Green Chinese onion harvester

A harvester and green onion technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of low production efficiency, high labor intensity, and a large amount of manpower input, so as to reduce the easy breaking of onions and improve work efficiency. Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

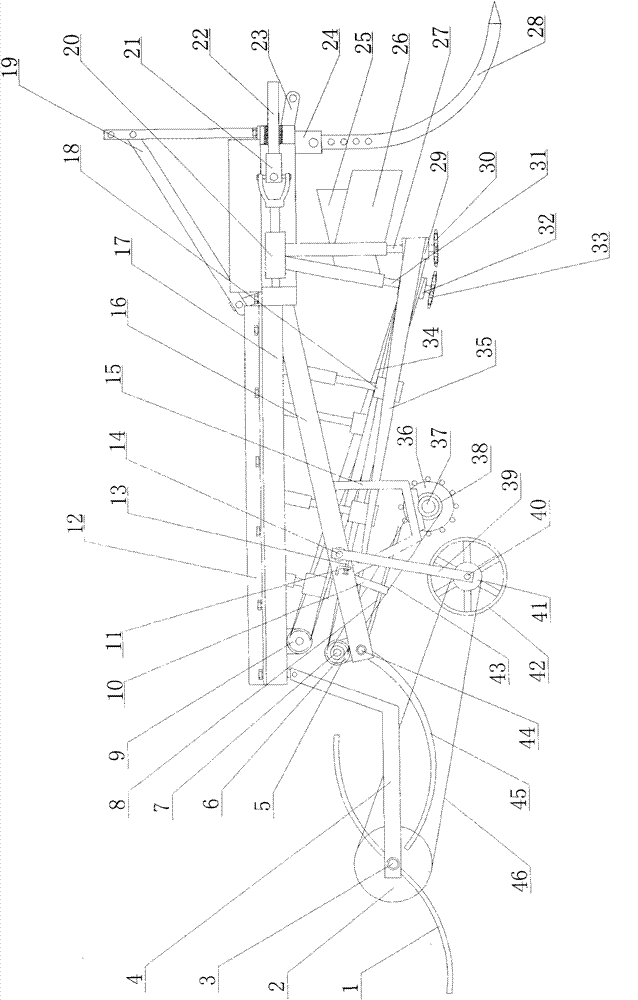

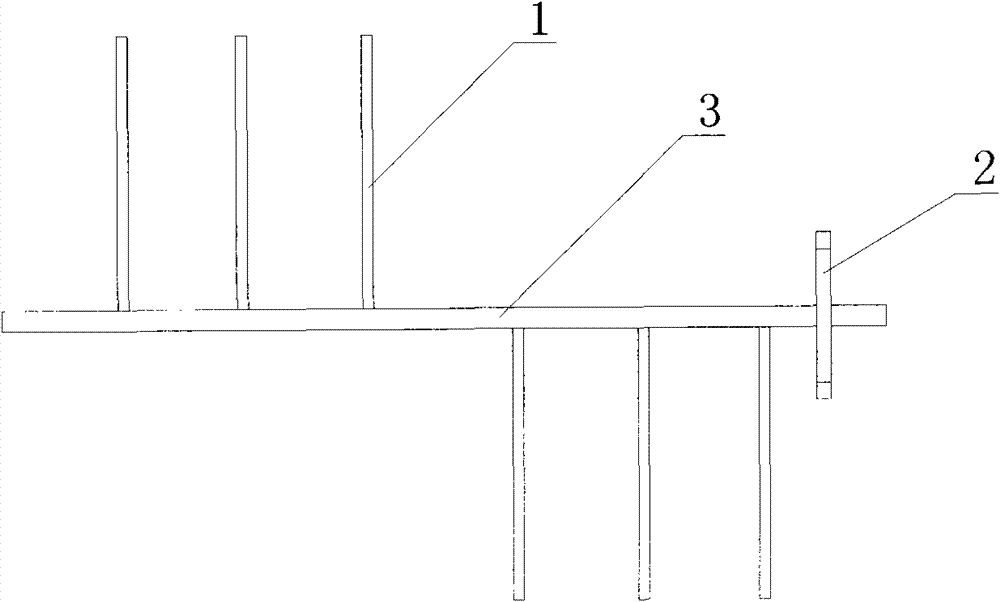

[0026] A green onion harvester, such as figure 1 Shown, comprise frame, be fixed on the hitch frame 23 of frame front end, be installed in the elevating frame 19 of frame front portion, dig onion knife 28 and transmission mechanism. Described frame comprises horizontal frame 17 and oblique frame 16, and the front end of oblique frame 16 is fixed on the middle front part of horizontal frame 17. A knife seat 24 is installed on the front end bottom surface of the horizontal frame 17, and the onion cutter 28 is fixed on the knife seat 24 by fastening bolts. The transmission mechanism includes a power input shaft 22 and a gearbox 20 connected through a universal joint 21 , and the top of the horizontal frame 17 is fixed with a cover 12 .

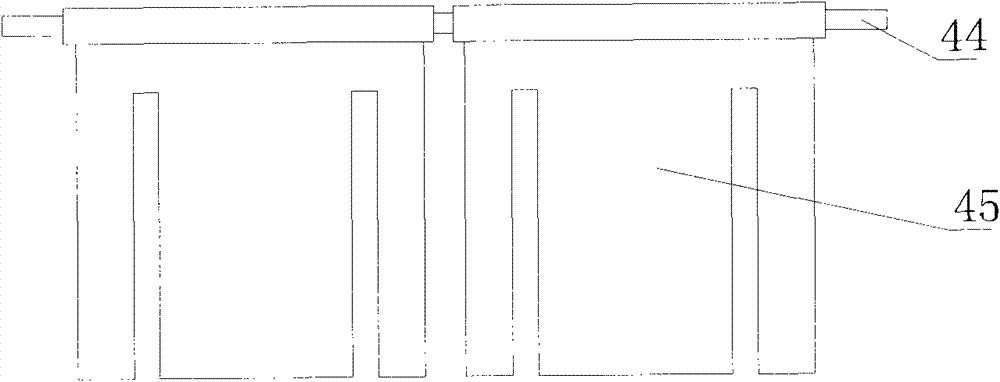

[0027] The lower part of the frame is equipped with a device for pulling up the shallots and transporting them backwards, and turning the shallots from vertical to horizontal during the process of conveying. The onion pulling device is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com