silver-nickel electric contact material and a preparing method thereof. The silver-nickel electric contact material comprises, by mass percent, larger than or equal to 8% and smaller than or equal to 30% of nickel, larger than or equal to 0.5% and smaller than or equal to 12% of molybdenum carbide, and the balance silver. A powder mixing-extrusion technology is adopted in a production technology for the silver-nickel electric contact material. Improvement of the welding resistance performance of the silver-nickel material is mainly taken into consideration, the molybdenum carbide is added to serve as a reinforcement phase, and the molybdenum carbide has the beneficial effects that the melting point is high, heat stability is good, and the density of the molybdenum carbide is close to that of silver and nickel; and component uniformity can be guaranteed through the ordinary powder mixing technology, and the silver-nickel electric contact material and the preparing method thereof are suitable for volume production. Compared with ordinary silver and nickel materials, the silver-nickel electric contact material has high welding resistance performance and low electric arc energy and is mainly applied to alternating current contactors and relays.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Method and circuit breaker for reducing arc flash during maintenance in a low voltage power circuit

InactiveUS20070097582A1Low levelReduce arc energyParameter calibration/settingCircuit-breaking switches for excess currentsArc flashLow voltage circuits

Owner:SHIPP DAVID D +4

Arc Extinction Arrangement and Method for Extinguishing Arcs

ActiveUS20130134890A1More currentSimple and cost-effective energy conversionElectric discharge tubesElectric light circuit arrangementPower flowEngineering

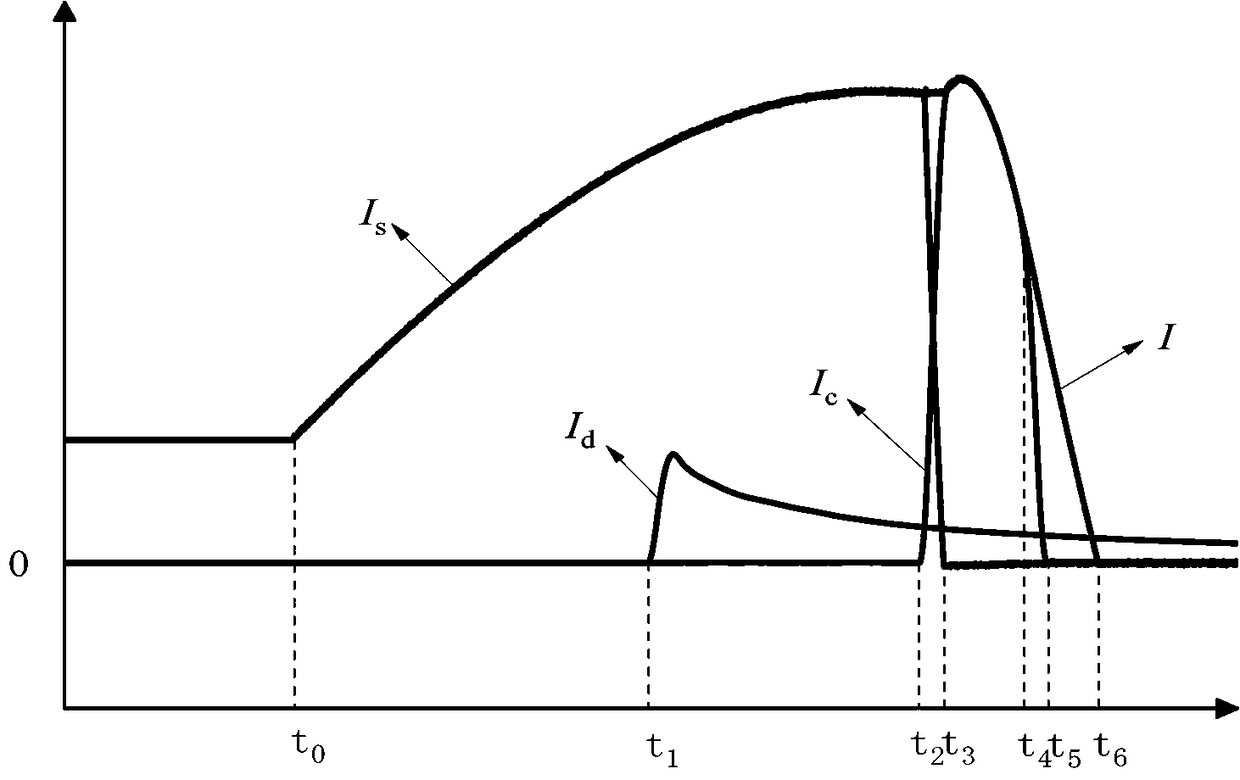

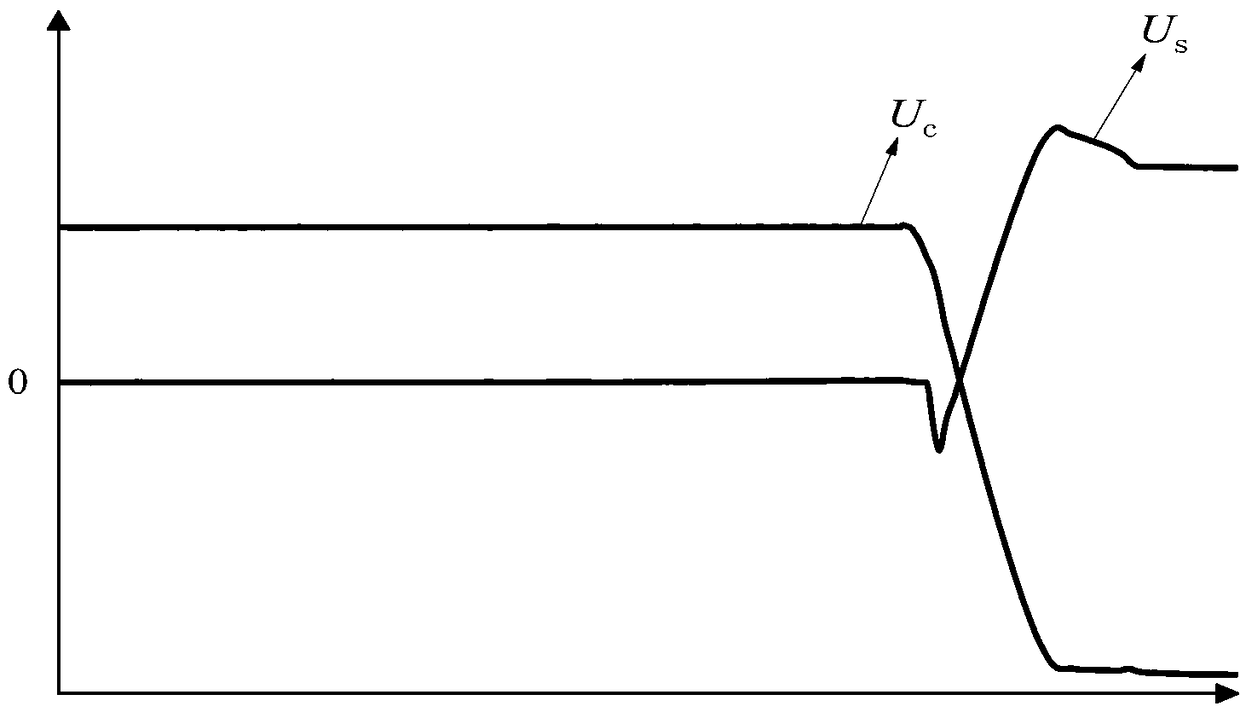

In a method for extinguishing an arc in a gas discharge chamber in which power is supplied to a gas discharge chamber and in which both with a current flow in a first direction and with a current flow in a second inverse direction there is produced a gas discharge, when an arc is identified, the power supply to the gas discharge chamber is interrupted, and residual energy which is in a supply line to the gas discharge chamber and / or in the gas discharge chamber is supplied to an energy store.

Owner:HUETTINGER ELECTRONICS GMBH & CO KG

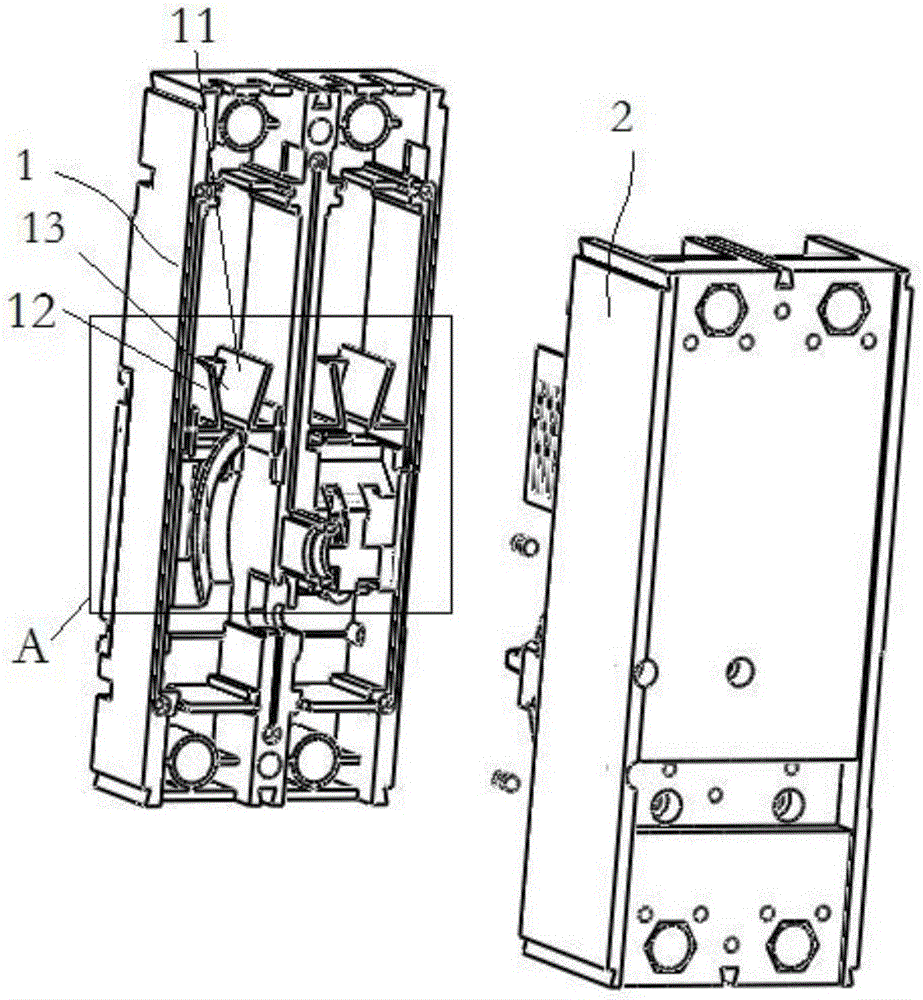

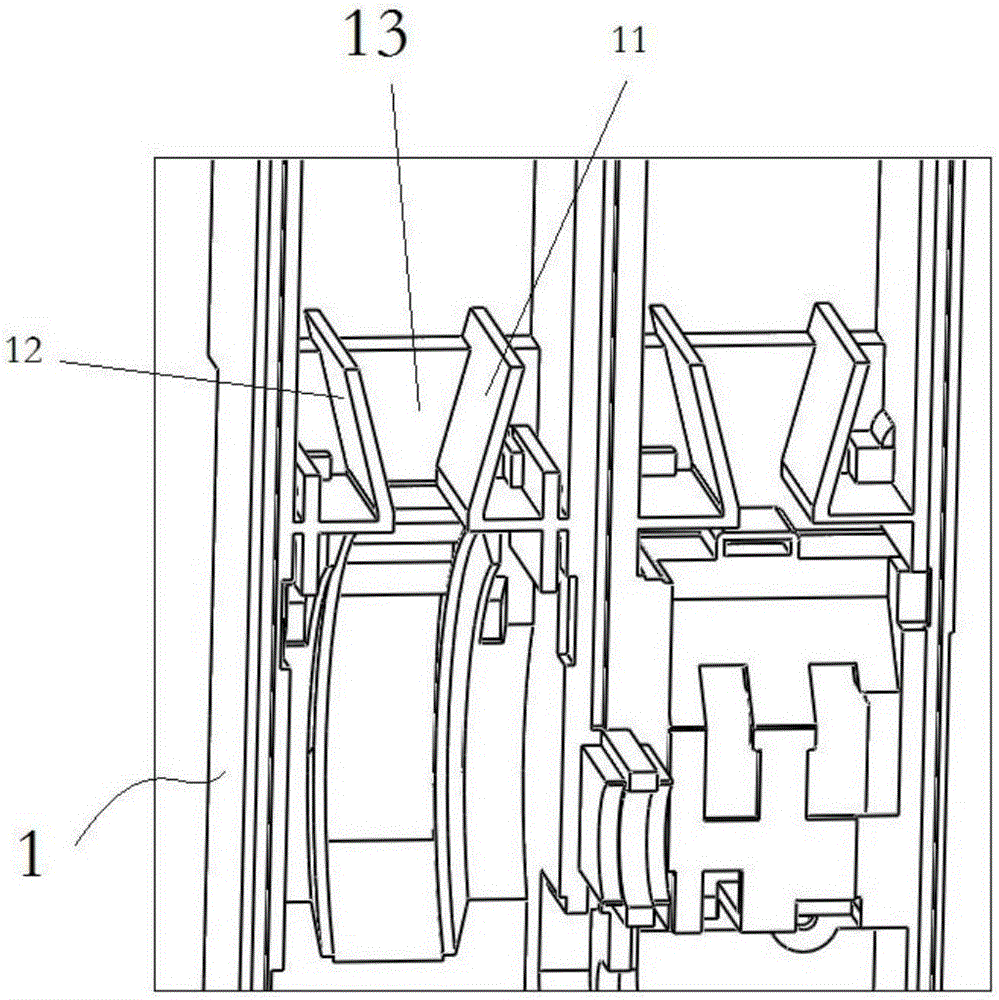

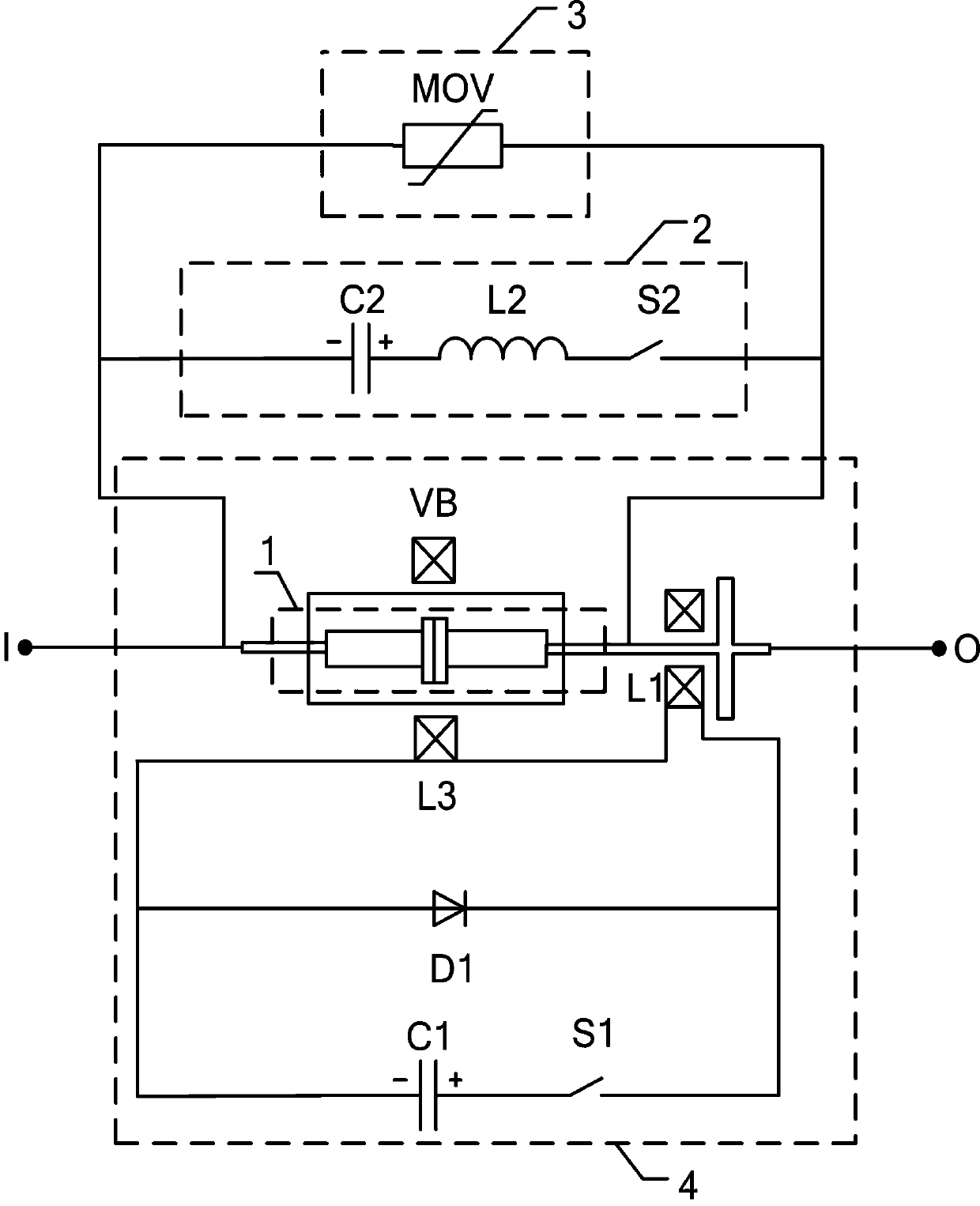

Direct-current vacuum circuit breaker

ActiveCN109360764AImprove breaking capacityIncrease the effective areaHigh-tension/heavy-dress switchesAir-break switchesCapacitanceEnergy absorption

The invention discloses a direct-current vacuum circuit breaker, which comprises a normal current branch, a conversion branch, an energy absorption branch and a magnetic field generating branch. The magnetic field generating branch is formed by sequential series connection of a drive capacitor C1, a repulsion coil L1 and a high-voltage cable L3 wound around an arc extinguishing chamber. A diode D1is parallelly connected to two sides of the L1 and the L3, and a stable and durable longitudinal magnetic field is generated in the arc extinguishing chamber through long-time follow current of the diode D1 by the repulsion coil L1 and the high-voltage cable L3 after discharging of the drive capacitor C1. The direct-current vacuum circuit breaker has advantages that the effective magnetic field can be generated without grooving a contact of the arc extinguishing chamber, contact area increasing, arc energy reduction, circuit breaker switching capacity increasing and the like are achieved, andthe direct-current vacuum circuit breaker is applicable to high-current power systems.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

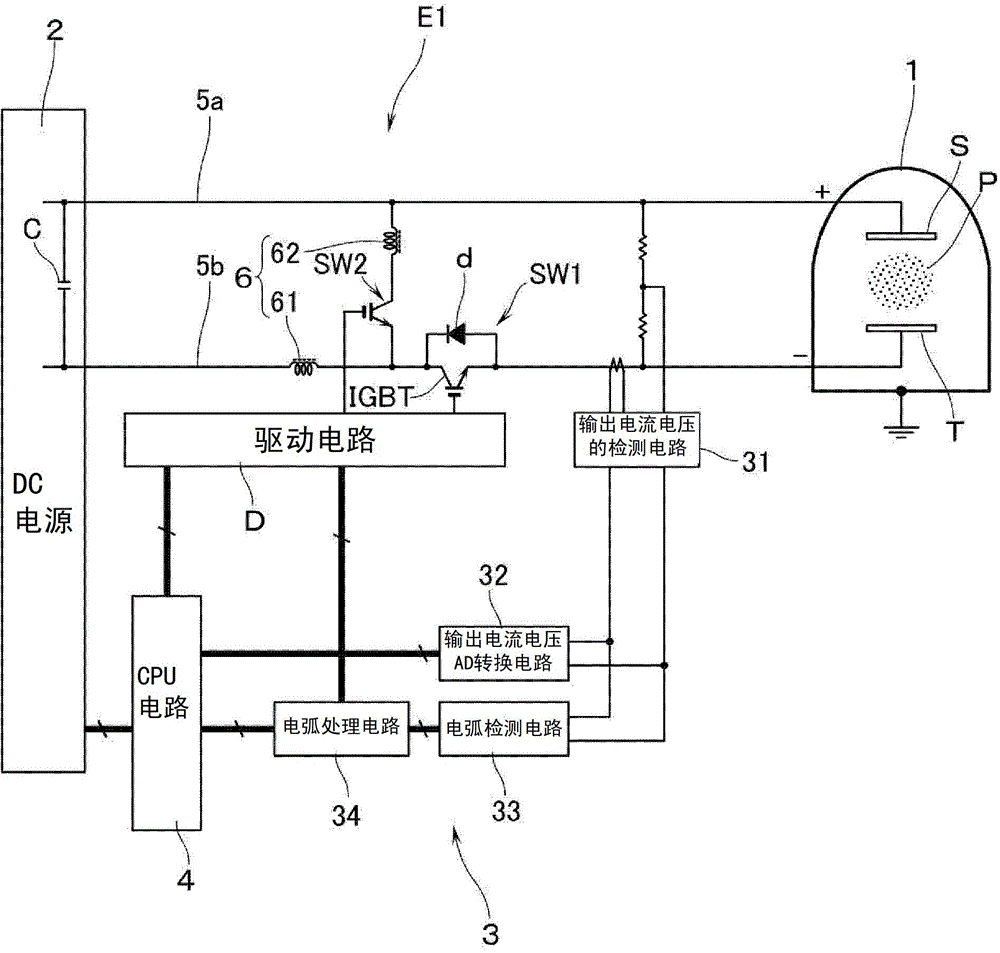

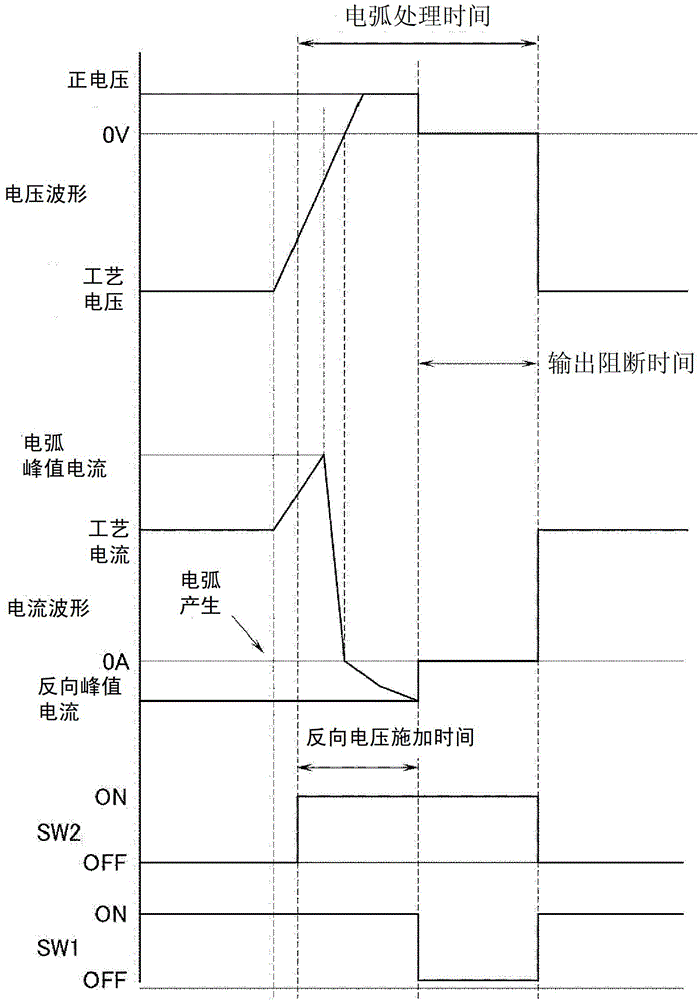

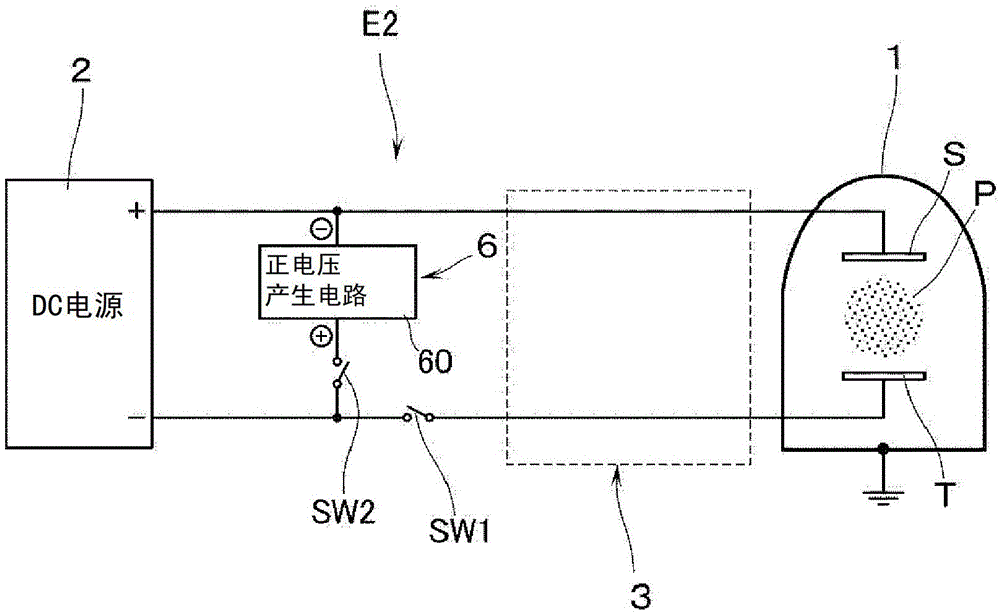

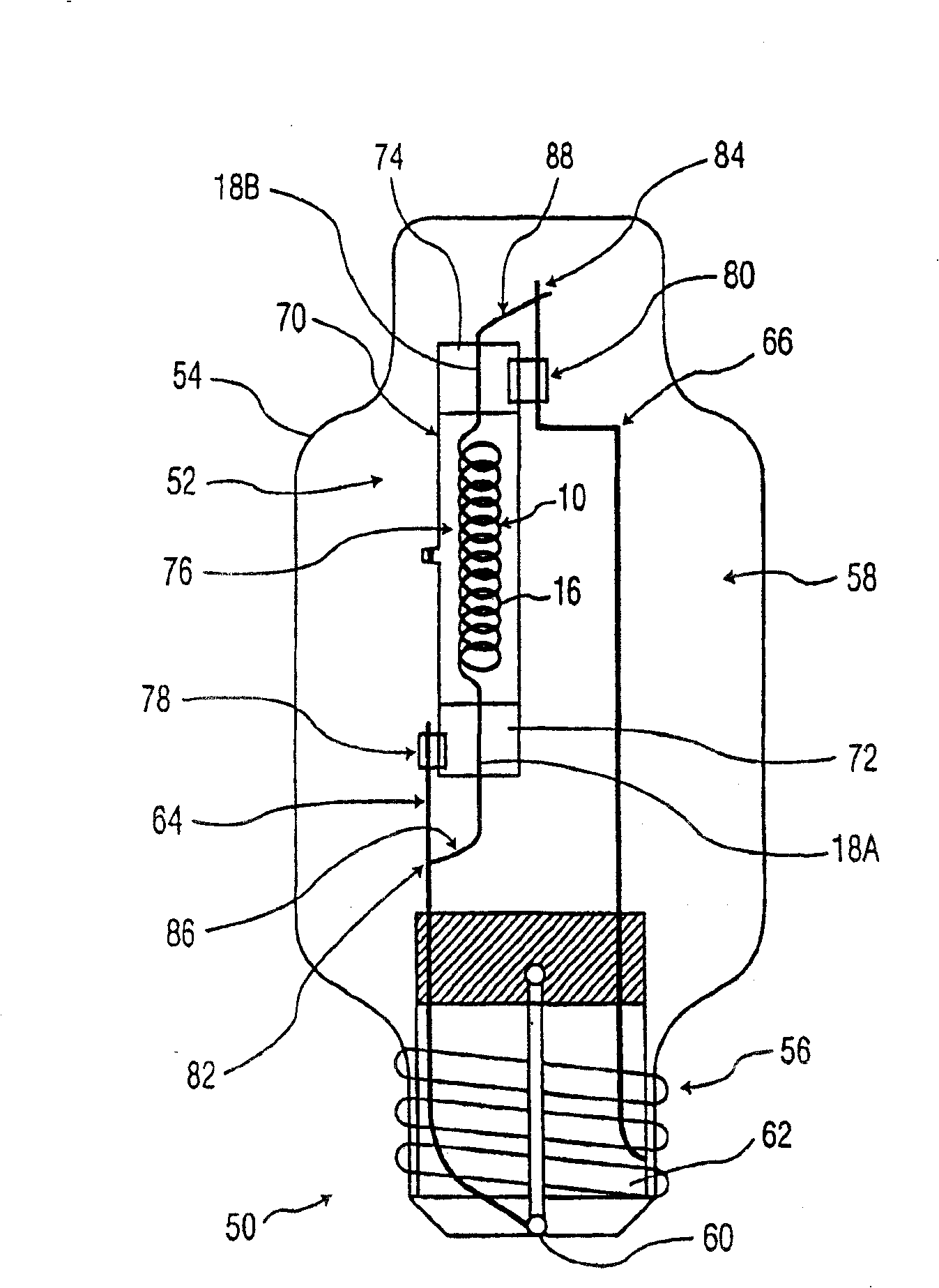

Direct current power supply device

ActiveCN103069928AReduce arc energyBest Arc Suppression TreatmentElectric discharge tubesVacuum evaporation coatingElectricityElectric power

Provided is a direct current power supply device, with which it is possible to apply a positive voltage and eliminate arc discharge, and to reliably suppress recurrences of arc discharge after said elimination thereof when normal operation is restored. The direct current power supply device comprises: a direct current power supply unit that injects electricity into a target; an arc sensor unit; a first switching element (SW1) disposed in series with the negative output; a second switching element (SW2) and an inverse voltage application unit that applies inverse voltage, which are disposed in parallel between the positive and negative outputs; and a control means (4). During normal operation, electricity is transmitted by the first switching element to the electrodes in a state wherein the application of inverse voltage from the inverse voltage application unit to the electrodes is interrupted by the second switching element. If an arc discharge is detected, inverse voltage electricity is transmitted to the electrodes by the second switching element from the inverse voltage application unit and applied over a prescribed interval. After said interval has elapsed, the transmission of electricity to the electrodes is cut off by the first switching element for a prescribed interval. The transmission of electricity to the electrodes recommences thereafter.

Owner:ULVAC INC

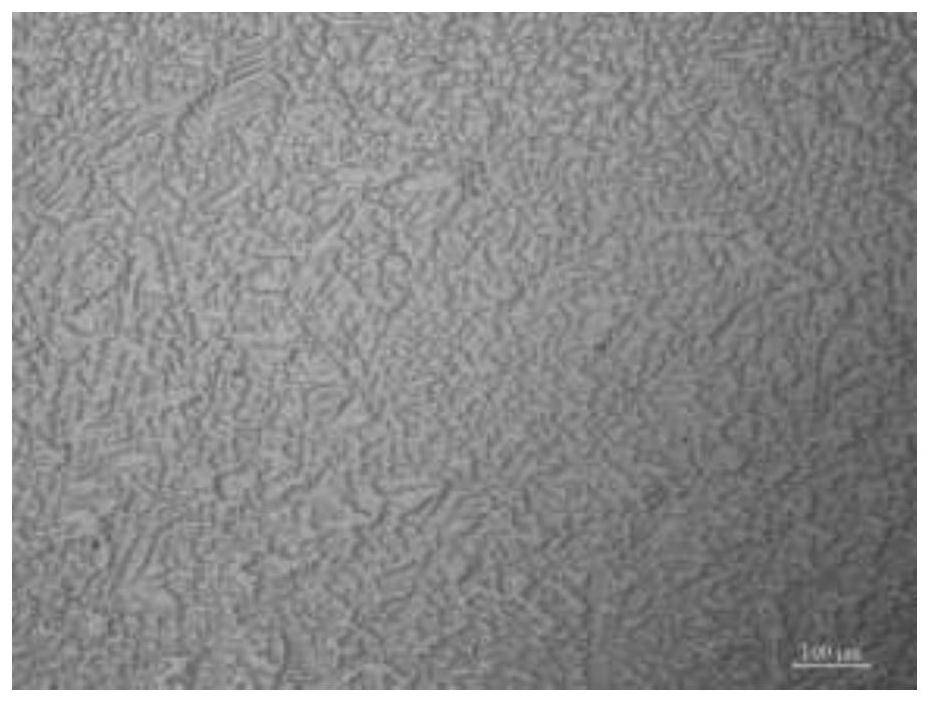

Process for preparing consumable electrode for electric arc melting by utilizing CuCr alloy powder material

PendingCN112458328AReduce arc energyReduce oxygen contentIncreasing energy efficiencySmelting processArc energy

The invention provides a process for preparing a consumable electrode for electric arc melting by utilizing a CuCr alloy powder material. The process specifically comprises the following steps of preparing the CuCr alloy powder material with the chromium content of 1-50 wt%; putting the prepared CuCr alloy powder material into a rubber sleeve, carrying out cool isostatic pressing molding, and arrying out rubber sleeve demolding after molding to obtain a consumable electrode bar blank; carrying out vacuum sintering treatment on the consumable electrode bar blank; and smelting the consumable electrode in a vacuum consumable arc smelting furnace in a high-current and low-voltage mode. According to the process, the consumable electrode is formed by pressing alloy chips or alloy powder, the phenomenon that the mixed powder is unevenly mixed due to performance difference is avoided, meanwhile, arc energy needed for melting the consumable electrode in the arc smelting process is reduced, thetemperature of a molten pool is reduced, and the microscopic structure of the material is optimized.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

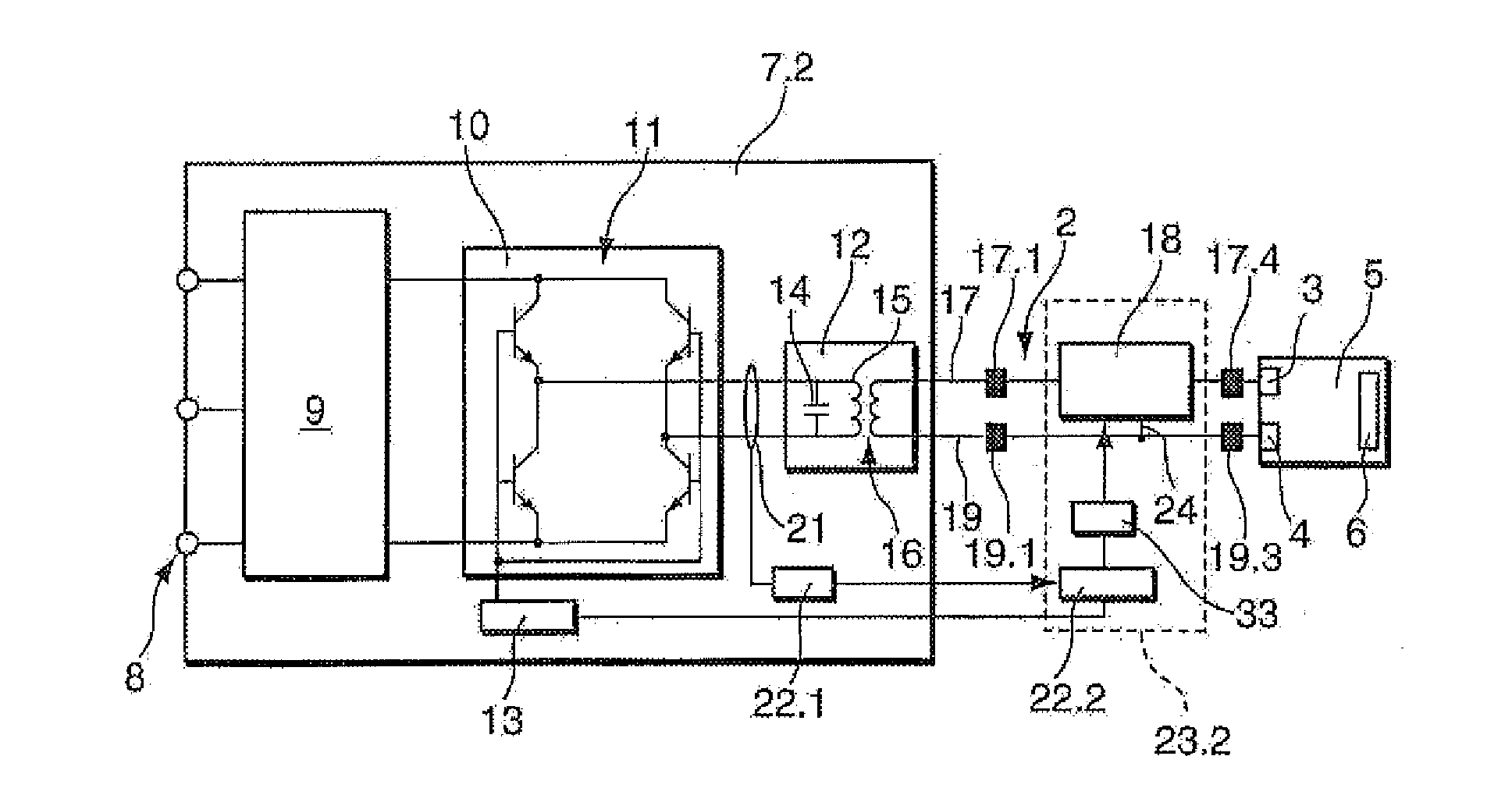

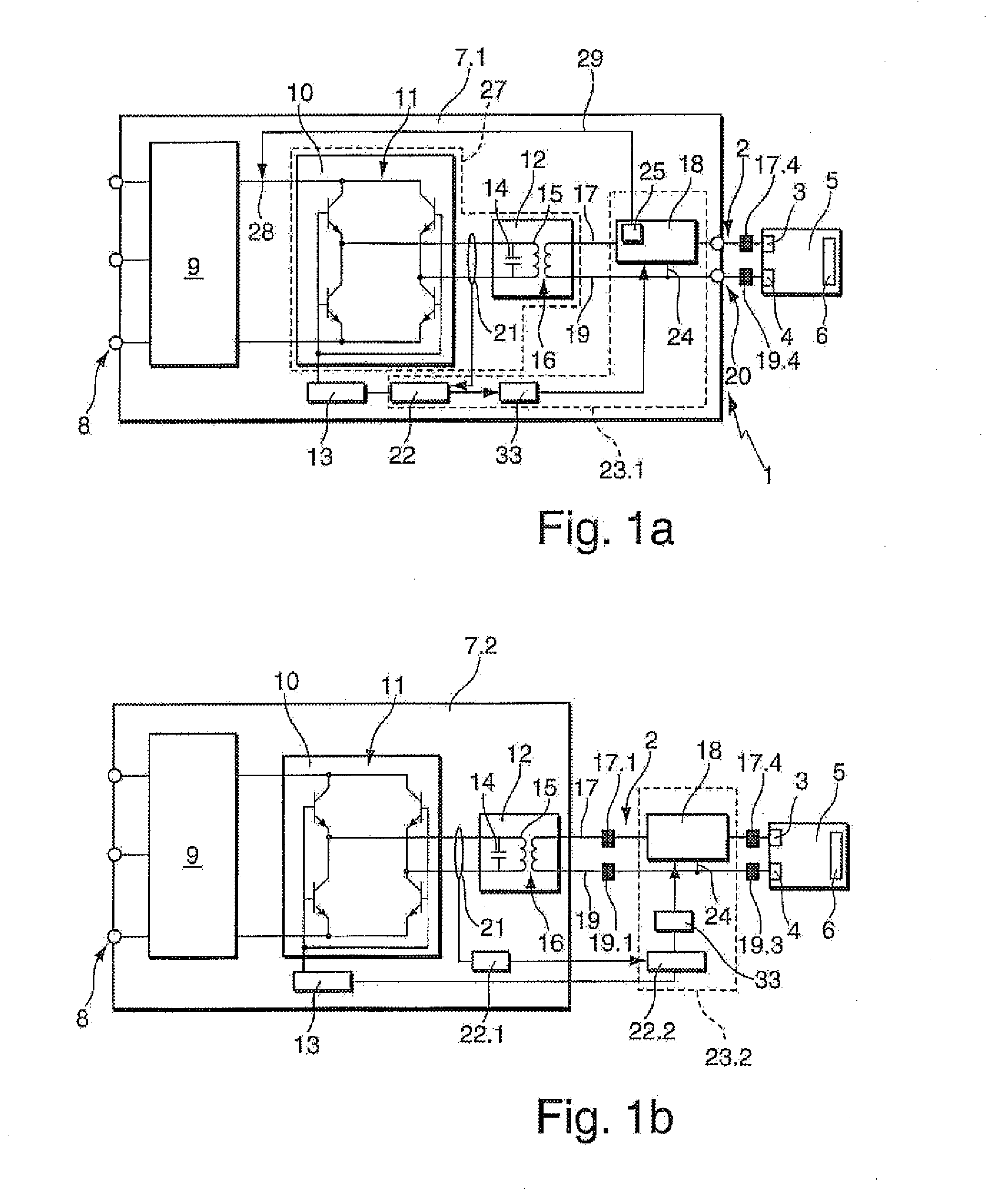

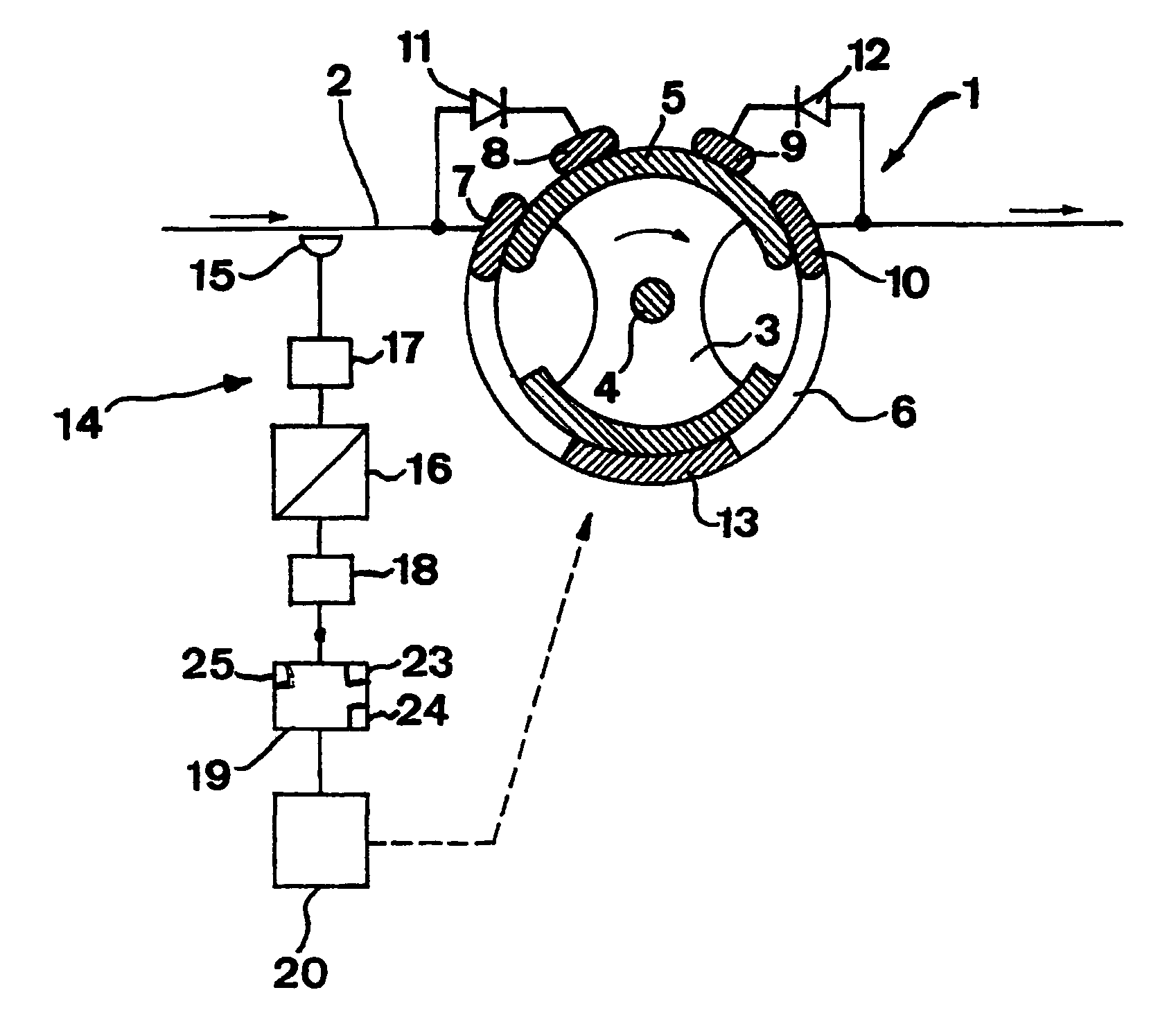

Method and an apparatus for controlling an electric switching device

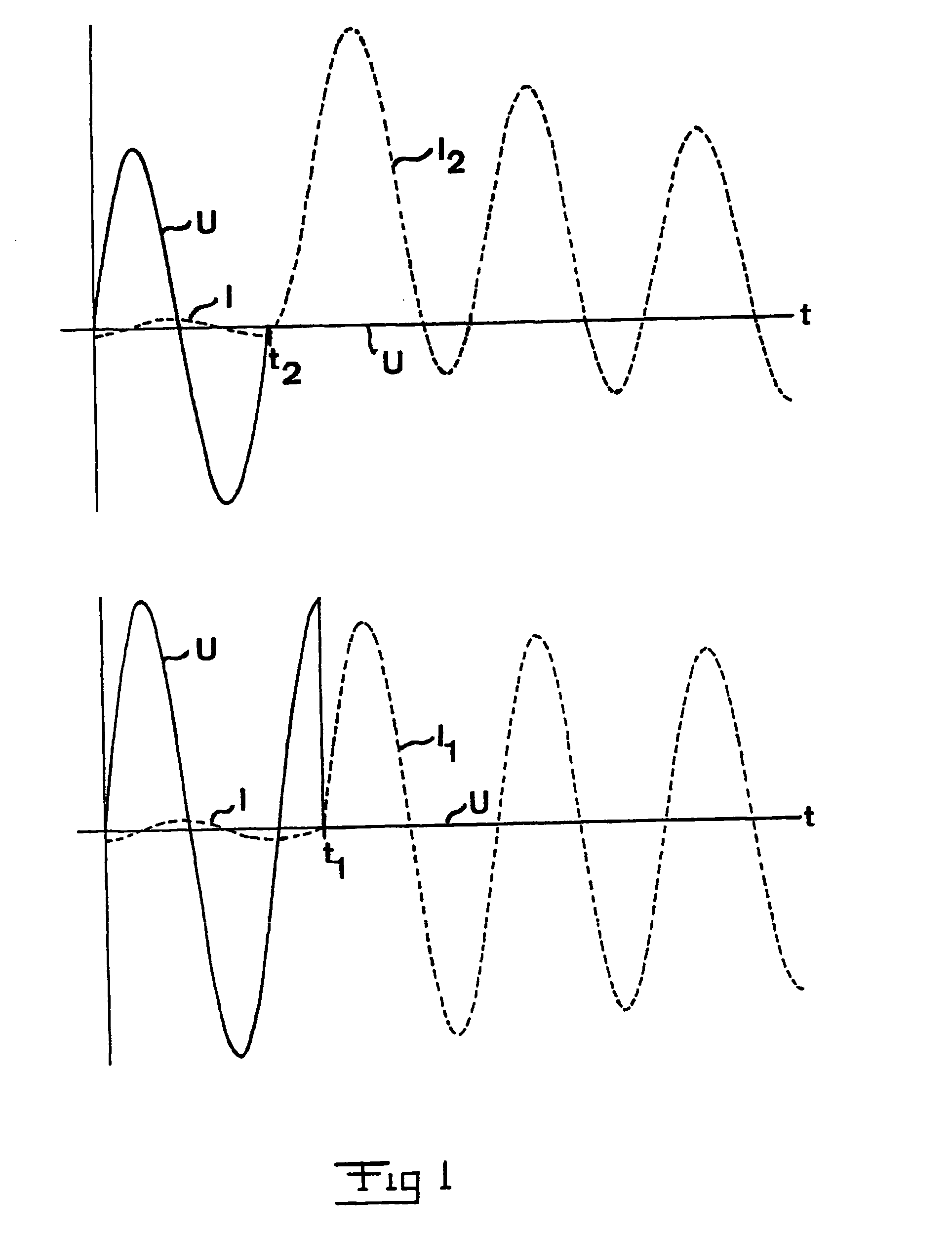

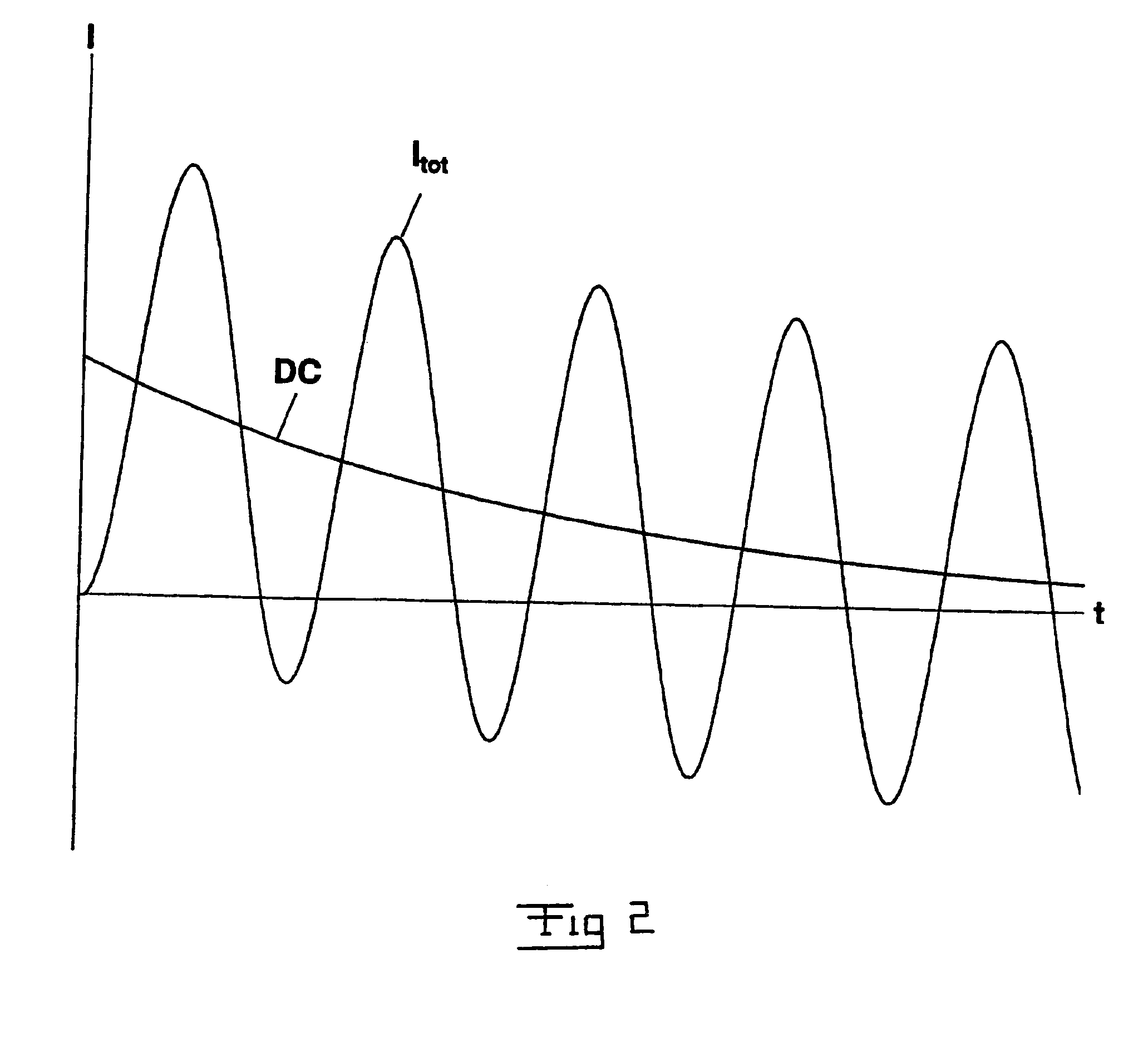

InactiveUS7166936B2Short breaking timeArc energy developed in conventional breakers may be minimizedTime-programme switchesHigh-tension/heavy-dress switchesElectricityCurrent limiting

An apparatus for controlling an electric switching device (1) for alternating current arranged in a current path for opening the switching device and for breaking the current in the current path after occurrence of a fault current comprises members (15) adapted to detect the current in the current path and a unit (20) adapted to control the electric switching device to break the current in the current path directly after a half wave of the alternating current having a peak value below a predetermined current limit value, so that the breaking is completed through a zero-crossing of the alternating current terminating a said half wave.

Owner:ABB GROUP SERVICES CENT

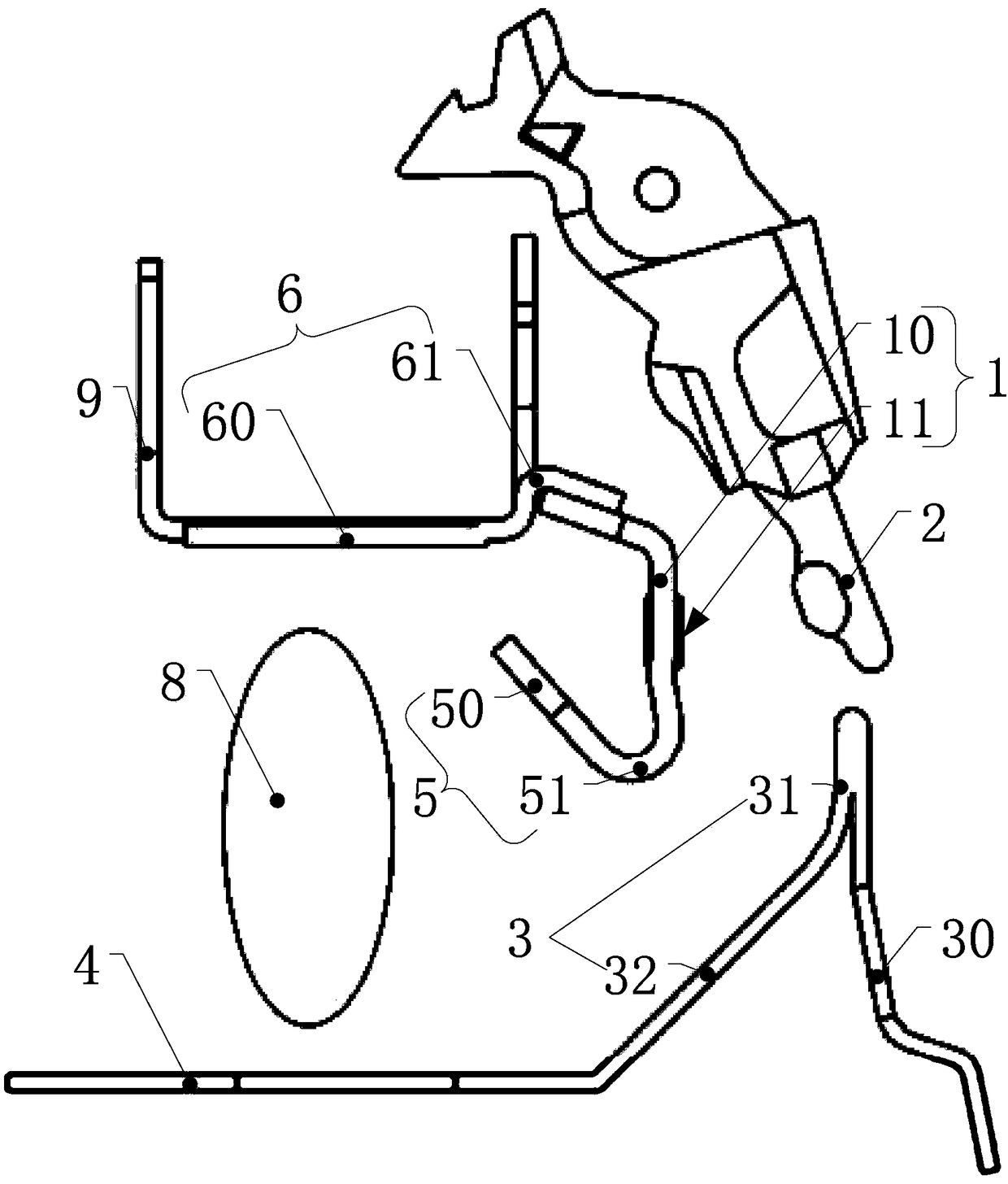

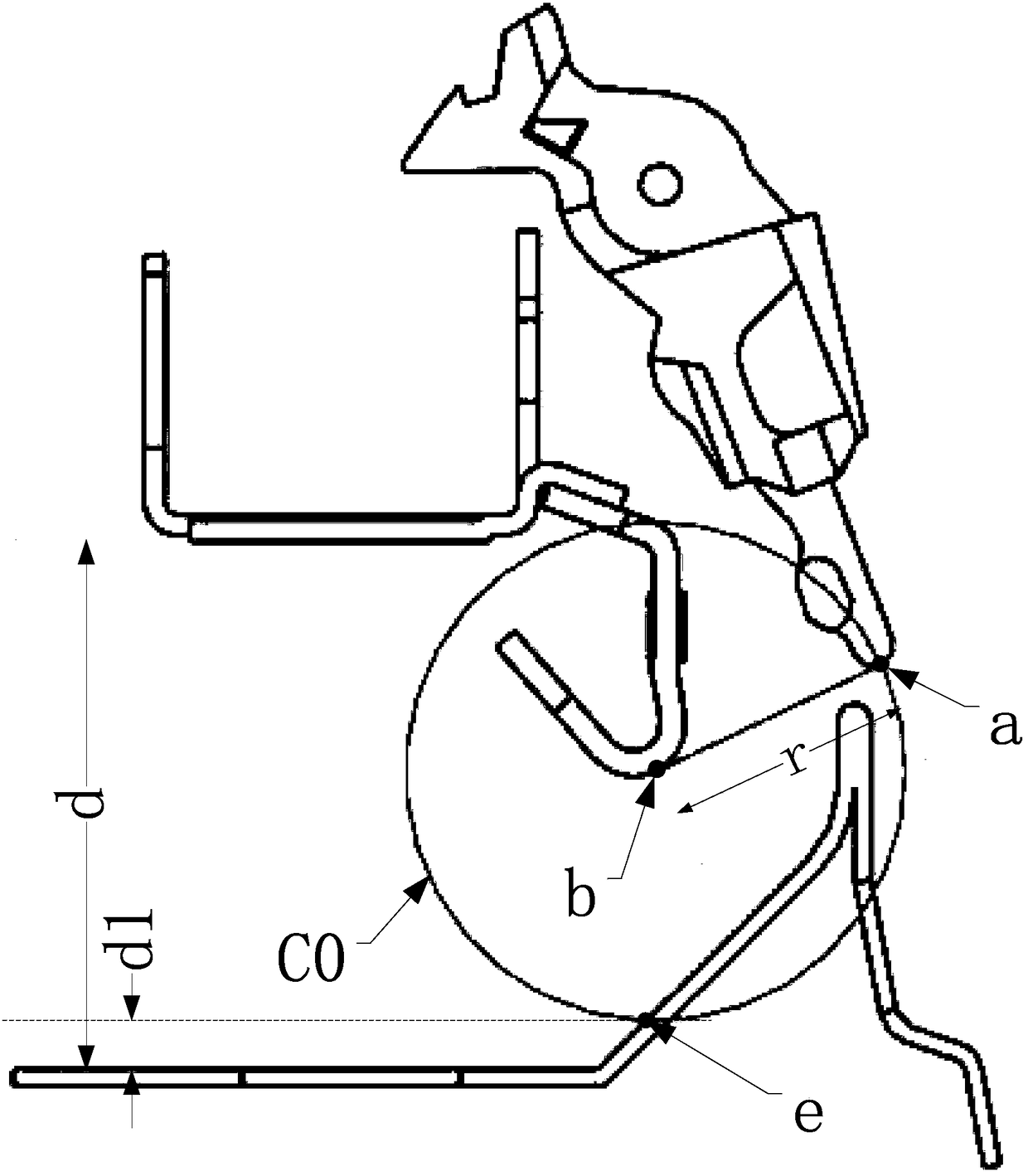

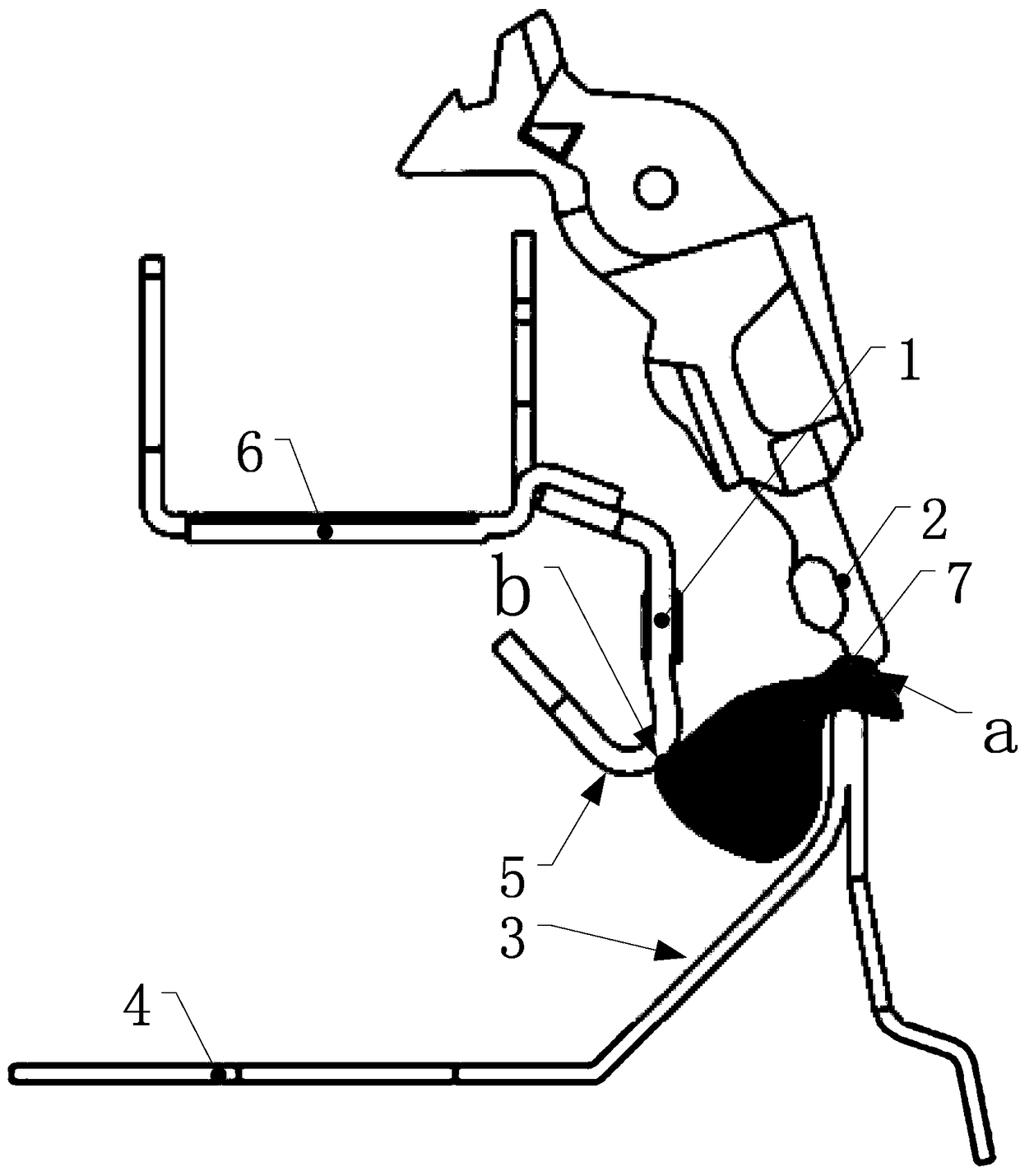

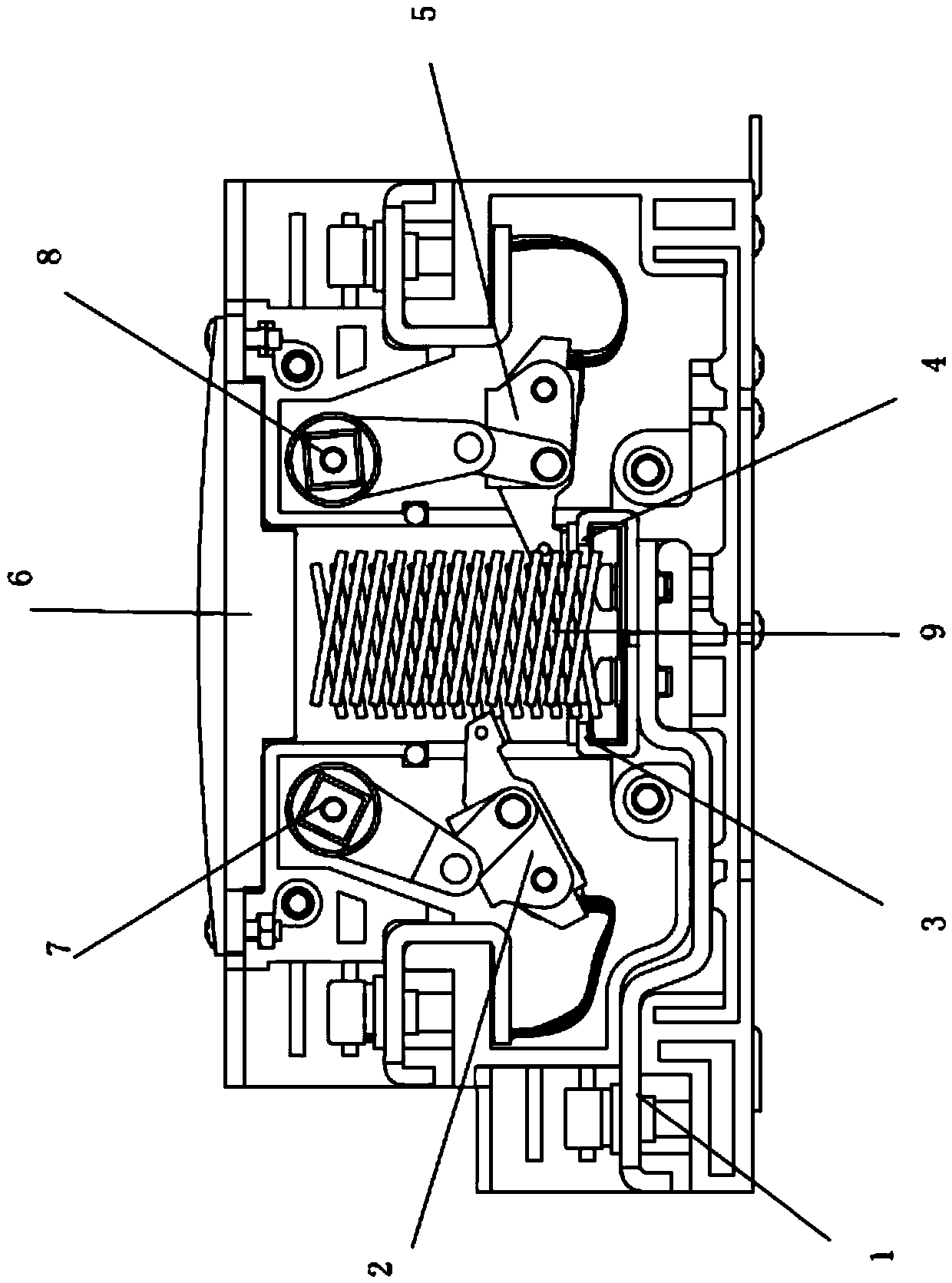

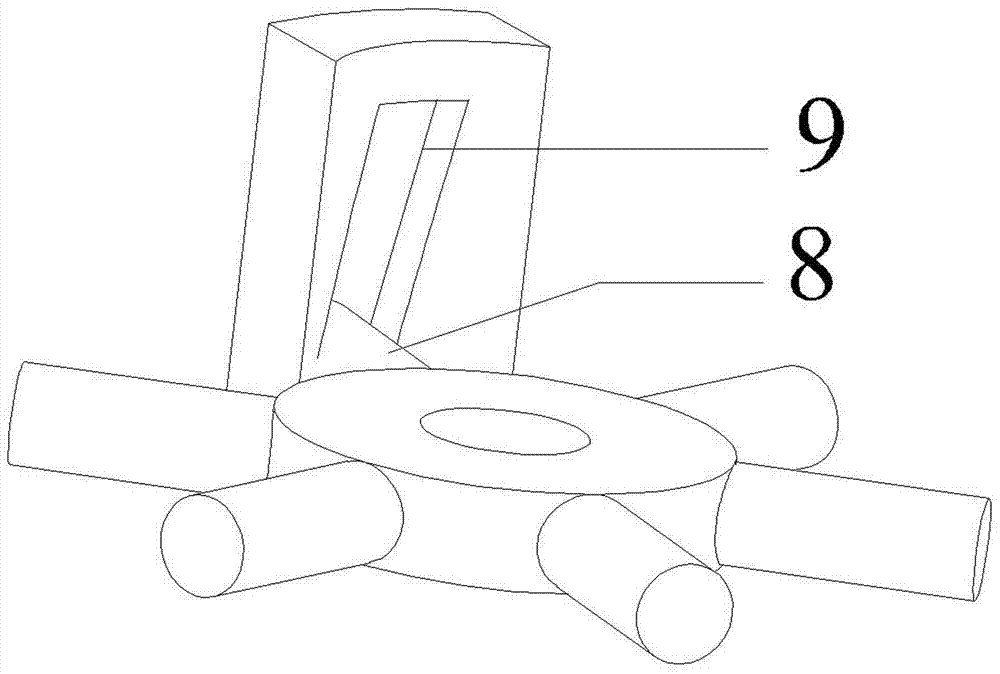

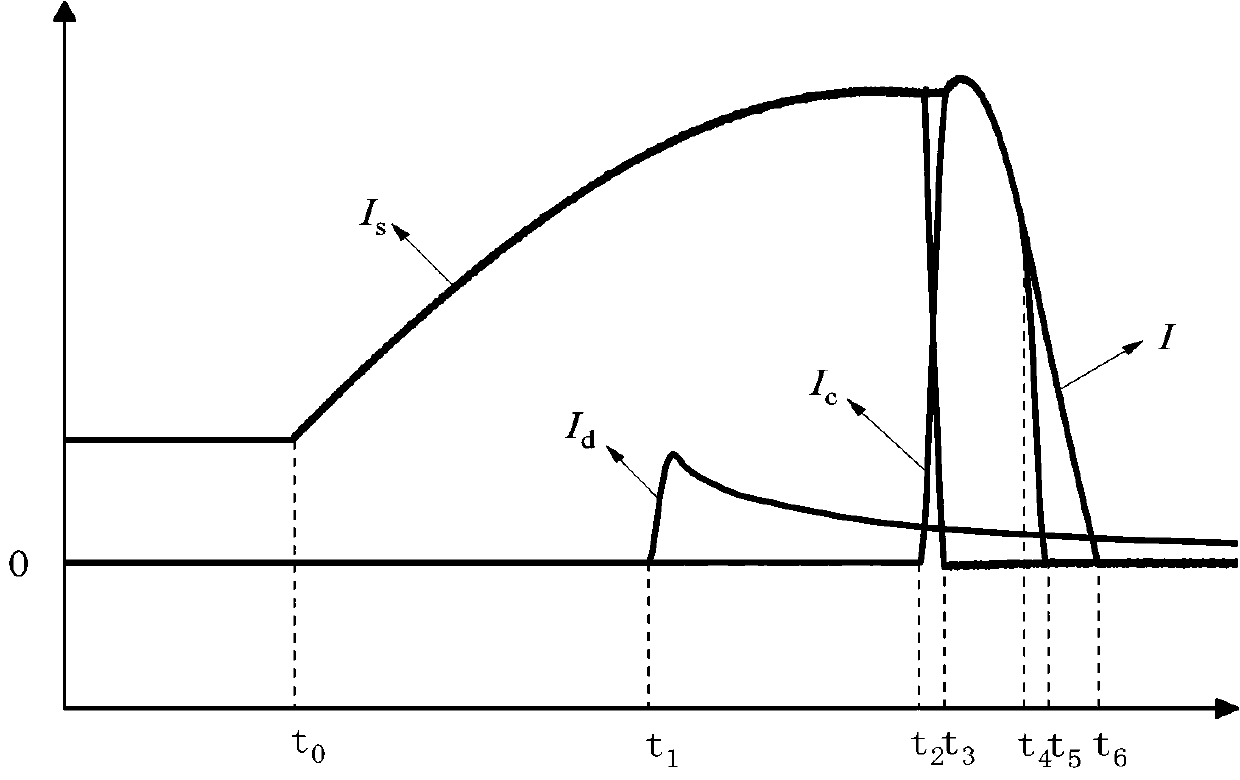

Arc striking and arc running structure

ActiveCN108447749AIncrease jump speedAvoid severe ablationElectric switchesCircuit-breaking switch detailsLow voltageLower pole

The invention relates to the field of a low-voltage electrical appliance, in particular to an arc striking and arc running structure. The arc striking and arc running structure comprises a static arcrunning way, a movable arc running way, an upper pole plate and a lower pole plate, wherein the static arc running way is connected with a static contact, the movable arc running way is matched with amovable contact, the upper pole plate and the lower pole plate are arranged in parallel, the distance between the upper pole plate and the lower pole plate is d, the static arc running way is arranged between the upper pole plate and the lower pole plate and is arranged opposite to the movable arc running way, the static arc running way comprises a static arc running way arc part, the static arcrunning way arc part protrudes towards the movable arc running way and is connected with the static arc running way, the movable contact is arranged at maximum opening distance, a tangential line is led from a tail end of the movable contact to the static arc running way arc part, the tangential line and the static arc running way arc part are tangent at a tangential point b, the distance betweenthe tail end of the movable contact and the tangential point b is r, a circle C0 is made by taking the tangential point b as a circle center and r as radius, the circle C0 and the movable arc runningway intersects at a point e, the vertical distance between the point e and the lower pole plate is d1, and d1 is smaller than or equal to d fourth. By the arc striking and arc running structure, rapidjump of an arc is achieved, and serious ablation of the arc to an arc extinguishing chamber is prevented.

Owner:SEARI ELECTRIC TECH

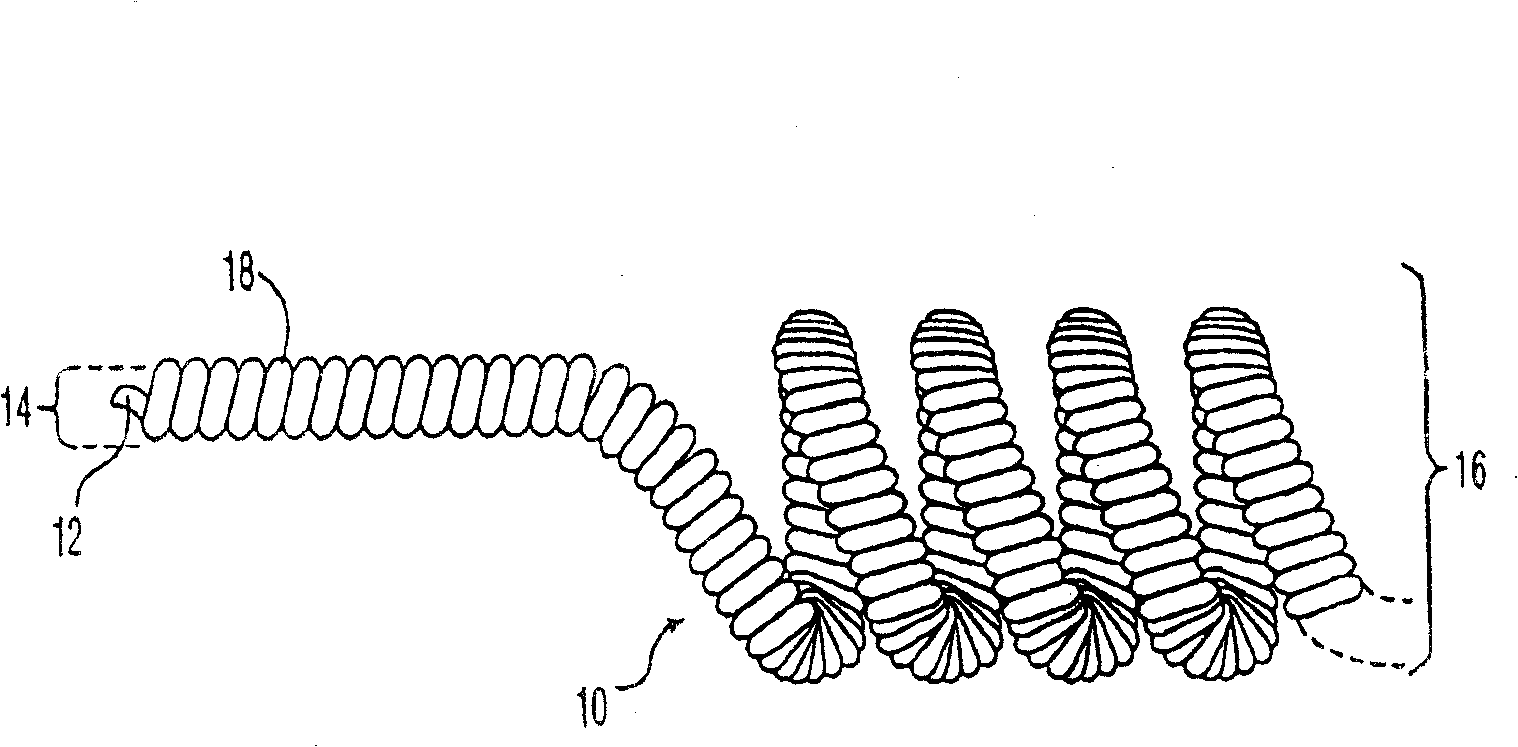

Halogen incandescent lamps

InactiveCN100437891CShorten the timeReduce arc energyIncadescent body mountings/supportLamp incadescent bodiesEngineeringTungsten filament

A lamp has a base and a light-transmitting soft-glass lamp envelope sealed to the base to form a sealed lamp cavity which is filled with a non-oxidizing gas. Current supply leads are connected to the stem feedthroughs and extend into the lamp cavity. A halogen incandescent burner is located in the lamp cavity and has a light-transmitting hard-glass burner envelope which encloses a sealed burner cavity filled with an inert gas containing halogen. The burner envelope has presses at its ends. A tungsten filament coil in the burner has extended legs at its ends that extend out of the burner cavity into the lamp cavity through the burner presses and are connected to the current supply leads in the lamp cavity to act as fuses which open upon breach of the lamp envelope, thus preventing further burner operations.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

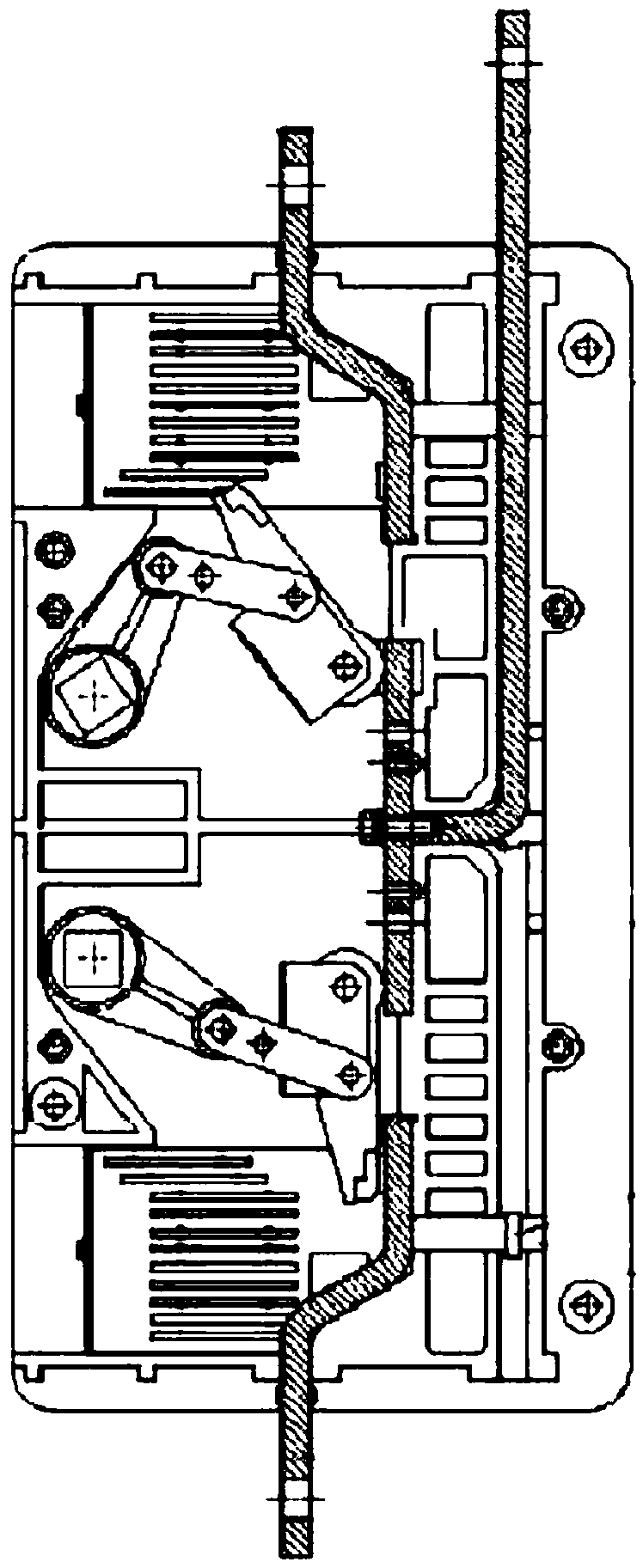

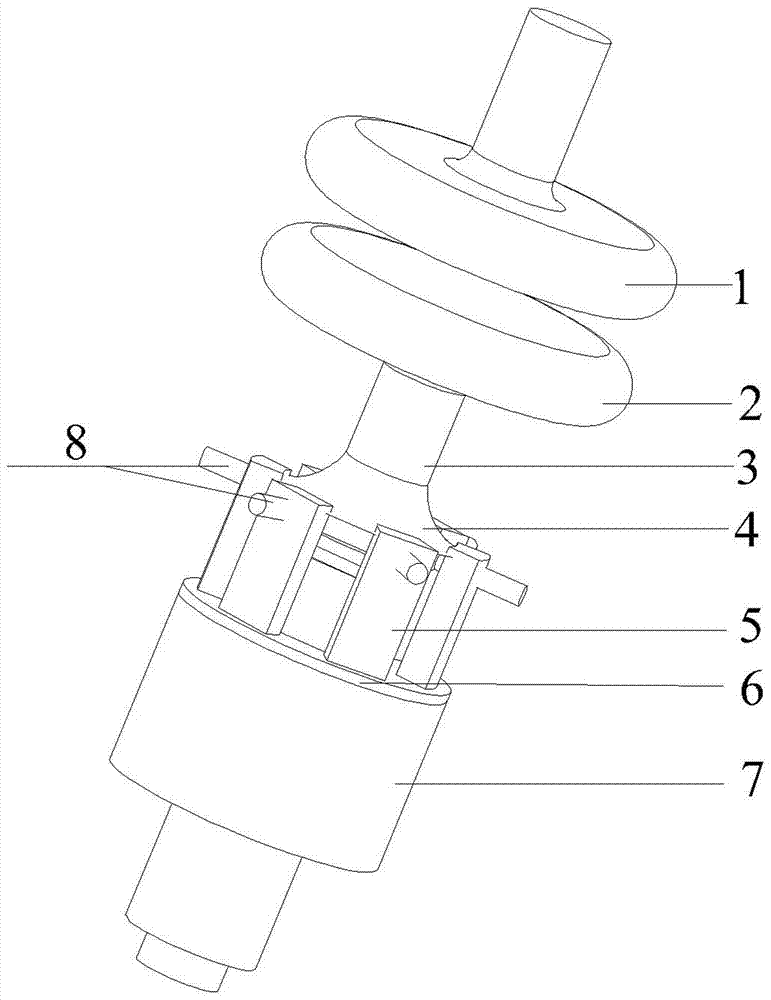

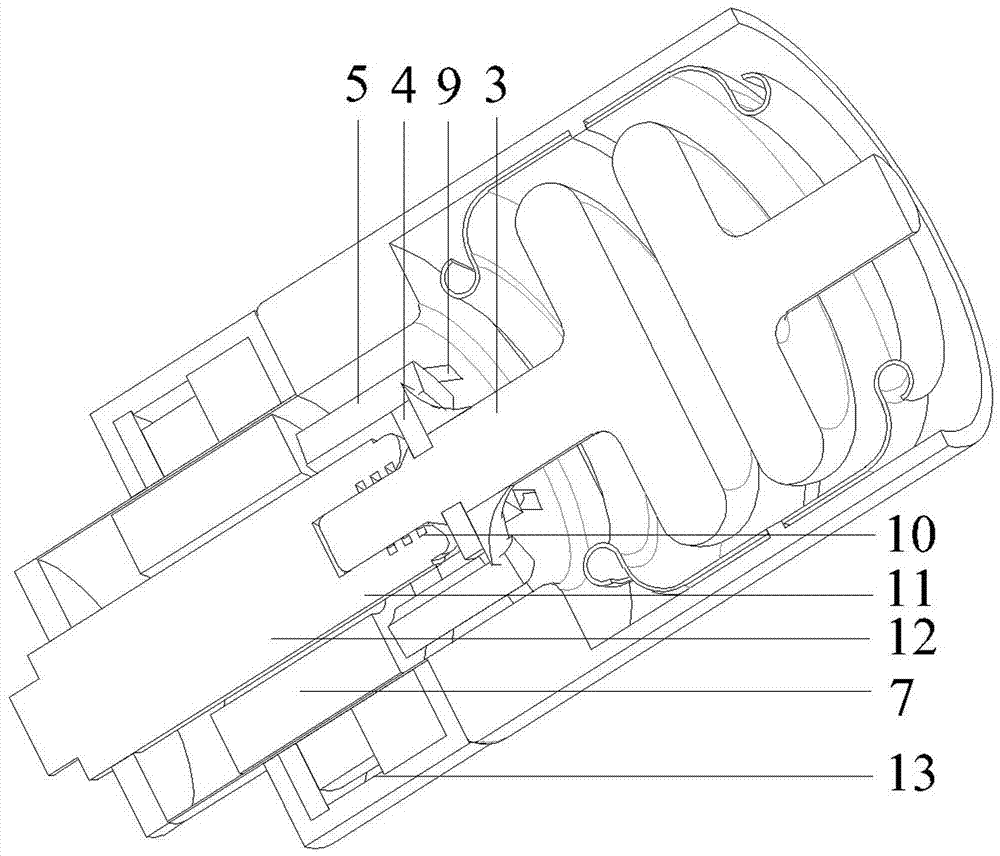

Contact arc-extinguishing system used for dual-power-supply automatic changeover switch

ActiveCN105374595AWork reliablySimple structureContacts enclosures/screensContact electric connectionUltrasound attenuationStandby power

The invention provides a contact arc-extinguishing system used for a dual-power-supply automatic changeover switch. The contact arc-extinguishing system comprises a commonly used power supply contact component, a backup power supply contact component and an arc-extinguishing shield. The backup power supply contact component and the commonly used power supply contact component are arranged in an opposing way. The moving contact acting surface of a commonly used power supply moving contact group and the moving contact actuating surface of a backup power supply moving contact group are arranged in different working planes. The arc-extinguishing shield is provided with a commonly used power supply arc-extinguishing chamber and a backup power supply arc-extinguishing chamber which are mutually isolated. The extension length of the commonly used power supply arc-extinguishing chamber and the backup power supply arc-extinguishing chamber along the longitudinal direction of the dual-power-supply automatic changeover switch is equivalent to distance from the commonly used power supply contact component to the backup power supply contact component. According to the contact arc-extinguishing system, the arc-extinguishing chambers are enabled to obtain maximum arc-extinguishing distance and arc-extinguishing time within the limited volume of the installing box of the dual-power-supply automatic changeover switch so that attenuation of arc energy is facilitated and a better arc extinguishing effect can be obtained; meanwhile, the contact arc-extinguishing system is simple in structure and stable and reliable in work.

Owner:BEIJING MINGRI ELECTRICAL EQUIP

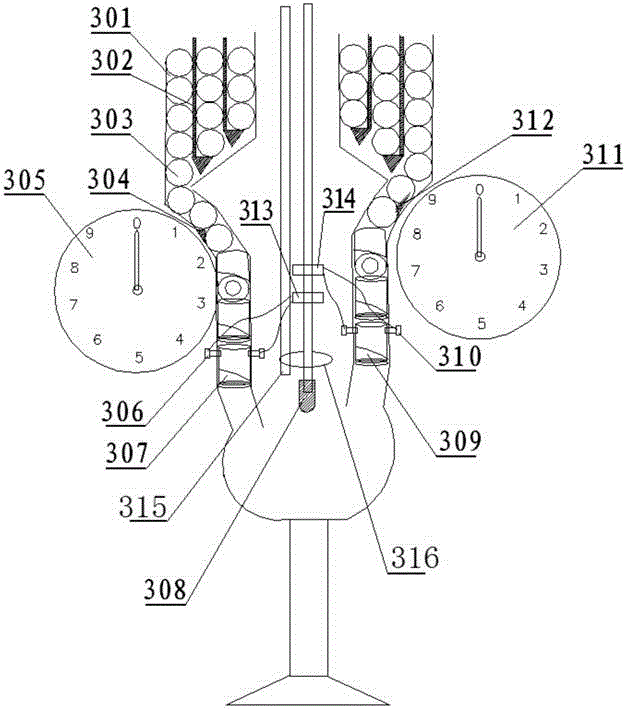

Combination cutter

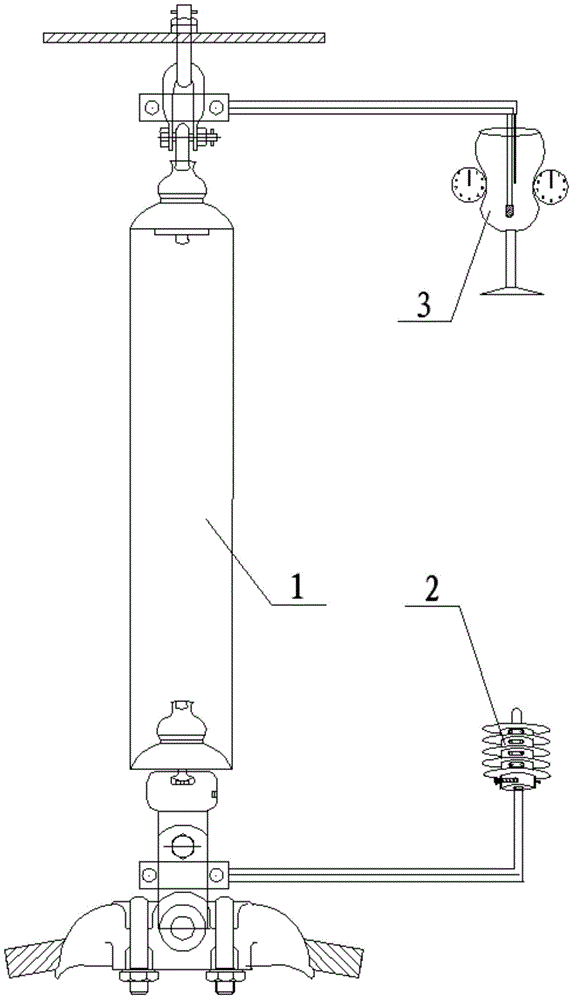

ActiveCN104701741AThe solution is not easy to extinguishSolve the phenomenon of re-ignitionSpark gap detailsOvervoltage arrestors using spark gapsEngineeringArc extinction

The invention discloses a combination cutter. The combination cutter comprises an arc extinction device with multiple breaks and a horizontal type arc extinction device, which are fixedly installed at two ends of an insulator respectively through a connection armor clamp I and a connection armor clamp II, wherein an arc extinction route composed of multiple segments of arc extinction channels and arranged in Z-shaped circulation mode is arranged on a main body of the arc extinction device with the multiple breaks, a left side bullet storage bin, a right side bullet storage bin and an arc strike electrode II are arranged in the horizontal type arc extinction device, vertical rails used to transversely place arc extinction gas bullets are arranged in the left side bullet storage bin and the right side bullet storage bin, a preparation rail in a slope shape is arranged at the bottom of each vertical rail, and a gas bullet trigger position is arranged at the tail end of each preparation rail. The combination cutter is simple in structure, reasonable in design, strong in arc extinction ability, stable and reliable in work, capable of counting, and convenient to maintain and replace in a later period.

Owner:王巨丰 +1

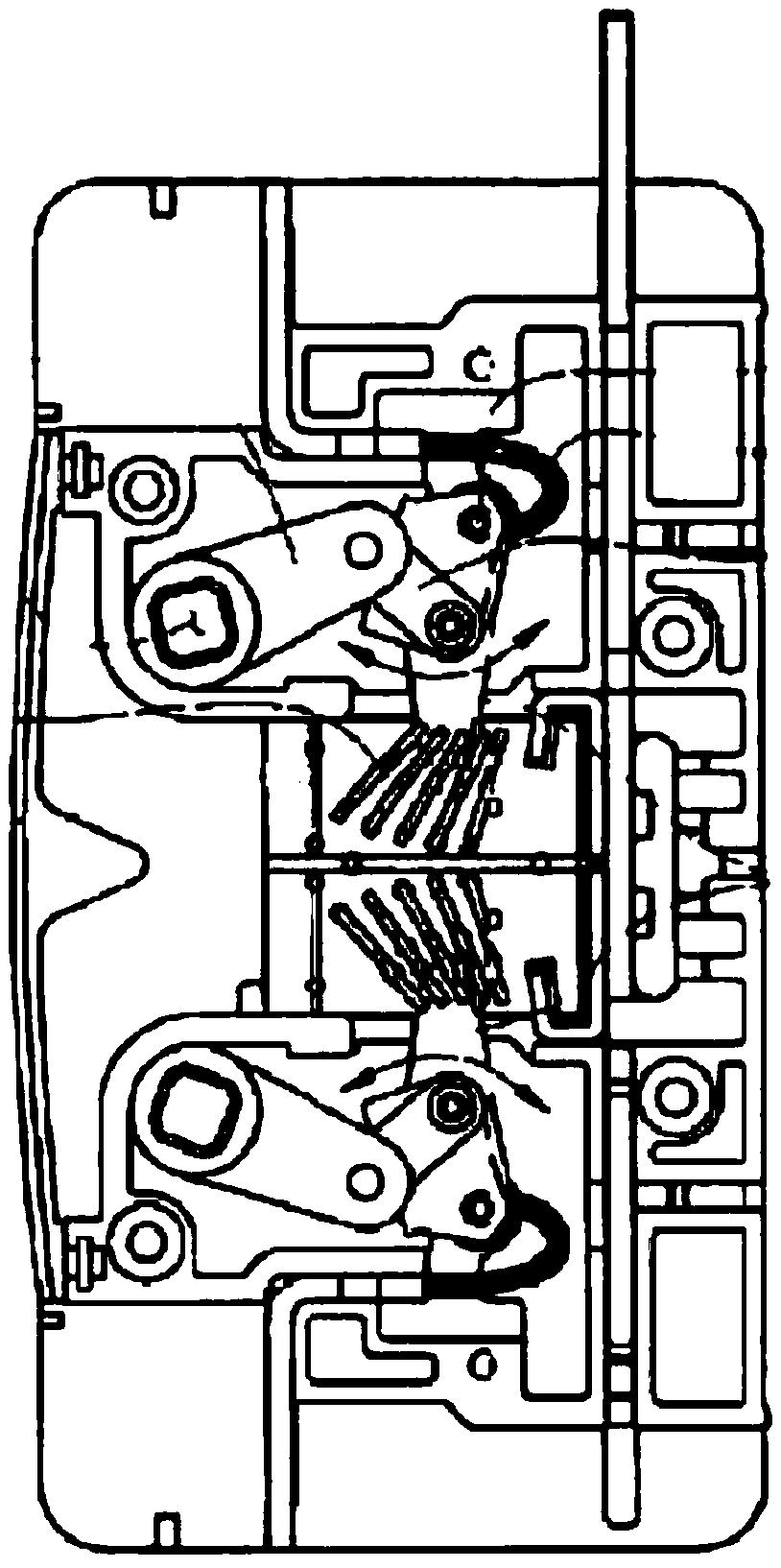

Self-powered type direct-current quick circuit breaker

InactiveCN102420084AExtended service lifeRealize passive operationCircuit-breaking switch detailsElectrical polarityArc energy

The invention discloses a self-powered type direct-current quick circuit breaker which comprises a circuit breaker switch main body, a first transient connecting device, a second transient connecting device, an arc voltage suppressing device and an energy absorbing device, wherein a series branch circuit consisting of the arc voltage suppressing device and the first transient connecting device is connected at two ends of the circuit breaker switch main body in parallel and is used for generating a suppression voltage of which the polarity is opposite to that of the arc voltage; and a series branch circuit consisting of the energy absorbing device and the second transient connecting device is connected at two ends of the circuit breaker switch main body in parallel and is used for absorbing arc energy generated by the circuit breaker switch main body in the switching in / off process. According to the self-power type direct-current quick circuit breaker, the switching on / off passive operation of the circuit breaker switch main body can be realized; meanwhile, the roles in reducing the arc energy and extinguishing the arc can be played; the electromagnetic pollution is avoided; and the service life of the circuit breaker can be prolonged.

Owner:XUJI GRP +1

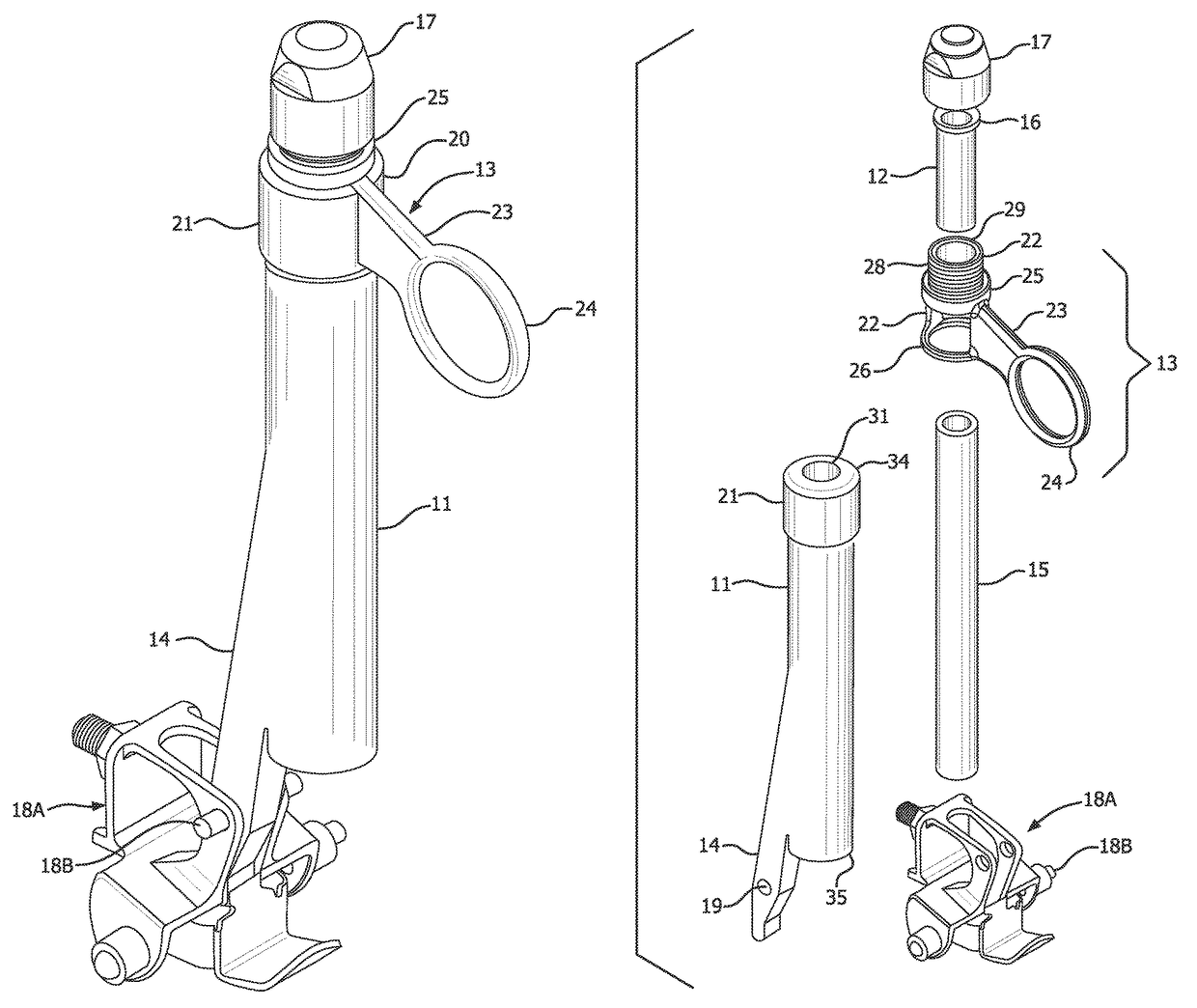

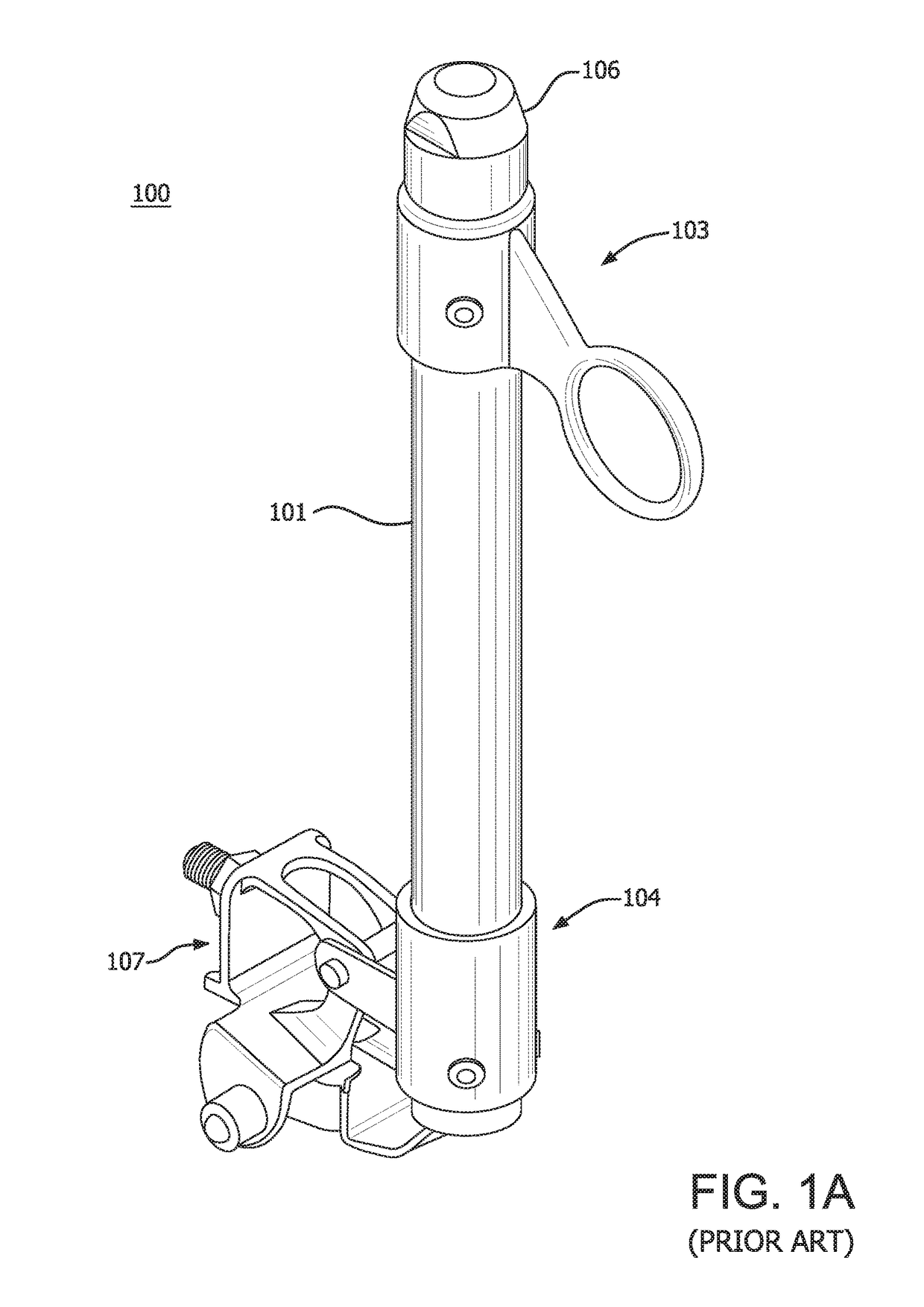

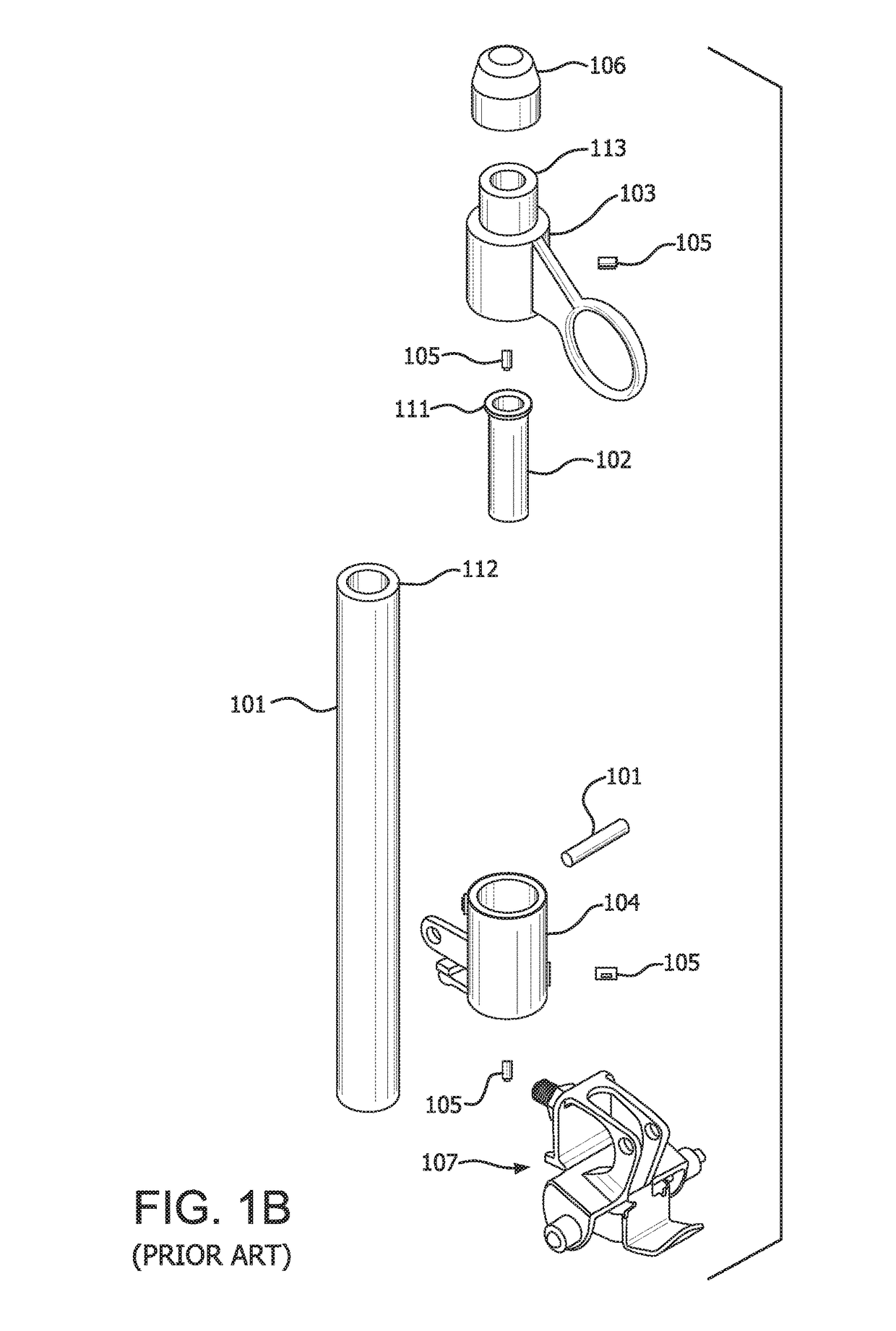

Fuse holder

ActiveUS9704674B2Reduce wall thicknessRaise the possibilityAir-break switch detailsEmergency protective devicesEngineeringScrew cap

A fuse holder for a fuse cutout includes a molded member including a short fuse tube section and a downwardly extending fin member adapted for securing to a trunnion assembly. An arc quenching liner is disposed in the interior of the tube section and a top casting is connected to the top of the fuse holder and adapted to receive and hold an arc flange of an arc sleeve on a top edge, thereby keeping the arc flange above the top casting. A conductive screw cap seals the assembly. The shorter tube and the provision of the arc flange above the top casting provides superior arc quenching properties.

Owner:HUBBELL INC

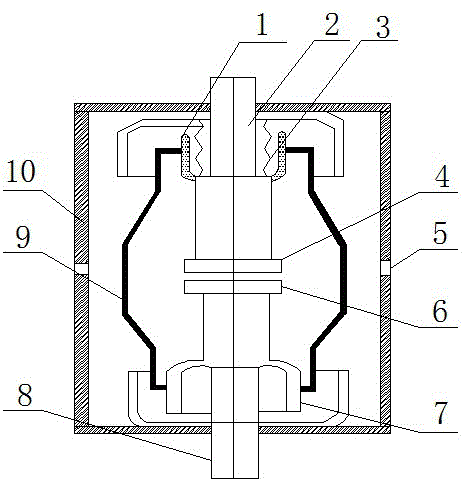

Vacuum switch with vacuum arc-extinguishing chamber

InactiveCN105590785AReduce wearExtended maintenance cycleHigh-tension/heavy-dress switchesAir-break switchesCombustionControl power

The invention discloses a vacuum switch with a vacuum arc-extinguishing chamber. The vacuum switch comprises insulating housings which are internally provided with an intermediate shielding cover. Furthermore the intermediate shielding cover is internally provided with a corrugated pipe protecting cover. The corrugated pipe protecting cover is internally provided with a corrugated pipe. Furthermore the corrugated pipe is internally provided with a dynamic conductive rod. One end of the dynamic conductive rod is provided with a moving contact, and furthermore one side of the moving contact is provided with a static contact. One end of the static contact is connected with a static conductive rod. A static grading shield is arranged outside the static contact. The insulating housings are connected with each other through an intermediate sealing ring. According to the vacuum switch with the vacuum arc-extinguishing chamber, arc is extinguished in a sealed container, thereby realizing no leakage of arc and hot gases; small clearance between 1mm and 40mm is realized between the static contact and the moving contact; and furthermore the vacuum switch with the vacuum arc-extinguishing chamber has advantages of short arc combustion time, low arc voltage, low arc energy, low contact wearing, large number of allowed on-and-off times, small inertia of the dynamic conductive rod, high suitability for high-frequency operation, small size of the operating mechanism, small size of the vacuum switch, small weight and low control power.

Owner:钟斐琴

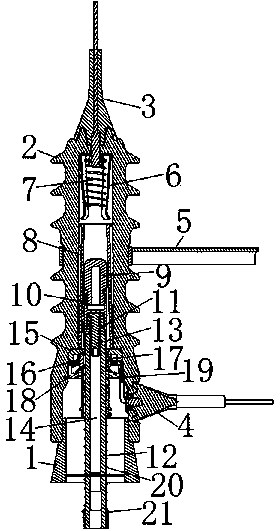

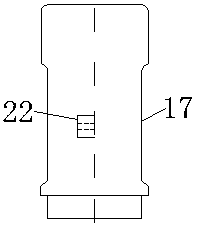

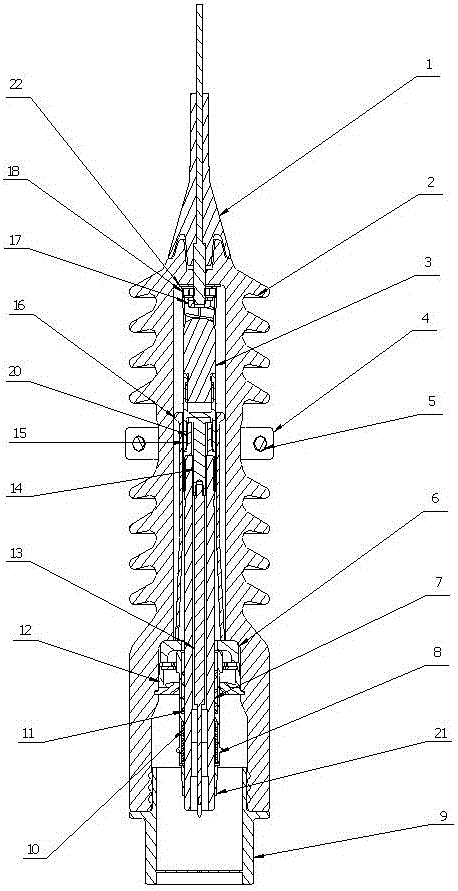

Fully-insulated enclosed fuse

PendingCN108493078AEnsure load breaking capabilityGuaranteed to workEmergency protective devicesEngineeringPorcelain insulator

The invention relates to a fully-insulated enclosed fuse comprising a rubber pedestal. An upper static contact is arranged at the upper part inside an outer insulating porcelain insulator; and an upper auxiliary spring is arranged inside the upper static contact. An arc extinguishing tube is arranged at the lower part of the upper static contact; and an arc extinguishing rod is arranged in the arcextinguishing tube. An upper moving contact is arranged at the lower end of the arc extinguishing rod and is connected with a fusion tube by a fusion tube connecting element. An arc shrinkage bar isarranged at the upper part inside the fusion tube and is connected with a fuse wire. A buffer cover is arranged at the upper part outside the fusion tube; a lower static contact is arranged at the inner side of the buffer cover; and a lower moving contact is arranged outside the fusion tube. The lower inner pipe of the fusion tube has a segmented stepped structure with the larger bottom and the smaller top. Besides, a fuse wire connection boss is arranged at one side with the central line corresponding to the straight line of the outer wall of the lower moving contact. The fully-insulated enclosed fuse has advantages of stable operation, high usage safety and reliability, powerful product carrier and breaking capabilities, and long service life.

Owner:江苏新澳电力技术有限公司

Electrode structure with rotation on-off

ActiveCN107086150AEasy to controlEvenly distributedHigh-tension/heavy-dress switchesAir-break switchesLinear motionRelative motion

The invention relates to the technical field of electric appliance switches, and specifically relates to an electrode structure with rotation on-off for a vacuum circuit breaker. The control capability of arc can be improved, the on-off performance of the vacuum circuit breaker is enhanced, and the rotation motion of the electrode is realized in an on-off process. The electrode structure comprises a static electrode assembly and a rotation movable electrode assembly, a movable electrode of the rotation movable electrode assembly and a static electrode of the static electrode assembly are switched on or switched off through relative motion, and the relative motion refers to linear motion and rotation motion at the same time.

Owner:华珑(辽宁)高新技术有限公司

Full-insulation closed-type load fuse

InactiveCN106449331ASimple structureReduce arc energyEmergency protective devicesEngineeringPorcelain insulator

The invention provides a full-insulation closed-type load fuse, and the fuse comprises an upper end insulating incoming wire and an external porcelain insulator. The upper end insulating incoming wire is disposed at the upper end of the external porcelain insulator. The interior of the external porcelain insulator is provided with an arc extinguishing rod, and the exterior of the external porcelain insulator is provided with a clamping ring. The clamping ring is provided with a bolt. The lower end of the interior of the external porcelain insulator is provided with a static contact end cover, and the static contact end cover is provided with a fuse tube. The lower end of the fuse tube is provided with a lower moving contact, and the bottom of the external porcelain insulator is provided with a rubber pedestal. The lower part of the fuse tube is provided with a compression spring, and a buffering spring is disposed above the compression spring. The interior of the static contact end cover is provided with a static contact part. The interior of the fuse tube is provided with a fuse, and the top of the fuse is provided with an arc shrinking rod, and the upper part of the arc shrinking rod is provided with an upper moving contact, wherein the exterior of the upper moving contact is provided with an arc extinguishing tube. The fuse reduces the arc performances, and guarantees the reliability of a product. The fuse reduces the loop resistance and temperature rise, improves the through-flow performance of the product body, optimizes the structure of the fuse tube, and greatly improves the current-carrying and breakage capabilities of the product.

Owner:HUBBELL ELECTRIC WUHU

Easy-breaking direct current breaker

ActiveCN105788987AIncrease pressureBreakout preventionElectric switchesCircuit-breaking switch detailsDc circuit breakerEngineering

The invention provides an easy-breaking direct current breaker. An arc extinguish chamber is mounted on a second case body and is provided with a side opening which is opposite to a first case body; a gas generating cover is mounted at a lower part inside the arc extinguish chamber and comprises two gas generating plates which are oppositely arranged and a baffle plate; the baffle plate is opposite to the side opening and is arranged closely to the second case body; a moving contact and a fixed contact are mounted inside an installing space; the breaking position is inside a hold space and is close to the baffle plate; when arc is generated during the breaking of the moving contact and the fixed contact, the gas generating plate and the baffle plate are triggered by the arc, and large quantity of gas is generated to push the arc to move in a direction away from the baffle plate; one side, facing the hold space, of arc extinction chute plates installed at the upper side of the inside of the arc extinguish chamber is provided with a lower part opening; the lower part opening is tapering in the direction from the second case body to the first case body; the arc is blocked during the process of moving by the arc extinction chute plates with tapering lower part opening continuously so that the arc cannot rush out from the side opening of the arc extinguish chamber but can only enter the space between the arc extinction chutes and be extinguished as soon as possible.

Owner:ZHEJIANG PEOPLE ELE APPLIANCE

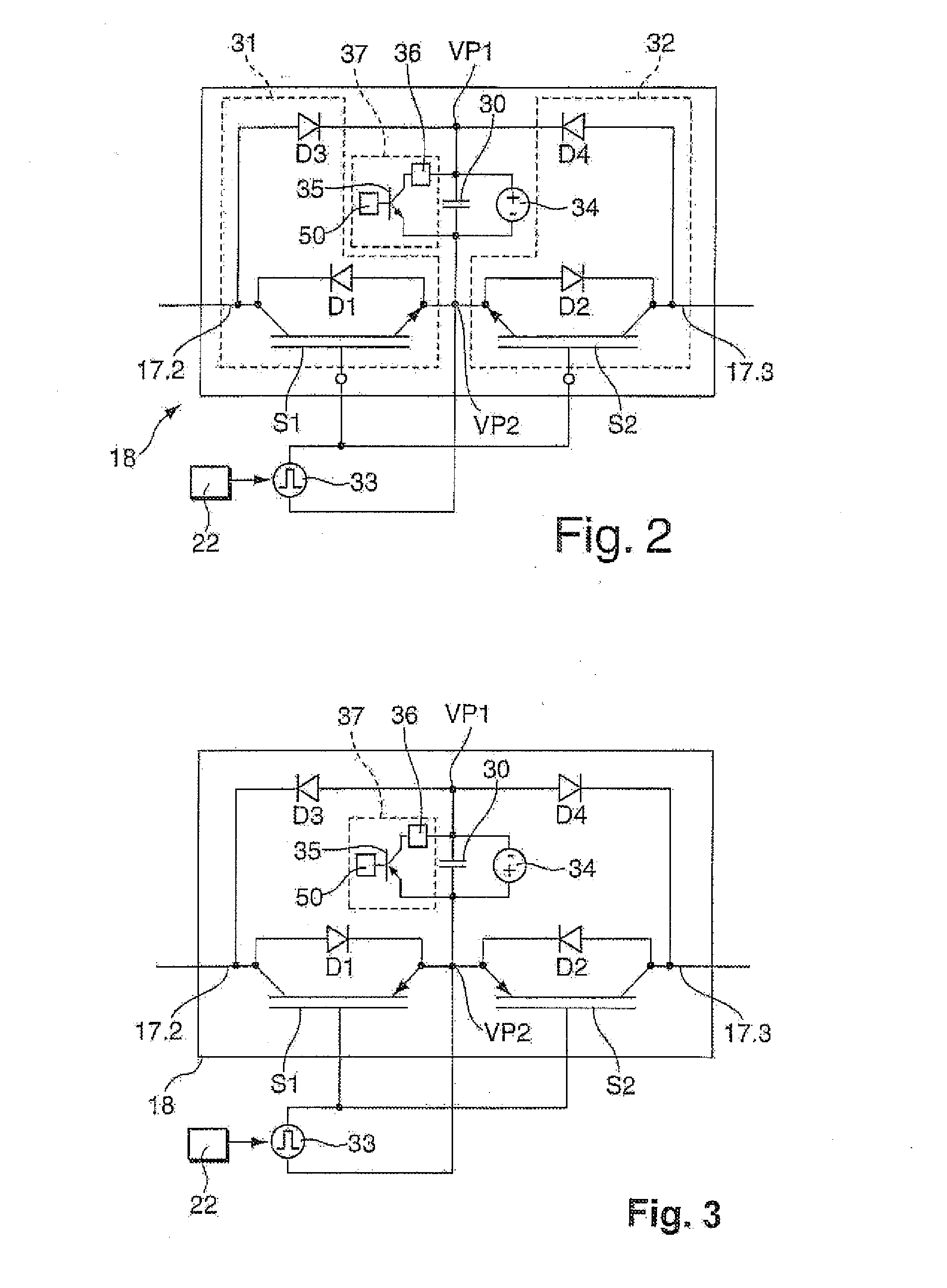

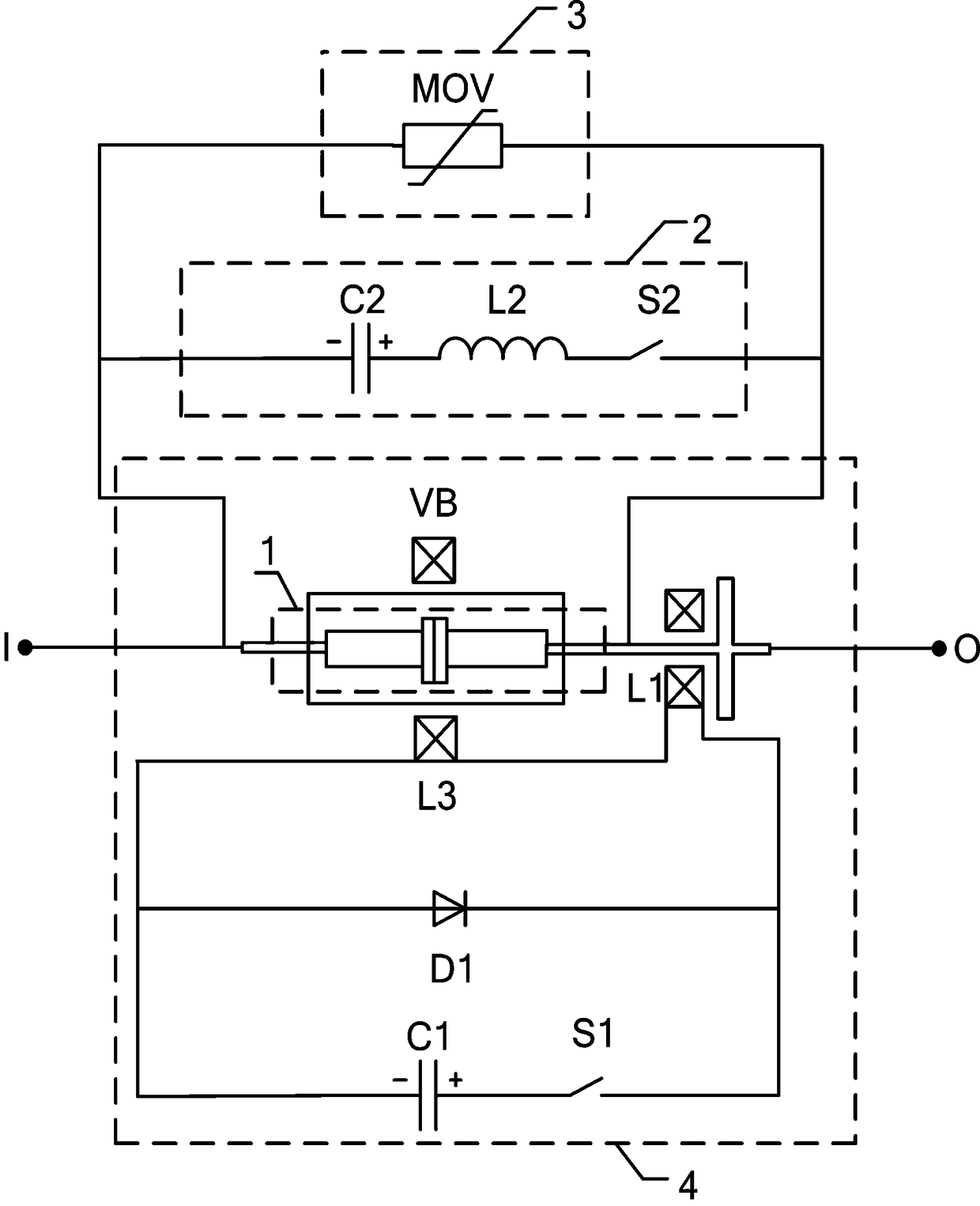

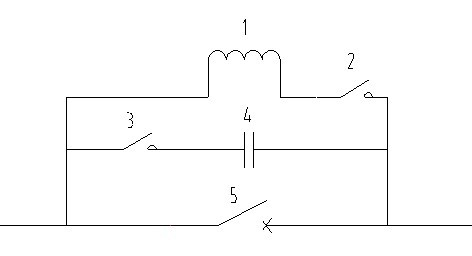

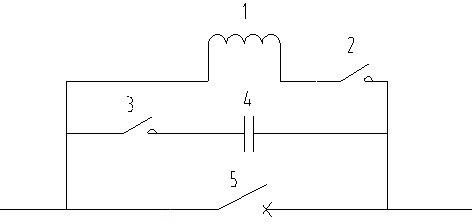

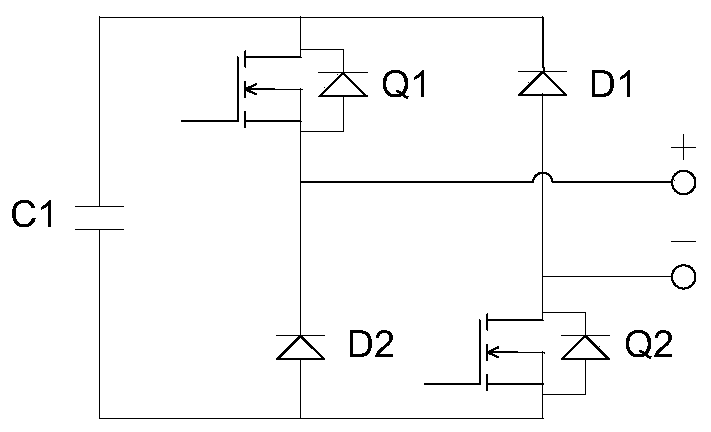

A DC vacuum circuit breaker

ActiveCN109360764BImprove breaking capacityIncrease the effective areaHigh-tension/heavy-dress switchesAir-break switchesCapacitanceElectric power system

The invention discloses a direct-current vacuum circuit breaker, which comprises a normal current branch, a conversion branch, an energy absorption branch and a magnetic field generating branch. The magnetic field generating branch is formed by sequential series connection of a drive capacitor C1, a repulsion coil L1 and a high-voltage cable L3 wound around an arc extinguishing chamber. A diode D1is parallelly connected to two sides of the L1 and the L3, and a stable and durable longitudinal magnetic field is generated in the arc extinguishing chamber through long-time follow current of the diode D1 by the repulsion coil L1 and the high-voltage cable L3 after discharging of the drive capacitor C1. The direct-current vacuum circuit breaker has advantages that the effective magnetic field can be generated without grooving a contact of the arc extinguishing chamber, contact area increasing, arc energy reduction, circuit breaker switching capacity increasing and the like are achieved, andthe direct-current vacuum circuit breaker is applicable to high-current power systems.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

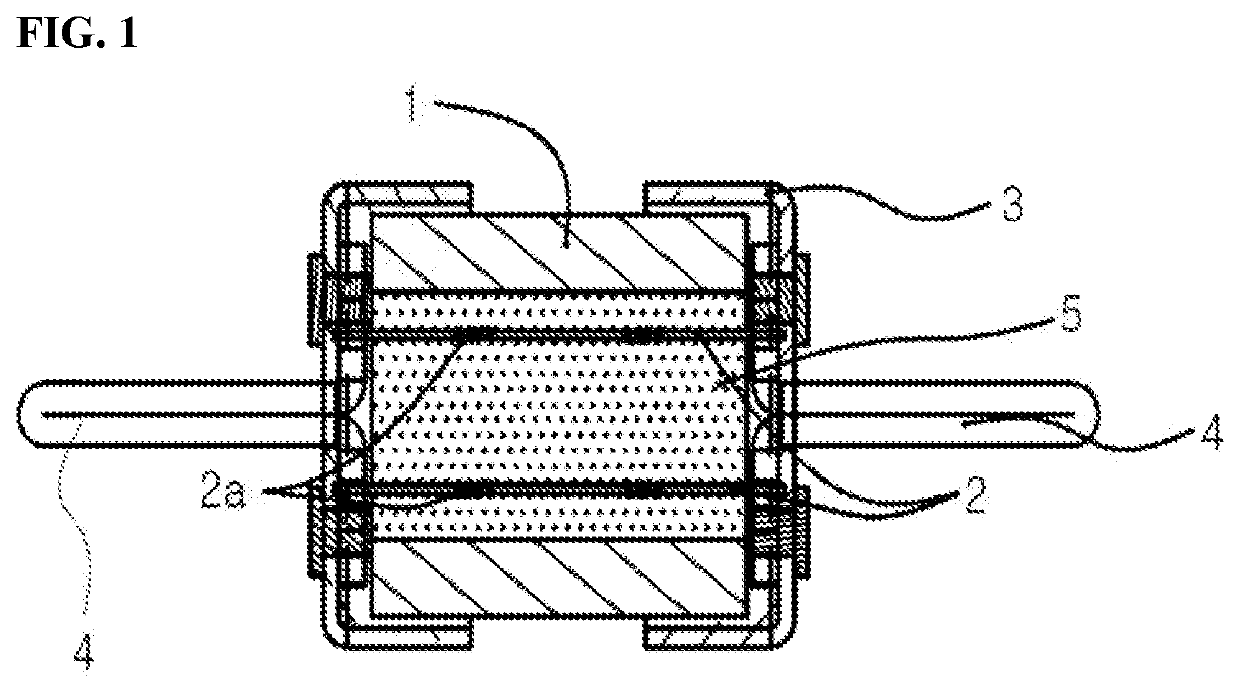

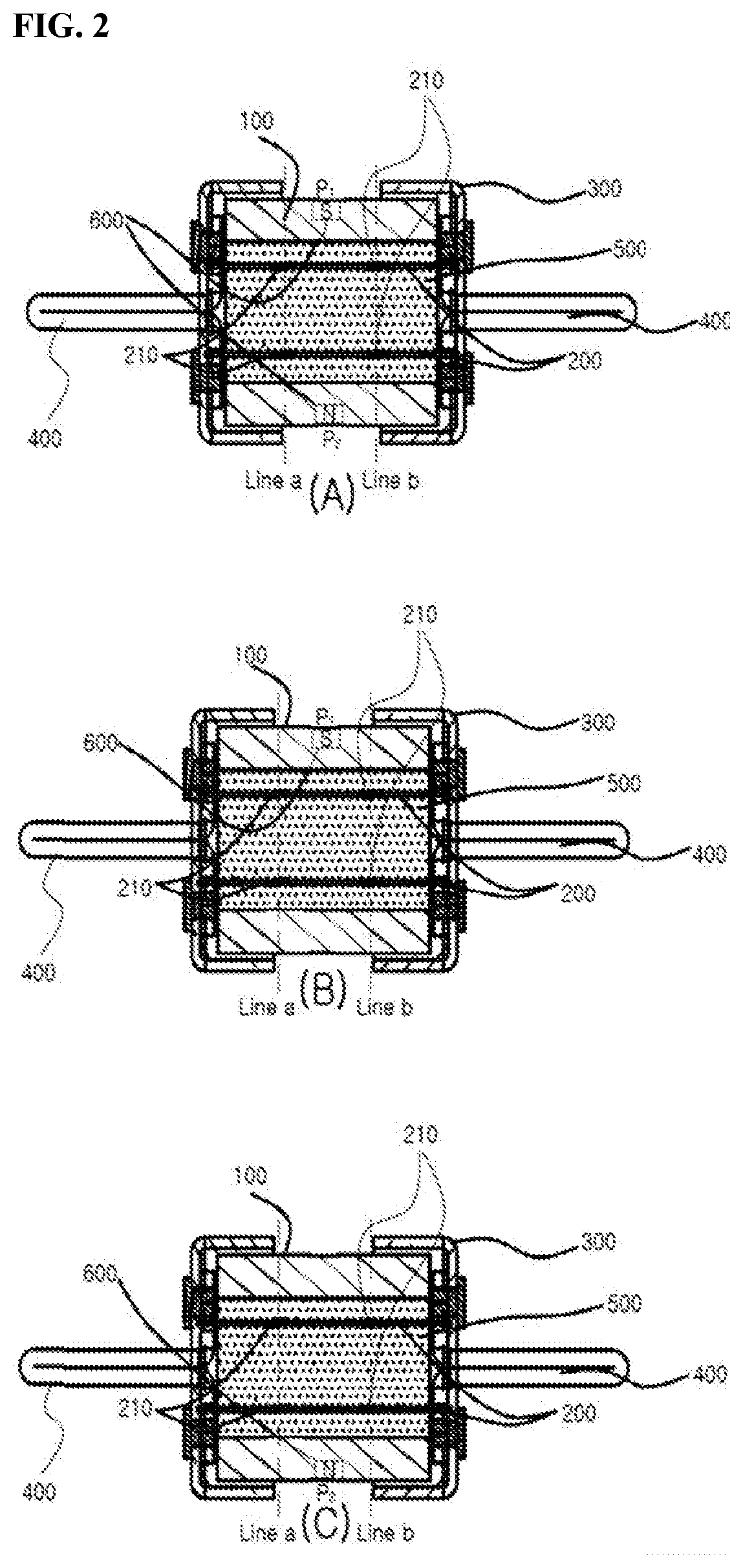

electrical dc switching system

ActiveCN110024069BEasy to handleReduce arc energyHigh-tension/heavy-dress switchesAir-break switchesHemt circuitsEngineering

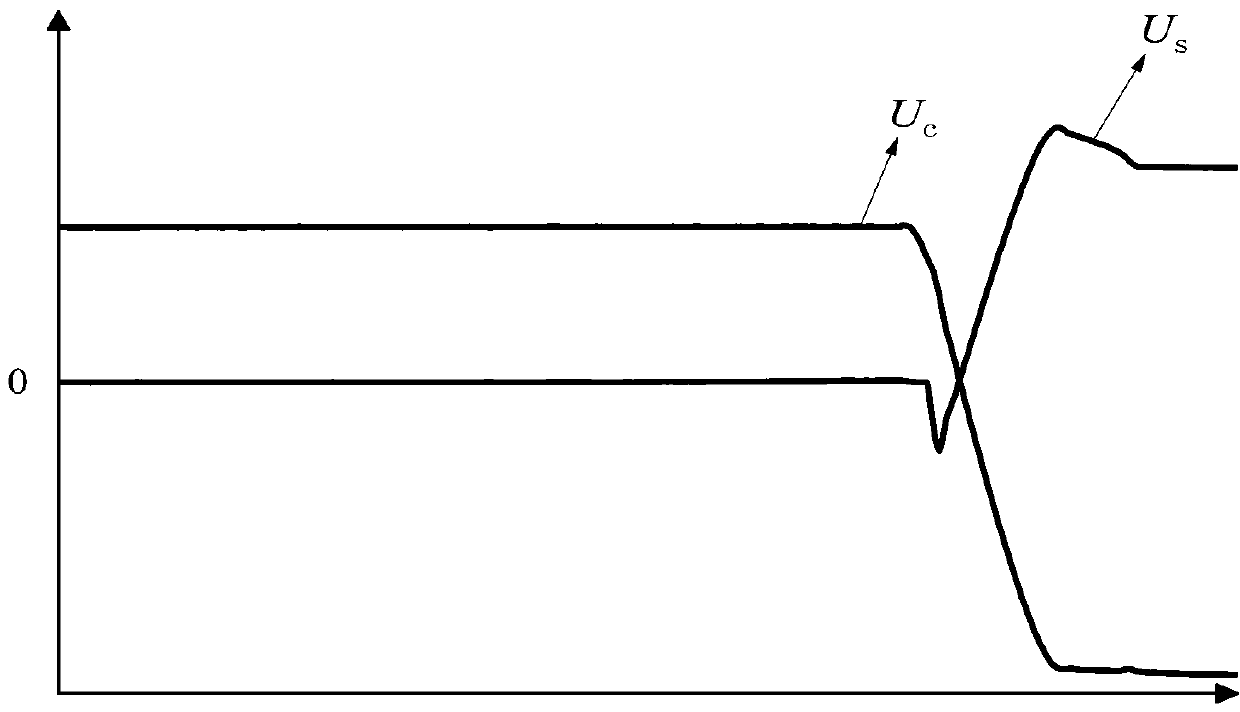

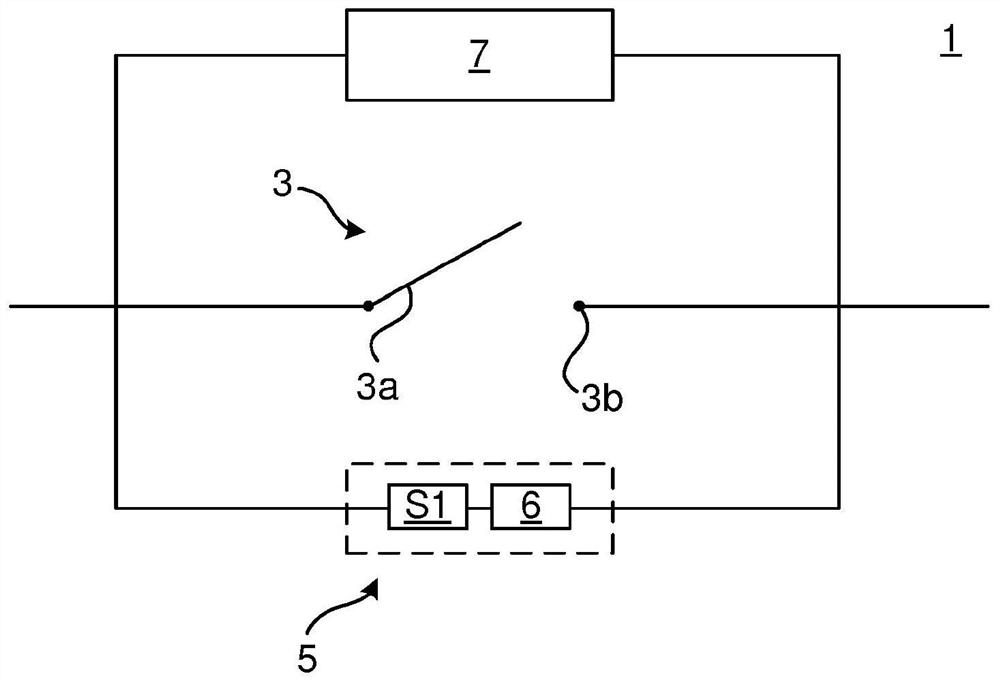

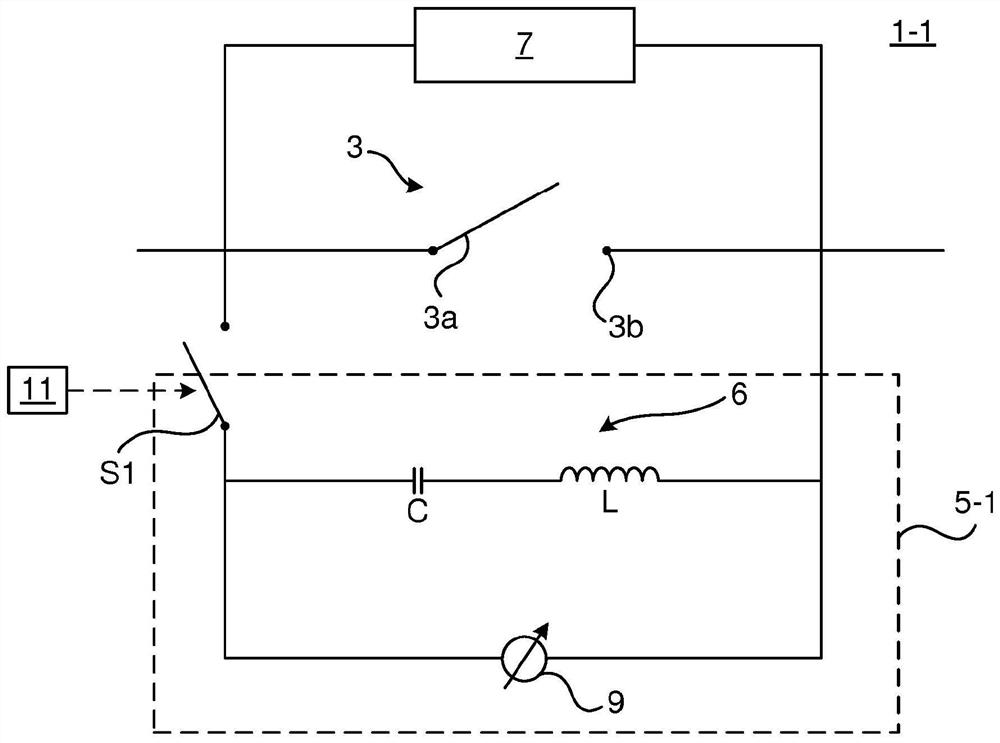

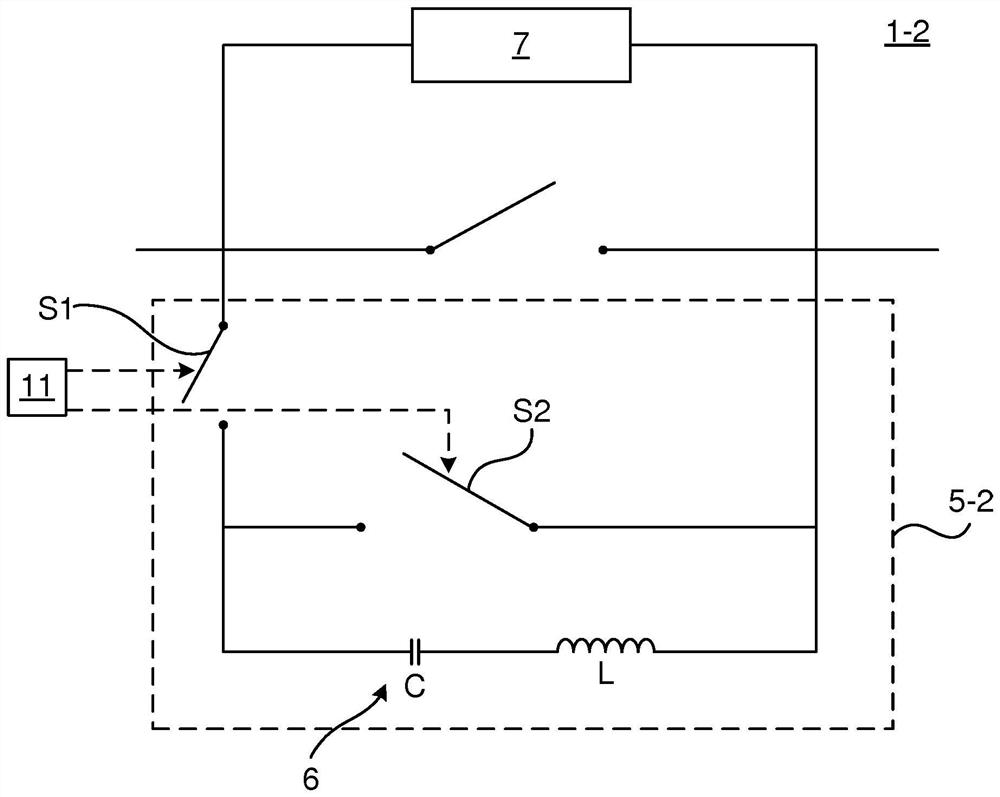

The present disclosure relates to an electrical DC switching system (1) for extinguishing an electric arc, wherein the electrical DC switching system comprises: a contact arrangement (3) having a first contact (3a) and a second contact (3b), a current injection circuit (5) including a resonance circuit configured to be connected across the contact arrangement (3), and a first switch connected to the resonance circuit (6) and to the first contact (3a), wherein the first switch (S1) is configured to be switched between an open state and a closed state, wherein in the closed state the first switch is configured to enable an injection current to flow through the resonance circuit (6) in a first flow direction and into the contact arrangement (3) in a direction opposite to a flow direction of a contact arrangement arc current, and an arc chute assembly (7) comprising a plurality of splitter plates configured to extinguish an electric arc across the first contact (3a) and the second contact (3b), wherein each splitter plate of the plurality of splitter plates has a layered configuration comprising a magnetic layer and two non-magnetic layers.

Owner:ABB (SCHWEIZ) AG

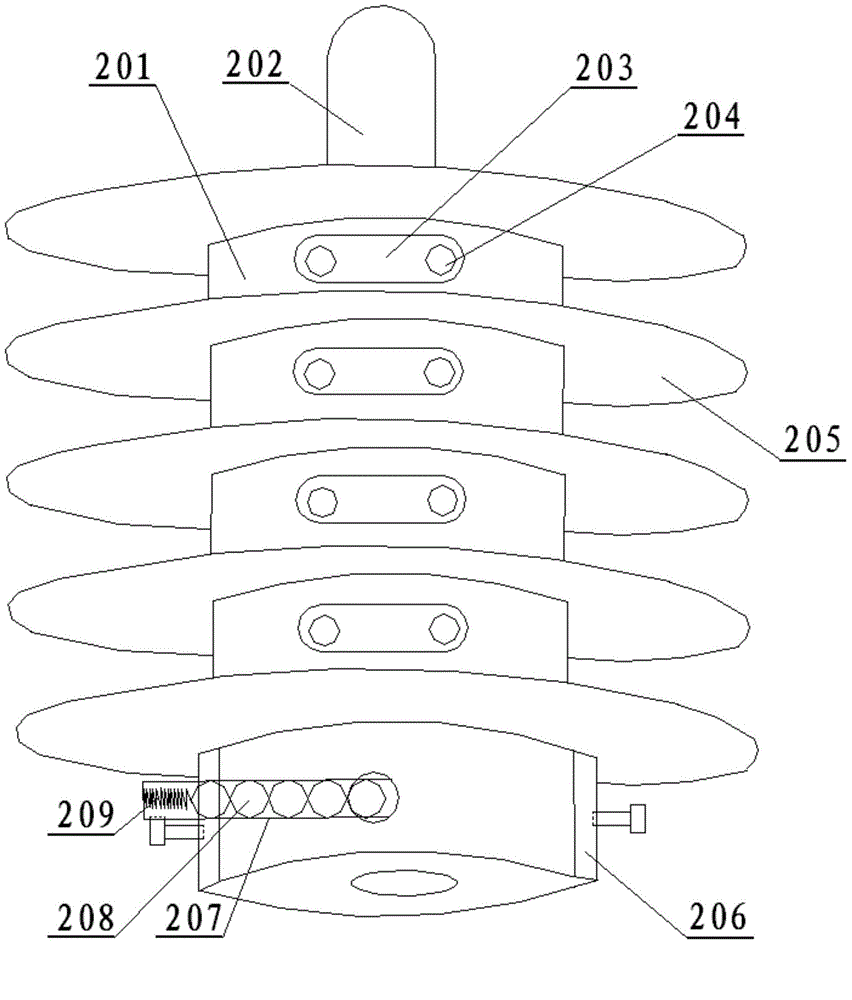

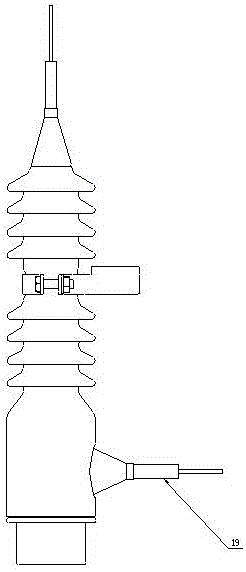

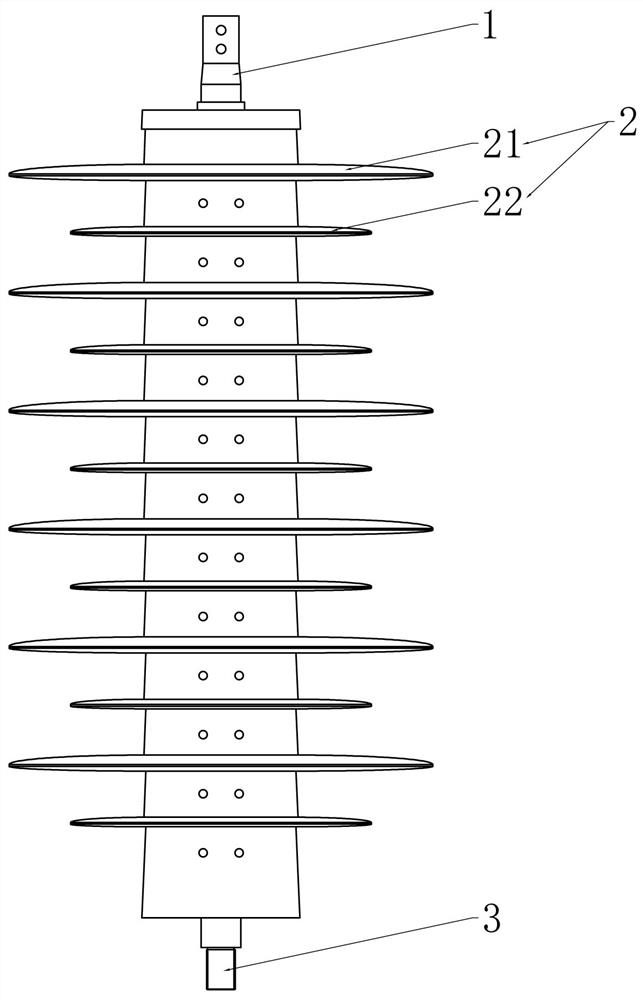

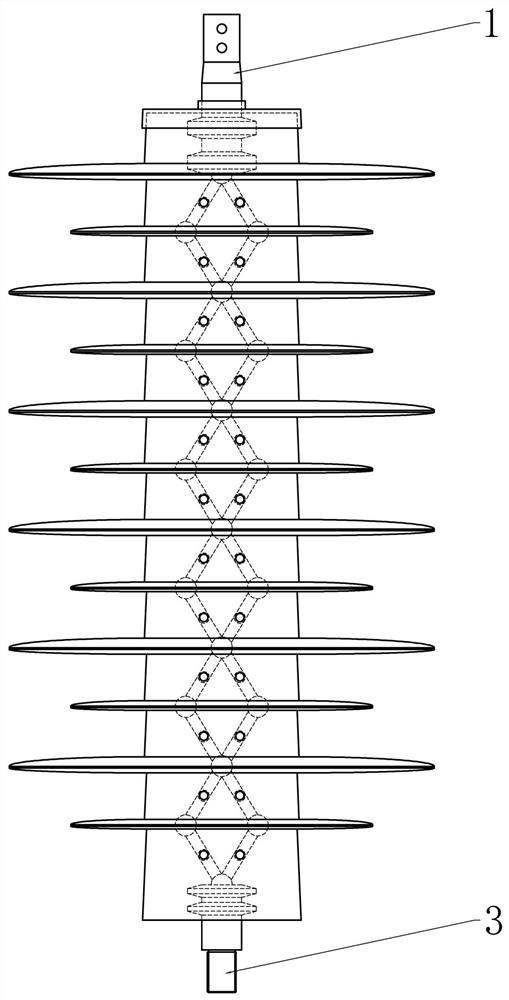

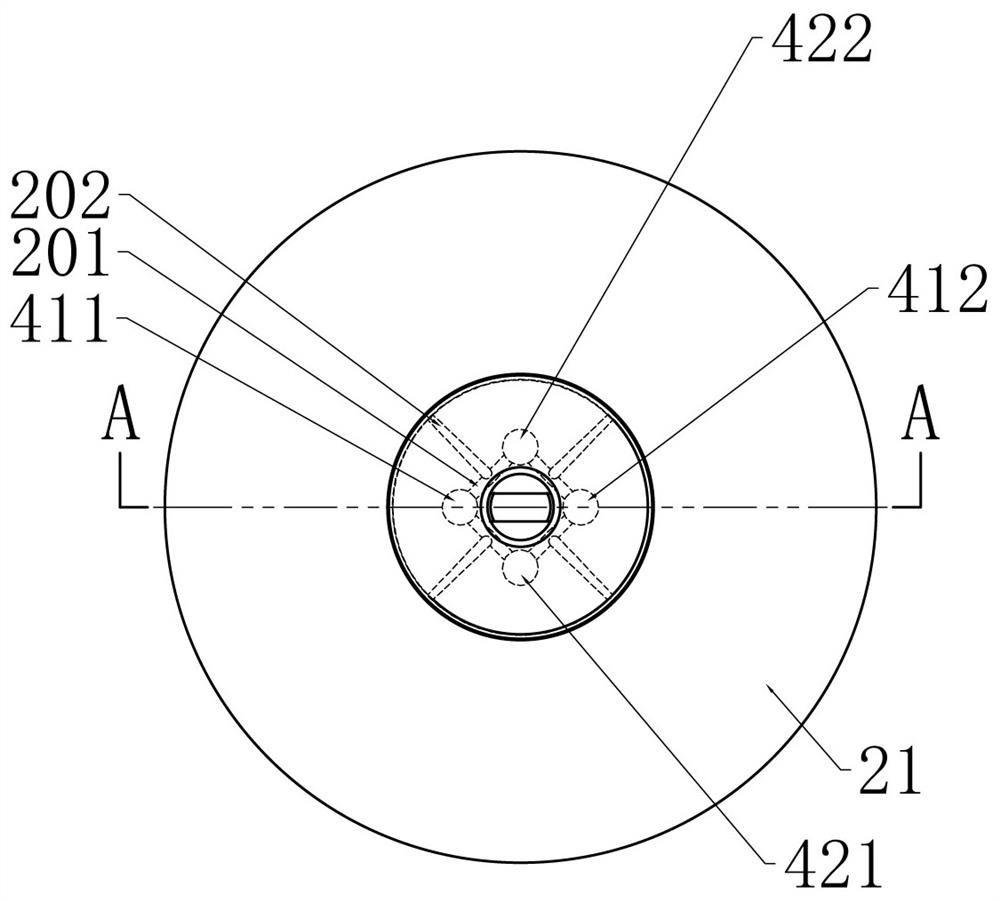

Series Gap Arrester

ActiveCN112769041BReduce the passing currentToleranceSpark gap detailsVaristor coresEngineering physicsArc extinction

A series gap arrester, comprising an insulator and a plurality of conductor groups arranged in the gap along the main axis direction of the insulator, the adjacent two groups of conductor groups arranged in the gap in the main axis direction of the insulator are the first conductor group, the second conductor group respectively. Two conductor groups, the first conductor group includes A first conductors, the second conductor group includes B second conductors, A+B≥3, the first conductor group The lengths of all the gas discharge channels formed by a conductor and the second conductors of the second conductor group are equal. It can improve the arc extinguishing effect of the series gap arrester and reduce its leakage current under the condition of taking into account the lightning protection effect.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

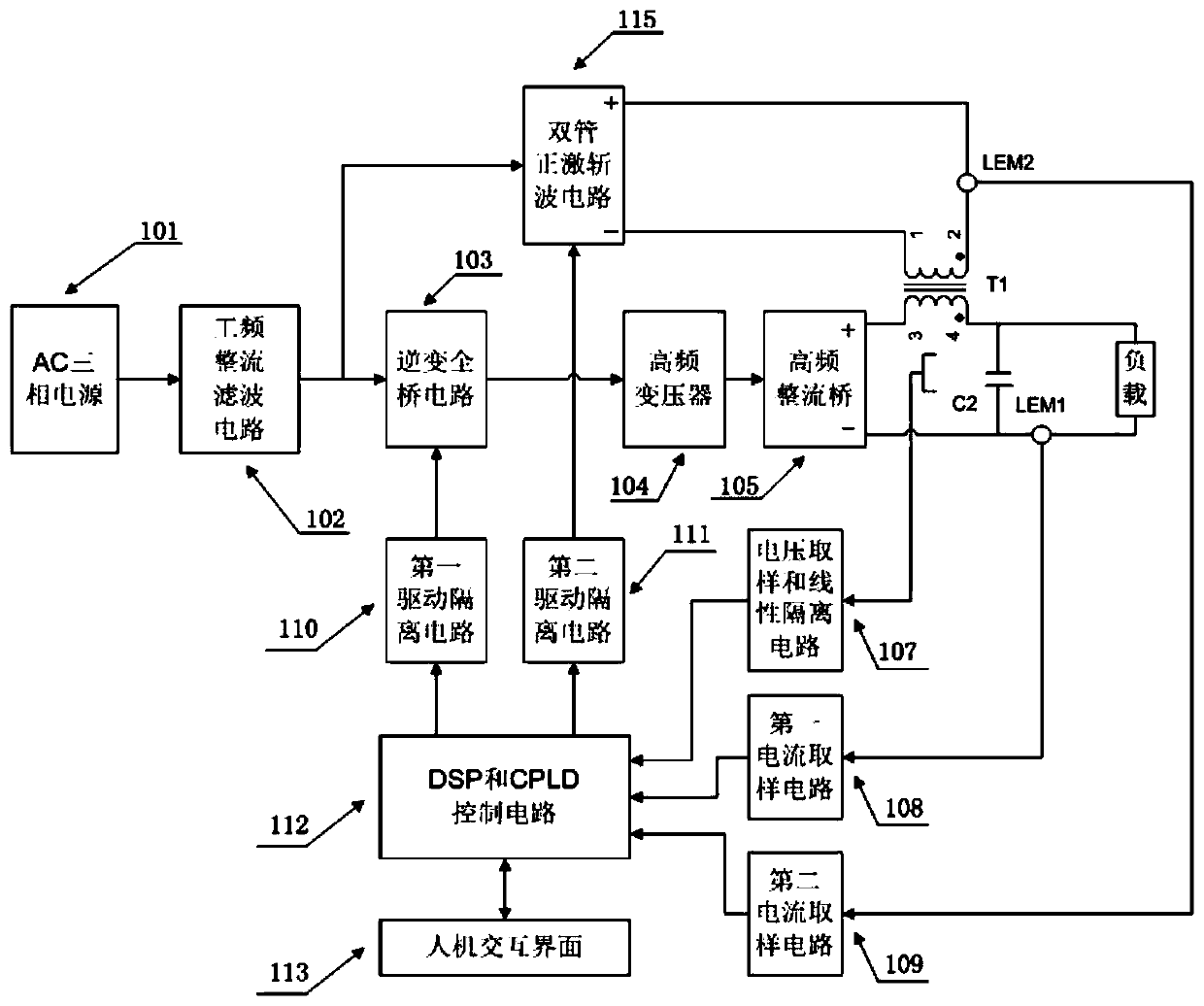

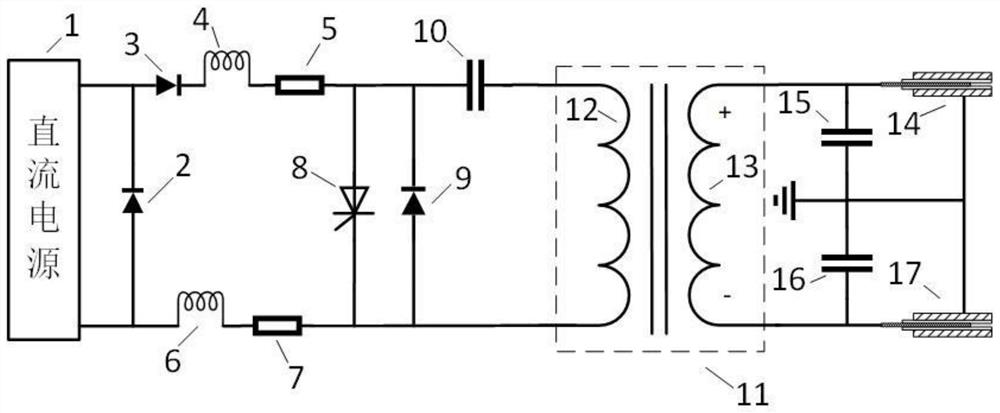

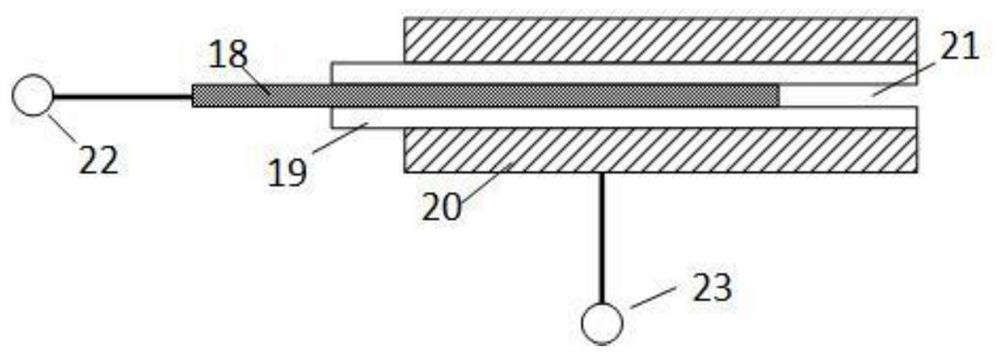

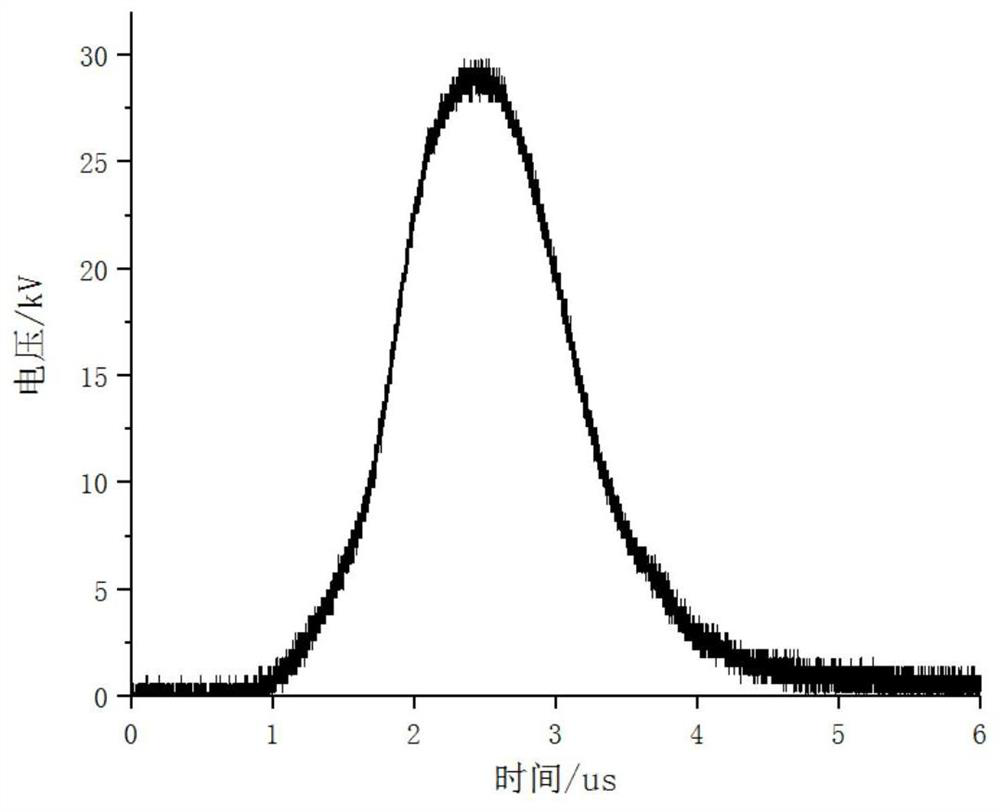

Fast and reliable combustion-supporting circuit of direct current magnetron sputtering coating power supply

The invention belongs to the technical field of automatic control and power electronics, and particularly relates to a fast and reliable combustion-supporting circuit of a direct current magnetron sputtering coating power supply. By adding a combustion-supporting circuit, the voltage output by the combustion-supporting circuit is superposed with the voltage output by a high-frequency rectifier bridge of a high-frequency inverter switching power supply to reach the amplitude of the combustion-supporting starting voltage; when the starting is successful, the output current of the direct currentmagnetron sputtering power supply exceeds a starting success determination threshold value, or the output voltage of the direct current magnetron sputtering power supply is lower than a no-load voltage determination threshold value of a main power supply, the combustion-supporting circuit stops working, and the voltage and the current required by the direct current magnetron sputtering process aresupplied by the main circuit of the direct current magnetron sputtering coating power supply; once the glow is extinguished, the combustion-supporting circuit is started to output, and the output voltage of the power supply reaches the amplitude of the combustion-supporting starting voltage, so that the continuity of the coating process is ensured; and the arc energy is reduced, and the coating quality is improved.

Owner:中核同创(成都)科技有限公司

A capillary two-way trigger device for series gap and its application

ActiveCN112230134BTurn fasterReliable conductionCircuit interrupters testingCapacitanceCapillary Tubing

Owner:XI AN JIAOTONG UNIV

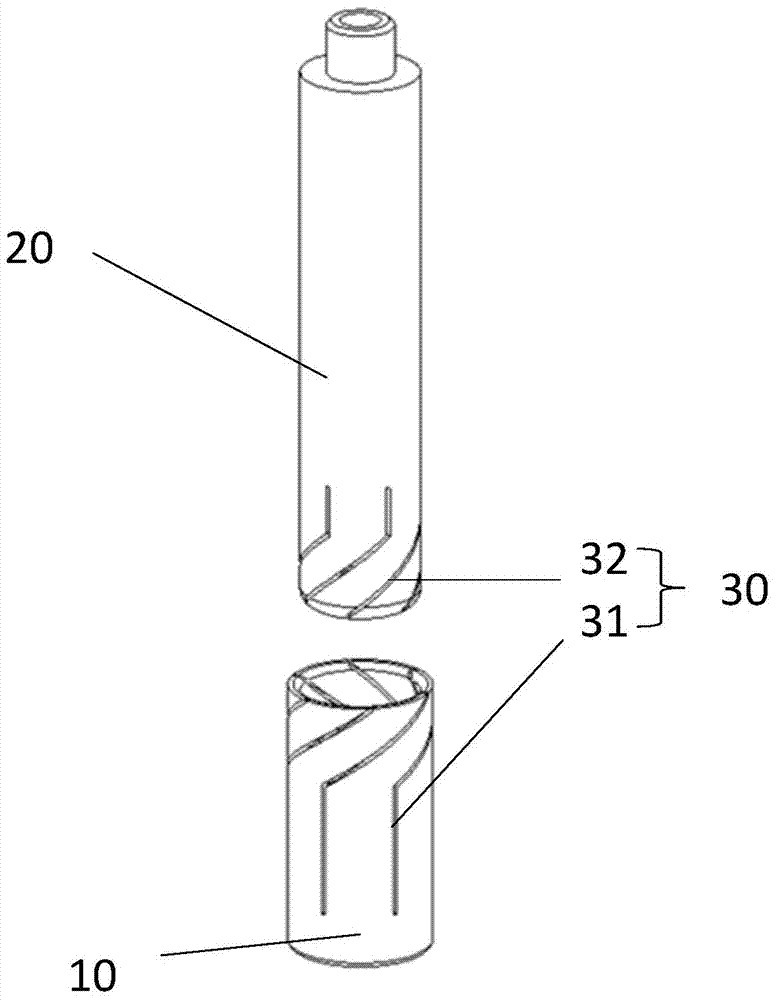

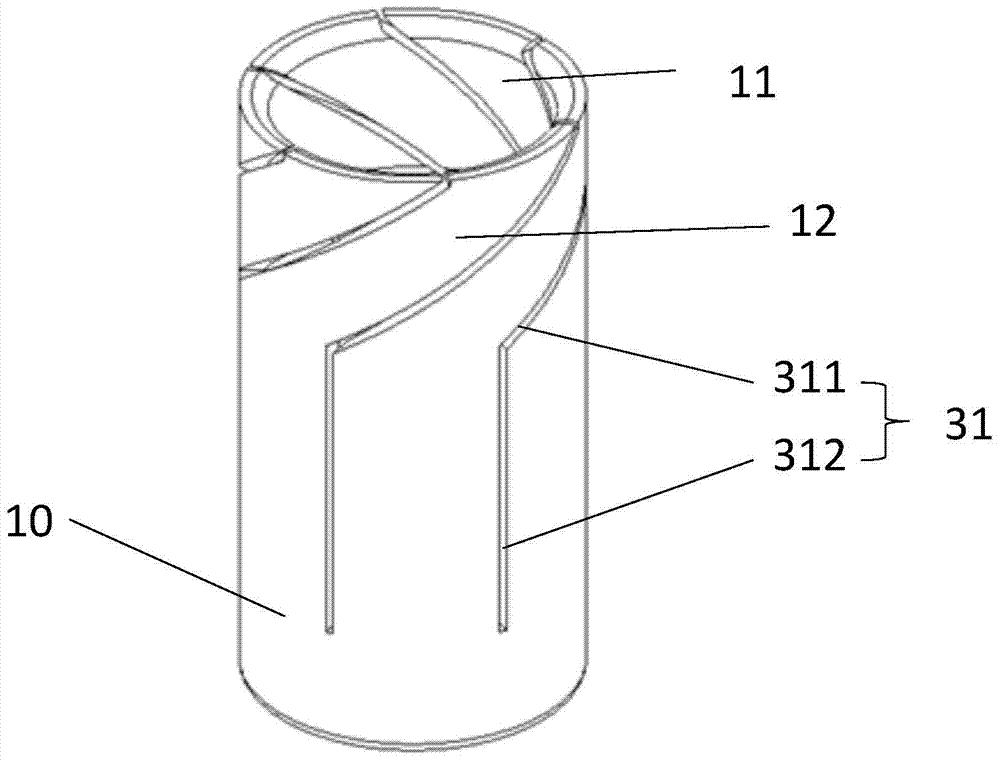

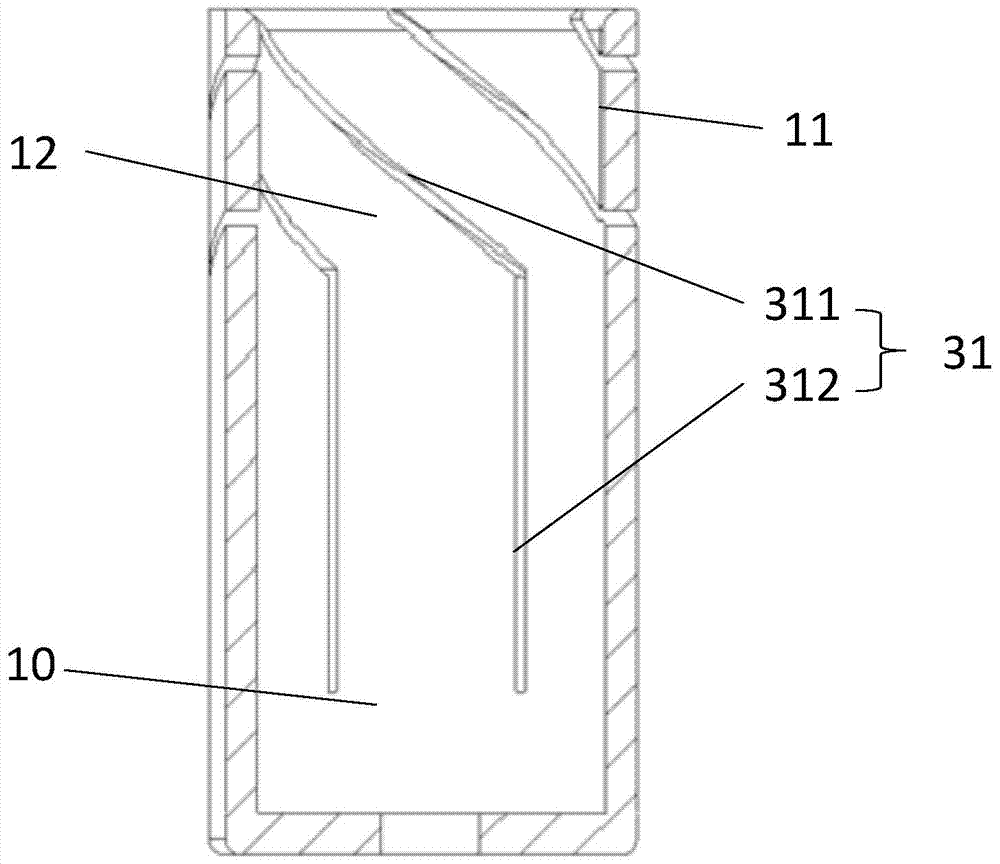

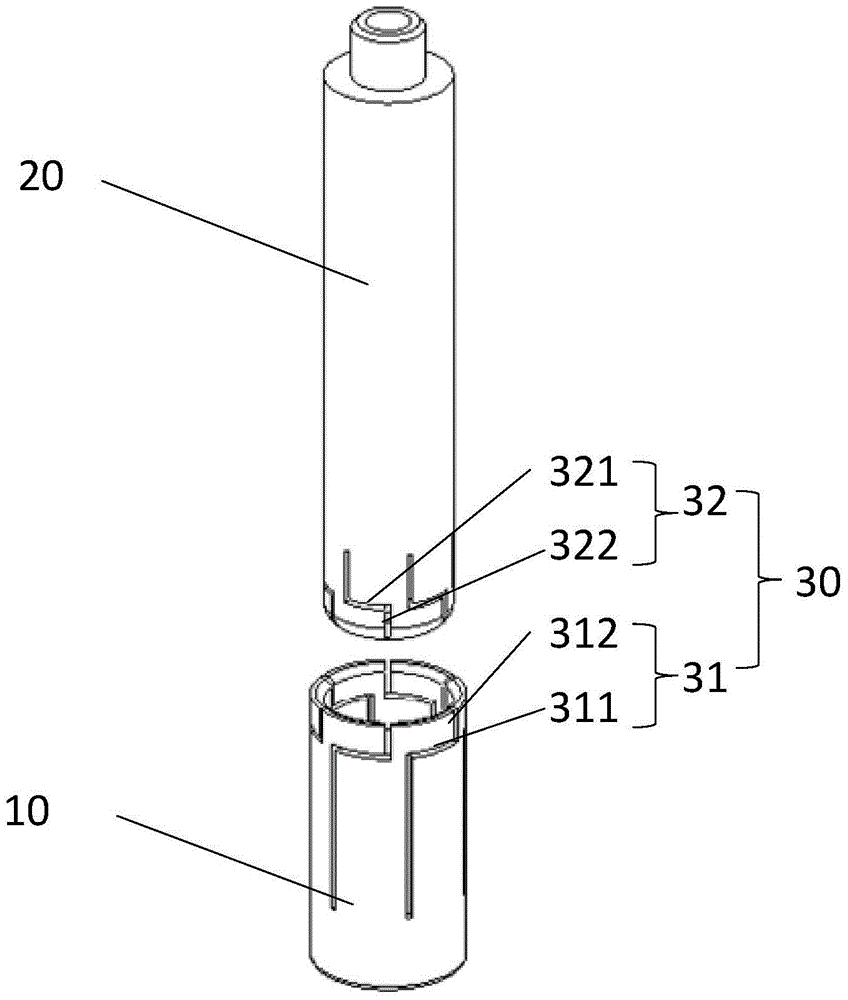

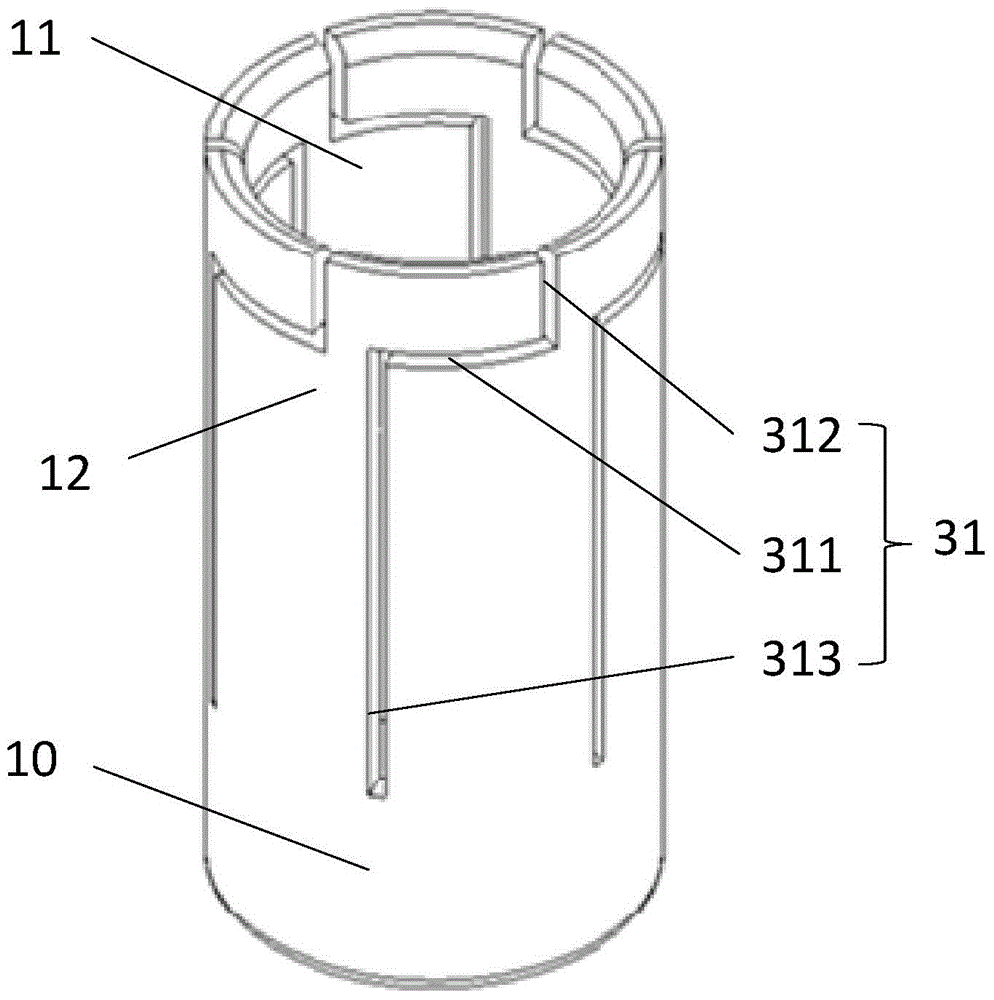

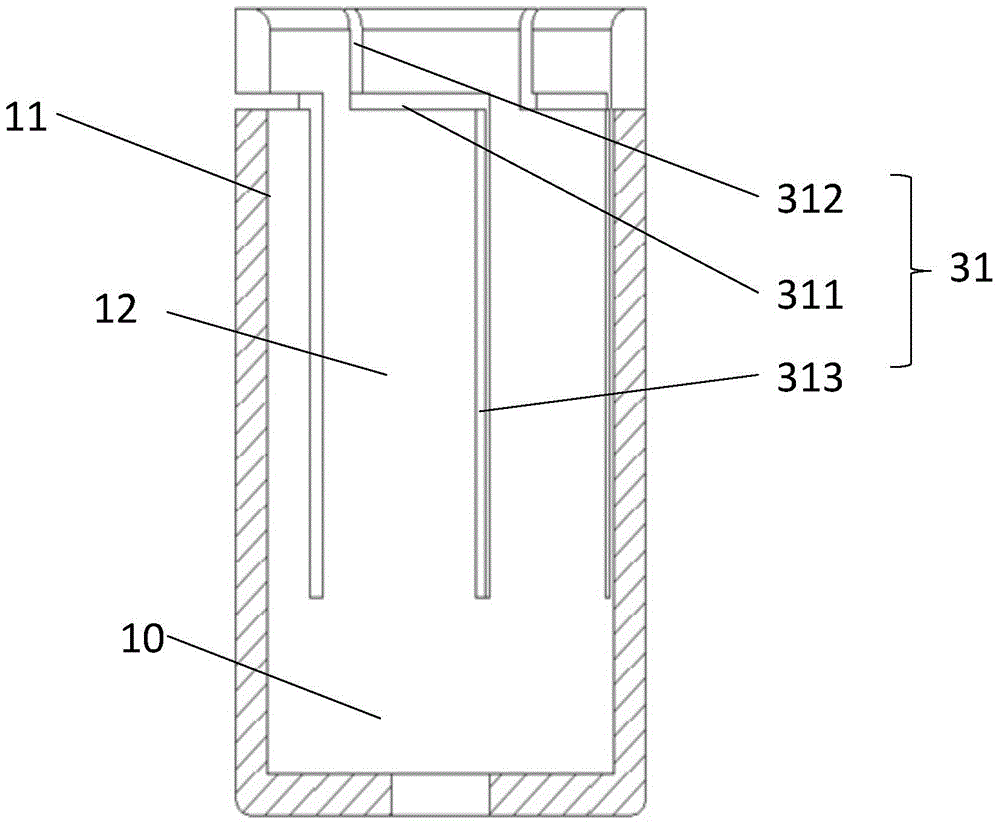

Grounding switch contact and direct-acting plug-in grounding switch with same

ActiveCN104576162BImprove opening and closing effectReduce closing speed requirementsHigh-tension/heavy-dress switchesAir-break switchesLinear motionPower flow

The invention provides a grounding switch contact and a straight movement plug-in type grounding switch with the grounding switch contact. The grounding switch contact comprises a static end contact electrode and a dynamic end contact electrode, wherein the static end contact electrode is fixedly arranged, and the dynamic end contact electrode is movably arranged in the axial direction of the static end contact electrode and has a conduction position at which the dynamic end contact electrode and the static end contact electrode can be embedded to each other and a disconnection position at which the dynamic end contact electrode and the static end contact electrode can be separated from each other. The grounding switch contact further comprises a magnetic control device, and when the dynamic end contact electrode is switched to the conduction position from the disconnection position and generates a pre-breakdown arc, the magnetic control device can generate a transverse magnetic field perpendicular to the pre-breakdown arc or a longitudinal magnetic field parallel to the pre-breakdown arc through the current of the static end contact electrode and the current of the dynamic end contact electrode. Due to the technical scheme, the problem that a straight movement plug-in type grounding switch in the prior art cannot be turned off or on easily at a large current can be effectively solved.

Owner:BEIJING SOJO ELECTRIC

A kind of silver-nickel electrical contact material and preparation method thereof

ActiveCN106282640BImprove welding resistanceGuaranteed uniformityContactsHigh volume manufacturingHeat stability

The invention relates to the field of electrical contact materials, in particular to a silver-nickel electrical contact material and a preparation method thereof, which is composed of the following components and their mass percentages are: 8%≤nickel≤30%, 0.5%≤molybdenum carbide≤12 %, the balance being silver. The production process of this silver-nickel electric contact material adopts powder mixing-extrusion process. The present invention mainly considers improving the anti-welding performance of silver-nickel materials, and adds molybdenum carbide as a reinforcing phase. Molybdenum carbide has the advantages of high melting point, good thermal stability, and density similar to silver and nickel, which can be guaranteed by ordinary powder mixing process. Uniformity of ingredients, suitable for mass production. Compared with common silver-nickel materials, the material of the invention has high welding resistance and low arc energy, and is mainly used in AC contactors and relays.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

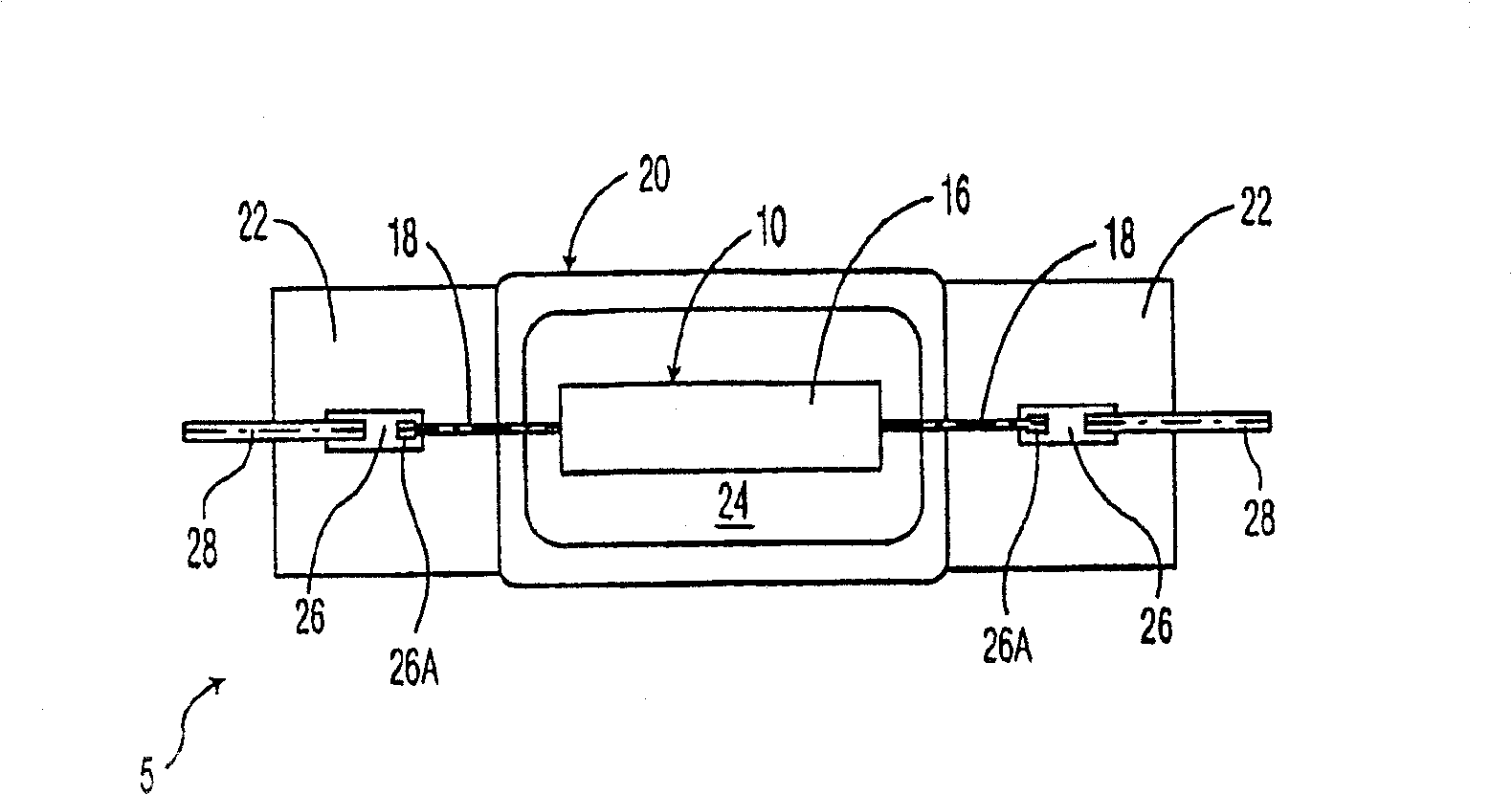

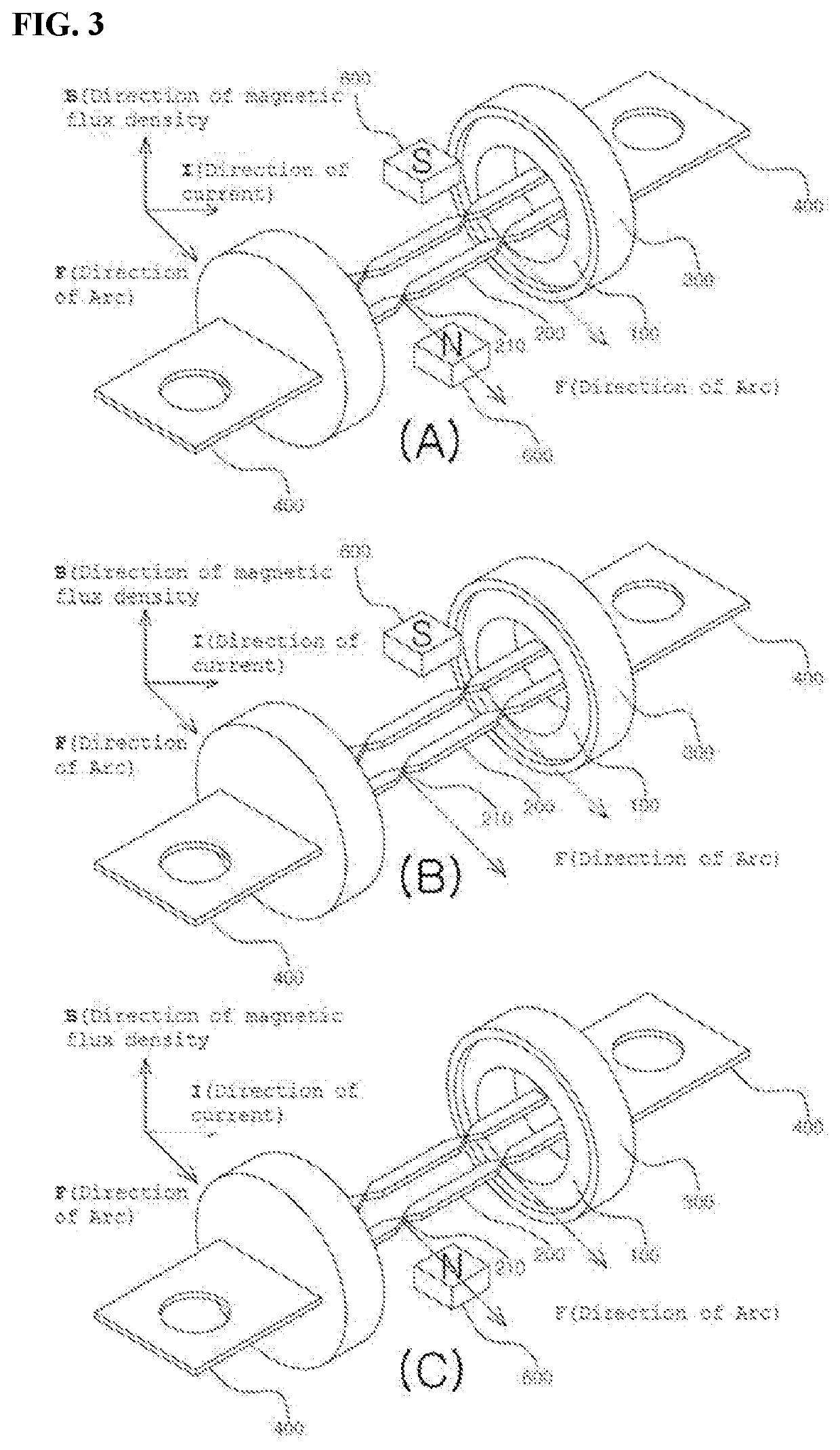

Fuse link comprising permanent magnet for inducing arc directivity

InactiveUS20210358711A1Reduces link sizeReduction in arc energyFuse disposition/arrangementElectric switchesMagnetic orientationArc energy

A fuse link including magnet for inducing arc directivity is provided, in which the magnet is arranged in an inner surface, an outer surface or the inside of an insulating tube forming the fuse link, and the progress direction of arc energy is coherently directed in a certain direction in accordance with Fleming's left-hand rule by the direction of magnetic field of the arranged magnet so as to increase a disconnection speed of an element (i.e., reducing a blocking speed of a fault current), thereby increasing fault current blocking performance of the fuse link. In particular, a position of the magnet arranged on the insulating tube is arranged at a middle point between a notched portion and the notched portion, a point of notched portion, and the insulating tube corresponding to the middle point between the notched portion and the notched portion and the point of notched portion.

Owner:HONG SEUNG PYO

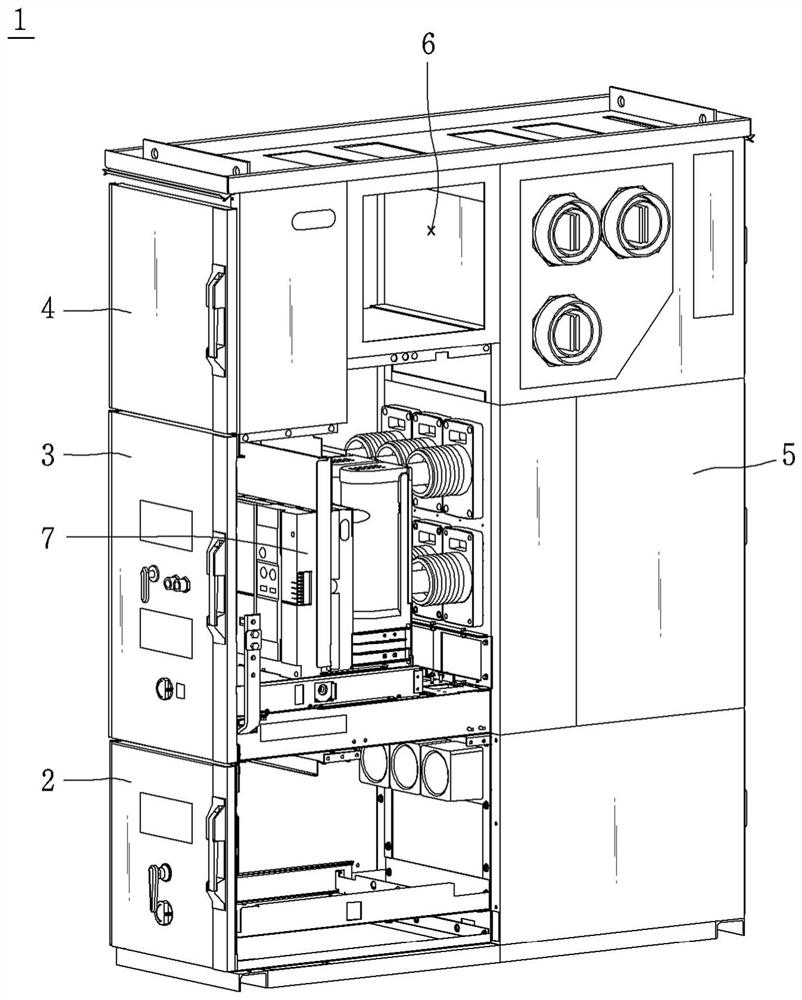

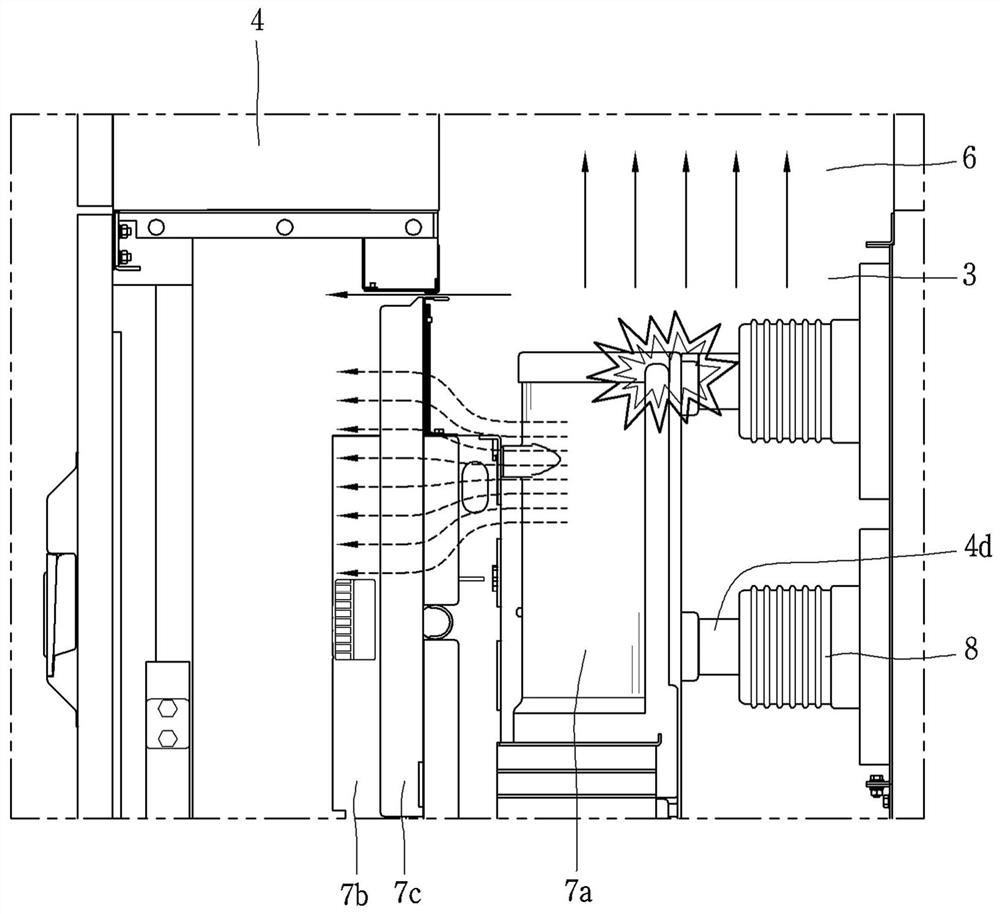

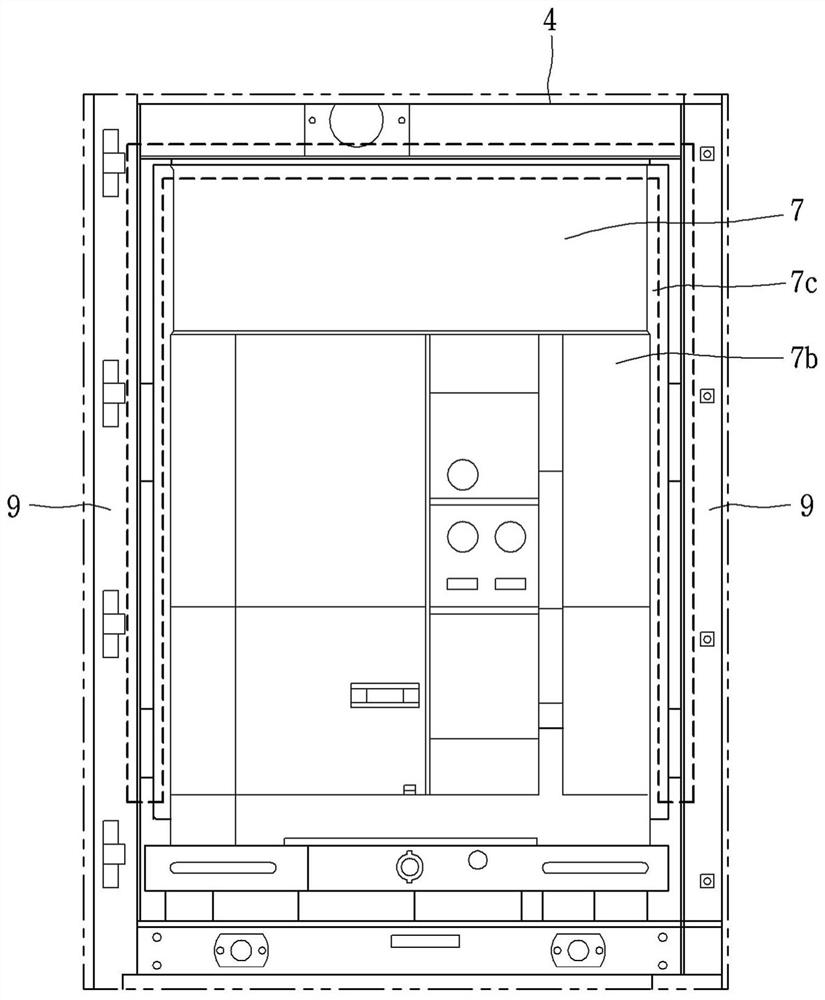

Arc ventilation system of distributing board

ActiveCN111697478AReduce arc energyDischarge safetySwitchgear arrangementsSubstation/switching arrangement detailsControl theoryMechanical engineering

Owner:LSIS CO LTD

Grounding switch contact and direct movement plug-in type grounding switch with grounding switch contact

ActiveCN104538237AReduce closing speed requirementsReduce focused ablationHigh-tension/heavy-dress switchesAir-break switchesTransverse grooveEngineering

The invention provides a grounding switch contact and a direct movement plug-in type grounding switch with the grounding switch contact. The grounding switch contact comprises a fixed end contact electrode and a movable end contact electrode, and further comprises a magnetic control device, the magnetic control device comprises a plurality of first switching grooves and a second switching grooves; each first switching groove comprises a first transverse groove and a first extending groove, the first transverse grooves extend in the circumferential direction of the fixed end contact electrode, the first end of each first extending groove is connected to one end of the corresponding first transverse groove, and the second end of each first extending groove extends to the movable end contact electrode; each second switching groove comprises a second transverse groove and a second extending groove, the second transverse grooves extend in the circumferential direction of the movable end contact electrode, the first end of each second extending groove is connected to one end of the corresponding second transverse groove, and the second end of each second extending groove extends to the fixed end contact electrode. By means of the technical scheme, the problem that large-current opening and closing cannot be achieved through a direction movement plug-in type grounding switch in the prior art easily can be effectively solved.

Owner:BEIJING SOJO ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com