Swing type steel pipe feeding device

A feeding device and swing type technology, applied in the field of swing type steel pipe feeding device, can solve the problems of increasing the workload of equipment management personnel, lack of long-term stability of the gear rack, and many transmission links of the cylinder force, so as to reduce the Maintenance and inspection work intensity, guarantee the opening and closing effect, and reduce the effect of the transfer link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

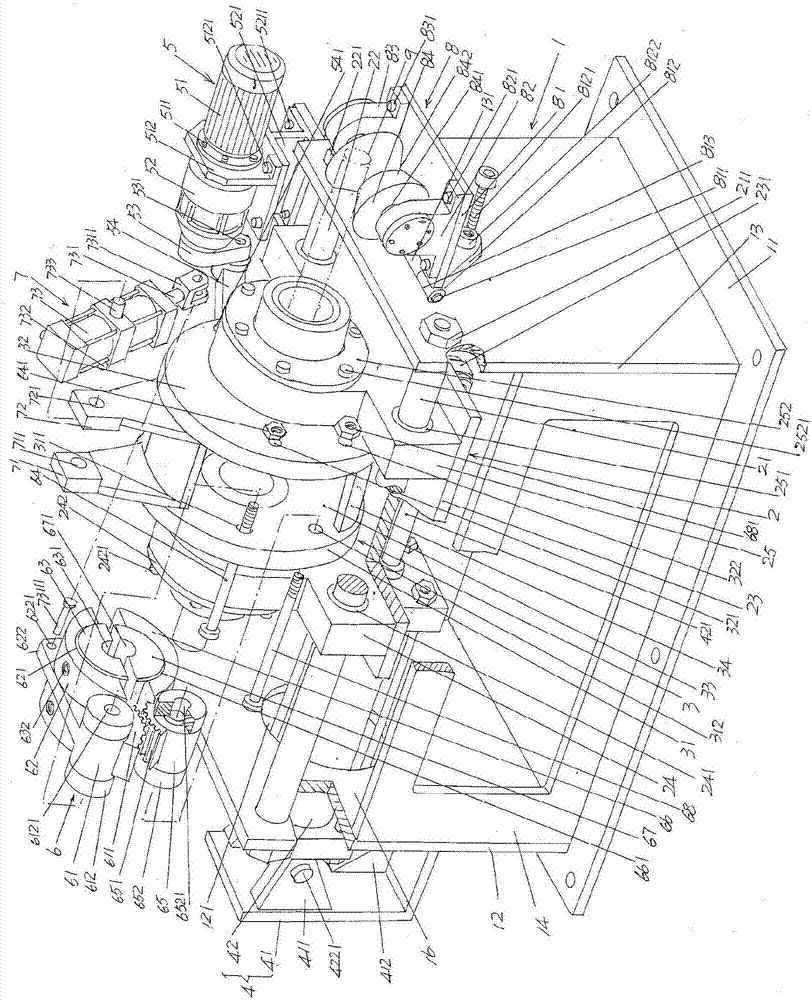

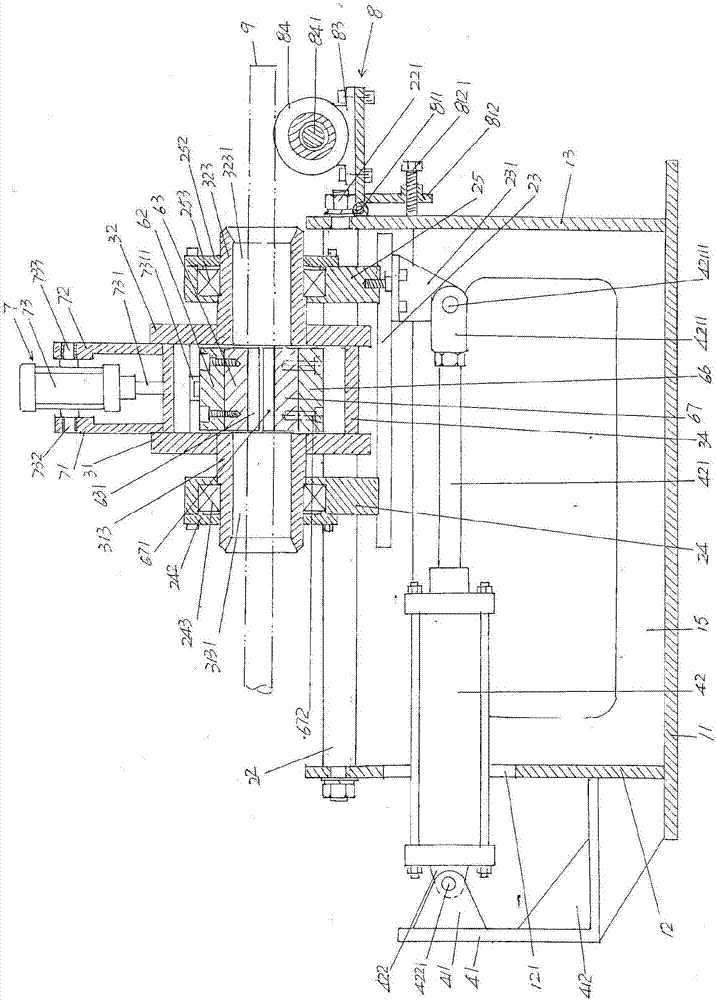

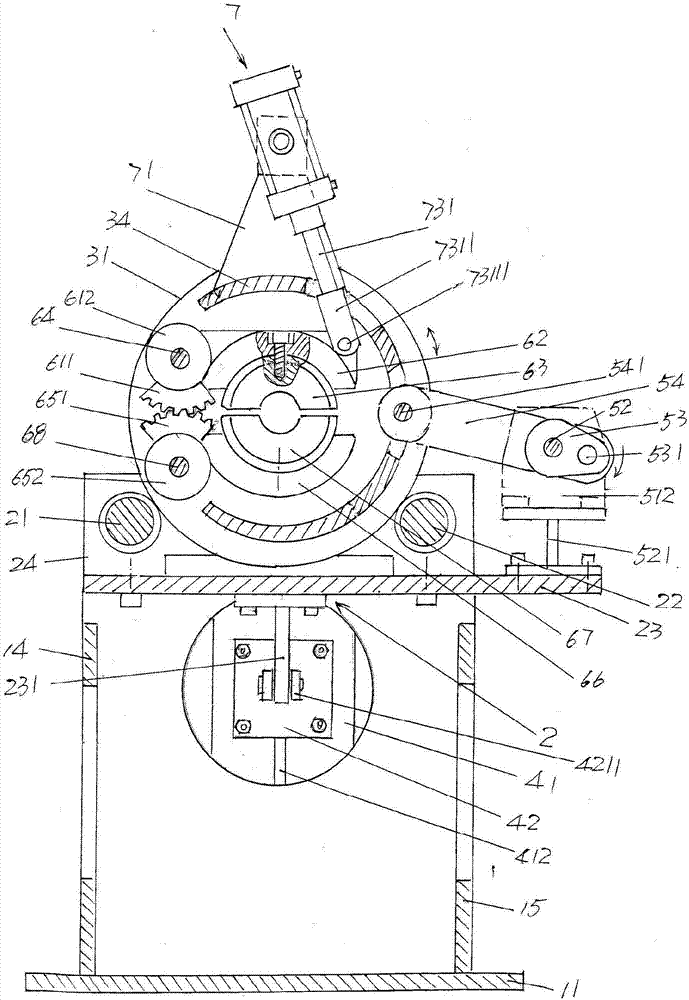

[0021] In order to facilitate a clearer understanding of the technical essence and beneficial effects of the present invention, the applicant will describe in detail the following in the form of examples, but the description of the examples is not a limitation to the solution of the present invention. Equivalent transformations that are only formal but not substantive should be regarded as the scope of the technical solution of the present invention.

[0022] In the following descriptions, all concepts related to directionality or orientation of up, down, left, right, front and back are based on figure 1 The shown position status is a reference, so it cannot be understood as a special limitation on the technical solution provided by the present invention.

[0023] See figure 1 and figure 2 , shows a frame 1, the frame 1 is set on the floor of the place of use corresponding to the position of the head block of the steel pipe heading machine in the use state, the steel pipe h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com