Grounding switch contact and direct-acting plug-in grounding switch with same

A grounding switch and contact technology, which is applied in the field of high-voltage switchgear equipment, can solve problems such as difficult to achieve high-current closing, achieve the effects of reducing pre-breakdown arc energy, improving opening and closing capabilities, and reducing concentrated ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

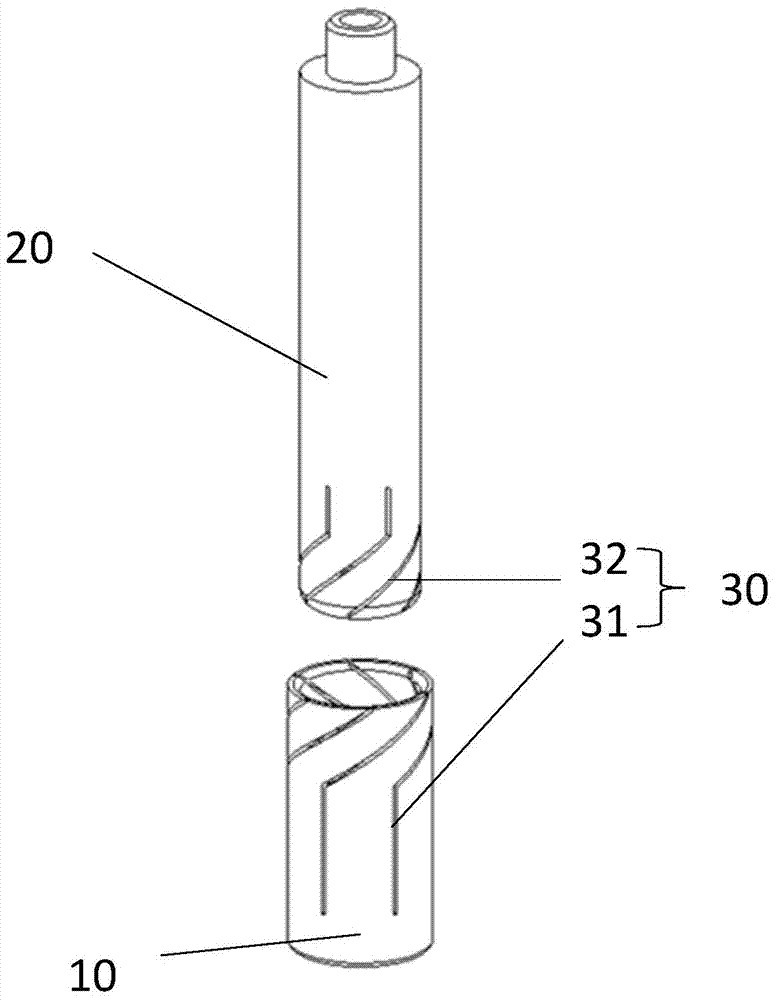

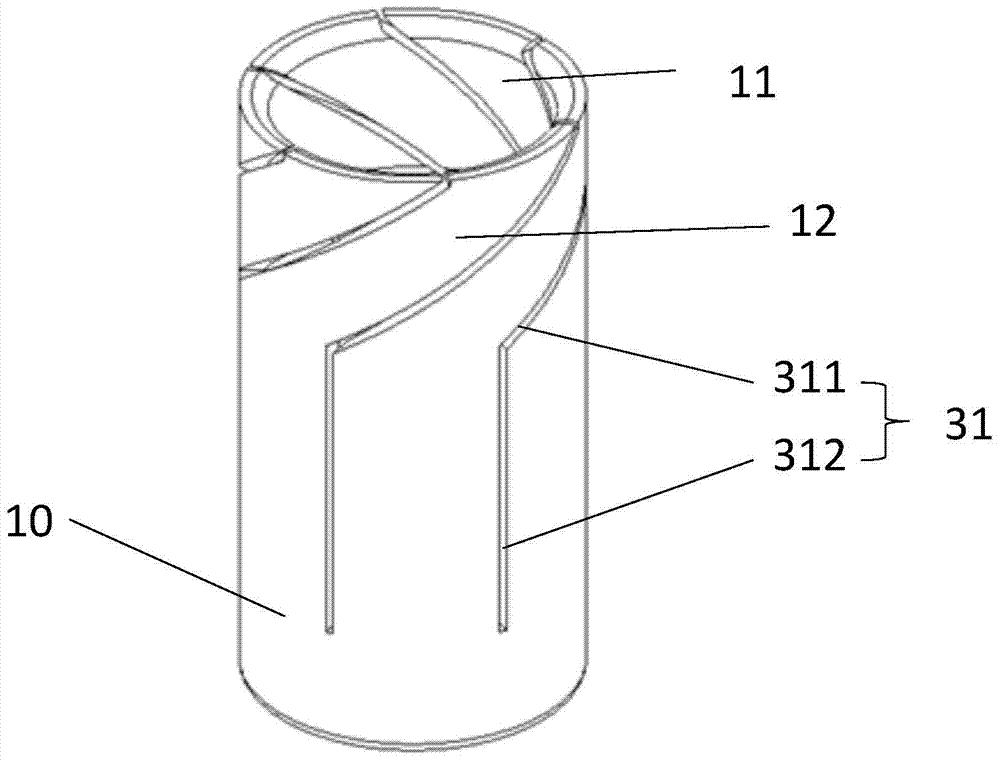

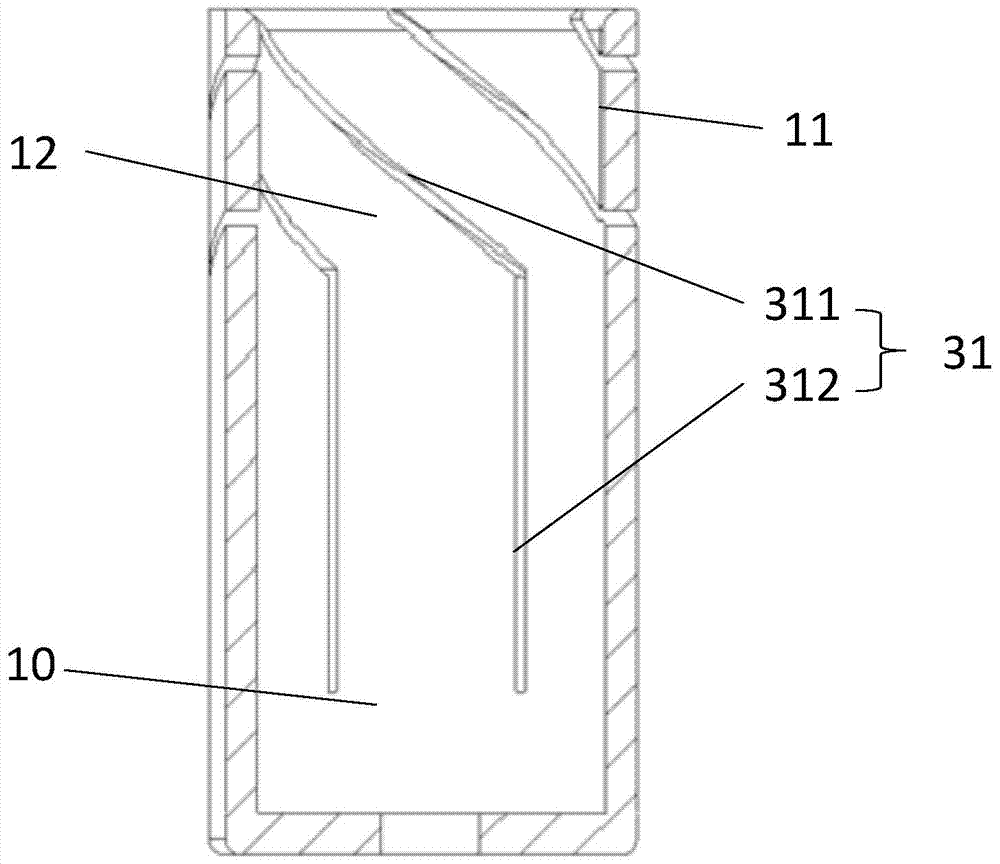

[0027] It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

[0028] In the prior art, the contact design of the traditional direct-acting plug-in earthing switch still lacks the consideration of the influence of the magnetic field of the electrode contact gap on the pre-breakdown arc, and the magnetic blowing effect of the magnetic field cannot be successfully applied to the earthing switch. In the closing operation, it is still difficult for the grounding switch to successfully close the short-circuit current.

[0029] The inventor of the present application applies the magnetic blowing effect of the magnetic field on the arc to the in-line grounding switch for the first time. The magnetic field control technology produces tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com