Blank blade correction method

A technology of blades and blanks, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as high cost of straightening, impact on casting quality, and lengthened production cycle, so as to save production cost and cycle, and reduce the impact of welding heat Area, orthopedic process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

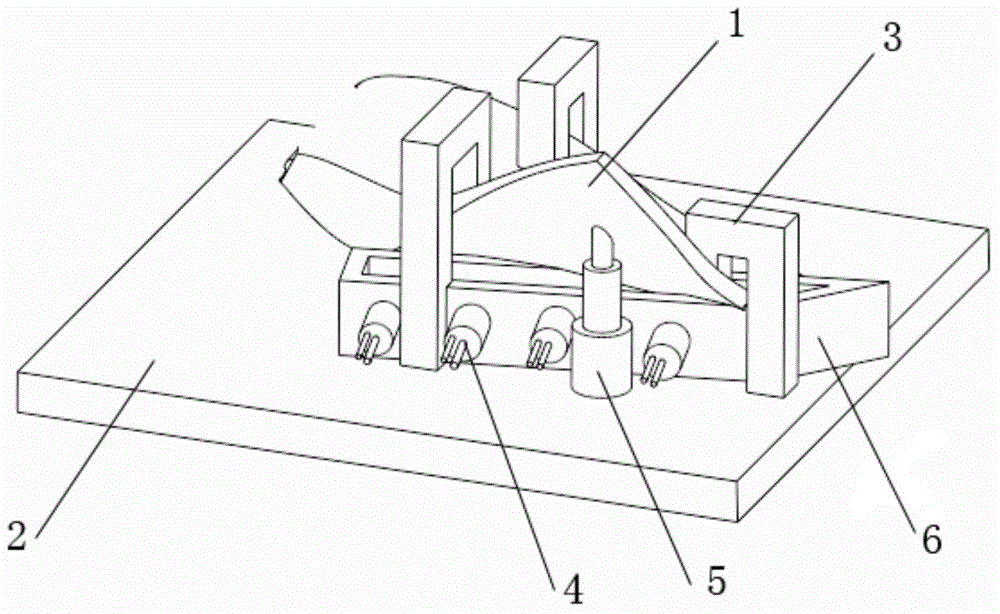

[0020] Such as figure 1 As shown, a piece of Shula Haiwei blank blade is listed below.

[0021] 1) Take a photo of the cast blank blade and send the image to the computer. After comparing the three-dimensional digital-analog imaging, it is found that the upper surface of the blade corner is 30mm less than the standard digital model, and the lower surface is 30mm longer. (The deformation area is about 1.6㎡)

[0022] 2) Place the Shula Haiwei blank blade (hereinafter referred to as the blank blade) on the steel plate platform, clamp the blank blade and the steel plate platform with a clamping tool, and spot weld the two ends of the clamping tool with the blank blade and the steel plate platform respectively ;

[0023] 3) Use refractory bricks to build a hollow heating wall on the steel plate platform below the deformation area of the blank blade. The heating wall is built to the lower edge of the blank blade. The periphery of the heating wall is surrounded by rock wool felt ...

Embodiment 2

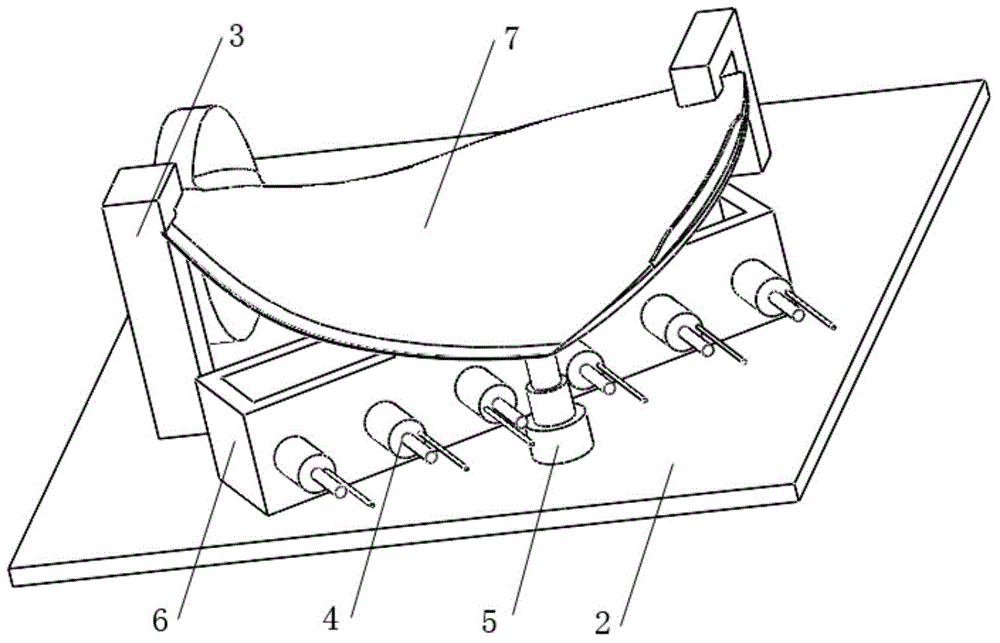

[0029] Such as figure 2 As shown, a piece of rough leaves of Tugutang is listed below.

[0030] 1) Take a picture of the cast blank blade, and send the image to the computer. After comparing the three-dimensional digital-analog imaging, it is found that the upper surface of the blade corner is 50mm shorter than the standard digital analog, and the lower surface is 50mm longer. (The deformation area is about 6㎡)

[0031] 2) Put the blank blade of Tugutang (hereinafter referred to as the blank blade) on the steel plate platform, clamp the blank blade and the steel plate platform with a clamping tool, and spot weld the two ends of the clamping tool with the blank blade and the steel plate platform respectively;

[0032] 3) Use refractory bricks to build a hollow heating wall on the steel plate platform below the deformation area of the blank blade. The heating wall is built to the lower edge of the blank blade. The periphery of the heating wall is surrounded by rock wool felt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com