Nanometer tungsten carbide silver contact material and manufacturing method

A nano-tungsten carbide and silver contact technology, applied in electrical components, circuits, electrical switches, etc., to achieve the effect of suppressing excessive cold welding, good electrical conductivity, and improving powder yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Choose the tungsten carbide powder that average particle size is 1.06 μ m, particle size be-300 mesh silver powder and particle size be-200 mesh nickel powder, be 2kg by gross weight, weight ratio is silver: tungsten carbide: nickel=50:49:1, weighs Put tungsten carbide powder and nickel powder into a ball mill jar, add 150ml of alcohol and 10kg of Ф6mm hard alloy balls, install the ball mill jar on the planetary ball mill, and continue ball milling for 48 hours at a speed of 250r / min; take out the powder Dry at 120°C for 2 hours, put the dried powder and silver powder weighed in proportion, 0.04kg of stearic acid and 20kg of Ф6 hard alloy balls into a ball mill jar, seal the ball mill jar, and vacuumize , install the ball mill jar on the planetary ball mill, and mill continuously for 12 hours at a speed of 250r / min; take out the mixed powder and reduce it for 1.5 hours under the condition of hydrogen atmosphere and temperature of 400°C; use 3T / cm 2 The pressure of the m...

Embodiment 2

[0043] Choose tungsten carbide powder whose average particle size is 5.32 μm, particle size be-200 mesh silver powder and particle size be-100 mesh nickel powder, be 2kg by total weight, weight ratio silver: tungsten carbide: nickel=30:68:2, weigh carbonization Put tungsten powder and nickel powder into a ball mill jar, add 200ml of alcohol and 6kg of Ф20mm hard alloy balls, install the ball mill jar on the planetary ball mill, and continue ball milling for 36 hours at a speed of 350r / min; take out the powder Dry at 150°C for 1.5 hours, put the dried powder and previously weighed silver powder, 0.08kg of stearic acid and 20kg of Ф20 hard alloy balls into a ball mill jar, seal the ball mill jar, and evacuate it. Install the ball mill jar on the planetary ball mill, and mill continuously for 18 hours at a speed of 350r / min; take out the mixed powder and reduce it for 1 hour at a temperature of 450°C in a hydrogen atmosphere; use 4T / cm 2 The pressure of the mixed powder is presse...

Embodiment 3

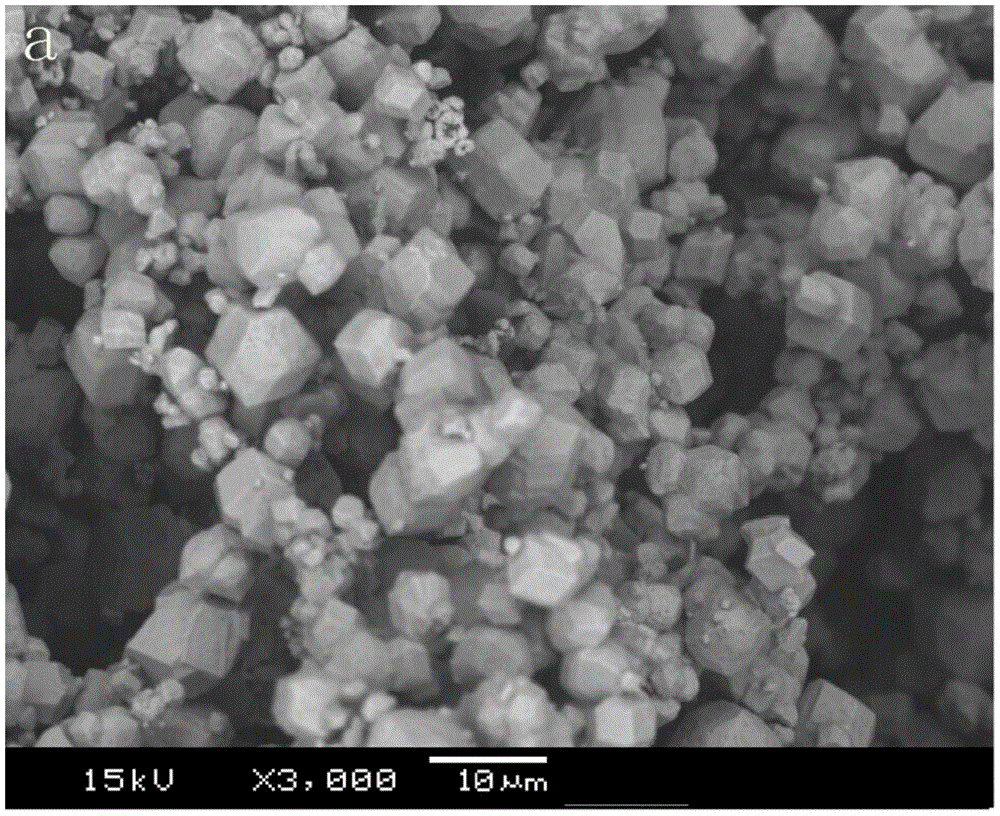

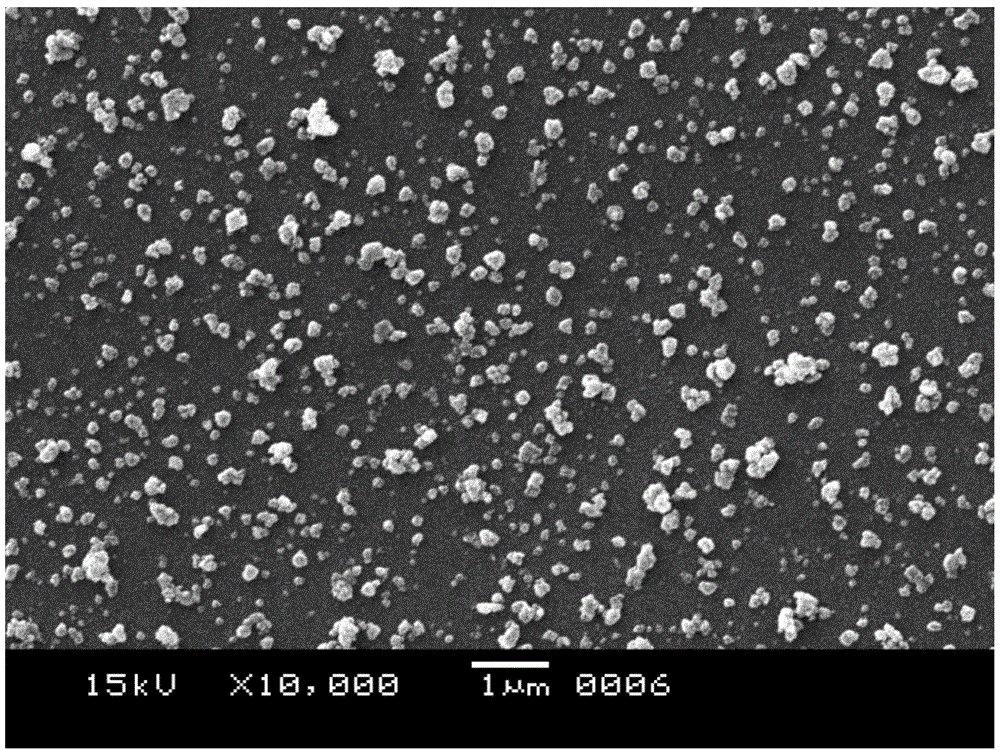

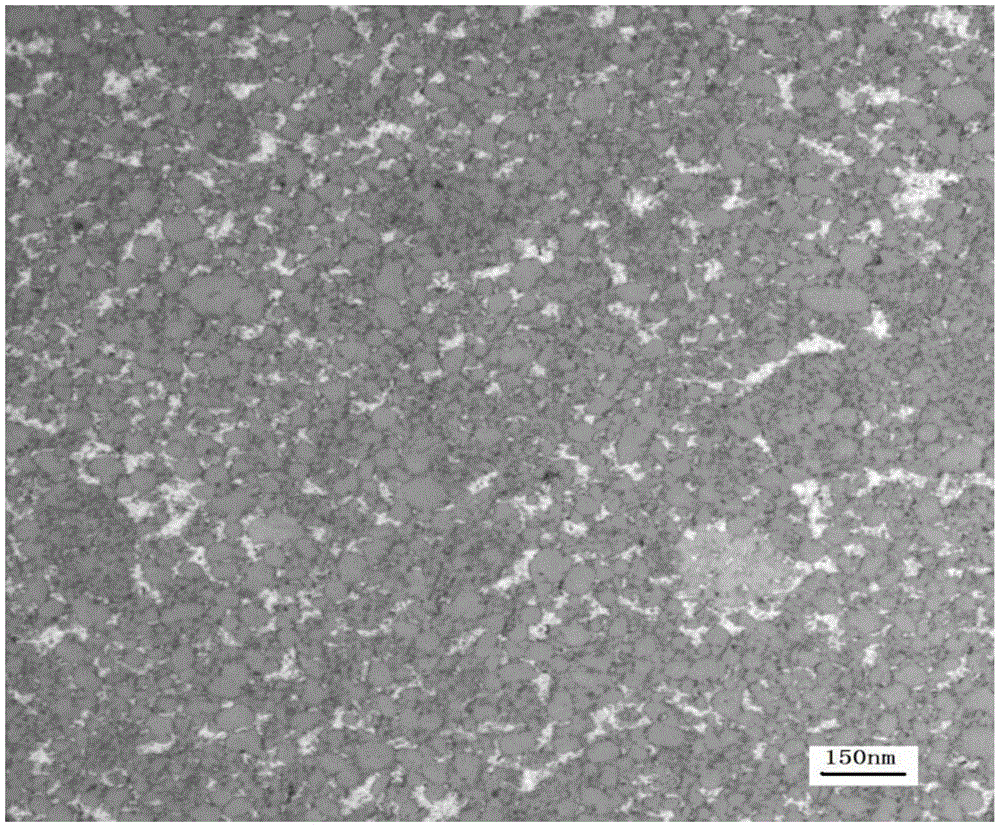

[0045] Choose the tungsten carbide powder whose average particle size is 2.54 μm, the silver powder and the particle size of-300 mesh nickel powder and the particle size of 2.54 μm, by a total weight of 2kg, the weight ratio is silver: tungsten carbide: nickel=40:58:2, weighed Put tungsten carbide powder and nickel powder into the ball mill jar, add 180ml of alcohol and 12kg of hard alloy balls with a combination of Ф6~Ф20mm (the weight ratio is Ф6:Ф10:Ф20=4:5:1), and install the ball mill jar On a planetary ball mill, ball milling was continued at a speed of 300r / min for 60 hours; the powder was taken out and dried at 120°C for 3 hours, and the SEM photo of the obtained powder was as follows: figure 2 As shown; the cemented carbide balls that combine the dried powder and the previously weighed silver powder with 0.06kg of stearic acid and 20kg of Ф6~Ф20mm (weight ratio Ф6:Ф10:Ф20=4:5:1) Put into the ball mill jar, seal the ball mill jar, and evacuate it, install the ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com