A 3-5mm stainless steel plate single side welding double side free forming welding method

A single-sided welding double-sided, stainless steel plate technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large spatter, increased welding process, low production efficiency, etc., achieve high automation and improve weld seam Quality, the effect of reducing welding spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

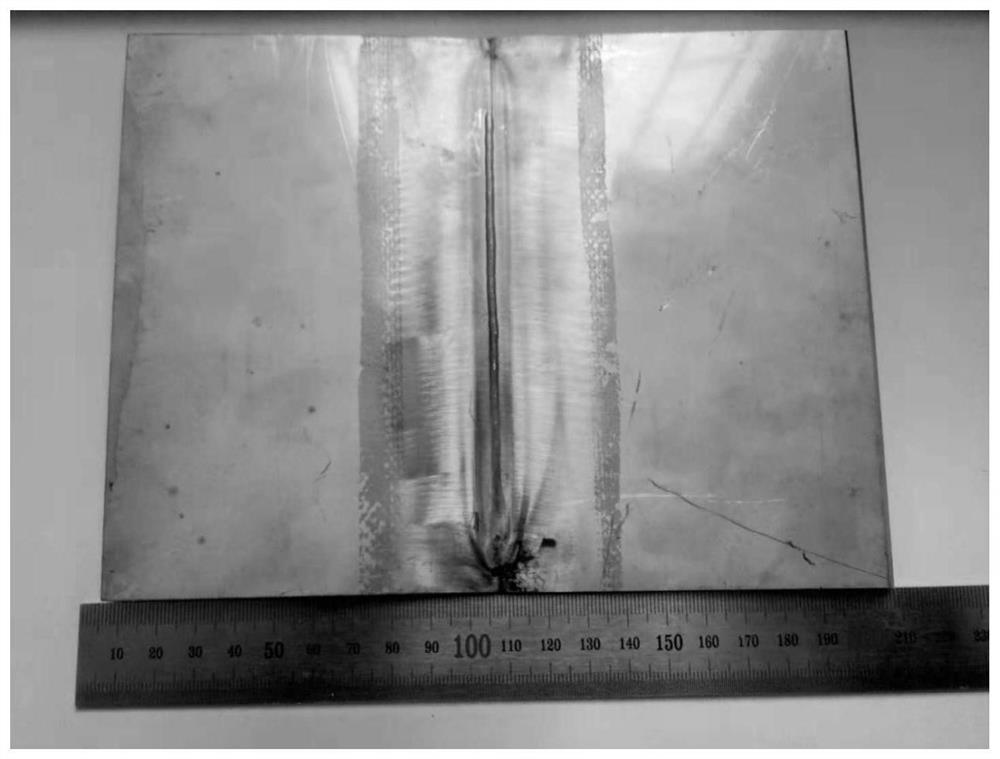

[0022] The workpieces to be welded are two pieces of 304 stainless steel, and the thickness of the base metal is 3mm. The details of the single-sided welding and double-sided free forming welding process are as follows:

[0023] Step 1: Use a CNC milling machine to flatten the surface of the workpiece to be welded to ensure that the end surfaces are parallel, then use an air gun to blow off the burrs on the processed surface, and then use a cotton ball to wipe it with an appropriate amount of acetone solvent to remove 15mm around the weld. Impurities and oils within the range.

[0024] The second step: use manual MIG welding to spot weld the workpiece to be welded, the spot welding current is 140A, the arc voltage is 18V, the argon gas flow rate is 8L / min, and the butt gap is 0.5mm.

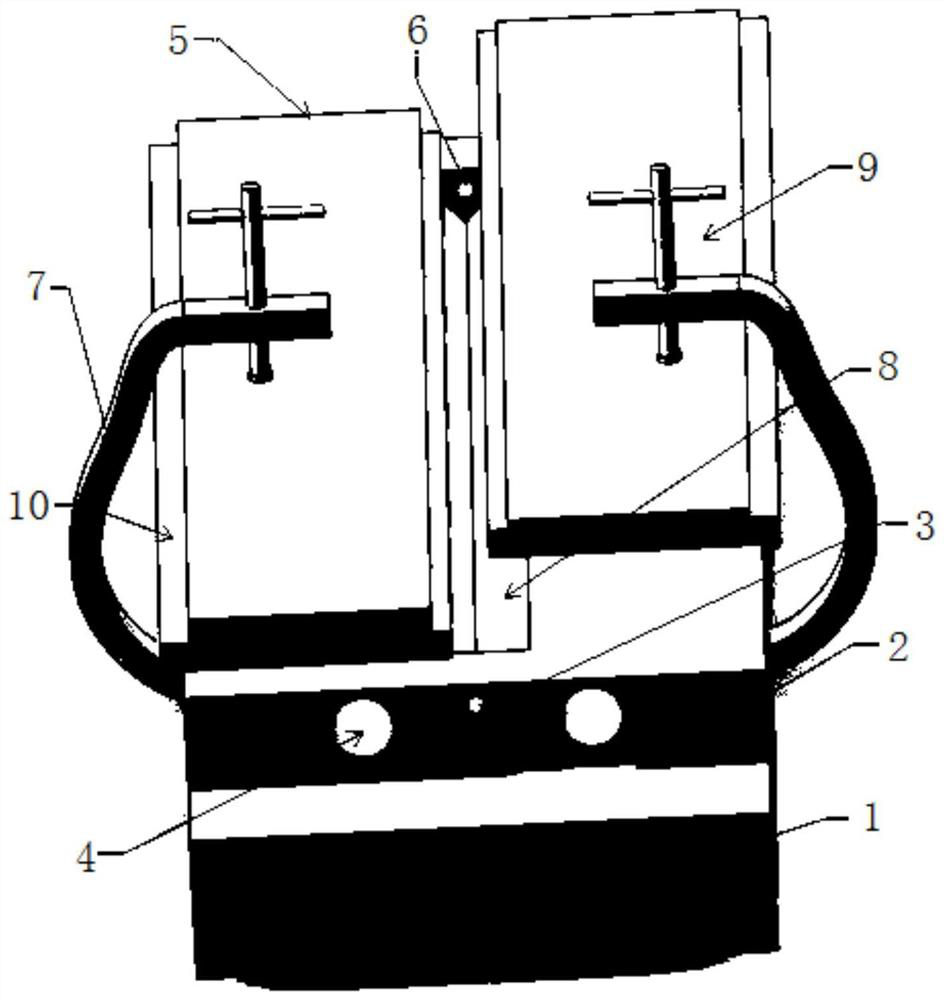

[0025] Step 3: After the spot welding is completed, place the workpiece to be welded on the welding table, and then place a pressure plate of appropriate size (155mm long, 25mm wide, and 1mm thic...

Embodiment 2

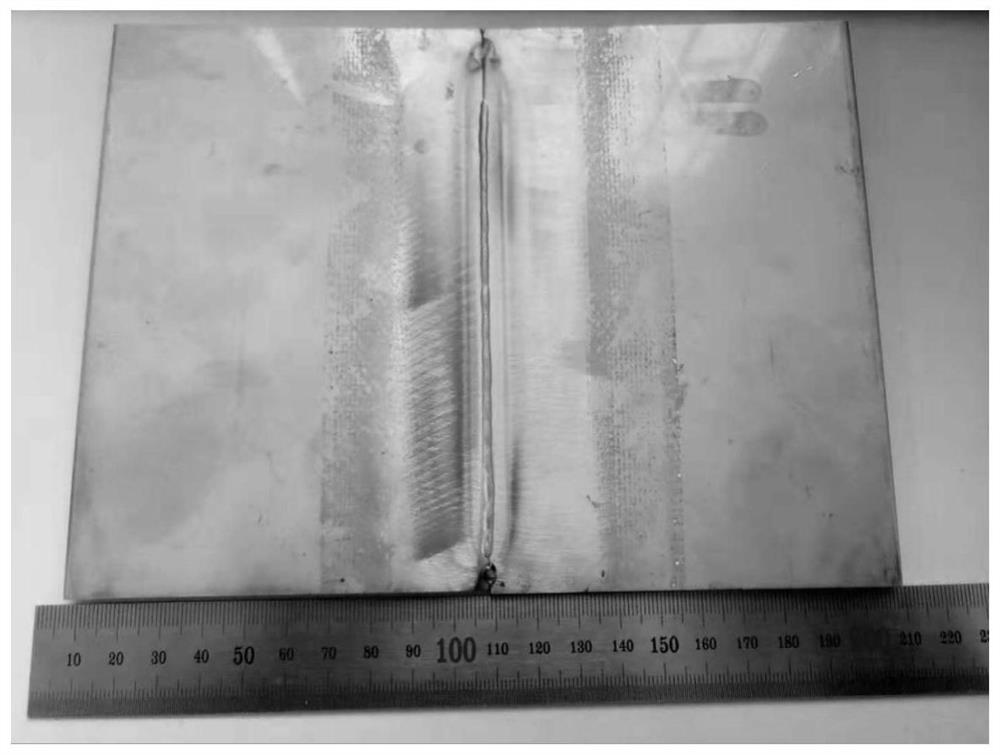

[0028] The workpieces to be welded are two pieces of 304 stainless steel, and the thickness of the base metal is 5mm. The details of the single-sided welding and double-sided free forming welding process are as follows:

[0029] Step 1: Use a CNC milling machine to flatten the surface of the workpiece to be welded to ensure that the end surfaces are parallel, then use an air gun to blow off the burrs on the processed surface, and then use a cotton ball to wipe it with an appropriate amount of acetone solvent to remove 15mm around the weld. Impurities and oil stains inside.

[0030] The second step: use manual MIG welding to spot weld the workpiece to be welded, the spot welding current is 157A, the arc voltage is 20.1V, the argon gas flow rate is 10L / min, and the butt gap is 1mm.

[0031] Step 3: After the spot welding is completed, place the workpiece to be welded on the welding table, and then place a pressure plate of appropriate size (155mm long, 25mm wide, and 1mm thick) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com