Direct current power supply device

A technology of DC power supply and power supply unit, applied in the direction of output power conversion devices, circuits, discharge tubes, etc., can solve problems such as arc discharge, low impedance, excessive reverse current, etc., and achieve the best effect of arc suppression treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

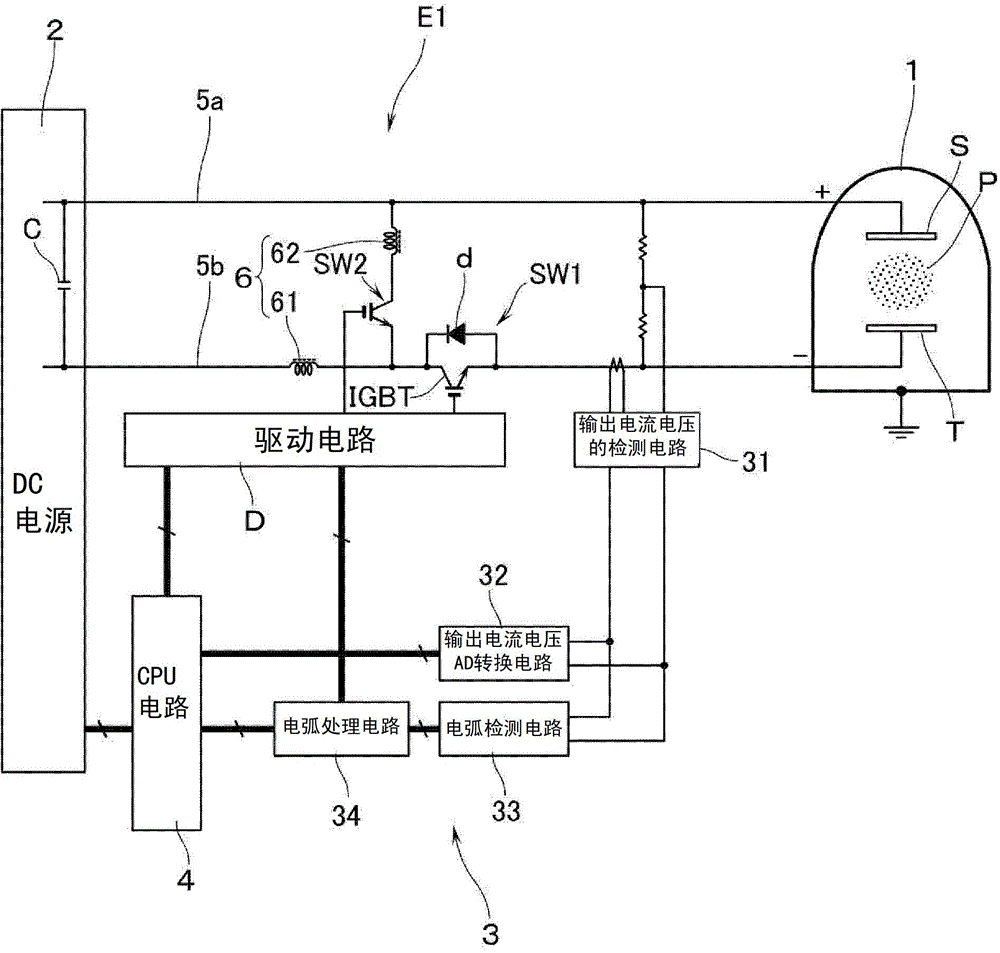

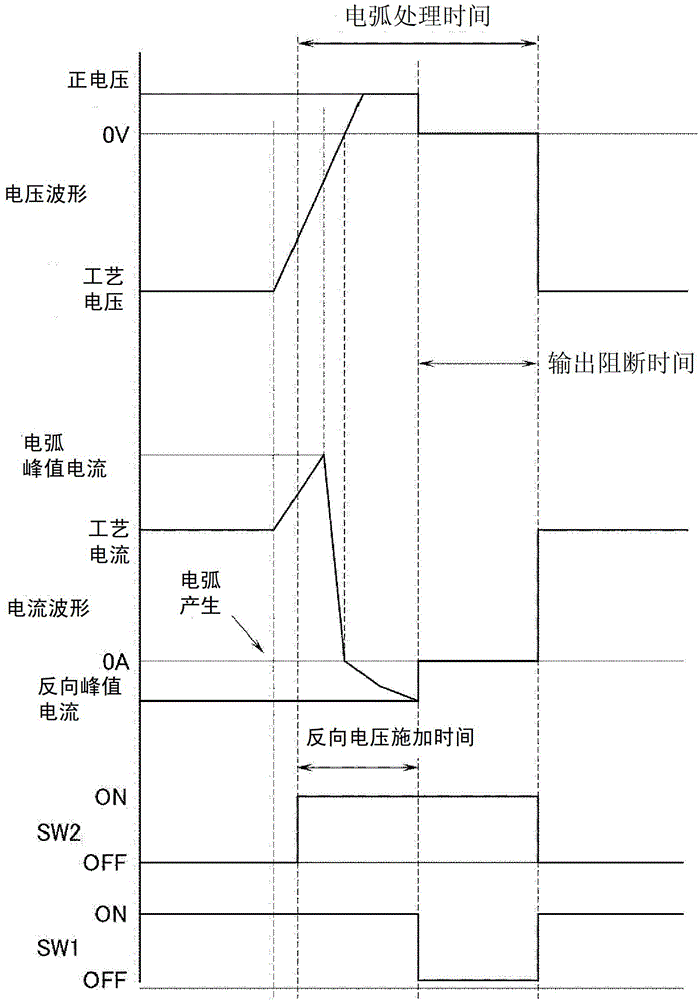

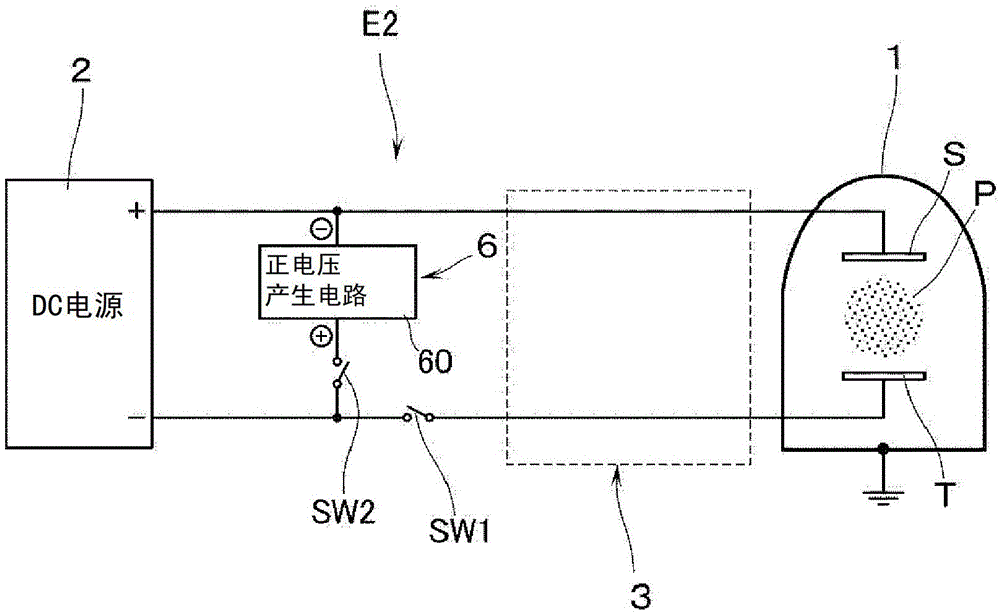

[0037] Referring to the following drawings, DC power supply devices E1 and E2 according to the embodiment of the present invention will be described by taking a case where a DC power is applied to a target by a sputtering apparatus as an example.

[0038] Such as figure 1 As shown, the DC power supply device E1 is arranged opposite to the substrate S arranged in the processing chamber 1 of the sputtering apparatus, for example, and is a device that applies DC power to the target T that is an electrode contacting the plasma load P. The DC power supply unit E1 has a DC power supply unit 2 capable of supplying DC power, an arc detection unit 3 , and a CPU circuit 4 as a control unit for collectively controlling the operation of the DC power supply unit E1 . Although not particularly shown in the figure, the DC power supply unit 2 inputs commercial AC power (for example, single-phase AC200V, three-phase AC200, etc.), rectifies the input AC power into DC power, and converts it into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com