Silver-nickel electric contact material and preparing method thereof

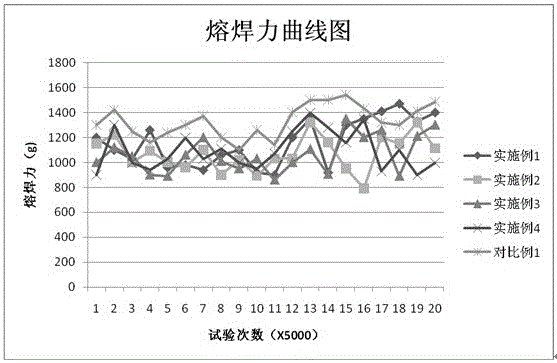

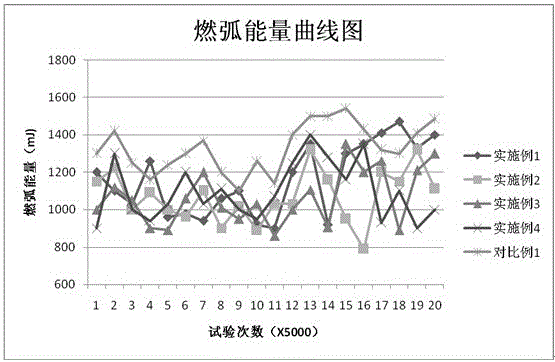

An electrical contact material, silver-nickel technology, used in contacts, circuits, electrical switches, etc., can solve the problems of inability to ensure material uniformity and consistency, increase in resistivity of silver-nickel materials, and inability to ensure distribution uniformity, etc. To achieve good anti-fusion welding performance, reduce arc energy, improve the effect of anti-fusion welding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

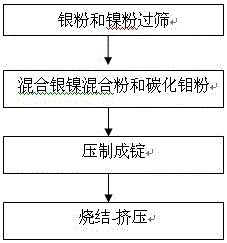

[0021] Take 8.9kg of silver powder and 1kg of nickel powder, and sieve through 200 mesh;

[0022] Silver-nickel mixed powder and 0.1kg molybdenum carbide powder were mixed in a plow-shovel mixer for 4 hours;

[0023] The silver-nickel-molybdenum carbide mixed powder is pressed into a spindle on a cold isostatic press under a pressure of 200 MPa and a holding time of 20 seconds;

[0024] Under the protection of argon, the ingot was sintered at 850°C for 2 hours, and then extruded into a wire with a specification of Φ6mm;

[0025] The wire is processed by cold drawing to make rivet contacts.

Embodiment 2

[0027] Get 16kg silver powder and 2kg nickel powder, sieve 100 mesh;

[0028] Mix the silver-nickel mixed powder with 2kg of molybdenum carbide powder in a plow-shovel mixer for 2 hours;

[0029] The silver-nickel-molybdenum carbide mixed powder is pressed into a spindle on a cold isostatic press under a pressure of 150 MPa and a holding time of 30 seconds;

[0030] Under the protection of argon, the ingot was sintered at 850°C for 2 hours, and then extruded into strips with a specification of 50×5mm;

[0031] The strip is cold-rolled-punched and processed into sheet contacts.

Embodiment 3

[0033] Take 8kg silver powder and 0.8kg nickel powder, and sieve 100 mesh;

[0034] Silver-nickel mixed powder and 1.2kg of molybdenum carbide powder were mixed in a plow-shovel mixer for 10 hours;

[0035] The silver-nickel-molybdenum carbide mixed powder is pressed into a spindle on a cold isostatic press under a pressure of 150 MPa and a holding time of 30 seconds;

[0036] Under the protection of argon, the ingot was sintered at 850°C for 2 hours, and then extruded into strips with a specification of 50×5mm;

[0037] The strip is cold-rolled-punched and processed into sheet contacts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com