Rocket engine jet pipe brazing strip automatic rolling point welding machine and rolling point welding process

A technology of rolling point welding machine and rocket engine, which is applied in welding equipment, manufacturing tools, metal processing, etc., can solve the problems of time-consuming, labor-intensive and low work efficiency, and achieves time-saving and labor-saving operation, good welding quality, and improved welding work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

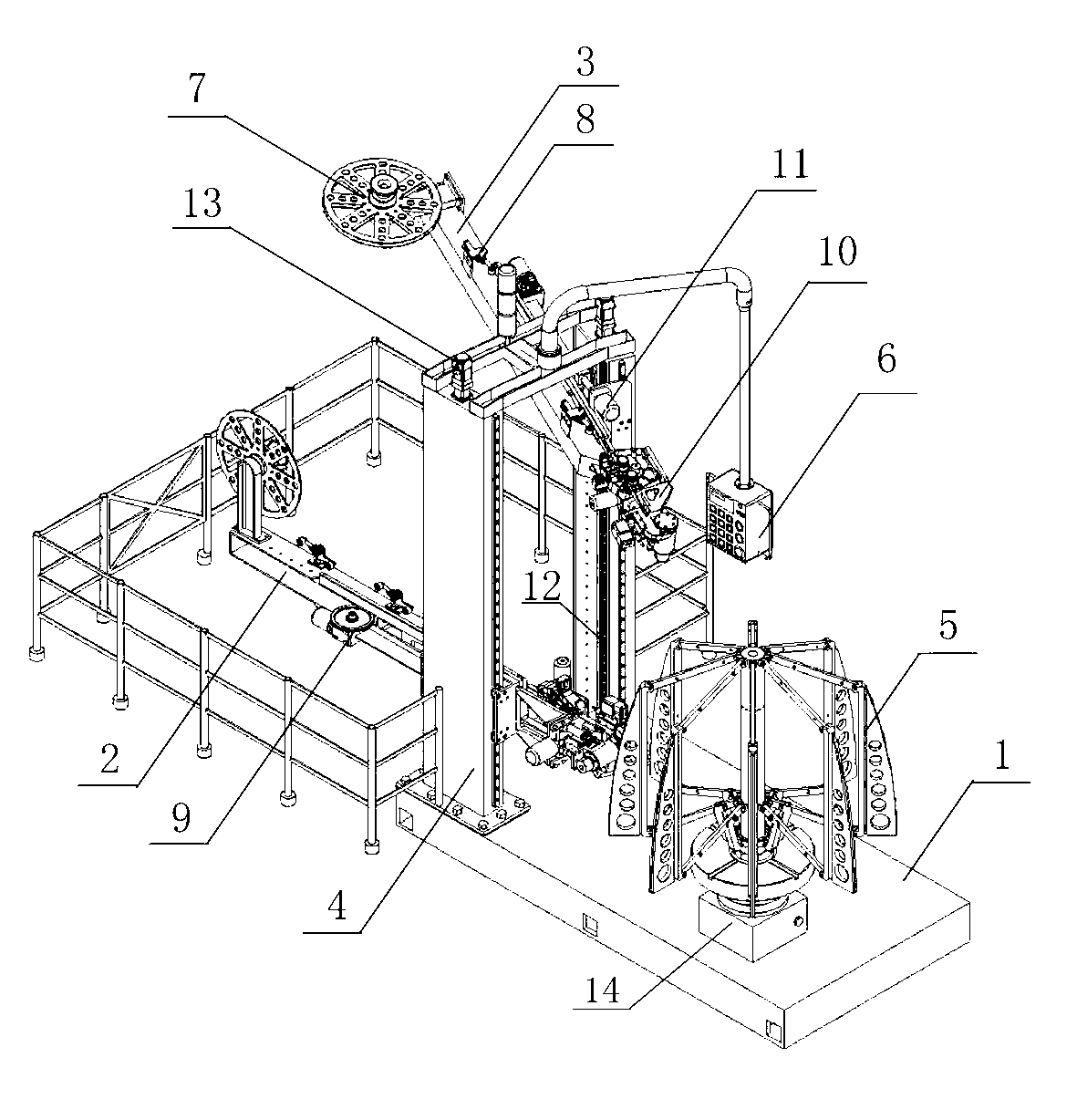

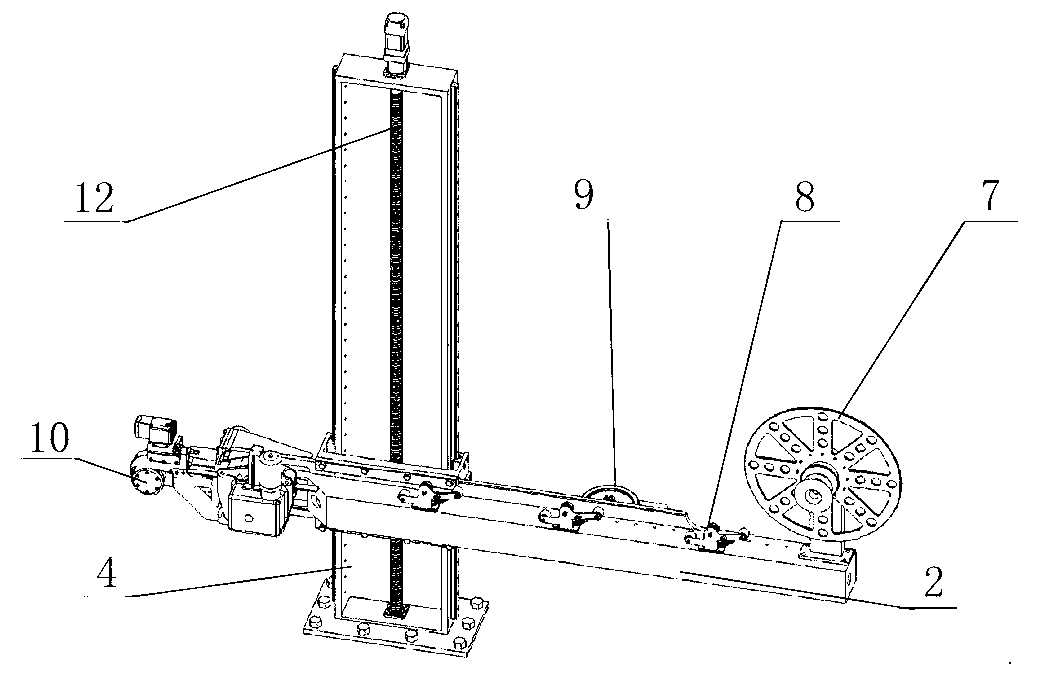

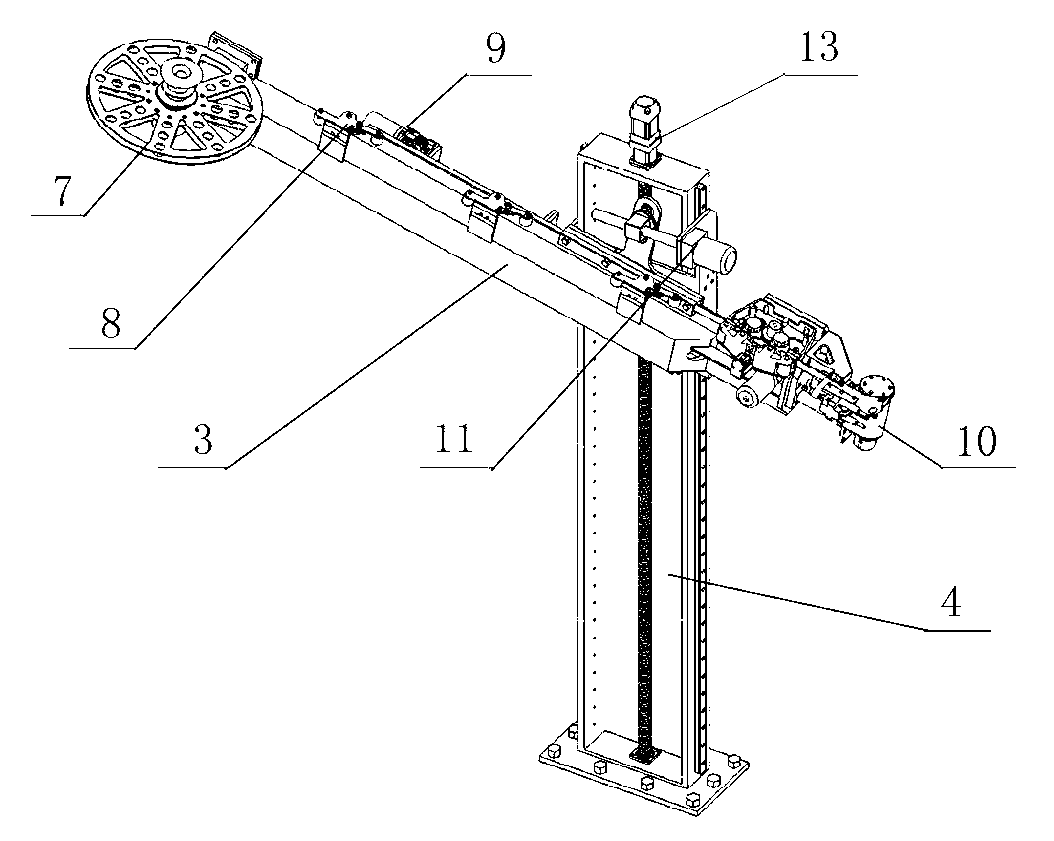

[0050] like figure 1 As shown, the automatic rolling spot welding machine for the rocket engine nozzle brazing material belt of the present invention includes a bed base 1, a rotary table 14, a tensioning mold 5, a portal support 4, a lead screw 12, a servo motor 13, Longitudinal rolling spot welding operation manipulator 2, circumferential rolling spot welding operation manipulator 3, solder belt rolling spot welding head 10, angle adjustment mechanism 11, solder belt positioning guide buffer mechanism 8, solder belt reel 7 and controller 6 Wait.

[0051] A rotary table 14 is arranged on the table at one end of the bed base 1, and a door-shaped support 4 and a peripheral guardrail are installed at the other end. On the rotary table 14, a stretching mold 5 for supporting the workpiece of the nozzle is installed. Leading screws 12 are respectively installed in the two columns of the door-shaped support 4 , and servo motors 13 which respectively drive the two leading screws to...

Embodiment 2

[0059] Rocket engine nozzle solder strip rolling spot welding process of the present invention comprises three major steps:

[0060] Step 1: Prepare the brazing filler metal strips for longitudinal rolling spot welding and circumferential rolling spot welding respectively, and wind the two kinds of brazing filler metal ribbons made on a brazing filler metal strip reel 7 respectively, and then wrap the two brazing filler metals The tape reel 7 is correspondingly installed on the longitudinal rolling spot welding operation manipulator 2 and the circumferential rolling spot welding operation manipulator 3, and the solder tape is pulled out from the solder tape reel 7, and is guided to the solder tape roll along the guide belt groove plate 20. The tape guide nozzle 16 at the front end of the spot welding machine head 10.

[0061] The preparation method of the solder strip is as follows: firstly, the solder plate is cut into several solder strips according to the set width. This p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com