Halogen incandescent lamps

An incandescent lamp and halogen technology, applied in the field of halogen incandescent lamps, can solve the problem of inoperability of the internal arc tube, and achieve the effect of eliminating strain and eliminating fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Before these embodiments are explained in detail, it is to be understood that the invention is not limited in its application or use to the details of construction and arrangement of parts shown in the drawings and description. It can be appreciated that the exemplary embodiments according to the present invention can be implemented or included in other embodiments, alterations and modifications, and can be implemented or performed in various ways. Furthermore, the terms and expressions used herein have been chosen for the purpose of introducing the illustrated embodiments of the invention and for the convenience of the reader's understanding and not for the purpose of limitation unless otherwise specified.

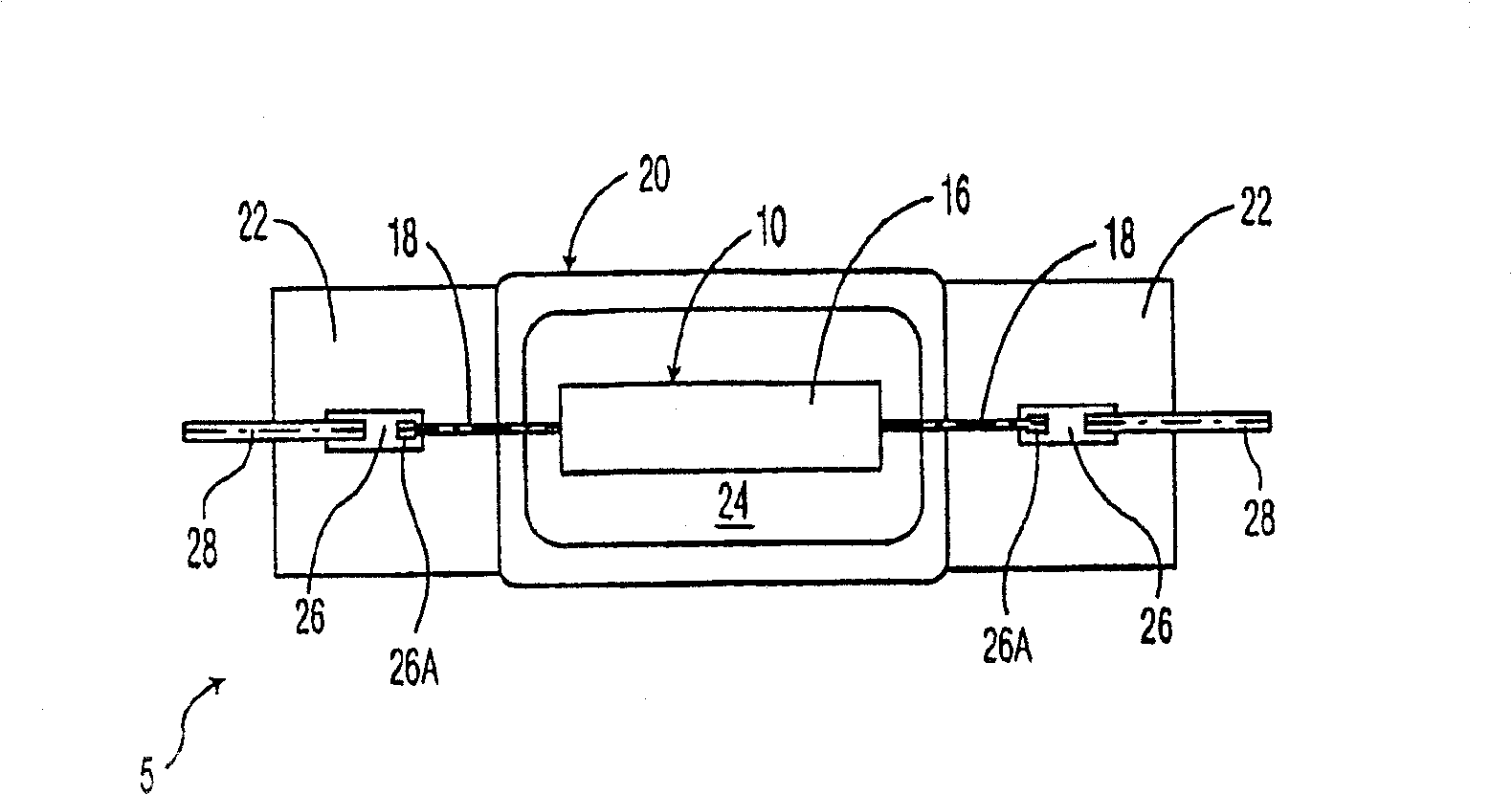

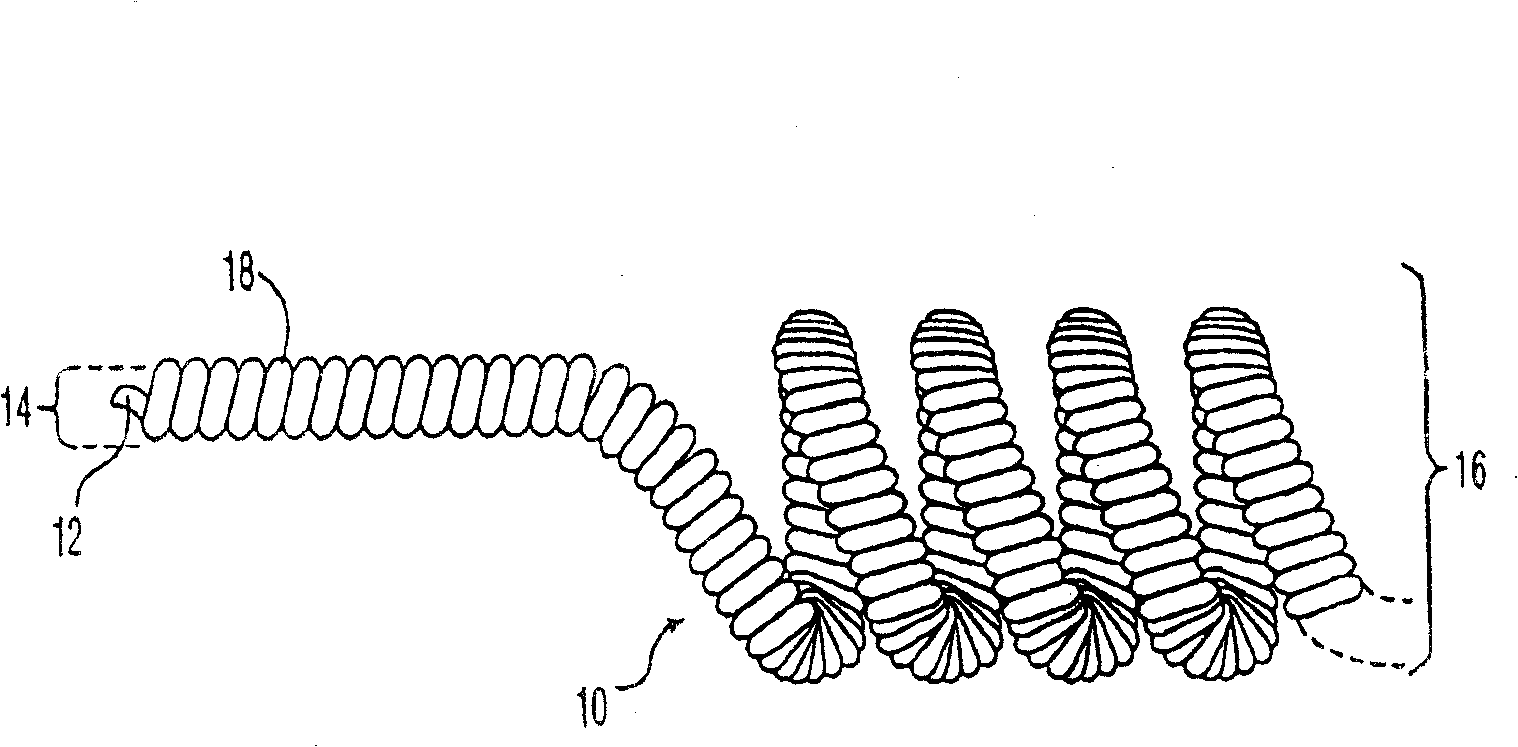

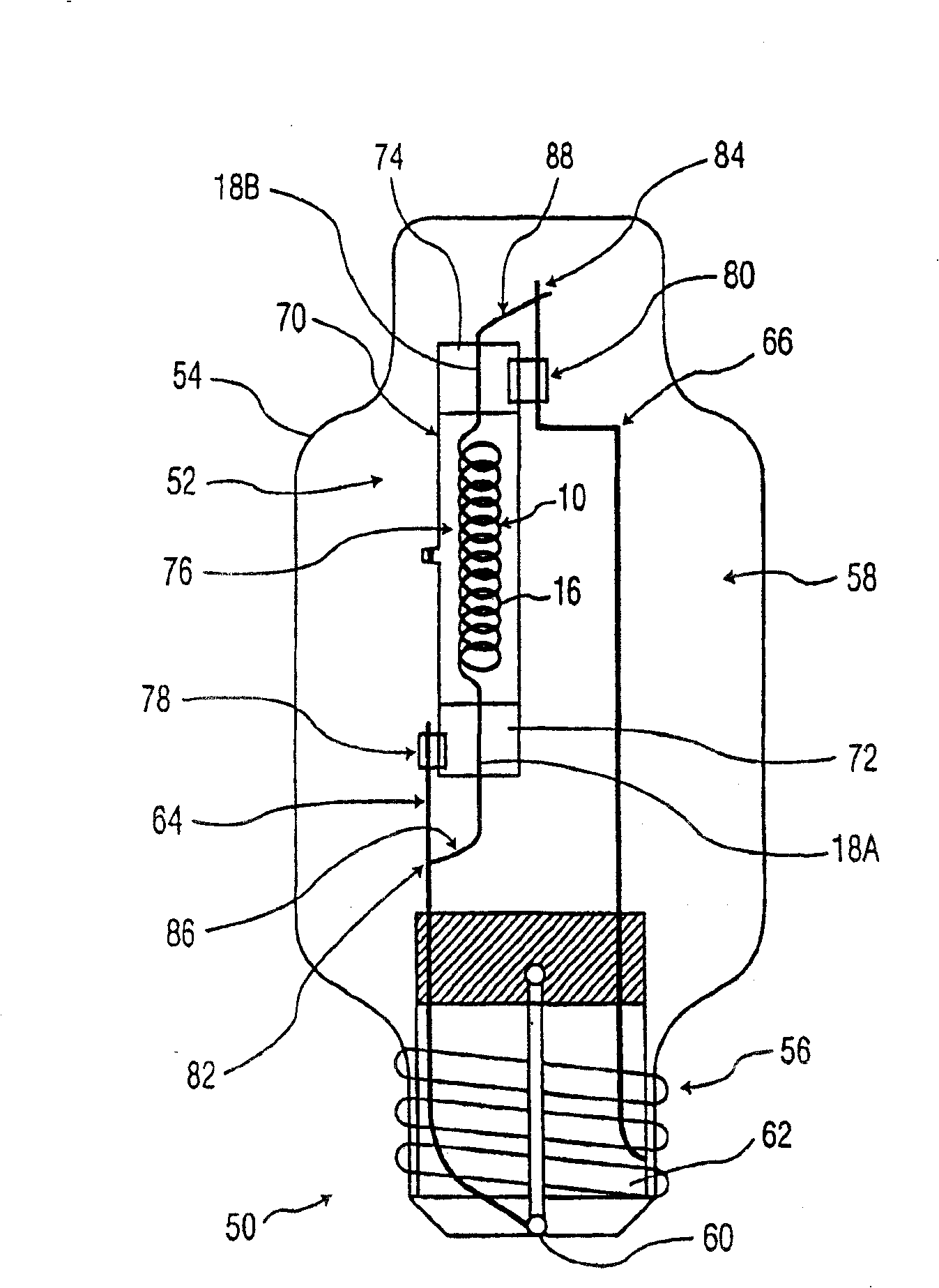

[0027] End-of-life failure mechanisms can be classified as passive and non-passive. Changing the geometry of the arc tube to induce an end-of-life mechanism of passive failure in the lamp would improve product safety. The safety of the lamp of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com