Fully-insulated enclosed fuse

A closed and fully insulated technology, which is applied to electrical components, circuits, emergency protection devices, etc., can solve problems such as safety performance degradation, fusion tube malfunction, power outage, and reduced service life of fuses, etc. High flow and breaking capacity, long overall service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

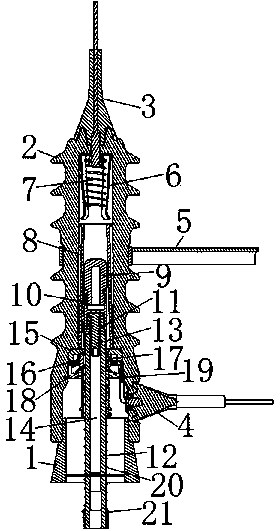

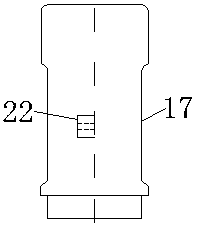

[0015] Such as figure 1 and figure 2 As shown, the fully insulated closed fuse of the present invention includes a rubber base 1, an outer insulating porcelain bottle 2 is arranged on the rubber base 1, and an upper rubber sealing incoming line is arranged on the top of the outer insulating porcelain bottle 2. The connecting piece 3 is provided with a lower rubber seal inlet connector 4 at the lower part of the outer insulating porcelain bottle 2 perpendicular to it, and a mounting bracket 5 is arranged at the middle and upper part of the outer insulating porcelain bottle 2, and a There is an upper static contact 6, an upper auxiliary spring 7 is arranged in the upper static contact 6, an arc suppression tube 8 is arranged at the lower part of the upper static contact 6, and an arc suppression tube 8 is arranged in the arc suppression tube 8 The arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com